Abstract

Purpose. To characterize the avalanche behavior of different powders and to compare the results of the strange-attractor and novel characterization approaches.

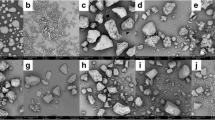

Methods. The following nine different materials were tested: three lactoses, maltodextrin, two microcrystalline celluloses, sodium chloride, sucrose, and glass beads. Morphology, size, and size distribution, true density, bulk and tap density, angle of repose, flow index, and avalanching behavior were quantified for each excipient by scanning electron microscopy, laser time-of-flight analysis, helium pycnometer, graduated cylinder, fixed-height funnel, Flodex (Hanson Research Corp., Chatsworth, California) method, and AeroFlow (TSI, Inc., St. Paul, Minnesota), respectively. Environmental factors were controlled, and the avalanches were studied at various speeds.

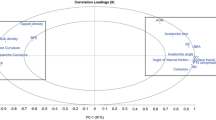

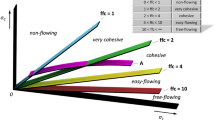

Results. The strange-attractor graph obtained at 1 rotation per 120 s showed that it was difficult to appreciate the flowability differences among 3-mm glass beads, lactose 100, and lactose 325. However, plotting the raw data as a relationship of the time between each avalanche and the inverse of speed revealed a characteristic linear slope for each sample. Furthermore, a new flowability index based on the SD calculated from the raw data gave results that were consistent with Carr's index. A cohesive index also can be determined by avalanche behavior, and it reflects the stability of the rapid particular rearrangements of powder.

Conclusion. A novel method of evaluating avalanche measurements makes it possible to better characterize powder flowability and to predict powder behavior under working conditions.

Similar content being viewed by others

REFERENCES

J. Schweder and D. Shulze. Measurement of flow properties of bulk solids. Powder Technol. 61:59–68 (1990).

G. E. Amidon and M. E. Houghton. Powder flow testing in preformulation and formulation development. Pharm. Manuf. July: 21–31 (1985).

A. C. Abdillah and D. Geldart. The use of bulk density measurement as flowability indicators. Powder Technol. 102:151–165 (1999).

G. K. Bolhuis and Z. T. Chowhan. Materials for direct compaction. In G. Alderborn and C. Nyström (eds.), Pharmaceutical Powder Compaction Technology, Marcel Dekker, New York, 1996 pp. 419–500.

Y. S. Lee, R. Poynter, F. Podczeck, and M. Newton. Development of a dual approach to assess powder flow from avalanching behavior. AAPS PharmSciTech 1: Article 21, (2000) http://www. pharmscitech.com.

R. G. Iacocca and R. M. German. The experimental evaluation of die compaction lubricants using deterministic chaos theory. Powder Technol 102:253–265 (1999).

S. Rastogi and G. E. Klinzing. Characterizing the rheology of powders by studying dynamic avalanching of the powder. Part. Part. Syst. Charact. 11:453–456 (1994).

N. Standish. A. B. Yu, and Q. L. He. An experimental study of the packing of a coal heap. Powder Technol. 68:187–193 (1991).

L. Bocquet, E. Charlaix, S. Ciliberto, and J. Crassous. Moisture-induced ageing in granular media and the kinetics of capillary condensation. Nature 396:735–737 (1998).

J. J. McCarthy, T. Shinbrot, G. Metcalfe, J. E. Wolf, and J. M. Ottino. Mixing of granular materials in slowly rotated containers. AIChE J. 42:3351–3363 (1996) http//www.aiche.org/aichejournal.

J. A. Drahun and J. Bridgwater. The mechanisms of free surface segregation. Powder Technol. 36:39–53 (1983).

H. A. Makse, S. Havlin, P. R. King, and H. E. Stanley. Spontaneous stratification in granular mixtures. Nature 386:379–382 (1997).

J. Baxter, U. Tüzün, D. Heyes, I. Hayati, and P. Fredlund. Stratification in poured granular heaps. Nature 391:136 (1998).

J. P. Koeppe, M. Enz, and J. Kakalios. Phase diagram for avalanche stratification of granular media. Phys. Rev. 58:R4104–R4107 (1998).

B. H. Kaye, J. Gratton-Liimatainen, and J. Lloyd. The effect of flow agents on the rheology of a plastic powder. Part. Part. Syst. Charact. 12:194–197 (1995).

H. Nyqvist. Saturated salt solutions for maintaining specified relative humidity. Int. J. Pharm. Technol. Prod. Manuf. 4:47–48 (1983).

B. H. Kaye. Characterizing the flow of metal and ceramic powders using the concepts of fractal geometry and chaos theory to interpret the avalanching behavior of a powder. In T. P. Battle and H. Henein (eds.), Processing and Handling of Powders and Dusts, Minerals Metals & Materials Society, Warrendale, PA, 1997 pp. 277–282.

B. H. Kaye. Characterizing the flowability of a powder using the concepts of fractal geometry and chaos theory. Part. Part. Syst. Charact. 14:53–66 (1997).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lavoie, F., Cartilier, L. & Thibert, R. New Methods Characterizing Avalanche Behavior to Determine Powder Flow. Pharm Res 19, 887–893 (2002). https://doi.org/10.1023/A:1016125420577

Issue Date:

DOI: https://doi.org/10.1023/A:1016125420577