Abstract

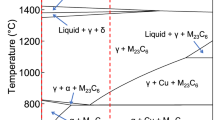

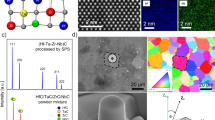

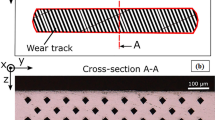

Transition-metal carbides and nitrides are hard materials widely used for cutting tools and wear-resistant coatings. Their hardness is not yet understood at a fundamental level. A clue may lie in the puzzling fact that transition-metal carbonitrides that have the rock-salt structure (such as TiCxN1−x) have the greatest hardness for a valence-electron concentration of about 8.4 per cell1,2,3, which suggests that the hardness may be determined more by the nature of the bonding than by the conventional microstructural features that determine the hardness of structural metals and alloys. To investigate this possibility, we have evaluated the shear modulus of various transition-metal carbides and nitrides using ab initio pseudopotential calculations. Our results show that the behaviour of these materials can be understood on a fundamental level in terms of their electronic band structure. The unusual hardness originates from a particular band of σ bonding states between the non-metal p orbitals and the metal d orbitals that strongly resists shearing strain or shape change. Filling of these states is completed at a valence-electron concentration of about 8.4, and any additional electrons would go into a higher band which is unstable against shear deformations.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Holleck, M. Material selection for hard coatings. J. Vac. Sci. Technol. A 4, 2661–2669 (1986).

Richter, V., Beger, A., Drobniewski, J., Endler, I. & Wolf, E. Characterization and wear behavior of TiN- and TiCxN1−x-coated cermets. Mater. Sci. Eng. A 209, 353–357 (1996).

Toth, L. E. Transition Metal Carbides and Nitrides (Academic, New York, (1971).

Kelly, A. & Macmillan, N. H. Strong Solids 3rd edn (Clarendon, Oxford, (1986).

Gilman, J. J. The plastic resistance of crystals. Aust. J. Phys. 13, 327–346 (1960).

Clerc, D. G. & Ledbetter, H. M. Mechanical hardness: a semiempirical theory based on screened electrostatics and elastic shear. J. Phys. Chem. Solids 59, 1071–1095 (1998).

Teter, D. M. Computational alchemy: the search for new superhard materials. Mater. Res. Soc. Bull. 23, 22–27 (1998).

Krenn, C. R., Morris, J. W., Jhi, S.-H. & Ihm, J. in Hard Coatings Based on Borides, Carbides & Nitrides (eds Kumar, A., Chung, Y.-W. & Chia, R. W. J.) 379–388 (The Minerals, Metals & Materials Soc., Warrendale, PA, (1998).

Ihm, J., Zunger, A. & Cohen, M. L. Momentum-space formalism for the total energy of solids. J. Phys. C 12, 4409–4422 (1979).

Pickett, W. E. Pseudopotential methods in condensed matter applications. Comput. Phys. Rep. 9, 115–197 (1989).

Liu, A. Y. & Cohen, M. L. Prediction on new low compressibility solids. Science 245, 841–842 (1989).

Samuels, L. E. in Microindentation Technique in Materials Science and Engineering (eds Blau, P. J. & Lawn, B. R.) 5–24 (ASTM, Philadelphia, (1985).

Gilman, J. J. Physical chemistry of intrinsic hardness. Mater. Sci. Eng. A 209, 74–81 (1996).

Nikitenko, V., Farber, B. & Iunin, Yu. Experimental investigation of the dynamics of kinks of dislocation lines in semiconductor single crystals. Sov. Phys. JETP 66, 738–746 (1987).

Hull, D. & Bacon, D. J. Introduction to Dislocations 3rd edn (Pergamon, Oxford, (1984).

Jiang, X. et al. Elastic constants and hardness of ion-beam-sputtered TiNxfilms measured by Brillouin scattering and depth-sensing indentation. J. Appl. Phys. 69, 3053–3057 (1991).

Jhi, S.-H. & Ihm, J. Electronic structure and structural stability of TiCxN1−xalloys. Phys. Rev. B 56, 13826–13829 (1997).

Acknowledgements

S.-H.J. and J.I. were supported by the SNI, the SRC programme of KOSEF, and the BSRI programme of KRF. S.G.L. and M.L.C. were supported by the NSF and DOE. The support of a Korea-US Cooperative Grant by KOSEF and NSF is acknowledged. S.G.L acknowledges the hospitality of the Korea Institute for Advanced Study, where part of this Letter was written.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jhi, SH., Ihm, J., Louie, S. et al. Electronic mechanism of hardness enhancement in transition-metal carbonitrides. Nature 399, 132–134 (1999). https://doi.org/10.1038/20148

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/20148

This article is cited by

-

Off-stoichiometry and molybdenum substitution effects on elastic moduli of B1-type titanium carbide

Scientific Reports (2023)

-

Electronic correlations in epitaxial CrN thin film

Scientific Reports (2023)

-

First-principles study on the stability and mechanical properties of TiC\(_x\)N\(_{1-x}\)

Journal of Materials Science (2023)

-

First-principles calculations of structural, electronic, elastic, and thermal properties of phase M2CdC (M = Sc, V, and Nb)

Indian Journal of Physics (2023)

-

Distilling physical origins of hardness in multi-principal element alloys directly from ensemble neural network models

npj Computational Materials (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.