Abstract

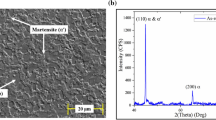

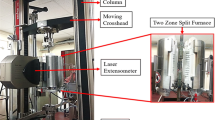

Dual-phase (DP) steel has an excellent blend of various mechanical properties; hence it is used immensely in the automotive industries. It is challenging to form high strength DP steel into desirable complex shapes because of their limited formability at room temperature conditions. One of the proven alternatives is warm/hot forming. In-detail investigation of forming limits over DP590 steel has been carried out in present work. Firstly, various constitutive models and yield criteria have been formulated for DP steel at different temperatures and strain rates. The modified Arrhenius (m-A) constitutive model and Barlat 1989 yielding function displayed the best prediction of flow stress and anisotropic yielding behavior, respectively. The experimental forming limits (FLD) were evaluated at 300, 473 and 673 K temperatures using Nakazima tests. The forming limits of the material are improved by approximately 24% on increasing the temperature from 300 to 673 K. The textural analysis of the deformed surface has been done using electron back scattered diffraction (EBSD) studies, and γ fibers are found to be responsible for improvement in the formability of the material. Additionally, Marciniak and Kuczynski (MK) model was used to predict the theoretical FLD using all the possible combinations of constitutive models and yield criteria. Finally, the m-A constitutive model, along with Barlat 1989 yielding function has shown the best prediction for forming limits at all the temperatures. The finite element study has also been performed using mentioned material models for accurate prediction of dome height, surface strain and thickness distribution across the specimens.

Similar content being viewed by others

References

Pandre S, Morchhale A, Kotkunde N, Singh SK. Influence of processing temperature on formability of thin-rolled DP590 steel sheet. Mater Manuf Process. 2020;35:901–9. https://doi.org/10.1080/10426914.2020.1743854.

Pandre S, Kotkunde N, Takalkar P, Morchhale A, Sujith R, Singh SK. Flow stress behavior, constitutive modeling, and microstructural characteristics of DP 590 steel at elevated temperatures. J Mater Eng Perform. 2019;28:7565–81. https://doi.org/10.1007/s11665-019-04497-y.

Basak S, Katiyar BS, Orozco-Gonzalez P, Baltazar-Hernandez VH, Arora KS, Panda SK. Microstructure, forming limit diagram, and strain distribution of pre-strained DP-IF steel tailor–welded blank for auto body application. Int J Adv Manuf Technol. 2019;104:1749–67. https://doi.org/10.1007/s00170-019-03938-1.

Lin YC, Chen X-M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des. 2011;32:1733–59. https://doi.org/10.1016/j.matdes.2010.11.048.

Badrish A, Morchhale A, Kotkunde N, Singh SK. Parameter optimization in the thermo-mechanical V-bending process to minimize spring back of Inconel 625 alloy. Arab J Sci Eng. 2020;45:5295–309. https://doi.org/10.1007/s13369-020-04395-9.

Li Y, Cheng Z, Chen X, Long Y, Li X, Li F, Li J, Twiefel J. Constitutive modeling and deformation analysis for the ultrasonic-assisted incremental forming process. Int J Adv Manuf Technol. 2019;104:2287–99. https://doi.org/10.1007/s00170-019-04031-3.

Morchhale A, Kotkunde N, Singh SK. Prediction of flow stress and forming limits for IN625 at elevated temperature using the theoretical and neural network approach. Mater Perform Charact. 2021;10:146–65. https://doi.org/10.1520/MPC20200153.

Wu M, Zha G, Zirui G. FEA of vertical parts formed with multistage incremental sheet metal forming based on the forming limit stress diagram. Int J Adv Manuf Technol. 2017;93:2155–60. https://doi.org/10.1007/s00170-017-0630-5.

Badrish CA, Morchhale A, Kotkunde N, Singh SK. Experimental and finite element studies of springback using split-ring test for Inconel 625 alloy. Adv Mater Process Technol. 2020;6:540–6. https://doi.org/10.1080/2374068X.2020.1728644.

Basak S, Panda SK. Failure strains of anisotropic thin sheet metals: experimental evaluation and theoretical prediction. Int J Mech Sci. 2019;151:356–74. https://doi.org/10.1016/j.ijmecsci.2018.10.065.

Badrish A, Morchhale A, Kotkunde N, Singh SK. Influence of material modeling on warm forming behavior of nickel based super alloy. Int J Mater Form. 2020;13:445–65. https://doi.org/10.1007/s12289-020-01548-x.

Keeler SP. Determination of forming limits in automotive stampings. SAE Tech. 1965;42:683–91.

Goodwin GM. Application of strain analysis to sheet metal forming problems in the press shop. SAE Tech Pap. 1968;60:764–74.

Mahalle G, Morchhale A, Kotkunde N, Gupta AK, Singh SK, Lin YC. Forming and fracture limits of IN718 alloy at elevated temperatures: experimental and theoretical investigation. J Manuf Process. 2020;56:482–99. https://doi.org/10.1016/j.jmapro.2020.04.070.

Sugimoto K, Kobayashi M, Nagasaka A, Hashimoto S. Warm stretch-formability of TRIP-aided dual-phase sheet steels. ISIJ Int. 1995;35:1407–14. https://doi.org/10.2355/isijinternational.35.1407.

Tokita Y, Nakagaito T, Tamai Y, Urabe T. Stretch formability of high strength steel sheets in warm forming. J Mater Process Technol. 2017;246:77–84. https://doi.org/10.1016/j.jmatprotec.2017.03.012.

Ma BL, Wan M, Liu ZG, Li XJ, Wu XD, Diao KS. Experimental and numerical determination of hot forming limit curve of advanced high-strength steel. J Mater Eng Perform. 2017;26:3299–306. https://doi.org/10.1007/s11665-017-2751-2.

Marciniak Z, Kuczyński K. Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci. 1967;9:609–20. https://doi.org/10.1016/0020-7403(67)90066-5.

Small NR, Williams DK, Roy R, Hazra SK. Accounting for the effect of heterogeneous plastic deformation on the formability of aluminium and steel sheets. Int J Adv Manuf Technol. 2020;109:397–410. https://doi.org/10.1007/s00170-020-05372-0.

Pandre S, Morchhale A, Mahalle G, Kotkunde N, Suresh K, Singh SK. Fracture limit analysis of DP590 steel using single point incremental forming: experimental approach, theoretical modeling and microstructural evolution. Archiv Civ Mech Eng. 2021; 21:95. https://doi.org/10.1007/s43452-021-00243-1.

Hussaini SM, Krishna G, Gupta AK, Singh SK. Development of experimental and theoretical forming limit diagrams for warm forming of austenitic stainless steel 316. J Manuf Process. 2015;18:151–8. https://doi.org/10.1016/j.jmapro.2015.03.005.

Johnson GR, Cook WH. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech. 1985;21:31–48. https://doi.org/10.1016/0013-7944(85)90052-9.

Lin YC, Chen X-M, Liu G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel. Mater Sci Eng A. 2010;527:6980–6. https://doi.org/10.1016/j.msea.2010.07.061.

Gao CY, Zhang LC. Constitutive modelling of plasticity of fcc metals under extremely high strain rates. Int J Plast. 2012;32–33:121–33. https://doi.org/10.1016/j.ijplas.2011.12.001.

Kotkunde N, Deole AD, Gupta AK, Singh SK. Comparative study of constitutive modeling for Ti–6Al–4V alloy at low strain rates and elevated temperatures. Mater Des. 2014;55:999–1005. https://doi.org/10.1016/j.matdes.2013.10.089.

Zerilli FJ, Armstrong RW. Dislocation-mechanics-based constitutive relations for material dynamics calculations. J Appl Phys. 1987;61:1816–25. https://doi.org/10.1063/1.338024.

Samantaray D, Mandal S, Bhaduri AK. A comparative study on Johnson Cook, modified Zerilli-Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr–1Mo steel. Comput Mater Sci. 2009;47:568–76. https://doi.org/10.1016/j.commatsci.2009.09.025.

Yuan Z, Li F, Ji G, Qiao H, Li J. Flow stress prediction of SiCp/Al composites at varying strain rates and elevated temperatures. J Mater Eng Perform. 2014;23:1016–27. https://doi.org/10.1007/s11665-013-0838-y.

Zener C, Hollomon JH. Effect of strain rate upon plastic flow of steel. J Appl Phys. 1944;15:22–32. https://doi.org/10.1063/1.1707363.

Kotkunde N, Badrish A, Morchhale A, Takalkar P, Singh SK. Warm deep drawing behavior of Inconel 625 alloy using constitutive modelling and anisotropic yield criteria. Int J Mater Form. 2019;13:355–69. https://doi.org/10.1007/s12289-019-01505-3.

Khan AS, Liang R. Behaviors of three BCC metal over a wide range of strain rates and temperatures: experiments and modeling. Int J Plast. 1999;15:1089–109. https://doi.org/10.1016/S0749-6419(99)00030-3.

Banabic D. Sheet metal forming processes: constitutive modelling and numerical simulation. Berlin Heidelberg: Springer-Verlag; 2010. https://doi.org/10.1007/978-3-540-88113-1.

Hill R, Orowan E. A theory of the yielding and plastic flow of anisotropic metals. Proc Roy Soc Lond A Math Phys Sci. 1948;193:281–97. https://doi.org/10.1098/rspa.1948.0045.

Barlat F, Lian K. Plastic behavior and stretchability of sheet metals. Part I: a yield function for orthotropic sheets under plane stress conditions. Int J Plast. 1989;5:51–66. https://doi.org/10.1016/0749-6419(89)90019-3.

Pandre S, Takalkar P, Morchhale A, Kotkunde N, Singh SK. Prediction capability of anisotropic yielding behaviour for DP590 steel at elevated temperatures. Adv Mater Process Technol. 2020;6:476–84. https://doi.org/10.1080/2374068X.2020.1728647.

Kotkunde N, Deole AD, Gupta AK, Singh SK. Experimental and numerical investigation of anisotropic yield criteria for warm deep drawing of Ti–6Al–4V alloy. Mater Des. 2014;63:336–44. https://doi.org/10.1016/j.matdes.2014.06.017.

Dharavath B, Morchhale A, Singh SK, Kotkunde N, Naik MT. Experimental determination and theoretical prediction of limiting strains for ASS 316L at hot forming conditions. J Mater Eng Perform. 2020. https://doi.org/10.1007/s11665-020-04968-7.

Prasad KS, Panda SK, Kar SK, Murty SVSN, Sharma SC. Prediction of fracture and deep drawing behavior of solution treated Inconel-718 sheets: numerical modeling and experimental validation. Mater Sci Eng A. 2018;733:393–407. https://doi.org/10.1016/j.msea.2018.07.007.

Choi S-H, Kim E-Y, Woo W, Han SH, Kwak JH. The effect of crystallographic orientation on the micromechanical deformation and failure behaviors of DP980 steel during uniaxial tension. Int J Plast. 2013;45:85–102. https://doi.org/10.1016/j.ijplas.2012.11.013.

Jieyun ZZ, Wang YZ, Zhao A, Chen J. Microstructures, mechanical properties and textures of deep drawing. Adv Mater Res. 2012;535–537:670–3. https://doi.org/10.4028/www.scientific.net/AMR.535-537.670.

Wang Z, Zhao Z, Zhao A, Ye J. Microstructure and recrystallization texture characterization of cold-rolled dual-phase steel. Adv Mater Res. 2012;430–432:1223–6.

Adhikary M, Chakraborty A, Das A, Venugopalan T, Ravi Kumar B. Influence of annealing texture on dynamic tensile deformation characteristics of Dual phase steel. Mater Sci Eng A. 2018;736:209–18. https://doi.org/10.1016/j.msea.2018.08.103.

Raabe L. Rolling and textures of BCC metals. Mater Sci Forum. 1994;162:597–610.

Hajian M, Assempour A. Numerical study on the effects of main BCC rolling texture components on the formability of sheet metals. Int J Adv Manuf Technol. 2015;80:245–53. https://doi.org/10.1007/s00170-015-6793-z.

Menapace C, Sartori N, Pellizzari M, Straffelini G. Hot deformation behavior of four steels: a comparative study. J Eng Mater Technol. 2018;140: 021006. https://doi.org/10.1115/1.4038670.

Sellars CM, Tegart WJM. Relationship between strength and structure in deformation at elevated temperatures. Mem Sci Rev Met. 1966;63:731–45.

Shen F, Münstermann S, Lian J. Forming limit prediction by the Marciniak-Kuczynski model coupled with the evolving non-associated Hill48 plasticity model. J Mater Process Technol. 2021;287: 116384. https://doi.org/10.1016/j.jmatprotec.2019.116384.

Banabic D, Kami A, Comsa D-S, Eyckens P. Developments of the Marciniak-Kuczynski model for sheet metal formability: a review. J Mater Process Technol. 2021;287: 116446. https://doi.org/10.1016/j.jmatprotec.2019.116446.

Singh SK, Mahesh K, Kumar A, Swathi M. Understanding formability of extra-deep drawing steel at elevated temperature using finite element simulation. Mater Des. 2010;31:4478–84. https://doi.org/10.1016/j.matdes.2010.04.049.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no financial or commercial conflict of interest.

Ethical approval

The authors declare that the research was conducted according to the ethical standards.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pandre, S., Morchhale, A., Kotkunde, N. et al. Prediction of forming limits and microstructural evolution during warm stretch forming of DP590 steel. Archiv.Civ.Mech.Eng 21, 108 (2021). https://doi.org/10.1007/s43452-021-00262-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00262-y