Abstract

A facile strategy has been adopted for the preparation of ZnFe2O4/NRG composite by anchoring ultrasmall ZnFe2O4 nanoparticles on nitrogen-doped reduced graphene (denoted as NRG) for high-performance supercapacitor electrode. Remarkably, the growth of ZnFe2O4 nanocrystals, the reduction of graphitic oxide and the doping of nitrogen to graphene have been simultaneously achieved in one process. It is found that the NRG employed as substrate can not only control the formation of nano-sized ZnFe2O4, but also guarantee the high dispersion without any agglomeration. Benefiting from this novel combination and construction, the hybrid material has large surface area which can provide high exposure of active sites for easy access of electrolyte and fast electron transport. When served as supercapacitor electrode, the ZnFe2O4/NRG composite exhibits a favorable specific capacitance of 244 F/g at 0.5 A/g within the potential range from −1 to 0 V, desirable rate stability (retain 131.5 F/g at 10 A/g) and an admirable cycling durability of 83.8% at a scan rate of 100 mV/s after 5000 cycles. When employed as symmetric supercapacitor, the device demonstrates favorable performance. These satisfactory properties of the ZnFe2O4/NRG composite can make it be of great promise in the supercapacitor application.

Similar content being viewed by others

Introduction

With the ever-increasing demand in the practical application of new-type portable electronics and electric vehicles, it is of great significance to develop energy storage devices with high performance and environmentally friendly properties1,2,3,4,5,6. Compared with the conventional dielectric capacitors and rechargeable batteries, supercapacitors have attracted more considerable attention owning to their high power density, long cycle lifetime and excellent reliability in the fields of energy storage and conversion7,8,9,10. In terms of the operational charge storage mechanism, supercapacitors can be classified into pseudocapacitors and electrochemical double layer capacitors (EDLCs)11,12,13,14,15. Especially, pseudocapacitors, based on reversible redox reactions between the electrolyte and the electrode bulk, can achieve admirable specific capacitance and energy density, which can be as promising candidate for constructing novel energy storage devices16,17,18,19. Accordingly, a variety of pseudocapacitive electrode materials, such as metal oxides/hydroxides and conductive polymer, have been employed to realize practical application of supercapacitor20,21,22,23. However, the performance of pseudocapacitors has often been restricted by low-electronic conductivity of the active materials resulting from insufficient transport for ion and electron at the electrode/electrolyte interface and in electrodes, leading to undesirable faradaic redox reactions in high current rate. To solve this problem, an effective strategy is to combine them with the highly conductive support materials, which can provide sufficient electroactive species exposed to electrolyte for the favorable reaction kinetics24,25.

Among various good conductive materials, graphene, as one of carbonaceous materials, represents an attractive substrate for the immobilization of active species to provide good electron transfer paths and improve stability of the entire hybrid, because of its porous two-dimensional structure, large specific surface area and exceptional high conductivity26,27,28. Simultaneously, it has been certified that graphene can act as a support to prevent the loaded nanomaterials from aggregation by balancing their high interface energy29,30,31. By the virtue of these advantages, a variety of electrode materials integrating pseudocapacitive component with graphene have been successfully constructed for achieving high-performance energy storage devices32,33,34. In addition, many investigations revealed that doping of heteroatoms (N and S) to the internal or surface carbon matrix, can significantly improve the performance of carbon-based supercapacitors and provide numerous active sites and extrinsic defects for the generation of pseudocapacitive nanomaterials35,36,37,38.

Recently, binary metal oxides (based on AB2O4), especially spinel ferrites with the general formula MFe2O4 (M = Mn, Co, Ni, Zn or Mg), has been intensively studied as qualified pseudocapacitive electrode material8,39,40,41,42. Compared with the monometallic oxides, Fe-based binary oxides, triggering synergetic effect from both Fe and M ions, can offer richer redox chemistry to obtain higher specific capacitance43,44,45. As an important member of ferrite family, zinc ferrite (ZnFe2O4) exhibits promising potential for the application of supercapacitor, due to abundant resources, low cost, environmental friendliness and high electrochemical activity46,47. However, the ZnFe2O4 based electrode often suffers from low conductivity, leading to unsatisfactory rate capability48,49. Furthermore, the morphology and size of the electrode materials also play important roles in determining the performance of supercapacitors50,51,52,53,54,55. Therefore, it is significant to fabricate electrode material utilizing the combination of nano-sized ZnFe2O4 and nitrogen-doped graphene.

In this paper, we present the preparation of nano-sized ZnFe2O4 particles uniformly loaded on the surface of porous nitrogen-doped graphene (denoted as ZnFe2O4/NRG) without any agglomeration, via a facile solvothermal strategy followed by calcining treatment. It is worth noting that the solvent, N, N-dimethylmethanamide (DMF), plays dual important roles for the fabrication of NRG. On one hand, the DMF can provide nitrogen source for the chemical doping of graphene. On the other hand, GO can be reduced in the DMF solution which can be served as reducing agent under solvothermal condition and ensure the formation of ZnFe2O4 nanoparticles. With the doping of nitrogen element, the graphene can not only possess favorable structural stability at high rate, but also offer numerous active sites for the growth and bonding of ZnFe2O4 nanoparticles. This unique combination between ZnFe2O4 and NRG can remarkably enhance electrical conductivity and create a speedy diffusion way from the electrolyte to the electrode. When applied as supercapacitor electrode, the ZnFe2O4/NRG shows favorably electrical performance including specific capacitance, rate capability and cycling performance. When fabricated as symmetric device, the material also exhibits ideal electrochemical performance. These results demonstrate that this process towards graphene and binary metal oxides is promising for the future fabrication of supercapacitor electrode material.

Results and Discussion

Phase and morphology properties

Figure 1 presents the overall procedure for the preparation of ZnFe2O4/NRG. When Fe(acac)3 and Zn(acac)2 were added into GO/DMF solution, the Fe3+ and Zn2+ ions can bind with the O atoms of the negatively charged oxygen-containing functional groups on GO sheets via an electrostatic force. During the hydrothermal process, the nitrogen was successfully doped into the network of reducing graphene. Meanwhile, ZnFe2O4 crystals can be formed and uniformly anchored on the surface of NRG, and the nano-sized ZnFe2O4/NRG can be finally obtained by the followed calcination treatment to remove residue of organic matter.

The crystallographic structure of the samples was investigated through X-ray diffraction (XRD) technique. As shown in Fig. 2, the XRD pattern of GO contains a strong and sharp peak centered at 10.5°, which corresponds to the interplanar distance (002 plane) of 0.84 nm according to Bragg equation. The larger interplanar distance of GO compared with the graphite (d002 = 0.34 nm) can be ascribed to oxidation of graphite, triggering the introduction of oxygen functional groups and the exfoliation of monolayer sheets. As contrast, a broad (002) diffraction peak of NRG can be observed at 25.3° (corresponding to the interlayer distance of 0.35 nm), indicating restacking of GO under the hydrothermal conditions. The disappearance of NRG located at 10.5° can be assigned to the thorough reduction from GO to NRG. For ZnFe2O4/NRG, the main characteristic diffraction peaks at 2θ values of 29.7°, 35.1°, 42.6°, 53.1°, 56.4° and 62.4° can be ascribed to (220), (311), (400), (422), (511) and (440) crystal planes of spinel ZnFe2O4 (JCPDS No. 89-4926), indicating a successful preparation of ZnFe2O4 without other impurity phase. The value average crystallite size of ZnFe2O4 can be calculated from the Scherrer formula: Dhkl = Kλ/(β cos θ), where K is a constant (0.89), θ is the diffraction angle, and β is the full width at half-maximum. The calculated crystallite size is 8.5 nm. The broad peak of RGO at 25.3° is negligible due to the strong peaks of ZnFe2O4.

Raman spectroscopy has been also employed to further determine the degree of graphitization and the crystalline structure of ZnFe2O4/NRG composites. As shown in Fig. 3, two characteristic peaks of the D and G bands for these three samples are located at about 1360 and 1595 cm−1, respectively. It is acceptable that the intensity ratio between the D and G bands (ID/IG) can be served as a significant parameter to estimate carbon hybridization state of materials56,57. The values of ID/IG ratios for NRG and ZnFe2O4/NRG composites increase slightly from 0.80 (GO) to 0.99 and 1.02, revealing the presence of plentiful defects of NRG, which can be attributed to the heteroatomic doping of nitrogen and the firm attaching of ZnFe2O4 nanoparticles. In addition, the Raman spectrum of ZnFe2O4/NRG presents two weak peaks located at 322 and 658 cm−1, assigned to motions of atoms in metallic oxide, further confirming the formation of ZnFe2O4.

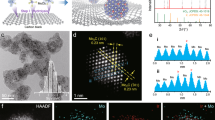

The detailed morphology and structure of the products were examined by SEM and TEM measurements, as shown in Fig. 4. The TEM image of GO (Fig. 4a) shows that the nanosheets are almost transparent as thin film and consist of a large amount wrinkles and folds, suggesting desirable properties for anchoring the ultra-small ZnFe2O4 particles. As shown in Fig. 4b and c, the pristine ZnFe2O4 nanoparticles, prepared without the addition of GO, randomly aggregate with each other with a diameter of about 9 nm. From the SEM images of ZnFe2O4/NRG (Fig. 4d and e), it can be seen that the ultra-small ZnFe2O4 nanoparticles are relatively homogeneously distributed on the wrinkled NRG at a high density. It is notably that the NRG can act as qualified support for the growth of ZnFe2O4 particles, while the decoration of ZnFe2O4 nanoparticles on NRG can effectively prevent the aggregation of the NRG. And the TGA curve of the ZnFe2O4/NRG displayed in Figure S1 revealed that the content of the rGO in the composite is about 35%. The TEM image (Fig. 4f) of ZnFe2O4/NRG can further confirm the high-dispersedly decoration of ZnFe2O4 particles on the surface of NRG. A closer observation of the ZnFe2O4/NRG (Fig. 4g) reveals that ZnFe2O4 exhibits an average diameter of 7.8 nm, which is basically consistent with the analysis of XRD, indicating the positive effect of NRG to control the nanoscale of ZnFe2O4, which is beneficial for the exposure of abundant active sites to the electrolyte. In the HRTEM image of composite (Fig. 4h), an obvious lattice between the adjacent fringes with interplanar spacing of 0.24 nm can be clearly identified, which is in agreement with the (311) plane of cubic ZnFe2O4. Besides, the selected area electronic diffraction pattern (Fig. 4i) shows some well-defined rings, which correspond to the XRD data of ZnFe2O458.

In order to clarify the chemical composition and valence of ZnFe2O4/NRG, X-ray photoelectron spectroscopy (XPS) measurements were adopted and the results are shown in Fig. 5. In contrast with GO, the existence of N, Zn and Fe in the XPS spectrum (Fig. 5a) of ZnFe2O4/NRG composite can be clearly observed. In the high resolution C 1 s spectrum of GO (Fig. 5b), there are three dominant peaks at 284.6, 286.8 and 288.8 eV, corresponding to C-C/C = C, C-O and C=O, respectively. With regard to that of ZnFe2O4/NRG (Fig. 5c), an additional peak appears at 285.3 eV, which can be associated with C-N bond. Besides, the peak intensities of C–O and C=O for ZnFe2O4/NRG are much weaker than those for the pure GO, due to the reduction of graphene oxide during the hydrothermal reaction. As shown in Fig. 5d, the N 1 s spectrum of the ZnFe2O4/NRG can be divided into three types centered at 398.7, 399.9, and 401.1 eV, assigned to Pyridinic-N, Pyrrolic-N and Graphitic-N, which can demonstrate the successful doping of nitrogen into graphene network59. It has been proved that pyridinic N and pyrrolic N can create large number of defects on the surface of graphene, providing more diffusion channels and active sites for the fast transportation of ions60,61. Figure 5e displayed two major peaks at 1021.5 and 1044.6 eV, which can be ascribed Zn 2p3/2 and Zn 2p1/262. The high-resolution Fe 2p spectrum has been depicted in Fig. 5f. The spectrum exhibits two major peaks located at 711.2 and 724.7 eV, corresponding to Fe 2p3/2 and Fe 2p1/2, respectively, with a spin-energy separation of 13.5 eV, which is characteristic oxidation state of iron in ZnFe2O462. In addition, some extra peaks donated as satellite peak around the Fe 2p3/2 and Fe 2p1/2 signals are also found. These XPS results are well consistent with the XRD and Raman analysis.

Surface area and pore size play important roles in determining the electrochemical properties of electrode materials55,59. Therefore, N2 adsorption/desorption were performed to study the specific surface area and porous nature of ZnFe2O4/NRG composites. As displayed in Fig. 6, the isotherm of ZnFe2O4/NRG possesses a typical type IV with a H3 hysteresis loop in the range between 0.4 and 0.8, manifesting the typical mesoporous structure of the composite. The Brunauer-Emmett-Teller (BET) surface area of ZnFe2O4/NRG is determined to be 212 m2/g. The high surface area can offer sufficient surface sites for Faradaic redox reactions, leading to better capacitive performance of the electrode materials. According to the Barrett-Joyner-Halenda (BJH) method, the pore-size distribution curve of ZnFe2O4/NRG displays an average pore diameter of 3.8 nm. This appropriate pore size can effectively favor diffusion and accession of ions into the interior voids of the materials, which contributes to high rate capability.

Electrochemical properties

To explore the potential of the prepared composites as supercapacitor electrodes, the electrochemical measurements have been performed in a three-electrode system using 1 M KOH as aqueous electrolyte. Figure 7a shows the cyclic voltammetry (CV) curves of ZnFe2O4 NPs, NRG and ZnFe2O4/NRG within the potential range from −1 to 0 V at a scan rate of 5 mV/s. As known, the encircled area of CV curves is proportional to the specific capacitance of the electrodes. According to this theory, we can easily deduce from Fig. 7a that the capacitance of ZnFe2O4/NRG composite is much higher than those of ZnFe2O4 NPs and NRG, due to the synesthetic effect between ZnFe2O4 and NRG. Notably, the CV curve of NRG presents a typical rectangular shape with no obvious peaks for oxidation and reduction, indicating a characteristic of the electric double layer charging mechanism. While the curves of ZnFe2O4 NPs and ZnFe2O4/NRG exhibit an anodic peak located at approximate −0.8 V and a corresponding cathodic peak potential at around −0.9 V, assigned to the reversible electrochemical reactions from ZnFe2O4 to ZnOOH and FeOOH, implying the pseudocapacitive contribution to the electrochemical performance of the electrodes44. The effect of scan rate on stability of the ZnFe2O4/NRG electrode was investigated with a wide scan range from 2 to 100 mV/s. As depicted in Fig. 7b, the CV curves retained similar quasi-rectangular shape at all scan rates, suggesting relatively high rate capability of ZnFe2O4/NRG, due to its unique structure beneficial for the fast ion diffusion into the electrode. Galvanostatic charging–discharging (GCD) has been also carried out to evaluate the capacitive performance of these three samples. The specific capacitance of the three electrodes can be calculated from the galvanostatic discharge curves using the following equation:

Where I is the response current density, Δt is the discharge time, m is the mass of the active materials on single electrode, and ΔV is the potential range during the charge-discharge measurement. Figure 8a exhibits the charge–discharge curves of the electrode materials at the current density of 0.5 A/g with voltage windows between −1 and 0 V. As expected, the ZnFe2O4/NRG electrode exhibits longest discharge time, corresponding to the highest specific capacitance of 244 F/g, which is in accordance with the analysis of CV curves.

Galvanostatic charge-discharge curves of ZnFe2O4 NPs, NRG and ZnFe2O4/NRG (a); galvanostatic charge-discharge curves of ZnFe2O4/NRG composite tested at various discharge current (b); current density dependent specific capacitance of ZnFe2O4 NPs, NRG and ZnFe2O4/NRG (c); Nyquist plots of the EIS for ZnFe2O4 NPs, NRG and ZnFe2O4/NRG (d).

The GCD curves of the ZnFe2O4/NRG measured at various current densities are displayed in Fig. 8b. It can be seen that the shape of the curves displays an apparent deviation from a straight line, which can be also ascribed to the feature of pseudocapacitive behavior61. The charge-discharge curves at all current densities can maintain a similarly symmetric shape, demonstrating high Coulombic efficiency result and low polarization from admirably reversible performance of ZnFe2O4/NRG during faradic reactions.

Good rate capability is also a key parameter to assess the potential application of supercapacitors21,56. Encouragingly, as shown in Fig. 8c, all the specific capacitances for ZnFe2O4/NRG at the same current density are much higher than those of other samples, and the specific capacitance of ZnFe2O4/NRG reached up to 244 F/g at 0.5 A/g, and retain at 131.5 F/g for a scan rate as high as 10 A/g, suggesting admirable rate performance of this composite. In contrast, for ZnFe2O4 NPs, the specific capacitance decreases rapidly from 94 F/g to 30 F/g with a very low capacitive retention rate of 32%. The possible reason for the superb electrochemical properties can be attributed to the facile combination of ZnFe2O4 NPs and NRG, which can motivate the synthetic effect between pseudocapacitors and electrical double layer capacitors. For one thing, a plenty of active sites derived from small-sized ZnFe2O4 can ensure completely faradic reaction. Moreover, the introduction of NRG can provide rapid ions transport paths and facilitate high exposure of the electroactive sites.

Electrochemical impedance spectroscopy (EIS) measurements were also conducted to obtain the electrical conductivity of each sample. As displayed in Fig. 8d, all these Nyquist plots exhibit a semicircle in the high frequency region and vertical line in the low frequency region. It is accepted that the semicircle diameter corresponds to the charge transfer impedance of the electrode and the straight line reveals the frequency dependence of ion diffusion/transport from electrolyte to the electrode surface30,34. Compared with ZnFe2O4 NPs, the ZnFe2O4/NRG owns a much smaller semicircle and a more vertical line, indicating faster reaction kinetics and lower ion diffusion resistance. The values of charge-transfer resistance for NRG, ZnFe2O4 NPs and ZnFe2O4/NRG composites are 0.59 Ω, 0.67 Ω and 0.73 Ω, respectively. The improvement of electrical conductivity can be ascribed to the indispensable role of NRG served as substrate, which can offer high contact interface for electrode and electrolyte.

Since long term cycling stability is a key parameter to evaluate the practical application of a supercapacitor material, ZnFe2O4/NRG electrode was also tested at 100 mV/s a potential range between −1 and 0 V for 5000 cycles, using 1 M KOH aqueous solution as electrolyte. The specific gravimetric capacitance is calculated from discharge regions of the CV using the following equation:

where C (F/g) is the specific capacitance of single electrode, I is the current response (mA), v1 and v2 are the vertex potentials of the voltage range, m is the grams of one electrode (g), v is the potential scan rate (mV/s), and ∆V is the voltage window (V). As shown in Fig. 9, the ZnFe2O4/NRG electrode exhibits an excellent long-term electrochemical durability, with capacitance retention of 83.8% after repetitive 5000 cycles. In addition, the CV curve (inset in Fig. 9) maintains its initial CV shape without any variation, suggesting excellent cycling stability. The excellent cycling performance of ZnFe2O4/NRG is attributable to its unique structure, which effectively improves interconnection of active materials and thus inhibits the capacitance loss during repetitive cycles.

To further evaluate the practical application of the ZnFe2O4/NRG composite as electrode, a symmetric supercapacitor has been designed and assembled. Figure 10a shows the CV curves of the composites at different scan rate from 2 mV/s to 100 mV/s. It can be seen that the area of the curves increases obviously with increasing potential scan rate, and the curves can maintain their shape at various scan rates, confirming the good rate behavior of the symmetric device. The galvanostatic charge/discharge curves are shown in Fig. 10b. It is noted that the charge curves are symmetrical to their corresponding discharge curves, further indicating the favorable electrochemical properties of the as-fabricated device. According to the specific capacitance of the symmetric supercapacitor at different current densities (Figure S2), the Ragone plot revealing the relationship between energy density and power density is presented in Fig. 10c. The values of energy density and power density can be calculated by the following equation:

Where E the energy density (Wh/kg) is, C is the specific capacitance (F/g), ΔV is the cell voltage (V), P is the power density (W/kg), and Δt is the discharge time (s). The maximum energy density and power density of 6.7 Wh/kg and 3000 W/kg can be achieved at an operating voltage of 1.2 V, which can be of potential in practical application.

In order to determine the stability of the symmetric device, CV cycling was also conducted at 100 mV/s for 1000 cycles. The capacitance of the device retention after 1000 cycles is about 84.4%, indicating an excellent long-term stability of the symmetric supercapacitor.

Methods

Preparation of the samples

Graphene oxide (GO) was synthesized on the basis of a modified Hummers method63. The prepared GO was treated with dialysis process to completely remove residual salts and acids. Certain amount of the purified GO was then dispersed and wished with DMF solution for several times. After continuous ultrasonication at room temperature for 6 h, the GO/DMF solution was obtained with a concentration about 0.8 mg/mL.

For a typical synthesis of ZnFe2O4/RNG, 0.5 mmol Zn(acac)2 and 1 mmol Fe(acac)3 were slowly added into the 40 ml of GO/DMF suspension. After stirring for 30 min, the resulting mixture was moved to a Teflon-lined autoclave followed by maintaining at 180 °C for 12 h, and then the resultant black precipitates were cleaned with ethanol and DI water several times by centrifuging. Finally, the ZnFe2O4/RNG samples were dried in a vacuum oven at 60 °C for 24 h and annealing in muffle furnace at 250 °C for 2 h to remove the residue of the organic matter. For comparison, NRG and ZnFe2O4 NPs composite were prepared in the absence of organic metal salt and GO solution under the same conditions.

Fabrication of electrode and electrochemical measurement

The conventional three-electrode cell consisted of the counter electrode (Pt foil 1 × 1 cm2), the reference electrode (a Hg/HgO electrode) and working electrode (Ni foam coated with active material) employed to determine electrochemical performance of ZnFe2O4/RNG composites. The fabrication of working electrode was presented as follows. First, active material powder, acetylene black, and polytetrafluoroethylene (PTFE), with a weight ratio of 80:10:10, were mixed to form homogeneous slurry and coated on a nickel foam. After dried in a vacuum at 60 °C overnight, the obtained nickel foam was pressed under a pressure of 3 MPa to ensure firmly attachment of electrode materials. In a two-electrode system, the test capacitor was fabricated by sandwiching a porous polymer membrane separator between two as-prepared electrodes. All the tests were conducted at room temperature with a 1 M KOH aqueous solution as the electrolyte.

Characterization

Crystalline structure, the morphology, and chemical composition of the samples were investigated by powder X-ray diffraction (XRD) (Rigaku D/max TTR-III diffractometer with graphite monochromatized Cu Kα radiation (λ = 0.15405 nm)), scanning electron microscope (SEM, JSM-6480A), transmission electron microscopy (TEM, FEI Tecnai G2 S-Twin), high-resolution transmission electron microscopy (HRTEM), and the X-ray photoelectron spectra XPS (VG ESCALAB MK II electron energy spectrometer using Mg KR (1253.6 eV) as the X-ray excitation source). Raman spectra were conducted on a confocal laser microRaman spectrometer (LABRAM-HR, JY Co.), and N2 adsorption/desorption isotherms were measured from Micromeritics ASAP Tristar II 3020 apparatus. The electrochemical properties were carried out by a CHI 666D electrochemical workstation.

Additional Information

How to cite this article: Li, L. et al. Uniformly Dispersed ZnFe2O4 Nanoparticles on Nitrogen-Modified Graphene for High-Performance Supercapacitor as Electrode. Sci. Rep. 7, 43116; doi: 10.1038/srep43116 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Xiao, J. W., Wan, L., Yang, S. H., Xiao, F. & Wang, S. Design hierarchical electrodes with highly conductive NiCo2S4 nanotube arrays grown on carbon fiber paper for high-performance pseudocapacitors. Nano Lett. 14, 831–838 (2014).

Yang, P. H. et al. Low-Cost High-performance solid-state asymmetric supercapacitors based on MnO2 nanowires and Fe2O3 nanotubes. Nano Lett. 14, 731–736 (2014).

Yu, D. S. et al. Scalable synthesis of hierarchically structured carbon nanotube-graphene fibres for capacitive energy storage. Nat. Nanotechnol. 9, 555–562 (2014).

Balogun, M. S., Luo, Y., Qiu, W. T., Liu, P. & Tong, Y. X. A review of carbon materials and their composites with alloy metals for sodium ion battery anodes. Carbon 98, 162–178 (2016).

Sharifi, N., Ardjmand, M., Ahangari, M. G. & Ganji, M. D. Si-decorated graphene: a superior media for lithium-ions storage. Struct. Chem. 24, 1473–1483 (2013).

Jacques, E., Lindbergh, G., Zenkert, D., Leijonmarck, S. & Kjell, M. H. Piezo-electrochemical energy harvesting with lithium-intercalating carbon fibers. ACS Appl. Mater. Interfaces 7, 13898–13904 (2015).

Acerce, M., Voiry, D. & Chhowalla, M. Metallic 1T phase MoS2 nanosheets as supercapacitor electrode materials. Nat. Nanotechnol. 10, 313–318 (2015).

Xu, L. et al. Reactable ionic liquid assisted solvothermal synthesis of graphite-like C3N4 hybridized α-Fe2O3 hollow microspheres with enhanced supercapacitive performance. J. Power Sources 245, 866–874 (2014).

Wang, H., Feng, H. B. & Li, J. H. Graphene and Graphene-like layered transition metal dichalcogenides in energy conversion and storage. Small 10, 2165–2181 (2014).

Yan, J. et al. Template-assisted low temperature synthesis of functionalized graphene for ultrahigh volumetric performance supercapacitors. ACS Nano 8, 4720–4729 (2014).

Jiang, L. L. & Fan, Z. J. Design of advanced porous graphene materials: from graphene nanomesh to 3D architectures. Nanoscale 6, 1922–1945 (2014).

Han, S., Wu, D. Q., Li, S., Zhang, F. & Feng, X. L. Porous graphene materials for advanced electrochemical energy storage and conversion devices. Adv. Mater. 26, 849–864 (2014).

Yu, Z. N., Tetard, L., Zhai, L. & Thomas, J. Supercapacitor electrode materials: nanostructures from 0 to 3 dimensions. Energy Environ. Sci. 8, 702–730 (2015).

Fan, X. H., Phebus, B. D., Li, L. J. & Chen, S. W. Graphene-based composites for supercapacitor electrodes. Sci. Adv. Mater. 7, 1916–1944 (2015).

Li, W. Y. et al. Facile synthesis of porous Mn2O3 nanocubics for high-rate supercapacitors. Electrochim. Acta 157, 108–114 (2015).

Hu, Z. M. et al. Al-doped alpha-MnO2 for high mass-loading pseudocapacitor with excellent cycling stability. Nano Energy 11, 226–234 (2015).

Shown, I., Ganguly, A., Chen, L. C. & Chen, K. H. Conducting polymer-based flexible supercapacitor. Energy Sci. Eng. 3, 2–26 (2015).

Chen, X., Chen, K. F., Wang, H. & Xue, D. F. A colloidal pseudocapacitor: Direct use of Fe(NO3)3 in electrode can lead to a high performance alkaline supercapacitor system. J. Colloid. Interface Sci. 444, 49–57 (2015).

Hu, L. B. et al. Symmetrical MnO2-carbon nanotube-textile nanostructures for wearable pseudocapacitors with high mass loading. ACS Nano 5, 8904–8913 (2011).

Zhang, Y. F. et al. Selective synthesis of hierarchical mesoporous spinel NiCo2O4 for high-performance supercapacitors. Nanoscale 6, 4303–4308 (2014).

Zhong, J. H. et al. Co3O4/Ni(OH)(2) composite mesoporous nanosheet networks as a promising electrode for supercapacitor applications. J. Mater. Chem. 22, 5656–5665 (2012).

Gao, H. & Lian, K. Proton-conducting polymer electrolytes and their applications in solid supercapacitors: a review. RSC Adv. 4, 33091–33113 (2014).

Laforgue, A. All-textile flexible supercapacitors using electrospun poly(3,4-ethylenedioxythiophene) nanofibers. J. Power Sources 196, 559–564 (2011).

Mao, L., Zhang, K., Chan, H. S. O. & Wu, J. S. Nanostructured MnO2/graphene composites for supercapacitor electrodes: the effect of morphology, crystallinity and composition. J. Mater. Chem. 22, 1845–1851 (2012).

Xiang, C. C., Li, M., Zhi, M. J., Manivannan, A. & Wu, N. Q. A reduced graphene oxide/Co3O4 composite for supercapacitor electrode. J. Power Sources 226, 65–70 (2013).

Huang, Y., Liang, J. J. & Chen, Y. S. An Overview of the applications of graphene-based materials in supercapacitors. Small 8, 1805–1834 (2012).

Guo, C. X. & Li, C. M. A self-assembled hierarchical nanostructure comprising carbon spheres and graphene nanosheets for enhanced supercapacitor performance. Energy. Environ. Sci. 4, 4504–4507 (2011).

Wang, B., Park, J., Wang, C. Y., Ahn, H. & Wang, G. X. Mn3O4 nanoparticles embedded into graphene nanosheets: preparation, characterization, and electrochemical properties for supercapacitors. Electrochim. Acta 55, 6812–6817 (2010).

Cui, H. T., Xue, J. Y. & Wang, M. M. Synthesis of high electrochemical performance Ni(OH)2 nanosheets through a solvent-free reaction for application in supercapacitor. Adv. Powder Technol. 26, 434–438 (2015).

Fu, W. D. et al. beta-Ni(OH)2 nanosheets grown on graphene as advanced electrochemical pseudocapacitor materials with improved rate capability and cycle performance. Mater. Lett. 134, 107–110 (2014).

Umeshbabu, E., Rajeshkhanna, G. & Rao, G. R. Effect of solvents on the morphology of NiCo2O4/graphene nanostructures for electrochemical pseudocapacitor application. J. Solid State Electrochem. 20, 1837–1844 (2016).

Zhou, W. W. et al. Fabrication of Co3O4-reduced graphene oxide scrolls for high-performance supercapacitor electrodes. Phy. Chem. Chem. Phys. 13, 14462–14465 (2011).

Cai, X. Y. et al. High-performance asymmetric pseudocapacitor cell based on cobalt hydroxide/graphene and polypyrrole/graphene electrodes. J. Power Sources 275, 298–304 (2015).

Huang, M. L., Gu, C. D., Ge, X., Wang, X. L. & Tu, J. P. NiO nanoflakes grown on porous graphene frameworks as advanced electrochemical pseudocapacitor materials. J. Power Sources 259, 98–105 (2014).

Sahu, V. et al. Heavily nitrogen doped, graphene supercapacitor from silk cocoon. Electrochim. Acta 160, 244–253 (2015).

Chen, J., Xu, J., Zhou, S., Zhao, N. & Wong, C.-P. Nitrogen-doped hierarchically porous carbon foam:a free-standing electrode and mechanical support for high-performance supercapacitors. Nano Energy 25, 193–202 (2016).

Akhter, T. et al. Self-assembled N/S codoped flexible graphene paper for high performance energy storage and oxygen reduction reaction. ACS Appl. Mater. Interfaces 8, 2078–2087 (2016).

Parveen, N., Ansari, M. O., Ansari, S. A. & Cho, M. H. Simultaneous sulfur doping and exfoliation of graphene from graphite using an electrochemical method for supercapacitor electrode materials. J. Mater. Chem. A 4, 233–240 (2016).

Rusi & Majid, S. R. High performance super-capacitive behaviour of deposited manganese oxide/nickel oxide binary electrode system. Electrochim. Acta 138, 1–8 (2014).

Krishnan, S. G. et al. Characterization of MgCo2O4 as an electrode for high performance supercapacitors. Electrochim. Acta 161, 312–321 (2015).

Javed, M. S., Zhang, C. L., Chen, L., Xi, Y. & Hu, C. G. Hierarchical mesoporous NiFe2O4 nanocone forest directly growing on carbon textile for high performance flexible supercapacitors. J. Mater. Chem. A 4, 8851–8859 (2016).

Pendashteh, A., Palma, J., Anderson, M. & Marcilla, R. Nanostructured porous wires of iron cobaltite: novel positive electrode for high-performance hybrid energy storage devices. J. Mater. Chem. A 3, 16849–16859 (2015).

Zhu, M. et al. Facile solvothermal synthesis of porous ZnFe2O4microspheres for capacitive pseudocapacitors. RSC Adv. 5, 39270–39277 (2015).

Xiong, P. et al. Ternary manganese ferrite/graphene/polyaniline nanostructure with enhanced electrochemical capacitance performance. J. Power Sources 266, 384–392 (2014).

Zhang, W. et al. One-step facile solvothermal synthesis of copper ferrite-graphene composite as a high-performance supercapacitor material. ACS Appl. Mater. Interfaces 7, 2404–14 (2015).

Vadiyar, M. M. et al. Low cost flexible 3-D aligned and cross-linked efficient ZnFe2O4nano-flakes electrode on stainless steel mesh for asymmetric supercapacitors. J. Mater. Chem. A 4, 3504–3512 (2016).

Raut, S. S. & Sankapal, B. R. First report on synthesis of ZnFe2O4 thin film using successive ionic layer adsorption and reaction: approach towards solid-state symmetric supercapacitor device. Electrochim. Acta 198, 203–211 (2016).

Zhu, M. Y. et al. Facile solvothermal synthesis of porous ZnFe2O4 microspheres for capacitive pseudocapacitors. RSC Adv. 5, 39270–39277 (2015).

Vadiyar, M. M. et al. Contact angle measurements: a preliminary diagnostic tool for evaluating the performance of ZnFe2O4 nano-flake based supercapacitors. Chem. Commun. 52, 2557–60 (2016).

Pang, H. et al. Facile synthesis of porous ZnO-NiO composite micropolyhedrons and their application for high power supercapacitor electrode materials. Dalton Trans. 41, 13284–13291 (2012).

Rakhi, R. B., Cha, D. K., Chen, W. & Alshareef, H. N. Electrochemical energy storage devices using electrodes incorporating carbon nanocoils and metal oxides nanoparticles. J. Phy. Chem. C 115, 14392–14399 (2011).

Shen, C. W., Wang, X. H., Zhang, W. F. & Kang, F. Y. A high-performance three-dimensional micro supercapacitor based on self-supporting composite materials. J. Power Sources 196, 10465–10471 (2011).

Liu, Y., Wang, R. & Yan, X. Synergistic Effect between ultra-small nickel hydroxide nanoparticles and reduced graphene oxide sheets for the application in high-performance asymmetric supercapacitor. Sci. Rep. 5, 11095 (2015).

Li, Q. et al. Electrocapacitive performance of graphene/Co3O4 hybrid material prepared by a nanosheet assembly route. Electrochim. Acta 119, 184–191 (2014).

Niu, L. Y. et al. Simple Synthesis of amorphous niwo4 nanostructure and its application as a novel cathode material for asymmetric supercapacitors. ACS Appl. Mater. Interfaces 5, 8044–8052 (2013).

Gao, F. et al. A green strategy for the synthesis of graphene supported Mn3O4 nanocomposites from graphitized coal and their supercapacitor application. Carbon 80, 640–650 (2014).

Yang, J. et al. Electroactive edge site-enriched nickel–cobalt sulfide into graphene frameworks for high-performance asymmetric supercapacitors. Energy Environ. Sci. 9, 1299–1307 (2016).

Xue, H., Li, Z., Wang, X. & Fu, X. Facile synthesis of nanocrystalline zinc ferrite via a self-propagating combustion method. Mater. Lett. 61, 347–350 (2007).

Yan, Y., Kuila, T., Kim, N. H., Lee, S. H. & Lee, J. H. N-doped carbon layer coated thermally exfoliated graphene and its capacitive behavior in redox active electrolyte. Carbon 85, 60–71 (2015).

Wang, H., Sun, X., Liu, Z. & Lei, Z. Creation of nanopores on graphene planes with MgO template for preparing high-performance supercapacitor electrodes. Nanoscale 6, 6577–84 (2014).

Fan, W. et al. Nitrogen-doped graphene hollow nanospheres as novel electrode materials for supercapacitor applications. J. Sources 243, 973–981 (2013).

Wu, L., Wu, T., Mao, M., Zhang, M. & Wang, T. Electrospinning Synthesis of Ni°, Fe° codoped ultrafine-ZnFe2O4/C nanofibers and their properties for lithium ion storage. Electrochim. Acta 194, 357–366 (2016).

Hummers, W. S. & Offeman, R. E. Preparation of graphitic oxide. J. Am. Chem. Soc. 80, 1339–1339 (1958).

Acknowledgements

Financial supports from the Natural Science Foundation of China (NSFC 21401032, 51472058, 51332008, 51502050), Outstanding Youth Foundation of Heilongjiang Province (JC2015003), and the Fundamental Research funds for the Central Universities are greatly acknowledged.

Author information

Authors and Affiliations

Contributions

L.L. designed the strategy for preparing the samples, carried out experiment and wrote the manuscript. X.Z., P.G., M.Z. and P.Y. provided the research approach and scientific discussion at various stages. H.B. and L.L. performed the electrochemical measurements. S.G., F.H., Y.D. and D.Y. collected data of phase and morphology. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Li, L., Bi, H., Gai, S. et al. Uniformly Dispersed ZnFe2O4 Nanoparticles on Nitrogen-Modified Graphene for High-Performance Supercapacitor as Electrode. Sci Rep 7, 43116 (2017). https://doi.org/10.1038/srep43116

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep43116

This article is cited by

-

Construction of Novel Z-scheme Heterojunction in ZnFe2O4/P25 @ MOF-5 Nanocomposite from Plastic Waste for Efficient Photodegradation of Aqueous BTX Under Visible Light

Journal of Inorganic and Organometallic Polymers and Materials (2024)

-

ZnFe2O4 nanorods encapsulated in reduced graphene oxide sheets as advanced electrodes for supercapacitor applications

Bulletin of Materials Science (2024)

-

Influence of Co doping on phase, structure and electrochemical properties of hydrothermally obtained CoxZn1−xFe2O4 (x = 0.0–0.4) nanoparticles

Scientific Reports (2023)

-

ZnFe-MOF derived ZnO/ZnFe2O4 nanocomposite as an electrode material for supercapacitor application

Journal of Materials Science: Materials in Electronics (2023)

-

Electrochemical investigation of silk G/MoS2/PDOT: PSS synthesized using supercritical fluid approach

Journal of Materials Science: Materials in Electronics (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.