Abstract

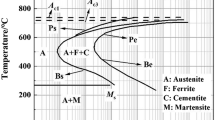

The CCT diagrams of a class of Fe-(0.1–0.6)C-(0.4–2.0)Si-(0.4–2.0)Mn-(0.5–2.0)Cr-(0.0–0.8)Mo steels are predicted by an artificial neural network (ANN) model. The model indicates that an increase in carbon concentration (C wt%) gives rise to a decrease in bainite start (BS) temperatures. The rate of decrease depends also on cooling rate. Additions of Si, Mn, Cr and Mo all decrease the bainite start temperature. The dependencies for different alloying elements vary: 32, 100–120, 100–130, and 70–150°C per wt% of Si, Mn, Cr, and Mo, respectively. Mn shifts the whole bainite transformation region to the far right-hand side of the CCT diagram, while C, Cr, and Mo have considerable, and Si has minor effects on the incubation period of bainite. Mn and Cr significantly decrease the MS temperature, while Si only has a minor influence. When Mo < 0.5 wt% it has a minor influence, whilst when Mo > 0.5 wt%, it increases MS temperature. Quasi-isochronal and quasi-isothermal methods have been used to analyze the influence of the proportion of Mo and C upon the BS and incubation period. Attempts, for qualitative explanations using the shear and diffusion mechanism, as well as a certain amount of thermodynamic analysis, have been made to interpret the influence of alloying elements on the nucleation of the bainite reaction. The results support that bainite reaction takes place utilizing a diffusion-controlled mechanism.

Similar content being viewed by others

References

H. K. D. H. Bhadeshia, Metal Science 16 (1982) 159.

K. R. Kinsman, E. Eichen and H. I. Aaronson, Metallurgical Transactions A 6A (1975) 303.

J. S. Kirkaldy, B. A. Thomson and E. A. Baganis, in “Hardenability Concepts with Applications to Steels,” edited by D. V. Doane and J. S. Kirkaldy (AIME: Warrendale PA, 1978) p. 82.

J. S. Kirkaldy and D. Venugopalan, in “Phase Trans-formations in Ferrous Alloys,” edited by A. R. Marder and J. I. Goldstein (AIME: Warrendale, Pennsylvania, 1984) p. 125.

M. Enomoto, ISIJ International 32 (1992) 297.

N. Saunders, A. P. Miodownik and R. W. Cahn, (eds.), CALPHAD Calculation of Phase Diagrams: A Comprehen-sive Guide. 1998, 1.

J. S. Kirkaldy and R. C. Sharma, Scripta Metallurgica 16 (1982) 1193.

I. Alexander and H. Morton, “An Introduction to Neural Computing” (Chapmann & Hall, London, 1993).

W. Steven and A. G. Haynes, JISI 183 (1956) 349.

C. Y. Kung and J. J. Rayment, “Hardenability concepts with applications to steel,” Anonymous TMS-AIME, Warrendale, PA, 1978; p. 229.

K. W. Andrews, JISI 203 (1965) 721.

R. Hecht-nielsen, “Neurocomputing” (Addison-Wesley Publishing Company, Inc. Reading, Massachusetts, 1991).

W. G. Vermeulen, Application of Artificial Neural Networks in Metal Production Processes, 1995.

H. K. D. H. Bhadeshia and J. W. Christian, Metall. Trans. A 21A(4) (1990) 767.

T. Ko and A. M. Cottrell, JISI 172 (1952) 307.

F. R. Hehemann, K. R. Kinsman and H. I. Aaronson, Metall. Trans. 3 (1972) 1077.

D. E. Coates, ibid. 4 (1973) 2313.

R. W. Kennard and L. A. Stone, Technometrics 11 (1969) 137.

W. W. Cias, Climax Molybdenum Company, Greenwich, 1973.

G. F. Van Der Voort, ASM International, Reading PA, 1991.

C. Dorrepaal, Modelling of CCT Diagrams Using Artificial Neural Networks. 1997, Delft University of Technology. Master.

J. Wang, P. Van Der Wolk and S. Van Der Zwaag, ISIJ International 39(10) (1999) 1038.

Y. Ohmori and T. Maki, Mat. Trans. JIM 32 (1991) 631.

J. W. Christian, Proc. ICOMAT-79, Anonymous MIT Press, Cambridge, MA, 1979, p. 220.

L. Kaufman, S. V. Radcliffe and M. Cohen, in “De-composition of Austenite by Diffusional Processes,” edited by V. F. Zackay and H. I. Aaronson (Interscience, 1962) p. 313.

L. Kaufman and M. Cohen, Prog. Metal Physics 1 (1958) 165.

C. L. Magee, “Phase Transformations” (ASM, 1970) p. 115.

M. Hillert, Acta Metallurgica 1 (1953) 764.

H. I. Aaronson, W. T. J. Reynolds, G. J. Shiflet and G. Spanos, Metall. Trans. A 21A(6) (1990) 1343.

S. K. Liu, L. Yang, D. G. Zhu and J. Zhang, Metall. Mat. Trans. A 25A (1994) 1991.

G. B. Olson and M. Cohen, Metallurgical Transactions A 7A (1976) 1905.

M. Cohen Idem., ibid. 7A (1976) 1897.

J. Wang, P. Van Der Wolk and S. Van Der Zwaag, EuroMat'99, Sep. 27-30, 1999, Munich, Germany.

H. Fang, J. Wang and Y. Zheng, Metall. Mat. Trans. A 25A(9) (1994) 2001.

M. Hillert, ibid. 25A(9) (1994) 1957.

S. J. Barnard, G. D. W. Smith, A. J. Garratt-reed and J. Vander Sande, in “Solid-Solid Phase Trans-formations,” edited by H. I. Aaronson, D. E. Laughlin, R. F. Sekerka and C. M. Wayman (Metallurgical Society of AIME, 345 Est 47th Street, New York, NY 10017, USA, 1982) p. 881.

S. K. Liu and J. Zhang, Metall. Trans. A 21A (1990) 1517.

S. A. Hackney and G. J. Shiflet, in “Phase Transforma-tions in Ferrous Alloys,” edited by A. R. Marder and J. I. Goldstein (AIME, Warrendale, Pennsylvania, 1984) p. 237.

G. J. Shiflet Idem., Acta Metallurgica 35 (1987) 1007.

B. P. J. Sandvik, Metallurgical Transactions A 13A (1982) 777.

J. Wang, H. Fang, Z. Yang and Y. Zheng, ISIJ Inter-national 35(8) (1995) 992.

K. R. Kinsman and H. I. Aaronson, “Transformation and Hardenability in Steels” (Climax Molybdenum Co., Ann Arbor, Michigan, 1967) p. 39.

E. S. Davenport and E. C. Bain,Trans. AIME 90 (1930) 117.

H. Goldenstein and H. I. Aaronson, Metall. Trans. A 21A (1990) 1465.

W. T. Reynolds, JR., F. Z. Li, C. K. Shui and H. I. Ronson, ibid. 21A (1990) 1433.

P. J. Van Der Wolk, W. G. Vermeulen and S. Van Der Zwaag, 2nd International Conference on Modelling of Metal Rolling Processes, edited by J. H. Beynon (The Institute of Materials, London, 1996) p. 378.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, J., Van Der Wolk, P.J. & Van Der Zwaag, S. On the influence of alloying elements on the bainite reaction in low alloy steels during continuous cooling. Journal of Materials Science 35, 4393–4404 (2000). https://doi.org/10.1023/A:1004865209116

Issue Date:

DOI: https://doi.org/10.1023/A:1004865209116