Abstract

An experimental technique based on the Kolsky pressure bar has been developed to investigate the behavior of ceramics under dynamic multiaxial compression. Experimental results for aluminum nitride (AlN), together with data available in the literature, indicate that a Mohr-Coulomb criterion and the Johnson–Holmquist model fit the experimental data for failure in a brittle manner, whereas the ceramic material exhibited pressure insensitive plastic flow at high pressures. A failure surface is constructed which represents the material failure behavior, including brittle failure, brittle/ductile transition and plastic flow, under various pressures. The effect of various material properties on the failure behavior was investigated. The Poisson's ratio is found to be a measure of brittleness for ceramic materials with low spall strength under shock wave loading conditions. Lower value of Poisson's ratio indicates that the material will fail in a brittle manner through axial splitting even under uniaxial strain loading; whereas materials with higher Poisson's ratio may be expected to deform plastically beyond the Hugoniot Elastic Limit (HEL). The applicability of the proposed failure surface to a range of ceramics is explored and the limitations of the model are outlined.

Similar content being viewed by others

References

Ashby, M.F. and Sammis, C.G. (1990). The damage mechanics of brittle solids in compression. PAGEOPH 133, 489–521.

Bhattacharya, K., Ortiz, M. and Ravichandran, G. (1998). Energy-based model of compressive splitting in heterogeneous brittle solids. Journal of the Mechanics and Physics and Solids 46, 2171–2181.

Chhabildas, L.C., Furnish, M.D. and Grady, D.E. (1997). Impact of alumina rods – A computational and experimental study. Journal de Physique 7(C3), 137–143.

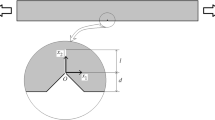

Chen, W. and Ravichandran, G. (1996a). An experimental technique for imposing dynamic multiaxialcompression with mechanical confinement. Experimental Mechanics 36, 435–438.

Chen, W. and Ravichandran, G. (1996b). Static and dynamic compressive behavior of aluminum nitride under moderate confinement. Journal of American Ceramic Society 79, 579–584.

Chen, W. and Ravichandran, G. (1997). Dynamic compressive failure of a glass ceramic under lateral confinement. Journal of the Mechanics and Physics of Solids 45, 1303–1328.

Chen, W., Subhash, G. and Ravichandran, G. (1994). Evaluation of ceramic specimen geometries used in a split Hopkinson pressure bar. Dymat Journal 1, 193–210.

Dandekar, D.P., Abbate, A. and Frankel, J. (1994). Equation of state of aluminum nitride and its shock response. Journal of Applied Physics 76, 4077–4085.

Deng, H. and Nemat-Nasser, S. (1994). Dynamic damage evolution of solids in compression – microcracking, plastic-flow, and brittle-ductile transition. Journal of Engineering Materials 116, 286–289.

Dorf, R.C. (1996). The Engineering Handbook, CRC Press.

Feng, R., Raiser, G.F. and Gupta, Y.M. (1996). Shock response of polycrystalline silicon-carbide undergoing inelastic deformation. Journal of Applied Physics 79, 1378–1387.

Follansbee, P. (1985). The Hopkinson bar, in Mechanical Testing, Metals Handbook, Vol. 8 [9th ed.], pp. 198–217, American Society for Metals, Metals Park, Ohio.

Grady, D.E. (1988). The spall strength of condensed matter. Journal of the Mechanics and Physics of Solids 36, 353–383.

Grady, D.E. and Kipp, M.E. (1989). Fragmentation of solids under dynamic loading, (Edited by T. Wurzbicki). Structural Failurepp. 1–39, John Wiley and Sons.

Grady, D.E. (1998). Shock wave compression of brittle solids, in Mechanics of Materialsin press.

Heard, H.C. and Cline, C.F. (1980). Mechanical behavior of polycrystalline BeO, Al2O3and AlN at high pressure. Journal of Materials Science 15, 1889–1897.

Holmquist, T.J., Johnson, G.R., Grady, D.E., Lopatin, C.M. and E.S. Hertel, Jr. (1995). High strain rate properties and constitutive modeling of glass, in: Proceedings of the 15th International Symposium on Ballistics, Jerusalem, Israel, May 21–24.

Horii, H. and Nemat-Nasser, S. (1986). Brittle failure in compression: splitting, faulting and brittle-ductile transition. Philosophical Transaction of the Royal Society of London A319, 337–374.

Jaeger, J.C. and Cook, N.G.W. (1979). Fundamentals of Rock Mechanics, Chapman and Hall.

Johnson, G.R. and Holmquist, T.J. (1994). An improved computational model for brittle materials, (Edited by S.C. Schmidt, J.W. Shaner, G.A. Samara and M. Ross). High Pressure Science and Technology – 1993, American Institute of Physics.

Kipp, M.E. and Grady, D.E. (1994). Shock phase transformation and release properties of aluminum nitride. Journal de Physique IV 4(C8), 249–256.

Klopp, R.W. and Shockey, D.A. (1991). The strength behavior of granulated silicon carbide at high strain rate and confining pressure. Journal of Applied Physics 70, 7318–7326.

Kolsky, H. (1949). An investigation of the mechanical properties of materials at very high rates of loading. Proceedings of the Royal Society of London B62, 676–700.

Krajcinovic, D. (1985). Constitutive theories for solids with defective microstructure, (Edited by N. Stubbs and D. Krajcinovic). Damage Mechanics and Continuum Modeling, ASCE, New York, 39–56.

Krajcinovic, D. and Mastilovic, S. (1995). Some fundamental issues of damage mechanics. Mechanics of Materials 21, 217–230.

Lankford, J. (1977). Compressive strength and microplasticity in polycrystalline alumina. Journal of Materials Science 12, 791–796.

Lankford, J. (1994). Utilization of the split Hopkinson pressure bar under hydrostatic confining pressure to characterize the compressive behavior of ceramics and ceramic composites, (Edited by A. Gilat). Mechanical Testing of Ceramics and Ceramic Composites, AMD 197, ASME, New York, 1–12.

Meyers, M.A., Lasalvia, J.C., Meyer, L.W., Hoke, D. and Niiler, A. (1991). Reaction synthesis dynamic compaction of titanium carbide and titanium diboride. Journal de Physique III 1(C3), 123–130.

Murakami, S. (1987). Anisotropic aspects of material damage and application of continuum damage mechanics, (Edited by D. Krajcinovic and J. Lemaitre) Continuum Damage Mechanics, Theory and Applications, Springer-Verlag, Wien-New York, 91–133.

Murrel, S.A.F. (1963). A criterion for brittle fracture of rocks and concrete under tri-axial stress and the effect of pore pressure on the criterion, (Edited by C. Fairhurst). Rock Mechanics, Pergaman, Oxford.

Rajendran, A.M. (1994). Modeling the impact behavior of AD85 ceramic under multiaxial loading. International Journal of Impact Engineering 15, 749–768.

Ravichandran, G. and Chen, W. (1991). Dynamic failure of brittle materials under uniaxial compression, (Edited by K.-S. Kim). Experiments in Micromechanics of Fracture Resistant Materialspp. 85–90. AMD-Vol. 130, ASME, New York.

Ravichandran, G. and Subhash, G. (1995). A micromechanical model for high strain rate behavior of ceramics. International Journal of Solids Structures 32, 2627–2646.

Richerson, D.A. (1992). Modern Ceramic Engineering, 2nd edition, Marcel Dekker, Inc., New York.

Rosenberg, Z. (1993). On the relation between the Hugoniot elastic limit and the yield strength of brittle materials. Journal of Applied Physics 74, 752–753.

Rosenberg, Z., Brar, N.S. and Bless, S.J. (1991). Dynamic high-pressure properties of AlN ceramic as determined by flyer plate impact. Journal of Applied Physics 70, 167–169.

Sairam, S. and Clifton, R.J. (1994). Pressure-shear impact investigation of dynamic fragmentation and flow of ceramics, (Edited by A. Gilat). Mechanical Testing of Ceramics and Ceramic Composites, AMD 197, ASME, New York.

Schmid, E. and Boas, W. (1935). Kristallplastizitat, Springer-Verlag, Berlin.

Subhash, G. and Nemat-Nasser, S. (1993). Dynamic stress induced transformation and fracture formation of Zirconia ceramics. Journal of American Ceramic Society 76, 153–165.

Subhash, G. and Ravichandran, G. (1998). Mechanical behavior of a hot pressed aluminum nitride under uniaxial compression. Journal of Materials Science 33, 1933–1939.

Wright, T.W. and Ravichandran, G. (1996). On shock induced damage in ceramics. Contemporary Research in the Mechanics and Mathematics of Materials, (Edited by R.C. Batra and M.E. Beatty), CIMNE, Barcelona, Spain, 480–488.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, W., Ravichandran, G. Failure mode transition in ceramics under dynamic multiaxial compression. International Journal of Fracture 101, 141–159 (2000). https://doi.org/10.1023/A:1007672422700

Issue Date:

DOI: https://doi.org/10.1023/A:1007672422700