Abstract

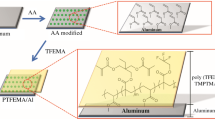

Slow release of corrosion-inhibitive paint pigments is a great challenge to the paint industry, because of the urgent need to replace chromate-containing pigments. Unfortunately, most effective corrosion inhibitors are too soluble for use in paints. In this paper, we present a novel method to modify selected water-soluble organic inhibitor particles to achieve the purpose of slow release. A plasma polymerization technique was used to deposit an ultrathin polymer film on the surface of the inhibitor particles. Infrared spectroscopy (FTIR), time-of-flight secondary ion mass spectroscopy (TOFSIMS), scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy (SEM/EDX), transmission electron microscopy (TEM), and contact angle data confirmed the successful deposition of the polymer thin film on the inhibitor particles. Using immersion tests and electrochemical techniques, we have demonstrated that the encapsulated water-soluble inhibitor can slowly release into the environment to protect a metal as needed. This technique is a feasible and promising method to promote the replacement of chromate pigments in paints.

Similar content being viewed by others

References

http://archive.metalformingmagazine.com/1995/10/alumin/aluminum.htm

R. G. Buchheit, Electrochem. Soc. Extend. Abstr., 95–2, Abstr. 182, Chicago, IL, 1995.

W. Clark and J. Ramsey, J. Electrochem. Soc. 149, B179(2002).

J. Sinko, Prog. Org. Coat. 42, 267(2001).

EPA Federal Register, National Emission Standards for Hazardous Air Pollutants for Source Categories: Aerospace Manufacturing and Rework Facilities 60, 45947(1995).

W. Qafaoui, Ch. Blanc, N. Pebere, A. Srhiri, and G. Mankowski, J. Appl. Electrochem. 30, 959(2000).

W. Qafsaoui, Ch. Blanc, N. Pebere, H. Takenouti, A. Srhiri, and G. Mankowski, Electrochim. Acta 47, 4339(2002).

C. Chen and C. Lin, Anal Chim. Acta 321, 215(1996).

A. M. S. Abdennabi, A. I. Abdulhadi, and S. Abu-Orabi, Anti-Corros. Meth. Mat. 45, 102(1998).

S. L. Cohen, V. A. Brusic, F. B. Kaufman, G. S. Frankel, S. Motakef, and B. Rush, J. Vac. Sci. Technol. A8, 2417(1990).

A. N. Önal and A. A. AksÜt, Anti-Corros. Meth. Mat. 47, 339(2000).

V. S. Sastri, Corrosion Inhibitors: Principles and Applications, John Wiley, New York (1998), p. 866.

D. Tromans and J. Silva, J. Electrochem. Soc. 143, 458(1996).

http://www.eurobonding.org/Englisch/Oberflaechen.

D. Shi, S. Wang, W. J. van Ooij, L. M. Wang, J. Zhao, and Z. Yu, Appl. Phys. Lett. 78, 1243(2001).

F. Homilius, A. Heilmann, and C. von Borczyskowski, Surf. Coat. Technol. 74, 594(1995).

D. Vollath and D. V. Szobó, J. Nanopart. Res. 1, 235(1999).

J. Janca, P. Stahel, J. Buchta, D. Subedi, F. Krcma, and J. Pryckova, Plasmas Polym. 6, 15(2001).

J. J. Caprari, A. R. Di Sarli, and B. del Amo, Pigment Resin Technol. 29, 16(2000).

M. A. Jackson, J. Protective Coat. Linings 7, 54(1990).

B. del Amo, R. Romagnoli, C. Deya, and J. A. Gonzalez, Prog. Org. Coat. 45, 389(2002).

http://www.resins.com/resins/am/pdf/SC2368.pdf.

R. C. MacQueen, R. R. Miron, and R. D. Granata, J. Coat. Technol., 68, 75(1996).

N. Inagaki, S. Tasaka, and H. Abe, J. Appl. Pol. Sci. 46, 595(1992).

R. Winston Revie, Uhlig's Corrosion Handbook, 2nd Ed., John Wiley, New York (2000), p. 1089.

N. Zhang, Surface modification of micron-size powders by plasma polymerization, Master Thesis, University of Cincinnati, Cincinnati (2000), p. 114.

C. Bayer, M. Karches, A. Matthews, and P. R. von Rohr, Chem. Eng. Technol. 21, 427(1998)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, H., van Ooij, W.J. Plasma Deposition of Polymeric Thin Films on Organic Corrosion-Inhibiting Paint Pigments: A Novel Method to Achieve Slow Release. Plasmas and Polymers 8, 297–323 (2003). https://doi.org/10.1023/A:1026389311431

Issue Date:

DOI: https://doi.org/10.1023/A:1026389311431