Abstract

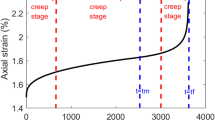

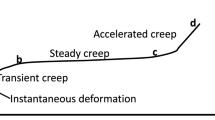

To study the damage characteristics of rock mass under multi-level creep load, damage variable D was defined based on the spatio-temporal evolution characteristics of deformation modulus E, and the Kachanov damage theory is used to describe the damage evolution, then the damage evolution equation of the rock mass under multi-level creep load is obtained. Combining the damage evolution equation with the Lemaitre strain equivalence principle, the creep damage constitutive model of rock mass under multi-level creep load considering initial damage is obtained. By comparing the results of uniaxial and triaxial tests with the calculated values of the model, the rationality, reliability, application range of the model proposed in this paper is verified. According to the results of parameter inversion, obtain the relationship between damage, stress and time. Results show that time and stress are the important factors influencing the damage of rock mass under multi-level creep loading, the damage increases with time and stress level. However, the influence of time and stress on damage has a significant stress response characteristics: under low stress, the instantaneous damage Dis caused by the instantaneous stress loading is the main reason for the damage. With the increase of the load level, the main cause of the damage gradually changes from the instantaneous loading of the stress to the creep accumulation of the damage, and the greater the initial damage, the higher the time-dependent damage DiT proportion in the global damage.

Similar content being viewed by others

Data availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

References

Potyondy DO. Simulating stress corrosion with a bonded-particle model for rock. Int J Rock Mech Min Sci. 2007;44(5):677–91. https://doi.org/10.1016/j.ijrmms.2006.10.002.

Lin H, Zhang X, Cao RH, Wen ZJ. Improved nonlinear Burgers shear creep model based on the time-dependent shear strength for rock. Environ Earth Sci. 2020;79(6):9. https://doi.org/10.1007/s12665-020-8896-6.

Zhou HW, Wang CP, Han BB, Duan ZQ. A creep constitutive model for salt rock based on fractional derivatives. Int J Rock Mech Min Sci. 2011;48(1):116–21. https://doi.org/10.1016/j.ijrmms.2010.11.004.

Tang H, Wang D, Huang R, Pei X, Chen W. A new rock creep model based on variable-order fractional derivatives and continuum damage mechanics. Bull EngGeolEnv. 2018;77(1):375–83.

Zhang X, Lin H, Wang Y, Yong R, Zhao Y, Du S. Damage evolution characteristics of saw-tooth joint under shear creep condition. Int J Damage Mech. 2020. https://doi.org/10.1177/1056789520974420.

Zhang S, Liu W, Lv H. Creep energy damage model of rock graded loading. Results Phys. 2019;12:1119–25. https://doi.org/10.1016/j.rinp.2018.12.081.

Shan R-L, Bai Y, Ju Y, Han T-Y, Dou H-Y, Li Z-L. Study on the triaxial unloading creep mechanical properties and damage constitutive model of red sandstone containing a single ice-filled flaw. Rock Mech Rock Eng. 2020. https://doi.org/10.1007/s00603-020-02274-1.

Wang RB, Xu WY, Wang W, Zhang JC. A nonlinear creep damage model for brittle rocks based on time-dependent damage. Eur J Environ CivEng. 2013;17:S111–25. https://doi.org/10.1080/19648189.2013.834589.

Zhou HW, Wang CP, Mishnaevsky L, Duan ZQ, Ding JY. A fractional derivative approach to full creep regions in salt rock. Mech Time-Depend Mater. 2013;17(3):413–25. https://doi.org/10.1007/s11043-012-9193-x.

Chen BR, Zhao XJ, Feng XT, Zhao HB, Wang SY. Time-dependent damage constitutive model for the marble in the Jinping II hydropower station in China. Bull EngGeolEnv. 2014;73(2):499–515. https://doi.org/10.1007/s10064-013-0542-z.

Zhao YL, Cao P, Wang WJ, Wan W, Liu YK. Viscoelasto-plastic rheological experiment under circular increment step load and unload and nonlinear creep model of soft rocks. J Cent South UnivTechnol. 2009;16(3):488–94. https://doi.org/10.1007/s11771-009-0082-7.

Xu S, Lei H, Li C, Liu H, Lai J, Liu T. Model test on mechanical characteristics of shallow tunnel excavation failure in gully topography. Eng Fail Anal. 2021. https://doi.org/10.1016/j.engfailanal.2020.104978.

Shi C, Yang B, Zhang Y, Yang J. Application of discrete-element numerical simulation for calculating the stability of dangerous rock mass: a case study. Int J Geomech. 2020. https://doi.org/10.1061/(asce)gm.1943-5622.0001872.

Zhang H, Meng X, Yang G. A study on mechanical properties and damage model of rock subjected to freeze-thaw cycles and confining pressure. Cold RegSciTechnol. 2020;174:103056. https://doi.org/10.1016/j.coldregions.2020.103056.

Li G, Cheng XF, Pu H, Tang CA. Damage smear method for rock failure process analysis. J Rock MechGeotechEng. 2019;11(6):1151–65. https://doi.org/10.1016/j.jrmge.2019.06.007.

Liu L, Ji H, Elsworth D, Zhi S, Lv X, Wang T. Dual-damage constitutive model to define thermal damage in rock. Int J Rock Mech Min Sci. 2020;126:104185. https://doi.org/10.1016/j.ijrmms.2019.104185.

He M, Li N, Zhu C, Chen Y, Wu H. Experimental investigation and damage modeling of salt rock subjected to fatigue loading. Int J Rock Mech Min Sci. 2019;114:17–23. https://doi.org/10.1016/j.ijrmms.2018.12.015.

Liu H, Yuan X, Xie T. A damage model for frost heaving pressure in circular rock tunnel under freezing-thawing cycles. TunnUndergr Space Technol. 2019;83:401–8. https://doi.org/10.1016/j.tust.2018.10.012.

Rabat A, Tomas R, Cano M, Miranda T. Impact of water on peak and residual shear strength parameters and triaxial deformability of high-porosity building calcarenite stones: interconnection with their physical and petrological characteristics. Constr Build Mater. 2020. https://doi.org/10.1016/j.conbuildmat.2020.120789.

Hu J, Wen G, Lin Q, Cao P, Li S. Mechanical properties and crack evolution of double-layer composite rock-like specimens with two parallel fissures under uniaxial compression. TheoretApplFractMech. 2020;108:102610. https://doi.org/10.1016/j.tafmec.2020.102610.

Chen Y, Lin H, Ding X, Xie S. Scale effect of shear mechanical properties of non-penetrating horizontal rock-like joints. Environ Earth Sci. 2021;80(5):192. https://doi.org/10.1007/s12665-021-09485-x.

Lin H, Lei D, Yong R, Jiang C, Du S. Analytical and numerical analysis for frost heaving stress distribution within rock joints under freezing and thawing cycles. Environ Earth Sci. 2020;79:305. https://doi.org/10.1007/s12665-020-09051-x.

Liu HY, Lv SR, Zhang LM, Yuan XP. A dynamic damage constitutive model for a rock mass with persistent joints. Int J Rock Mech Min Sci. 2015;75:132–9. https://doi.org/10.1016/j.ijrmms.2015.01.013.

Chen Y, Lin H, Wang Y, Zhao Y. Damage statistical empirical model for fractured rock under freezing-thawing cycle and loading. Geofluids. 2020. https://doi.org/10.1155/2020/8842471.

Gautam PK, Dwivedi R, Kumar A, Kumar A, Verma AK, Singh KH, et al. Damage characteristics of jalore granitic rocks after thermal cycling effect for nuclear waste repository. Rock Mech Rock Eng. 2020. https://doi.org/10.1007/s00603-020-02260-7.

Christopher J, Praveen C, Ganesan V, Reddy GVP, Albert SK. Influence of varying nitrogen on creep deformation and damage behaviour of type 316L in the framework of continuum damage mechanics approach. Int J Damage Mech. 2020. https://doi.org/10.1177/1056789520939622.

Zhang Q, Shen M, Ding W. The shear creep characteristics of a green schist weak structural marble surface. MechAdv Mater Struct. 2012;22(9):697–704. https://doi.org/10.1080/15376494.2011.584147.

Hu JH, Wen GP, Lin QB, Cao P, Li S. Mechanical properties and crack evolution of double-layer composite rock-like specimens with two parallel fissures under uniaxial compression. TheoretApplFractMech. 2020;108:11. https://doi.org/10.1016/j.tafmec.2020.102610.

Zhao Y, Zhang L, Liao J, Wang W, Liu Q, Tang L. Experimental study of fracture toughness and subcritical crack growth of three rocks under different environments. Int J Geomech. 2020;20(8):04020128.

Zhao Y, Wang Y, Wang W, Tang L, Liu Q, Cheng G. Modeling of rheological fracture behavior of rock cracks subjected to hydraulic pressure and far field stresses. TheoretApplFractMech. 2019;101:59–66.

Li K, Cheng Y, Yin ZY, Han DY, Meng JJ. Size effects in a transversely isotropic rock under brazilian tests: laboratory testing. Rock Mech Rock Eng. 2020;53:2623–42. https://doi.org/10.1007/s00603-020-02058-7.

Han D, Li K, Meng J. Evolution of nonlinear elasticity and crack damage of rock joint under cyclic tension. Int J Rock Mech Min Sci. 2020;128:104286. https://doi.org/10.1016/j.ijrmms.2020.104286.

Wu W, Gong F, Yang W. Experimental simulation study of spalling in deep rectangular tunnel with plastic fine grain marble. TunnUndergr Space Technol. 2020. https://doi.org/10.1016/j.tust.2020.103319.

Hou R, Zhang K, Tao J, Xue X, Chen Y. A nonlinear creep damage coupled model for rock considering the effect of initial damage. Rock Mech Rock Eng. 2018;52(5):1275–85. https://doi.org/10.1007/s00603-018-1626-7.

Zhao Y, Zhang L, Wang W, Wan W, Li S, Ma W, et al. Creep behavior of intact and cracked limestone under multi-level loading and unloading cycles. Rock Mech Rock Eng. 2017;50(6):1409–24. https://doi.org/10.1007/s00603-017-1187-1.

Li H, Yang DM, Zhong ZL, Sheng Y, Liu XR. Experimental investigation on the micro damage evolution of chemical corroded limestone subjected to cyclic loads. Int J Fatigue. 2018;113:23–32. https://doi.org/10.1016/j.ijfatigue.2018.03.022.

Zhang H, Guo P, Wang Y, Zhao Y, Lin H, Liu Y, et al. Fracture behavior of rock with initial damage: theoretical, experimental, and numerical investigations. Geofluids. 2020;2020:8886843. https://doi.org/10.1155/2020/8886843.

Zhang CY, Lin H, Qiu CM, Jiang TT, Zhang JH. The effect of cross-section shape on deformation, damage and failure of rock-like materials under uniaxial compression from both a macro and micro viewpoint. Int J Damage Mech. 2020;20:1–20. https://doi.org/10.1177/1056789520904119.

Zhang C, Zou P, Wang Y, Jiang T, Lin H, Cao P. An elasto-visco-plastic model based on stress functions for deformation and damage of water-saturated rocks during the freeze-thaw process. Constr Build Mater. 2020;250:118862. https://doi.org/10.1016/j.conbuildmat.2020.118862.

Lin H, Zhang X, Wang YX, Yong R, Fan X, Du SG, et al. Improved nonlinear Nishihara shear creep model with variable parameters for rock-like materials. Advances in Civil Engineering. 2020;2020:7302141. https://doi.org/10.1155/2020/7302141.

Xie S, Lin H, Wang Y, Cao R, Yong R, Du S, et al. Nonlinear shear constitutive model for peak shear-type joints based on improved Harris damage function. Arch Civil MechEng. 2020;20(3):95. https://doi.org/10.1007/s43452-020-00097-z.

Yang W, Li G, Ranjith PG, Fang L. An experimental study of mechanical behavior of brittle rock-like specimens with multi-non-persistent joints under uniaxial compression and damage analysis. Int J Damage Mech. 2019;28(10):1490–522. https://doi.org/10.1177/1056789519832651.

Mitaim S, Detournay E. Damage around a cylindrical opening in a brittle rock mass. Int J Rock Mech Min Sci. 2004;41(8):1447–57. https://doi.org/10.1016/j.ijrmms.2004.09.009.

Yang W, Zhang Q, Ranjith PG, Yu R, Luo G, Huang C, et al. A damage mechanical model applied to analysis of mechanical properties of jointed rock masses. TunnUndergr Space Technol. 2019;84:113–28. https://doi.org/10.1016/j.tust.2018.11.004.

Acknowledgements

This paper gets its funding from projects (51774322) supported by National Natural Science Foundation of China; Project (2018JJ2500) supported by Hunan Provincial Natural Science Foundation of China. The authors wish to acknowledge these supports.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhang, X., Lin, H., Wang, Y. et al. Creep damage model of rock mass under multi-level creep load based on spatio-temporal evolution of deformation modulus. Archiv.Civ.Mech.Eng 21, 71 (2021). https://doi.org/10.1007/s43452-021-00224-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00224-4