Abstract

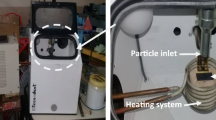

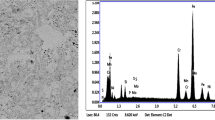

In this paper, the reciprocating wear behavior of titanium–titanium boride composites with 20 and 40 (by vol. %) titanium boride (TiB) particles IS investigated in dry sliding conditions against Al2O3 ceramic balls. The trials have been observed at three loading conditions such as 5, 10 and 15 N load. The composites were processed by three powder metallurgical techniques such as spark plasma sintering (SPS), vacuum sintering (VS) and hot isostatic pressing (HIP). The electron probe microanalysis (EPMA) was used to analyze the homogeneity of Ti and boride phases in the composites. The hardness and indentation fracture resistance were evaluated using nano-indentation technique. The load–depth curves of indents for Ti–TiB shows the deviations of the modulus of elasticity within the spark plasma sintering (SPS), vacuum sintering (VS) and hot isostatic pressing (HIP).The wear resistance of the fabricated samples was analyzed using reciprocating wear tester. The SPS composite (Ti–38.5% TiB) showed lower coefficient of friction (0.07), lower wear volume (0.4368 mm3) and wear rate (0.000276 mm3/m) when compared to HIP and VS, which is attributed to the presence of fine titanium boride needles of high hardness, contributing to improving wear resistance. The surface morphology reveals that the composites processed through spark plasma sintering (SPS) and hot isostatic pressing (HIP) are subjected to minor plastic deformation. The outcome of this work is more beneficial to automotive brake pad, precision manufacturing and locomotives to avoid critical wear failures.

Similar content being viewed by others

References

Peruzzo M, Serafini FL, Ordoñez MFC, Souza RM, Farias MCM. Reciprocating sliding wear of the sintered 316L stainless steel with boron additions. Wear. 2019;422–423:108–18.

Nazir MH, Khan ZA, Adilsaeed A. Experimental analysis and modeling for reciprocating wear behavior of nano composite coatings. Wear. 2018;416–417:89–102.

Mao C, Zhou F, Hu Y. Tribological behavior of cBN-WC-10Co composites for dry reciprocating sliding wear. Ceram Int. 2019;45(5):6447–58.

Monazzah AH, Pouraliakbar H, Jandaghi MR, Bagheri R, Reihani SMS. Influence of interfacial adhesion on the damage tolerance of Al6061/SiCp laminated composites. Ceram Int. 2017;43(2):2632–43.

Monazzah AH, Bagheri R, Reihani SMS. Toughness enhancement in architecturally modified Al6061-5 vol.% SiCp laminated composites. Int J Damage Mech. 2014;24(2):245–62.

Pouraliakbar H, HosseiniMonazzah A, Bagheri R, SeyedReihani SM, Khalaj G, Nazari A, Jandaghi MR. Toughness prediction in functionally graded Al6061/SiCp composites produced by roll-bonding. Ceram Int. 2014;40(6):8809–25.

Heidarzadeh A, Pouraliakbar H, Mahdavi S, Jandaghi MR. Ceramic nanoparticles addition in pure copper plate: FSP approach, microstructure evolution and texture study using EBSD. Ceram Int. 2018;44(3):3128–33.

Selvakumar M, Chandrasekar P, Ravisankar B, Balaraju JN, Mohanraj M. Mechanical properties of titanium-titanium boride composites through nanoindentation and ultrasonic techniques—an evaluation perspective. Powder Metall Met Ceram. 2015;53:557–65.

Ayyagari A, Barthelemy C, Gwalani B, Banerjee R, Scharfa TW, Mukherjee S. Reciprocating sliding wear behavior of high entropy alloys in dry and marine environments. Mater Chem Phys. 2018;210:162–9.

Kumar K, Van Swygenhoven H, Suresh S. Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 2003;51:5743–74.

Selvakumar M, Chandrasekar P, Mohanraj M, Ravisankar B, Balaraju JN. Role of powder metallurgy processing and TiB reinforcement on mechanical response of Ti-TiB composites. J Mater Lett. 2015;144:58–61.

Courant B, Hantzpergue JJ, Benayoun S. Surface treatment of titanium by laser irradiation to improve resistance to dry-sliding friction. Wear. 1999;236(1–2):39–46.

Lin YQ, Geng L, Ni DR. Dry sliding wear behavior of extruded titanium matrix composite reinforced by in situ TiB whisker and TiC particle. J Mater Sci. 2011;46(14):4980–5.

Ramkumar T, Selvakumar M, Mohanraj M, Chandrasekhar P. Experimental investigation and analysis of drilling parameters of metal matrix (Ti/TiB) composites. J Braz Soc Mech Sci Eng. 2019;41(8):2–12.

Vadiraj A, Kamaraj M, Gnanamoorthy R. Fretting wear studies on uncoated, plasma nitrided and laser nitrided biomedical titanium alloys. Mater Sci Eng A. 2007;445:446–53.

Selvakumar M, Ramkumar T, Chandrasekhar P. Thermal characterization of titanium-titanium boride composites. J Therm Anal Calorimetry. 2019;2019:1–9.

Lakshmipathy J, Kulendran B. Reciprocating wear behavior of 7075Al/SiC in comparison with 6061Al/Al2O3 composites. Int J Refract Metal Hard Mater. 2014;46:137–44.

Molinari A, Straffelini G, Tesi B, Bacci T. Dry sliding wear mechanisms of the Ti6Al4V alloy. Wear. 1997;208(1–2):105–12.

Alman DE, Hawk JA. The abrasive wear of sintered titanium matrix–ceramic particle reinforced composites. Wear. 1999;225–229(1):629–39.

Thulasiram R, Mani S, Pandiarajan N, Pandiarajan B. Effect of B4C in Ti-6Al-4V matrix on workability behavior of powder metallurgy composites during cold upsetting. Int J Mater Res. 2018;109(12):1146–52.

Yamaguchi T, Yonesho Y, Nishio K. Surface nitriding and improvement of wear resistance of titanium using laser irradiation. J Jpn Inst Met. 2011;75(12):697–704.

Kumar MS, Chandrasekar P, Chandramohan P, Mohanraj M. Characterisation of titanium–titanium boride composites processed by powder metallurgy techniques. Mater Charact. 2012;73:43–51.

Viáfara CC, Sinatora A. Unlubricated sliding friction and wear of steels: an evaluation of the mechanism responsible for the T1 wear regime transition. Wear. 2011;271:1689–700.

Selvakumar N, Ramkumar T. Effect of particle size of B4C reinforcement on Ti-6Al-4V sintered composite prepared by mechanical milling method. Trans Indian Ceram Soc. 2017;76(1):37.

Yang Y. Sensitivity of nano indentation strain rate in poly(ester-ester-ketone) using atomic force microscopy. Polym Testing. 2016;53:85–8.

Ramkumar T, Narayanasamy P, Selvakumar M, Balasundar P. Effect of B4C reinforcement on the dry sliding wear behaviour of Ti-6Al-4V/B4C sintered composites using response surface methodology. Arch Metall Mater. 2018;63(3):1179–200.

Jin C, Onuoha CC, Farhat ZN, Kipouros GJ, Plucknett KP. Microstructural damage following reciprocating wear of TiC-stainless steel cermets. Tribol Int. 2017;105:201–18.

Pirso J, Viljus M, Letunovits S. Sliding wear of TiC-NiMocermets. Tribol Int. 2004;37:817–24.

Selvakumar N, Ramkumar T. Effect of high temperature wear behaviour of sintered Ti-6Al-4V reinforced with nano B4C particles. Trans Indian Inst Met. 2016;69(6):1267–76.

Acknowledgements

The researchers would like to thank Mr. J.N. Balaraju, Surface Engineering Division, National Aerospace Laboratories, Bangalore-560017, India for his support in executing this research. The researchers would also like to thank Ducom Instruments, Bangalore for their support in carrying out the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Selvakumar, M., Ramkumar, T., Mohanraj, M. et al. Experimental investigations of reciprocating wear behavior of metal matrix (Ti/TiB) composites. Archiv.Civ.Mech.Eng 20, 26 (2020). https://doi.org/10.1007/s43452-020-00028-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00028-y