Abstract

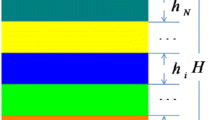

The most important properties of multilayer composites that are promising as structural and functional materials in view of their geometric structural characteristics are considered. A structural-geometrical classification of unidimensional composites is provided. Thermal conductivity and expansion of layered ceramic-metal composites taking account of the "inherent" thermal stresses are considered in detail, and conditions for loss of integrity at interlayer interfaces are analyzed. Special attention is devoted to the anisotropy of layered systems. Methods are described for calculating the effective values of thermophysical and elastic properties for unidimensional composites along and across layers, the upper and lower limits of properties are evaluated, and cases of deviation from additivity of these properties are analyzed. Some features are considered for failure of ceramic-metal composites with static and impact loading, and also the promising nature of their application as shock-resistant and heat-resistant high-temperature materials in structural elements that operate under extreme heat and mechanical conditions.

Similar content being viewed by others

REFERENCES

K. I. Portnoi (ed.), Composite Materials, Vol. 4 [Russian translation], Mashinostroenie, Moscow (1978).

G. Ondrachek, “The quantitative microstructure-field property correlation of multiphase and porous materials,” Reviews on Powder Metallurgy and Physical Ceramics, 3, Nos. 3–4, 205–322 (1987).

J. Nie, Physical Properties of Crystals [Russian translation], Izd. Inostr. Lit, Moscow (1960).

G. N. Dul'nev and V. V. Novikov, Transfer in Nonuniform Media [in Russian], Énergoatomizdat, Leningrad (1991).

Yu. V. Naidich, B. D. Kostyk, and A. I. Il'yash, “Features of the thermal expansion of multilayer metal-ceramic composites,” Poroshk. Metall., Nos. 7–8, 43–46 (1996).

V. Skorokhod, M. Shtern, and S. Kudela, “Strain path effect on debonding and nonlinear constitutive model for rigid particles reinforced metal-ceramic matrix composite,” in: Advanced Multilayered and Fiber-Reinforced Composites, Y. M. Haddad (ed.), Kluwer Acad. Publ., New York (1998).

J. S. Moya, J. A. Sanchez-Herencia, and J. F. Bartolome, “Elastic modulus in rigid Al2O3/ZrO2 ceramic laminates,” in: Advanced Multilayered and Fiber-Reinforced Composites, Y. M. Haddad (ed.), Kluwer Acad. Publ., New York (1998).

Short Chemical Encyclopaedia, Vol. 5, Sovetskaya Éntsiklopediya, Moscow (1967).

O. V. Roman, V. V. Skorokhod, and G. R. Fridman, Ultrasound and Resistometric Monitoring in Powder Metallurgy [in Russian], Vysh. Shkola, Minsk (1989).

A. G. Evans and T. G. Langdon, Structural Ceramics [Russian translation], Metallurgiya, Moscow (1980).

Zheng Chen and J. J. Mecholsky, “Toughening by metallic lamina in nickel/alumina composites,” J. Amer. Ceram. Soc., 76, No. 5, 1258–1264 (1993).

Yu. V. Naidich, B. D. Kostyuk, and A. I. Il'yash, “Impact resistance of layered composites,” Poroshk. Metall., Nos. 11–12, 83–87 (1997).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Skorokhod, V.V. Layered Composites: Structural Classification, Thermophysical and Mechanical Properties. Powder Metallurgy and Metal Ceramics 42, 437–446 (2003). https://doi.org/10.1023/B:PMMC.0000013215.36378.50

Issue Date:

DOI: https://doi.org/10.1023/B:PMMC.0000013215.36378.50