Abstract

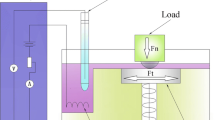

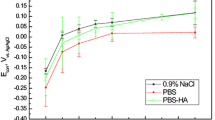

In this study, CoCrMo alloy was oxidized in plasma environment at the temperatures of 600 °C to 800 °C for 1 h to 5 h with 100% O2 gas and its tribological behavior was investigated. After the plasma oxidizing process, the compound and diffusion layers were formed on the surface. XRD results show that Cr2O3, α-Co and ε-Co phases diffracted from the modified layers after plasma oxidizing. The untreated and treated CoCrMo samples were subjected to wear tests both in dry and simulated body fluid conditions, and normal loads of 2 N and 10 N were used. For the sliding wear test, alumina balls were used as counter materials. It was observed that the wear resistance of CoCrMo alloy was increased after the plasma oxidizing process. The lowest wear rate was obtained from the samples that were oxidized at 800 °C for 5 h. It was detected that both wear environment and load have significant effects on the wear behavior of this alloy, and the wear resistance of oxidized CoCrMo alloy is higher when oxide-based counterface is used. The wear rates of both untreated and plasma oxidized samples increase under high loads.

Similar content being viewed by others

References

Gümüşderelioğlu M. Biyomalzemeler. Bilim ve Teknik Dergisi, TÜBİTAK, 2002, 7, 20–21. (in Turkish)

Liu C. Biomimetic synthesis of collagen/nano-hydro-xyapitate scaffold for tissue engineering. Journal of Bionic Engineering, 2008, 5, 1–8.

Niinomi M. Recent metallic materials for biomedical applications. Metallurgical and Materials Transactions A, 2001, 32A, 477–486.

Niinomi M. Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials, 2008, 1, 30–42.

Lanning B R, Wei R. High intensity plasma ion nitriding of orthopedic materials: Part II. Microstructural analysis. Surface and Coatings Technology, 2004, 186, 314–319.

Wei R, Brooker T, Rincon C, Arps J. High-intensity plasma ion nitriding of orthopedic materials: Part I. Tribological study. Surface and Coatings Technology, 2004, 186, 305–313.

Somers M A J, Christiansen T. Kinetics of microstructure evolution during gaseous thermochecical surface treatment. Journal of Phase Equilibria and Diffusion, 2005, 26, 520–528.

Chu P K, Chen J Y, Wang L P, Huang N. Plasma-surface modification of biomaterials. Material Science and Engineering R, 2002, 36, 143–206.

Luo Y, Yang L, Tian M. Influence of bio-lubricants on the tribological properties of Ti6Al4V alloy. Journal of Bionic Engineering, 2013, 10, 84–89.

Munoz A I, Mischler S. Effect of the environment on wear ranking and corrosion of biomedical CoCrMo alloys. Journal of Material Science-Materials in Medicine, 2011, 22, 437–450.

Wang Q, Zhang L, Dong J. Effects of plasma nitriding on microstructure and tribological properties of CoCrMo alloy implant materials. Journal of Bionic Engineering, 2010, 7, 337–344.

Tsai H, Lu F, Chieh Y. Plasma oxidation of Al thin films on Si substrates. Thin Solid Films, 2007, 516, 1871–1876.

Hodgson A W E, Kurz S, Virtanen S, Fervel V, Olsson C O A, Mischler S. Passive and transpassive behaviour of CoCrMo in simulated biological solutions. Electrochimica Acta, 2004, 49, 2167–2178.

Lewis A C, Heard P J. The effects of calcium phosphate deposition upon corrosion of CoCr alloys and the potential for implant failure. Journal of Biomedical Materials Research Part A, 2005, 75, 365–373.

Yetim A F., Yıldız F., Vangölü Y, Alsaran A, Çelik A. Several plasma diffusion processes for improving wear properties of Ti6Al4V alloy. Wear, 2009, 267, 2179–2185.

Vidal C V, Munoz A I. Effect of thermal and applied potential on the electrochemical behaviour of CoCrMo biomedical alloy. Electrochimica Acta, 2009, 54, 1798–1809.

Dong M, Shen B. Oxidation resistance of boronized Co-CrMo alloy. International Journal of Refractory Metals and Hard Materials, 2010, 28, 424–428.

Alsaran, A, Çelik A, Efeoğlu İ, Baran, Ö, Albayrak Ç. Friction and wear properties in SBF of Ti6Al4V alloy coated with various oxidation treatments. The 5th National Biomechanics Congress, Izmir, Turkey, 2010, 57–58.

Kokubo T, Takamada H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials, 2006, 27, 2907–2915.

Yilbas B S, Sahin A Z, Garni A Z, Said S A M, Ahmed Z, Abdulaleem B J, Sami M. Plasma nitriding of Ti-6Al-4V alloy to improve some tribological properties. Surface and Coatings Technology, 1996, 80, 287–282.

Ribeiro R, Ingole S, Usta M, Bindal C, Ucisik A H, Liang H. Tribological investigation of tantalum boride coating under dry and simulated body fluid conditions. Wear, 2007, 262, 1380–1386.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çelik, A., Aslan, M., Yetim, A.F. et al. Wear Behavior of Plasma Oxidized CoCrMo Alloy under Dry and Simulated Body Fluid Conditions. J Bionic Eng 11, 303–310 (2014). https://doi.org/10.1016/S1672-6529(14)60035-4

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(14)60035-4