Abstract

Bi2Te3 is a good thermoelectric compound that can be adjusted to p- or n-type with corresponding substitutions; however, less progress has been achieved for the property enhancement of n-type Bi2(TeSe)3 compared with p-type (BiSb)2Te3. Textured n-type Bi2(TeSe)3 with an enhanced thermoelectric performance has been developed in this study by combining texturing with in situ nanostructuring effects. The spark plasma-textured structure boosts the electrical transport properties and the power factors as benefits of the layered microstructure. It also leads to a simultaneous rise in the thermal conductivity along the a-axis. We developed a method to suppress increases in the thermal conductivity by inducing nanostructures, such as highly distorted regions and nanoscopic defect clusters, as well as dislocation loops that can form when texturing occurs at an optimized temperature. In this work, textured n-type Bi2(TeSe)3 materials having enhanced thermoelectric performances within a low temperature range are developed with a maximum dimensionless figure of merit (ZTmax) exceeding 1.1 at 473 K. The present method, which synergetically utilizes the texturing and nanostructuring effects, could also be applied to other thermoelectric compounds having layered structures.

Similar content being viewed by others

Introduction

Thermoelectric materials that can be used for converting waste heat into electrical energy and for cooling in solid-state applications have attracted worldwide interest for decades.1, 2, 3, 4 The thermoelectric conversion efficiency of a material depends on its dimensionless figure of merit ZT, defined as ZT=α2σT/κ, where α, σ, κ and T are the Seebeck coefficient, electrical conductivity, thermal conductivity and absolute temperature, respectively.5, 6 A great variety of thermoelectric materials have been developed and thoroughly studied,7, 8, 9 but industrial applications are still dominated by bismuth telluride (Bi2Te3)-based alloys.10 Therefore, extensive studies have been devoted to the enhancement of their properties. Industrially used ingots of Bi2Te3-based alloys are fabricated using a zone melting process, which is capable of enhancing the preferential crystal growth and chemical purity. Recent studies have demonstrated that property enhancements can be achieved with powder processes that facilitate nanostructuring and microstructure refinement, especially in p-type (BiSb)2Te3 alloys.11, 12, 13 In addition, powder-processed thermoelectric materials also possess better mechanical properties, which are beneficial in device manufacturing.14, 15 In particular, spark plasma sintering (SPS) combined with mechanical alloying (MA) has been increasingly used as a facile powder process for synthesizing thermoelectric materials.16, 17, 18, 19 Nevertheless, for the ZT enhancement of Bi2Te3-based alloys fabricated by MA and SPS, the optimal composition needs to be redefined; it is no longer the same as the ingots because of massive point defects and strong donor-like effect.19, 20 Our group has already confirmed that Bi2Te2.2Se0.8 is the optimal composition for samples prepared by MA and SPS.21

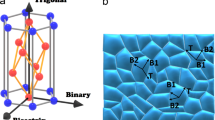

Bi2Te3 is anisotropic with a layered structure composed of a quintuple atomic series in the order of Te(1)-Bi-Te(2)-Bi-Te(1) along the c-axis. Their electrical and thermal conductivities along the a-axis (in the c-plane) are approximately four and two times higher, respectively, than those along the c-axis of Bi2Te3.22, 23 However, the Seebeck coefficient is less dependent on the crystallography.24 As a result, the ZT value in the c-plane is approximately two times higher than that perpendicular to the c-plane. Therefore, an improved ZT value can be expected when utilizing the anisotropic electrical and thermal transport properties,25 especially for n-type Bi2(TeSe)3, which has a larger ratio of the electrical conductivities along the a- and c-axes than that of thermal conductivities. However, the electrical transport properties do not improve as much as expected by texturing because of the many complex chemical defect reactions induced mechanically during the texturing process. Therefore, it is important to suppress a rise in the thermal conductivity by incorporating nanostructures into the textured microstructures, as demonstrated in this study.

This work revealed the importance of synergetically combined texturing and nanostructuring effects that are realized by simply optimizing the texturing temperature. In this work, highly textured n-type Bi2(TeSe)3 alloys were fabricated by a repeated SPS process as hot-forging,26, 27 and a thermoelectric property enhancement was achieved by optimizing the texturing temperatures. A maximum ZT value of 1.1 was obtained in textured n-type Bi2Te2.2Se0.8 (approximately 35% enhancement compared with the non-textured counterparts). A bottleneck has existed for the enhancement of n-type Bi2(TeSe)3 alloys, and high ZTs exceeding 1.0 have been seldom reported in powder-processed n-type Bi2(TeSe)3 despite higher ZT values demonstrated for p-type (BiSb)2Te3 alloys.19 We have demonstrated that a large quantity of nanoscopic defects inside the grains form at an optimized texturing temperature, decreasing the lattice thermal conductivity; meanwhile, a textured structure greatly enhances the electrical transport properties.

Experimental procedures

Materials synthesis

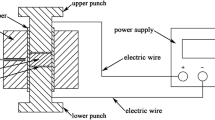

Mixtures of Bi (99.99%), Te (99.999%) and Se (99.999%) powders were subjected to MA in a planetary ball mill at 450 r.p.m. for 3 h, with a stoichiometric proportion of Bi2Te2.2Se0.8. The mill vials were filled with 95 vol. % Ar and 5 vol. % H2 to provide a protective atmosphere. The mechanically alloyed powders were sintered by SPS in a Φ12-mm graphite mold at 673 K for 5 min under an axial pressure of 50 MPa in vacuum. Then the sintered samples were set into bigger molds with diameters from Φ15 to Φ20 mm and pressed also by SPS under a pressure of 50 MPa at different temperatures; the samples were named TP 400, TP 460, TP 480 and TP 500, respectively, for the temperatures of 673, 733, 753 and 773 K. The TP 460 sample was further texture-processed an additional time by SPS at 733 K in a Φ25-mm mold and named TP 460-3.

Phase identification and microstructure characterization

Phase and textured structures were investigated by X-ray diffraction (XRD, D/max-RB, Rigaku, Tokyo, Japan) using Cu-Kα radiation (λ=1.5406 Å). The microstructures and nanostructures of the bulk samples were observed by field emission scanning electron microscopy (SEM, JSM-7001, JEOL, Tokyo, Japan) and transmission electron microscopy (TEM, JEOL-2011). The specimens used for the TEM observation were polished to ~30–40 μm and then thinned to electron transparency using a Leica precession ion-milling system (RES101, Bal-Tec, Pfäffikon, Switzerland) at a low angle (10–15°). High-resolution TEM (HRTEM) images of the pieces were recorded at 200 kV.

Thermoelectric transport property measurement

The electrical resistivity and Seebeck coefficient were measured on a ZEM-2 apparatus (Ulvac-Riko, Yokohama, Japan) from 323 to 573 K in a helium atmosphere using a four-probe method. The Hall coefficient (RH) was measured using a Hall measurement system (ResiTest 8340DC, Tokyo, Japan), and the Hall carrier concentration (nH) and mobility (μH) were calculated by nH=1/(eRH) and μH=RH/ρ in which ρ is electrical resistivity. The thermal diffusivity (D) was measured using the laser flash method (TC-9000, Ulvac-Riko) in vacuum at temperatures ranging from 300 to 573 K, which were measured along the same direction (in-plane) as the electrical property measurement to avoid overestimating the ZT values. Finally, the thermal conductivity (κ) was calculated using the equation κ=D × Cp × d, with the density (d) of the sample estimated by the Archimedes method, and the specific heat (Cp) measured by Simultaneous Thermal Analysis (STA 449F3, Netzsch, Selb, Germany). The measured Cp values, along with a comparison with the reported values, are given in Supplementary Figure S1. The longitudinal (υl) and transverse (υs) acoustic velocities were measured by an ultrasonic pulser/receiver (Ultrasonic Pulser/Receiver Model 5900 PR, Panametrics, Waltham, MA, USA). The average sound speed (υ) was then calculated by  .18 The thermal conductivities at low temperatures ranging from 4 to 350 K were measured using a physical property measurement system (PPMS-9T, Quantum Design, San Diego, CA, USA).

.18 The thermal conductivities at low temperatures ranging from 4 to 350 K were measured using a physical property measurement system (PPMS-9T, Quantum Design, San Diego, CA, USA).

Results and Discussion

XRD and microstructure analysis

Figure 1a presents the XRD patterns of the samples before and after texturing treatment at 633, 733 and 773 K. All the samples showed a single phase of Bi2(TeSe)3. The textured samples displayed an enhanced intensity of the (00l) peak and weakened intensities of the (110) and (015) peaks compared with the non-textured sample, indicating a preferred orientation along (00l). The degree of texturing was then determined by the orientation factors, F, using the following equations:28

where P and P0 are the integrated intensities of all (00l) planes to the intensities of all (hkl) planes for preferentially and randomly oriented samples. The F values of the samples before texturing and textured at 673, 733 and 773 K were 0.08, 0.38, 0.50 and 0.58, respectively, using the XRD pattern of the powder sample as a reference. The large F values obtained (0.38, 0.50 and 0.58) compared with the small value (0.08) of the non-textured sample certainly suggest a preferred crystalline orientation along (00l). Furthermore, the increasing F factors indicate a gradually enhanced, textured microstructure with increasing texturing temperature. Detailed studies of the textured structure were conducted by pole figures.

Figure 1b gives the pole figures of two representative crystallographic directions for samples processed under different conditions (no TP and TP 460). As shown in the upper panel, it is clear that the (006) peak intensity becomes concentrated after texturing, demonstrating a preferred orientation of (00l). To confirm this situation, (015) (the strongest peak of Bi2(TeSe)3) pole figures were also measured, and the results are shown in the lower panel. The diffraction was more uniform before texturing, but the intensities become concentrated with a circular shape at approximately 60° in the textured samples, suggesting a (00l)-oriented texture, which is consistent with the former results.

The textured morphologies and the distinct influence of the processing temperature are clearly illustrated in the SEM images shown in Figure 2. As shown in Figure 2a, despite the layered structure of Bi2(TeSe)3, it displayed a relatively isotropic microstructure with fine grain structures and a uniformly distributed porosity, when it had not been subjected to the intentionally texturing treatment. However, for the samples textured by repeated SPS, the grains clearly lengthened along the direction normal to the applied pressure, as depicted in Figures 2b–d, which was caused mainly by a crystalline plasticity slip, grain boundary sliding, grain rotation and dynamic recrystallization.29 Additionally, the shape of the layered structure was enhanced with increasing texturing temperature. The samples processed at higher temperatures apparently exhibited more similar lamellar structure, which is most apparent in TP 500. Therefore, the SEM images combined with the orientation factors and pole figures confirm that the textured samples were preferentially orientated along the (00l) direction, and the degree of texturing intensified with increasing texturing temperature.

Thermoelectric properties

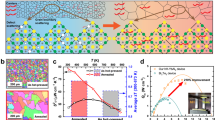

The electrical transport properties of the textured samples were investigated as a function of temperature, with the non-textured sample used as a reference. As shown in Figure 3a, the electrical conductivity greatly improved after the texturing treatment with the trend intensifying as the texturing temperature increased. It should be mentioned that the negative temperature dependence of the electrical conductivity, shown in Figure 3a, is indicative of semimetallic transport behavior, which is often observed in thermoelectric semiconductors. Interestingly, the absolute values of the Seebeck coefficient did not decrease but apparently increased after texturing at some temperatures, as shown in Figure 3b, although all of the textured samples exhibited higher electrical conductivities (the reasons will be discussed later). Consequently, benefiting from the simultaneous improvements of the electrical conductivity and the Seebeck coefficient, the power factors of the textured samples were remarkably enhanced as much as ~1.5 times at room temperature, as shown in the inset of Figure 3b.

Usually, the Seebeck coefficient decreases if the electrical conductivity is enhanced. Therefore, the above results motivated us to investigate the reasons for the simultaneous increase in the electrical conductivity and the Seebeck coefficient. The Hall experiments revealed that the carrier mobility greatly increased in the textured samples and remained almost unchanged even with increasing texturing temperature, as shown in Figure 3c. The enhanced carrier mobility was associated with a high in-plane mobility as well as weakened grain boundary scattering along the textured direction. The carrier concentration showed a more interesting change after the texturing treatment, as shown in Figure 3d. At first, the carrier concentration decreased when texturing occurs at low temperatures (673 and 733 K), and it then increased at higher texturing temperature (773 K); however, it should be noted that the change in carrier concentration was limited to a small range. Therefore, it is not difficult to understand why the simultaneous enhancement of the Seebeck coefficient and electrical conductivity was realized. The electrical conductivity improved mainly because of the greatly enhanced mobility, with little influence from the carrier concentration. The increased Seebeck coefficient, especially in the TP 400 and TP 460 samples, was due to the reduced carrier concentration after texturing.

We then refocused on how the texturing temperature affected the carrier mobility and concentration. As aforementioned, samples textured at different temperatures (673–773 K) showed almost the same carrier mobilities, as displayed in Figure 3c, which is ascribed to the combined effect of the degree of texturing and the carrier concentration. When only considering the increased degree of texturing, the carrier mobility was expected to improve with increasing texturing temperature. However, the carrier concentrations in the textured samples also increased with texturing temperature (see in Figure 3d), which suppressed any further rise in the carrier mobility. In other words, these two effects offset each other and kept the carrier mobility at a certain level.

Furthermore, a plot of lgμ versus lgT at the mid-temperature range from 373 to 473 K is used to understand the electron scattering mechanism before the bipolar effect. The inset in Figure 3c shows that all of the samples roughly obey a T−3/2 law, revealing a dominant acoustic phonon-scattering mechanism. Here, μ is defined from μH/A, where A is the Hall factor, which was determined to be approximately 1.1 by the following Equation (4):

where Fj denotes the Fermi integration

The reduced Fermi energy η can be derived from the Seebeck coefficient on the basis of a single band approximation,

Subsequently, the complicated behavior of the carrier concentration illustrated in Figure 3d was analyzed taking into account the point defects that strongly affected the electron density.15, 19, 30 As mentioned above, the carrier concentration decreased when textured at low temperatures (673 and 733 K) but exhibited an increasing trend at higher texturing temperature (773 K). For Bi2(TeSe)3 polycrystals, significant attention should be paid to the donor-like effect induced from mechanical deformation:31

The above reaction was likely intensified by increases in the texturing temperature. Therefore, an increased carrier concentration with texturing temperature could result from the above reaction, which was thermally assisted. However, it is quite difficult to understand why the textured samples (TP 400 and TP 460) showed lower concentrations than the sample before texturing. Multiple reasons may exist; the microstructural changes32 and the aging effect were likely influential because grain coarsening decreases the dangling bonds that donate electrons and fewer antisite defects suppress the above reaction.

As shown in Figure 4a, the total thermal conductivity obviously increased after texturing treatment and generally rose with increasing texturing temperature, with the exception of TP 460, which had the lowest values among the textured samples. Additionally, the upward trend of the thermal conductivity approximately 473 K is a result of the intrinsic excitation of minority carriers. The total thermal conductivity arises from electrical (κe), lattice (κl) and bipolar (κbipolar) contribution. The electrical component is well described by the Wiedemann–Franz’s law, κe=σLT, where σ is the electrical conductivity, L is the Lorenz number and T is the absolute temperature. The calculated Lorenz number L is shown in Supplementary Table S1. Thus the lattice thermal conductivity was obtained using the equation κl+κbipolar=κ−κe. The lattice thermal conductivity did not correlate neatly with texturing temperature, as illustrated in Figure 4b. The uncertainty of the lattice thermal conductivity was ~5%. Notably, even in consideration of the uncertainty, the lattice thermal conductivity of TP 460 was still lower than those of the TP 480 and TP 500 samples, and the difference likely originates from their microstructures/nanostructures, as shown later. Samples textured at low and high temperatures (673 and 773 K) exhibited high lattice thermal conductivities with tiny differences. Intriguingly, mid-temperature (733 and 753 K) textured samples presented much lower lattice thermal conductivities, which were even comparable to the non-textured one. Indeed, the lattice thermal conductivity of TP 460 was lower than the non-TP sample. Our previous study26 found that the thermal conductivity of textured Bi2Te3 samples was also dependent on the texturing temperature. The reason why the lowest lattice thermal conductivity was obtained in TP 460 strongly correlates to the following finding about the texturing induced nanoscale inhomogeneity. To confirm the existence of extra phonon-scattering centers, detailed TEM observations of the textured samples were conducted.

The TEM images in Figure 5 illustrate the presence of many nanostructures with a wide size distribution in the TP 460 sample textured at 773 K. Figures 5a and b show light and dark contrast regions with a large size of ~150 nm in which a bent lattice structure and missing atoms could be seen; therefore, these regions are considered highly distorted regions. Furthermore, defect clusters as small as 10 nm were also frequently observed. Figures 5c and d clearly show the sizes of these defect clusters. In addition, the samples also contain dislocation loops and twin structures, as shown in Figures 5e–h. Notably, defects easily form in Bi2Te3-based alloys, especially when MA is applied. High-temperature heat treatment with largely mechanical deformation leads to the formation of the nanostructured defects because of recrystallization, which has also been reported by Hu et al.33 Low lattice thermal conductivities were associated with the nanostructures that act as phonon-scattering centers.

To clarify the specific frequency range in which the nanostructures critically target the phonons, the Callaway model was adopted, where κl is expressed as:34

In Equation (8), z=ћω/kBT is the reduced phonon frequency, kB is the Boltzmann constant, ћ is the reduced Planck constant, θD is the Debye temperature, υ is the average sound velocity and τ is the total relaxation time, which can be written as:34

In Equation (9), d is the grain size and υ/d represents the boundary scattering and A, B and C are the preset factors for point defect scattering, Umklapp-process scattering and electron phonon scattering, respectively. For this work, θD was fixed at 180 K considering the Debye temperature of both Bi2Te3 and Bi2Se3.35, 36 The magnitudes of A, B and C were determined via the Debye approximation, and details can be found in Supplementary Figure S2. All of the parameters are shown in Table 1.

With all of the parameters defined, one can use Equation (8) to determine the role of each scattering mechanism in suppressing the thermal conductivity. The thermal conductivity is determined by considering the Umklapp-process, boundary scattering and point defect scattering, which are the gray, green and blue areas, respectively, as shown in Figure 6a. Because the grain boundaries decreased after texturing treatment and the alloy composition was constant, corresponding to a reduction of the green areas and the constant blue areas, respectively, the low/mid-frequency phonons were most likely to be scattered by the nanoscopic defects. Therefore, the contribution of the nanostructure-based scattering was roughly plotted in the low/mid-frequency range as the violet area under the red line (marked as NS, which is an abbreviation for nanostructures). It should be noted that, for heavily doped solid solutions (that is, Bi2Te2.2Se0.8 in this work), the scattering of low/mid-frequencies phonons may have a significant effect on the reduction of the lattice thermal conductivities because alloying scatters most of the high-frequency phonons.37 Figure 6b further presents a schematic diagram of the scattering process. The blue dots stand for the nanostructures and the red arrows represent the phonon transport waves. Heat-carrying phonons with distinct wavelength were scattered when they encounter sizable nanoscale defects, thereby causing a decrease in the thermal conductivity.

(a) The contribution of nanostructures (NS) in suppressing the lattice thermal conductivity, marked with violet parts. The gray, green and blue sections are the Umklapp-process (U) scattering, the grain boundary (GB) scattering and the point defect (PD) scattering, respectively. (b) A schematic diagram of phonon scattering by nanostructures (blue dots); the red arrows present the phonon transport waves.

Surprisingly, widely distributed nanoscopic defects were only found in the samples textured at high temperatures (>673 K) but not in TP 400. Figure 7a shows that the grains of TP 400 were quite clean, but defects (specified by the pink frame) were found in TP 460 and TP 500, shown as Figures 7b and c. Figure 7d presents the detailed HRTEM images of the defects in TP 500, showing a bent or distorted lattice within a small angle (circled in orange). The lower temperatures may require longer times to create a large number of defects.

As a consequence, the thermal conductivity was mainly influenced by nanoscale inhomogeneities, grain sizes and the degree of texturing, all of which clearly changed depending on the texturing temperature. Taking into account these three factors, TP 400 displayed a relatively high lattice thermal conductivity because few nanostructures existed as phonon-scattering centers, although with relatively fine grains. However, the high lattice thermal conductivity of TP 500 likely correlates to its highly textured structure and coarse grains. Notably, the nanoscopic inhomogeneities in TP 500 indeed limited the lattice thermal conductivity; if it had not, the lattice thermal conductivity of TP 500 would have been higher than TP 400 owing to a more textured structure and coarser grains. In contrast, the low lattice thermal conductivities of TP 460 and TP 480 were a result of the widely distributed nanoscopic inhomogeneities, medium grain sizes and moderate degree of texturing.

Because the power factors were greatly enhanced and the lattice thermal conductivity was notably reduced for TP 460, one more spark plasma texturing at 733 K was applied to TP 460, (which is referred to as TP 460-3). Figure 8 shows the detailed thermoelectric properties of TP 460-3. Remarkably, TP 460-3 exhibited an enhanced power factor and a further decrease in lattice thermal conductivity compared with TP 460, resulting in a high ZT value of 1.1 at 473 K. There are two obvious reasons for this result. First, TP 460-3 suffered again from mechanical deformation that strengthened the donor-like effect and thus increased the carrier concentration. Second, the mechanical deformation at 733 K induced more in situ nanoscopic defects, leading to a further decrease in the lattice thermal conductivity. This phenomenon of nano-inclusions scattering the phonons has also been reported in the melting zone of Bi2(TeSe)3 alloys, for which the concept of ‘nanoparticle-in-alloy’ using a metal nanoparticle-decorated Bi2(TeSe)3 alloy is adopted.38

The temperature dependence of the thermoelectric properties for TP 460-3. (a) Electrical conductivity, the inset is the Hall carrier mobility and carrier concentration. (b) Seebeck coefficient, the inset is power factor. (c) Total thermal conductivity and lattice thermal conductivity. (d) ZT values.

Consequently, the ZT exceeding 1.1 for the TP 460-3 sample textured at 733 K is 35% higher than the ZT of the non-textured sample, as shown in Figure 9a. Enhanced ZT values occur for all of the textured samples compared with the non-textured one. The ZT enhancement is also remarkable when compared with commercial n-type Bi2(TeSe)3 ingots, whose maximum ZT was measured to be <0.9 in our previous work.15 Although higher ZT values have been reported for p-type (BiSb)2Te3 polycrystals, the present work has achieved a highly improved performance of n-type Bi2(TeSe)3 alloys, which is required for high-efficiency thermoelectric modules. Figure 9b further presents the ZTmax (gray columns) as well as the parameter (μH/κl)(m*/m0)3/2 (blue circles), which is proportional to the thermoelectric efficiency,14 when compared with the ingots prepared by zone melting (red column)15 and Bridgman methods (green column)39 and with the ZT values of the textured samples.33, 40 Large improvements for both the ZTmax and (μH/κl)(m*/m0)3/2 have been achieved using a texturing treatment, and the highest (μH/κl)(m*/m0)3/2 up to 29.5 × 10−3 m3 K V−1 s−1 W−1 was obtained for the sample TP 460-3. The performance enhancement is a result of the texture-enhanced electrical transport properties, and the nanoscale defects suppressed the thermal conductivity.

Compared with work by Hu et al.,40 in which a top–down texture method was applied to Bi2Te2Se1 alloys, in this work nanoscale inhomogeneities could be introduced at appropriate temperatures to effectively decrease the lattice thermal conductivity and resulting in increased ZT values. Such temperature-controlled microstructure and nanostructure modulation is important for thermoelectric performance enhancement. Moreover, in this work we adopted spark plasma texturing with a bottom–up fabrication method to construct the multi-scale microstructures, which differs from the study by Hu et al.33 in which zone molten ingots were repeatedly hot pressed. Because the spark plasma texturing time is much shorter than that of hot pressing, the nanostructures induced by recrystallization would be weaker, resulting in nanoscale regions with smaller areas. On the other hand, spark plasma sintering has significant features, including discharge between the sintering particles,41 which might somehow affect the charged lattice defects as well as the microstructures. Moreover, in this work the optimization of the electrical and thermal performances were simultaneously realized, which was not achieved in the studies by Hu et al.33, 40

Conclusions

This work demonstrated the enhancement of ZT in n-type Bi2(TeSe)3 alloys, which is required for matching the high performances of p-type (BiSb)2Te3 alloys to manufacture high-efficiency thermoelectric devices. A significant ZT enhancement was achieved in compositionally optimized n-type Bi2(TeSe)3 resulting in a large ZTmax>1.1 at 473 K. This result was realized by simply optimizing the texturing temperature for a repeated SPS process as hot-forging. The texturing of structures greatly benefitted the electrical transport properties and led to an increase in the thermal conductivity; however, the nanostructured defects that formed during texturing at optimized temperatures could efficiently scatter low/mid-frequencies phonons, and consequently, the thermal conductivity decreased. Therefore, this work revealed the importance of combining texturing and nanostructuring techniques that can be easily realized using a spark plasma hot-forging process.

References

Bell, L. E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 321, 1457–1461 (2008).

Snyder, G. J. & Toberer, E. S. Complex thermoelectric materials. Nat. Mater. 7, 105–114 (2008).

Zhao, L.-D., Dravid, V. P. & Kanatzidis, M. G. The panoscopic approach to high performance thermoelectrics. Energy Environ. Sci. 7, 251–268 (2014).

Li, J.-F., Liu, W.-S., Zhao, L.-D. & Zhou, M. High-performance nanostructured thermoelectric materials. NPG Asia Mater. 2, 152–158 (2010).

Borup, K. A., de Boor, J., Wang, H., Drymiotis, F., Gascoin, F., Shi, X., Chen, M. I., Fedorov, E., Müller, B. B., Iversen, G. J. & Synder, X. Measuring thermoelectric transport properties of materials. Energy Environ. Sci. 8, 423–435 (2015).

Zhang, X. & Zhao, L.-D. Thermoelectric materials: energy conversion between heat and electricity. J. Materiomics 1, 92–105 (2015).

Qiu, W., Xi, L., Wei, P., Ke, X., Yang, J. & Zhang, W. Part-crystalline part-liquid state and rattling-like thermal damping in materials with chemical-bond hierarchy. Proc. Natl Acad. Sci. USA 111, 15031–15035 (2014).

Zhao, L.-D., Lo, S.-H., Zhang, Y., Sun, H., Tan, G., Uher, C., Wolverton, C., Dravid, V. P. & Kanatzidis, M. G. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 508, 373–377 (2014).

He, Y., Zhang, T., Shi, X., Wei, S.-H. & Chen, L. D. High thermoelectric performance in copper telluride. NPG Asia Mater. 7, e210 (2015).

Goldsmid, H. J. Bismuth telluride and its alloys as materials for thermoelectric generation. Materials 7, 2577–2592 (2014).

Hu, L.-P., Zhu, T.-J., Wang, Y.-G., Xie, H.-H., Xu, Z.-J. & Zhao, X.-B. Shifting up the optimum figure of merit of p-type bismuth telluride-based thermoelectric materials for power generation by suppressing intrinsic conduction. NPG Asia Mater. 6, e88 (2014).

Poudel, B., Hao, Q., Ma, Y., Lan, Y., Minnich, A., Yu, B., Yan, X., Wang, D., Muto, A., Vashaee, D., Chen, X., Liu, J., Dresselhaus, M. S., Chen, G. & Ren, Z. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320, 634–638 (2008).

Kim, S. I., Lee, K. H., Mun, H. A., Kim, H. S., Hwang, S. W., Roh, J. W., Yang, D. J., Shin, W. H., Li, X. S., Lee, Y. H., Snyder, G. J. & Kim, S. W. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 348, 109–114 (2015).

Zheng, Y., Zhang, Q., Su, X., Xie, H., Shu, S., Chen, T., Gangjian, T., Yonggao, Y., Tang, X., Uher, C. & Synder, G. J. Mechanically robust BiSbTe alloys with superior thermoelectric performance: a case study of stable hierarchical nanostructured thermoelectric materials. Adv. Energy Mater. 5, 1401391 (2015).

Pan, Y., Wei, T.-R., Cao, Q. & Li, J.-F. Mechanically enhanced p-and n-type Bi2Te3-based thermoelectric materials reprocessed from commercial ingots by ball milling and spark plasma sintering. Mater. Sci. Eng. B 197, 75–81 (2015).

Li, J.-F. & Liu, J. Effect of nano-SiC dispersion on thermoelectric properties of Bi2Te3 polycrystals. Phys. Stat. Sol. A 203, 3768–3773 (2006).

Liu, K. G., Dong, X. & Zhang, J. X. The effects of La on thermoelectric properties of LaxCo4Sb12 prepared by MA-SPS. Mater. Chem. Phys. 96, 371–375 (2006).

Li, F., Li, J.-F., Zhao, L.-D., Xiang, K., Liu, Y., Zhang, B.-P., Lin, Y.-H., Nan, C.-W. & Zhu, H.-M. Polycrystalline BiCuSeO oxide as a potential thermoelectric material. Energy Environ. Sci. 5, 7188–7195 (2012).

Hu, L., Zhu, T., Liu, X. & Zhao, X. Point defect engineering of high-performance bismuth-telluride-based thermoelectric materials. Adv. Funct. Mater. 24, 5211–5218 (2014).

Yamamoto, M. & Hamada, N. First-principles estimation of Seebeck coefficient of bismuth telluride and selenide. Jpn. J. Appl. Phys. 51, 125601 (2012).

Pan, Y., Wei, T.-R., Wu, C.-F. & Li, J.-F. Electrical and thermal transport properties of spark plasma sintered n-type Bi2Te3-xSex alloys: the combined effect of point defect and Se content. J. Mater. Chem. C 3, 10583–10589 (2015).

Delves, R. T., Bowley, A. E., Hazelden, D. W. & Goldsmid, H. J. Anisotropy of the electrical conductivity in bismuth telluride. Proc. Phys. Soc. 78, 838–844 (1961).

Goldsmid, H. J. Recent studies of bismuth telluride and its alloys. J. Appl. Phys. 32, 2198–2201 (1961).

Dennis, J. H. Anisotropy of the Seebeck coefficients of bismuth telluride. Adv. Energy Convers. 1, 99–105 (1961).

Yan, X., Poudel, B., Ma, Y., Liu, W. S., Joshi, G., Wang, H., Lan, Y., Wang, D., Chen, G. & Ren, Z. F. Experimental studies on anisotropic thermoelectric properties and structures of n-type Bi2Te2. 7Se0.3 . Nano Lett. 10, 3373–3378 (2010).

Zhao, L.-D., Zhang, B.-P., Li, J.-F., Zhang, H.-L. & Liu, W.-S. Enhanced thermoelectric and mechanical properties in textured n-type Bi2Te3 prepared by spark plasma sintering. Solid State Sci. 10, 651–658 (2008).

Noudem, J. G. A new process for lamellar texturing of thermoelectric Ca3Co4O9 oxides by spark plasma sintering. J. Eur. Ceram. Soc. 29, 2659–2663 (2009).

Lotgering, F. K. Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures—I. J. Inorg. Nucl. Chem. 9, 113–123 (1959).

Bhame, S. D., Pravarthana, D., Prellier, W. & Noudem, J. G. Enhanced thermoelectric performance in spark plasma textured bulk n-type BiTe2.7Se0.3 and p-type Bi0.5Sb1.5Te3 . Appl. Phys. Lett. 102, 211901 (2013).

Scanlon, D. O., King, P. D. C., Singh, R. P., de la Torre, A., Walker, S. M., Balakrishnan, G., Baumberger, F. & Catlow, C. R. A. Controlling bulk conductivity in topological insulators: key role of anti-site defects. Adv. Mater. 24, 2154–2158 (2012).

Zhao, L. D., Zhang, B.-P., Liu, W. S., Zhang, H. L. & Li, J.-F. Effects of annealing on electrical properties of n-type Bi2Te3 fabricated by mechanical alloying and spark plasma sintering. J. Alloys Compd. 467, 91–97 (2009).

Wu, H., Carrete, J., Zhang, Z., Qu, Y., Shen, X., Wang, Z., Zhao, L. D. & He, J. Strong enhancement of phonon scattering through nanoscale grains in lead sulfide thermoelectrics. NPG Asia Mater. 6, e108 (2014).

Hu, L., Wu, H., Zhu, T., Fu, C., He, J., Ying, P. & Zhao, X. Tuning multiscale microstructures to enhance thermoelectric performance of n-type bismuth-telluride-based solid solutions. Adv. Energy Mater. 5, 1500411 (2015).

Callaway, J. Model for lattice thermal conductivity at low temperatures. Phys. Rev. 113, 1046 (1959).

Shoemake, G. E., Rayne, J. A. & Ure, R. W. Jr. Specific heat of n-and p-type Bi2Te3 from 1.4 to 90 K. Phys. Rev. 185, 1046 (1969).

Toher, C., Plata, J. J., Levy, O., de Jong, M., Asta, M., Nardelli, M. B. & Curtarolo, S. High-throughput computational screening of thermal conductivity, Debye temperature, and Grüneisen parameter using a quasiharmonic Debye model. Phys. Rev. B 90, 174107 (2014).

Tritt, T. M. Thermal Conductivity: Theory, Properties, and Applications (Kluwer Academic/Plenum Publishers, New York, NY, USA, 2004).

Wang, S., Li, H., Lu, R., Zheng, G. & Tang, X. Metal nanoparticle decorated n-type Bi2Te3-based materials with enhanced thermoelectric performances. Nanotechnology 24, 285702 (2013).

Yim, W. M. & Rosi, F. D. Compound tellurides and their alloys for peltier cooling—a review. Solid-State Electron. 15, 1121–1140 (1972).

Hu, L. P., Liu, X. H., Xie, H. H., Shen, J. J., Zhu, T. J. & Zhao, X. B. Improving thermoelectric properties of n-type bismuth-telluride-based alloys by deformation-induced lattice defects and texture enhancement. Acta Mater. 60, 4431–4437 (2012).

Anselmi-Tamburinia, U., Gennari, S., Garay, J. E. & Munir, Z. A. Fundamental investigations on the spark plasma sintering/synthesis process: II. Modeling of current and temperature distributions. Mater. Sci. Eng. A 394, 139–148 (2005).

Acknowledgements

This work was supported by the National Basic Research Program of China (Grant No. 2013CB632503) and the National Natural Science Foundation (Nos. 11474176 and 51172121).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Pan, Y., Li, JF. Thermoelectric performance enhancement in n-type Bi2(TeSe)3 alloys owing to nanoscale inhomogeneity combined with a spark plasma-textured microstructure. NPG Asia Mater 8, e275 (2016). https://doi.org/10.1038/am.2016.67

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/am.2016.67

This article is cited by

-

High Thermoelectric Performance of Large Size Bi2Te2.7Se0.3 Alloy Ingots

Journal of Electronic Materials (2023)

-

The effect of powder synthesis method on thermoelectric properties of Bi2Te2.7Se0.3 thin films

Journal of Materials Science: Materials in Electronics (2023)

-

The effect of thermal evaporation parameters on thermoelectric properties of Bi2Te2.7Se0.3 thin films produced from ball milled powder

Journal of Materials Science: Materials in Electronics (2023)

-

Improved thermoelectric properties of zone-melted p-type bismuth-telluride-based alloys for power generation

Rare Metals (2022)

-

A Review on Doped/Composite Bismuth Chalcogenide Compounds for Thermoelectric Device Applications: Various Synthesis Techniques and Challenges

Journal of Electronic Materials (2022)