Abstract

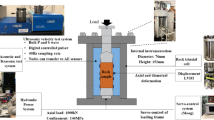

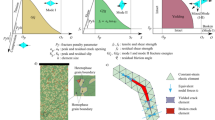

This paper investigated the relationship between the strength of fractured rock and the crack propagation process. A series of uniaxial compression tests were carried out on the rock-like material specimens with single pre-fabricated flaw. Moreover, DIC (digital image correlation) technology was utilized to monitor and analyze the failure process of specimens. The initiation of each crack was defined as a key event, and the relationship between several key events and the axial load of the specimen during the crack propagation was quantitatively analyzed. The time-sequence analysis of crack propagation was also conducted by selecting benchmark points on the both sides of major cracks. It can be found that only the wing crack propagation occurs and there is no obvious shear crack before the peak strength. When the first secondary crack initiated, the specimen reached its peak strength and the wing crack just reached its critical length. Beyond the peak strength, secondary cracks initiated and coalesced rapidly, which leads to the sudden failure of fractured rock. Therefore, the peak strength of the specimen can be assessed by taking the critical length of the steadily propagating wing crack as the condition which determines whether the specimen reaches the peak strength. Furthermore, the discrete element numerical simulation was also implemented to confirm the experimental results.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Yang SQ, Jiang YZ, Xu WY, Chen XQ. Experimental investigation on strength and failure behavior of pre-cracked marble under conventional triaxial compression. Int J Solids Struct. 2008;45(17):4796–819. https://doi.org/10.1016/j.ijsolstr.2008.04.023.

Xu Y, Dai F, Zhao T, Xu N-w, Liu Y. Fracture toughness determination of cracked chevron notched Brazilian disc rock specimen via Griffith energy criterion incorporating realistic fracture profiles. Rock Mech Rock Eng. 2016;49(8):3083–93. https://doi.org/10.1007/s00603-016-0978-0.

Dai F, Xu Y, Zhao T, Xu N-w, Liu Y. Loading-rate-dependent progressive fracturing of cracked chevron-notched Brazilian disc specimens in split Hopkinson pressure bar tests. Int J Rock Mech Min Sci. 2016;88:49–60. https://doi.org/10.1016/j.ijrmms.2016.07.003.

Zhang CY, Pu CZ, Cao RH, Jiang TT, Huang G. The stability and roof-support optimization of roadways passing through unfavorable geological bodies using advanced detection and monitoring methods, among others, in the Sanmenxia Bauxite Mine in China’s Henan Province. Bull Eng Geol Environ. 2019;78(7):5087–99. https://doi.org/10.1007/s10064-018-01439-1.

Zhang K, Cao P, Ma GW, Wang WH, Fan WC, Li KH. Strength, fragmentation and fractal properties of mixed flaws. Acta Geotech. 2016;11(4):901–12. https://doi.org/10.1007/s11440-015-0403-y.

Lin H, Yang H, Wang Y, Zhao Y, Cao R. Determination of the stress field and crack initiation angle of an open flaw tip under uniaxial compression. Theoret Appl Fract Mech. 2019;104:102358. https://doi.org/10.1016/j.tafmec.2019.102358.

Lee H, Jeon S. An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int J Solids Struct. 2011;48(6):979–99. https://doi.org/10.1016/j.ijsolstr.2010.12.001.

LNY W, HH E (2006) Fracturing behavior of prismatic specimens containing single flaws. In: Editor, editor. The 41st U.S. symposium on rock mechanics (USRMS): "50 years of rock mechanics: landmarks and future challenges. June 17–21, Golden, Colorado2006.

Zhuang X, Chun J, Zhu H. A comparative study on unfilled and filled crack propagation for rock-like brittle material. Theor Appl Fract Mech. 2014;72:110–20. https://doi.org/10.1016/j.tafmec.2014.04.004.

Aliha MRM, Ayatollahi MR, Smith DJ, Pavier MJ. Geometry and size effects on fracture trajectory in a limestone rock under mixed mode loading. Eng Fract Mech. 2010;77(11):2200–12. https://doi.org/10.1016/j.engfracmech.2010.03.009.

Jean-Pierre P, Michel B. Can natural faults propagate under mode II conditions? Tectonics. 1988;7(6):1243–56. https://doi.org/10.1029/TC007i006p01243.

Horii H, Nemat-Nasser S. Compression-induced microcrack growth in brittle solids: Axial splitting and shear failure. J Geophys Res Atmos. 1985;90(B4):3105–25. https://doi.org/10.1029/JB090iB04p03105.

Yang SQ, Chen M, Jing HW, Chen KF, Meng B. A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine. China Eng Geol. 2017;217:89–101. https://doi.org/10.1016/j.enggeo.2016.12.012.

Zhang XP, Wong LNY, Wang SJ. Effects of the ratio of flaw size to specimen size on cracking behavior. Bull Eng Geol Environ. 2015;74(1):181–93. https://doi.org/10.1007/s10064-014-0596-6.

Yan-Jun S, Geng-She Y, Hong-Wei H, Teng-Long R, Hai-Liang J. The impact of environmental temperature change on the interior temperature of quasi-sandstone in cold region: experiment and numerical simulation. Eng Geol. 2018;239:241–53. https://doi.org/10.1016/j.enggeo.2018.03.033.

Wong LNY, Einstein HH. Systematic evaluation of cracking behavior in specimens containing single flaws under uniaxial compression. Int J Rock Mech Min Sci. 2009;46(2):239–49. https://doi.org/10.1016/j.ijrmms.2008.03.006.

Jin J, Cao P, Chen Y, Pu CZ, Mao DW, Fan X. Influence of single flaw on the failure process and energy mechanics of rock-like material. Comput Geotech. 2017;86:150–62. https://doi.org/10.1016/j.compgeo.2017.01.011.

Park CH, Bobet A. Crack initiation, propagation and coalescence from frictional flaws in uniaxial compression. Eng Fract Mech. 2010;77(14):2727–48. https://doi.org/10.1016/j.engfracmech.2010.06.027.

Cao RH, Cao P, Lin H, Fan X, Zhang C, Liu T. Crack initiation, propagation, and failure characteristics of jointed rock or rock-like specimens: a review. Adv Civil Eng. 2019;PT.3:1–31. https://doi.org/10.1155/2019/6975751.

Zhao Y, Wang Y, Wang W, Tang L, Liu Q, Cheng G. Modeling of rheological fracture behavior of rock cracks subjected to hydraulic pressure and far field stresses. Theoret Appl Fract Mech. 2019;101:59–66.

Fan X, Li KH, Lai HP, Xie YL, Cao RH, Zheng J. Internal stress distribution and cracking around flaws and openings of rock block under uniaxial compression: a particle mechanics approach. Comput Geotech. 2018;102:28–38. https://doi.org/10.1016/j.compgeo.2018.06.002.

Dobroskok A, Ghassemi A, Linkov A. Extended structural criterion for numerical simulation of crack propagation and coalescence under compressive loads. Int J Fract. 2005;133(3):223–46. https://doi.org/10.1007/s10704-005-4042-4.

Baud P, Reuschlé T, Charlez P. An improved wing crack model for the deformation and failure of rock in compression. Int J Rock Mech Mining Ences Geomech Abs. 1996;33(5):539–42. https://doi.org/10.1016/0148-9062(96)00004-6.

Horii H, Nemat-Nasser S. Brittle failure in compression: splitting, faulting and brittle-ductile transition. Philosoph Transac Royal Soc A Math Phys Eng Sci. 1986;319(1549):337–74. https://doi.org/10.1098/rsta.1986.0101.

Steif PS. Crack extension under compressive loading. Eng Fract Mech. 1984;20(3):463–73. https://doi.org/10.1016/0013-7944(84)90051-1.

Cao R, Yao R, Meng J, Lin Q, Lin H, Li S. Failure mechanism of non-persistent jointed rock-like specimens under uniaxial loading: laboratory testing. Int J Rock Mech Min Sci. 2012. https://doi.org/10.1016/j.ijrmms.2020.104341.

Lin QB, Cao P, Cao RH, Lin H, Meng JJ. Mechanical behavior around double circular openings in a jointed rock mass under uniaxial compression. Arch Civ Mech Eng. 2020;20(1):18. https://doi.org/10.1007/s43452-020-00027-z.

Zhao Y, Zhang L, Liao J, Wang W, Liu Q, Tang L. Experimental study of fracture toughness and subcritical crack growth of three rocks under different environments. Int J Geomech. 2020;20(8):04020128.

Li YF, Sun T, Tian YS, Gao Q, Tan CQ. A stress intensity factor estimation method for the kinked crack under anti-plane load. Theor Appl Fract Mech. 2018;93:319–25. https://doi.org/10.1016/j.tafmec.2017.10.003.

Yang WD, Li GZ, Ranjith PG, Fang LD. An experimental study of mechanical behavior of brittle rock-like specimens with multi-non-persistent joints under uniaxial compression and damage analysis. Int J Damage Mech. 2019;28(10):1490–522. https://doi.org/10.1177/1056789519832651.

Wang M, Wan W. A new empirical formula for evaluating uniaxial compressive strength using the Schmidt hammer test. Int J Rock Mech Min Sci. 2019;123:11. https://doi.org/10.1016/j.ijrmms.2019.104094.

Jiang MJ, Liu J, Crostad GB, Li T. DEM analysis of the effect of joint geometry on the shear behavior of rocks. C R Mec. 2017;345(11):779–96. https://doi.org/10.1016/j.crme.2017.07.004.

Acknowledgements

This paper gets its funding from projects (51774322; 51774107; 42077249) supported by National Natural Science Foundation of China; Project (2018JJ2500) supported by Hunan Provincial Natural Science Foundation of China; Project (KFJJ20) supported by the State Key Laboratory of Explosion Science and Technology (Beijing Institute of Technology). The authors wish to acknowledge these supports.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, H., Lin, H., Wang, Y. et al. Investigation of the correlation between crack propagation process and the peak strength for the specimen containing a single pre-existing flaw made of rock-like material. Archiv.Civ.Mech.Eng 21, 68 (2021). https://doi.org/10.1007/s43452-021-00175-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00175-w