Abstract

The cure and pyrolysis behavior of a BlackglasTM resin and NextelTM 440 impregnated with BlackglasTM resin were studied. Cure of the BlackglasTM resin is an exothermic process and DSC studies indicate that with an increase of catalyst content from 0.1 to 1.0%, the onset and peak temperature of cure are decreased coupled with an increase in the enthalpy of cure indicating a greater extent of cross linking. However, pyrolysis char yield of the pyrolyzate is relatively insensitive to cure conditions.

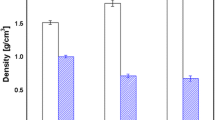

Cure pressure and pyrolysis environment are variables in the processing of BlackglasTM matrix composite reinforced with NextelTM 440 Plain weave fabric. Variations in cure pressure from 30 to 80 psi had no discernible effect on the chemistry of the pryrolyzate. However, the higher cure pressure resulted in top and bottom ply damage. Pyrolysis in an Ar environment resulted in incorporationj of up to 12 wt % C of which 8 wt % as graphitic in nature in the ceramic matrix. Pyrolysis in NH3 resulted in 3.9 wt % nitrogen and 1.5 wt % carbon in the matrix, with all the nitrogen and carbon bonded to Si. The cured panels have to be pyrolyzed/densified between 6–7 times to achieve required density and porosity content. Oxidation behavior of the composites at 1000°C indicate that the argon pyrolyzed CMC's lose more weight due to decomposition of the pyrolytic carbon, whereas, NH3 pyrolyzed CMC's are stable as both the N and C are bonded to Si in the matrix. Dielectric constants K′ and K′′ measured at 1 GHz in the as-processed condition are high in the argon pyrolyzed CMC, (K′ = 11−28) due to the presence of pyrolytic carbon. On the other hand NH3 pyrolyzed CMC exhibit low dielectric constant (K′ = 4). On oxidation, the dielectric constant in both the Ar and NH3 pyrolyzed panels is approximately 4.0.

Similar content being viewed by others

References

S. Yajima, Y. Hasegawa, J. Hayashi and M. Iimura, J. Mater. Sci. 13 (1978) 2569.

Y. Hasegawa, M. Iimura and S. Yajima, ibid. 15 (1980) 720.

R. M. Laine and F. Babonneau, Chem. Mater. 5 (1993) 260.

W. R. Schmidt, V. Sukumar, W. J. Hurley, Jr., R. Garcia, R. H. Doremus, L. V. Interrante and G. M. Rendlund, J. Amer. Ceram. Soc. 70 (8) (1990) 2412.

R. Y. Leung, T. Stanford and S.T. Gonczy, U.S. Patent 5,258,084, Nov. 2, 1993.

L. Bois, J. Maquet, F. Babonneau, H. Mutin, D. Bahloul, Chem Mater. 6 (1994) 796.

D. Mocaer, R. Pailler, R. Naslain, C. Richard, J. P. Pillot, J. Dunogues, C. Gerardin and F. Taulelle, J. Mater. Sci. 28 (1993) 2615–2631.

F. I. Hurwitz, L. Hyatt, J. Gorecki and L. D'amore, Ceram. Engg. Sci. Proc. 11 (7 8) (1990) 732–743.

F. I. Hurwitz, J. Z. Gyekenyesi, P. J. Conroy and A. L. RIVERA, ibid. 11 (7 8) (1990) 931–946.

S. H. Yu, R. E. Riman, S. C. Danforth and R. Y. Leung, J. Amer. Ceram. Soc. 78 (7) (1995) 1818.

F. I. Hurwitz, Approaches to polymer derived CMC matrices, in Twenty Fourth Inter. SAMPE Technical Conference, Oct 20–22, T950, (1992).

B. Boury, J. P. Corriu and W. E. Douglas, Chem. Mater. 3 (1991) 487.

W. R. Schmidt, P. K. Marchetti, L. V. Interrante, W. J. Hurley, R. H. Lewis, R. H. Doremus and G. E. Maciel, ibid. 4 (1992) 937–47.

ASTM C 20–92, Standard test methods for apparent porosity, apparent specific gravity, and bulk density of burned refractory brick and shapes by boiling water, Annual Book of ASTM Standards, Vol. 15.01 (1994).

E. L. Lukevits and M. G. Voronkov, Organic Insertion Reactions of Group IV Elements, Consultants Bureau, NY, USA (1966).

W. Noll, "Chemie und Technologie der Silicone" (Verlag Chemie, Weinheim, Germany, 1968).

D. Wewers, "Silicones, Chemistry and Technology" (CRC Press, Boca Raton, FL, USA 1991).

D. R. Anderson, in Chemical Analysis Vol. 41, "Analysis of Silicones," edited by A. Lee Smith (John Wiley & Sons, NY, 247, 1975).

S. T. Gonczy, R. Y. Leung and J. Evans, "Oxidation Effects on Fibrous Fracture in BlackglasTM Composites Reinforced with 3-D and 2-D NextelTM 440 (Carbon-Coated)", Presented at 16th Annual Conference on Composites, Materials and Structures, 15th Jan. 1992., Cocoa Beach, FL.

"Properties of NextelTM 312 and 440 Ceramic Fibers", Ceramics Materials Dept. Bulletin, 3M Corporation, St. Paul MN 55144, Jan. 1993.

Rights and permissions

About this article

Cite this article

Rangarajan, S., Belardinelli, R. & Aswath, P.B. Processing, physical and thermal properties of BlackglasTM matrix composites reinforced with NextelTM fabric. Journal of Materials Science 34, 515–533 (1999). https://doi.org/10.1023/A:1004590527954

Issue Date:

DOI: https://doi.org/10.1023/A:1004590527954