Abstract

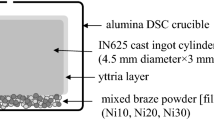

Induction brazing of Inconel 718 to Inconel X-750 using Ni-7Cr-3Fe-3.2B-4.5Si (wt.-%) foil as brazing filler metal was investigated in this paper. Brazing was conducted at the temperature range 1373–1473 K for 0–300 s in a flow argon environment. Both interfacial microstructures and mechanical properties of brazed joints were investigated to evaluate joint quality. The optical and scanning electron microscopic results indicate that good wetting existed between the brazing alloy and both Inconel 718 and Inconel X-750. Microstructures at joint interfaces of all samples show distinct multilayered structures that were mainly formed by isothermal solidification and following solid-state interdiffusion during joining. The diffusion of boron and silicon from brazing filler metal into base metal at the brazing temperature is the main controlling factor pertaining to the microstructural evolution of the joint interface. The element area distribution of Cr, Fe, Si, Ni and Ti was examined by energy dispersive X-ray analysis. It was found that silicon and chromium remain in the center of brazed region and form brittle eutectic phases; boron distribution is uniform across joint area as it readily diffuses from brazing filler metal into base metal. The influence of heating cycle on the microstructures of base material and holding time on the mechanical properties of brazed joint were also investigated.

Similar content being viewed by others

References

B. Mishra and J. J. Moore, Metall. Trans. A 19A (1988) 1295.

R. F. Decker and C. T. Sims, “The Superalloys,” edited by Sims and Hagel (John Wiley and Sons Inc., 1972) p. 33.

“Inconel Alloy X-750,” 4th ed. (Huntington Alloys Inc., 1979).

J. R. Kattus, “Aerospace Materials Handbook,” Vol. 4 (1981) p. 1.

S. J. Lee, S. K. Wu and R. Y. Lin, Acta Mater. 46 (1998) 1283.

Idem., ibid. 46 (1998) 1297.

I. Tuah-poku, M. Dollar and T. B. Massalski, Metall. Trans. A 19A (1988) 675.

Y. Zhou, W. F. Gale and T. H. North, International Materials Reviews 40(5) (1995) 181.

Y. Nakao and Y. Shinozaki, Mater. Sci. and Tech. 11(3) (1995) 304.

T. I. Khan and E. R. Wallach, J. Mater. Sci. 30 (1995) 5151.

M. S. Yeh and T. H. Chuang, Weld. J. 76(12) (1997) 517s.

W. D. Macdonald and T. W. Eager, Metall. Trans. A 29A(1) (1998) 315.

P. R. C. Camargo, R. E. Trevison and S. Liu, Weld. J. 72(12) (1993) 537s.

R. Johnson, Welding in the World 27(1, 2) (1989) 14.

T. B. Masslski, “Binary Alloy Phase Diagram” (Metals Park, OH, ASM International, 1986).

W. Chen, M. C. Chaturvedi, N. L. Richards and McMahon, Metall. Trans. A 29A(7) (1998) 1947.

T. J. Garosshen, T. D. Tillman and G. P. Mccarthy, ibid. 18A (1987) 69.

H. Kowawa, C. H. Lee and T. H. North, ibid. 22A (1991) 1627.

K. Saida, Y. Zhou and T. H. North, J. Mater. Sci. 28 (1993) 6427.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wu, X., Chandel, R.S. & Li, H. Evaluation of transient liquid phase bonding between nickel-based superalloys. Journal of Materials Science 36, 1539–1546 (2001). https://doi.org/10.1023/A:1017513200502

Issue Date:

DOI: https://doi.org/10.1023/A:1017513200502