Abstract

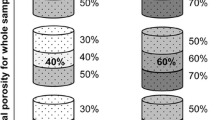

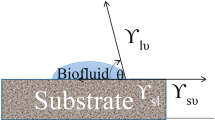

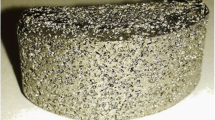

To be successful, an implant should be biocompatible, strong and contain surface pores to promote osseointegration. A one-step microwave sintering procedure of titanium powders was attempted in this work. The idea was to take advantage of the peculiar way microwave couple with metallic powders, i.e. generating heat in the interior of the sample and dissipating it away through the surface. This non-conventional heating of titanium powder produced a dense core with surface porosity. The dense core provides the strength while the surface pores promote bone growth. The experiments were carried out in a semi-industrial grade microwave cavity using a α-SiC susceptor. Power levels of 1–1.5 kW, and soaking periods of approximately 30 min were used. Microstructural characterization was carried out by a scanning electron microscope. The sintered titanium had gradient porosity on the surface with a thickness of about 100–200 μm depending on the microwave power. The pores were interconnected with size ranging from 30 to 100 μm. This kind of microstructure is favorable for cell growth. Tensile strength values as high as 400 MPa were obtained for these samples.

Similar content being viewed by others

References

P. I. Branemark, R. Adell, T. Albrektsson, U. Lekholm and S. Lundquist, Biomaterials 4 (1983) 25.

J. C. Keller, C. M. Stanford, J. P. Wightman, R. A. Draughn and R. Zaharias, J. Biomed. Mater. Res. 28 (1994) 939.

J. E. Davies, B. Lowenberg and A. Shiga, ibid. 24 (1990) 1289.

K. Asaoka and N. Kuwayama, ibid. 19 (1985) 699.

T. Kurachi, H. Nagao, H. Nagura and S. Enomoto, Arch. Oral Biol. 42 (1997) 465.

T. Nomura, S. Shingaki and T. Nakajima, J. Long-term Effects Med. Implants 8 (1998) 175.

T. Kokubo, Acta Mater. 46 (1998) 2519.

H. Kim, T. Kokubo, S. Fujibayashi, S. Nishiguchi and T. Nakamura, J. Biomed. Mater. Res. (USA) 52 (2000) 553.

Yoshiki Oshida, U.S. Patent No. 6183255, “Titanium Material for Implants” (2001).

H. Zreiqat and C. R. Howlett, J. Biomed. Mater. Res. 47 (1999) 360.

J. Lausmaa, M. Ask, U. Rolander and B. Kasemo, Mater. Res. Soc. Symp. Proc. 110 (1989) 647.

R. A. Ayers, S. J. Simske, T. A. Bateman, A. Petkus, R. L. C. Sachdeva and V. E. Gyunter, J. Biomed. Mater. Res. 45 (1999) 42.

D. Wolfarth and P. Ducheyne, ibid. 28 (1994) 417.

M. I. Lifland, D. K. Kim and K. Okazaki, Clin. Mater. 14 (1993) 13.

J. Qui, J. T. Dominici, M. I. Lifland and K. Okazaki, Biomaterials (UK), 18 (1997) 153.

M. I. Lifland and K. Okazaki, Clin. Mater. 17 (1994) 203.

K. Okazaki, D. K. Kim and R. A. Kopczyk, Conference Science and Engineering of Light Metals. RASELM '91 (Tokyo, Japan, 1991) 103.

Y. Z. Yang, J. M. Tian, J. T. Tian, Z. Q. Chen, X. J. Deng and D. H. Zhang, J. Biomed. Mater. Res. 52 (2000) 333-337.

D. De Santis, C. Guerriero, P. F. Nocini, A. Ungersbock, G. Richards, P. Gotte and U. Armato, J. Mater. Sci. Mater. Med. 7 (1996) 21.

D. H. Kohn and P. Ducheyne, J. Biomed. Mater. Res. 24 (1990) 1483.

C. K. Chang, J. S. Wu, D. L. Mao and C. X. Ding, ibid. 56 (2001) 17.

M. Thieme, K. P. Wieters, F. Bergner Scharnweber, H. Worch, J. Ndop, T. J. Kim and W. Grill, J. Mater. Sci. Mater. Med. 12 (2001) 225.

R. Roy, D. Agrawal, J. Cheng and S. Gedevanishvili, Nature 399 (1999) 668.

R. Roy, D. K. Agrawal, K. Dinesh and J. Cheng, U.S. Patent No. 6,183,689 (2001).

M. G. Kutty, S. Bhaduri, J. R. Jokisaari and S. B. Bhaduri, Ceram. Eng. Sci. Proc. 22 (2000) 587.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kutty, M.G., Bhaduri, S.B. Gradient surface porosity in titanium dental implants: relation between processing parameters and microstructure. Journal of Materials Science: Materials in Medicine 15, 145–150 (2004). https://doi.org/10.1023/B:JMSM.0000011815.50383.bd

Issue Date:

DOI: https://doi.org/10.1023/B:JMSM.0000011815.50383.bd