Abstract

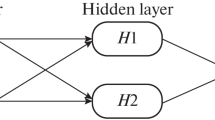

A neural network approach is applied to the problem of integrating design and manufacturing engineering. The self organising map (SOM) neural network recognizes products and parts which are modeled as boundary representation (B-rep) solids using a modified face complexity code scheme adopted, and forms the necessary feature families. Based on the part features, machines, tools and fixtures are selected. These information are then fed into a four layer feed-forward neural network that provides a designer with the desired features that meet the current manufacturing constraints for design of a new product or part. The proposed methodology does not involve training of the neural networks used and is seen to be a significant potential for application in concurrent engineering where design and manufacturing are integrated.

Similar content being viewed by others

References

Burke, L. and Kamal, S. (1992) Fuzzy ART for cellular manufacturing. Proceedings of the Conference on Artificial Neural Networks in Engineering, 1, 779–784.

Caudell, T. P., Smith, D. G., Johnson, G. C. and Wunsch, D. C., II, (1991) An application of neural networks to group technology. SPIE Applications of Artificial Neural Networks II, 1469, 612–621.

Carpenter, G. A. and Grossberg, S. (1988) The ART of adaptive pattern recognition by self-organising neural network. Computer, 77–88.

Coyne, R. D. and Postmus, A. G. (1990) Spatial application of neural networks in computer-aided design. Artificial Intelligence in Engineering, 5(1), 9–22.

Dagli, C. and Huggahalli, R. (1991) Neural network approach to group technology. Knowledge-based systems and neural networks: techniques and applications, (New York: Elsevier), 213–228.

Dhingra, A. K. and Rao, S. S. (1992) A neural network based approach to mechanical design optimisation. Engineering Optimisation, 20, 187–203.

Huang, S. H. and Zhang, H.-C. (1994) Artificial neural networks in manufacturing: concepts, applications and perspectives. IEEE Transaction on Components Packaging, and Manufacturing Technology-Part A, 17(2), 212–228.

Hwang, J.-L. and Henderson, M. R. (1992) Applying the perception to the three-dimensional feature recognition. Journal of Design and Manufacture, 2(4), 187–198.

Kamarthi, S. V., Kumara, S. T., Yu, F. T. S. and Ham, I. (1990) Neural networks and their applications in component design data retrieval. J. Intelligent Manufacturing, 1(2), 125–140.

Kao, Y. and Moon, Y. B. (1991) A unified group technology implementation using the backpropagation learning rule of neural networks. Computers and Industrial Engineering, 20(4), 425–437.

Kamal, S. and Burke, L. I. (1996) FACT: a new neural network-based clustering algorithm for group technology (1996). International Journal of Production Research, 34(4), 919–946.

Kaparthi, S. and Suresh, N. C. (1991) A neural system for shape-based classification and coding of rotational parts. International Journal of Production Research, 29(9), 1771–1784.

Kohonen, T. (1989) Self-organization and associative memory, 2nd ed. Springer-Verlag, Berlin.

Kumarar, S. R. T. and Kamarthi, S. V. (1991) Function-to-structure transformation in conceptual design: an associative memory-based paradigm. J. Intelligent Manufacturing, 2(5), 281–292.

Kusiak, A. (1990) Intelligent Manufacturing Systems, (Englewood-Cliffs, NJ: Prentice-Hall).

Kusiak, A. and Lee, H. (1996) Neural computing-based design of components for cellular manufacturing. International Journal of Production Research, 34(7), 1777–1790.

Malave, C. O. and Ramachandran, S. (1991) Neural network-based design of cellular manufacturing. J. Intelligent Manufacturing, 2(5), 305–314.

Moon, Y. B. (1990) Forming part-machine families for cellular manufacturing: a neural-network approach. International Journal of Advanced Manufacturing Technology, 5(4), 278–291.

Shah, J. J. and Rogers, M. T. (1988) Feature based modelling shell: design and implementation. Proceedings of 1988 ASME International Computers in Engineering Conference, 1, 255–26.

Venugopal, V. and Narendran, T. T. (1992) Neural network model for design retrieval in manufacturing systems. Computers in Industry, 20, 11–23.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Onwubolu, G.C. Design of parts for cellular manufacturing using neural network-based approach. Journal of Intelligent Manufacturing 10, 251–265 (1999). https://doi.org/10.1023/A:1008947824050

Issue Date:

DOI: https://doi.org/10.1023/A:1008947824050