Abstract

The mechanical behaviour of nanocrystalline materials (that is, polycrystals with a grain size of less than 100 nm) remains controversial. Although it is commonly accepted that the intrinsic deformation behaviour of these materials arises from the interplay between dislocation and grain-boundary processes, little is known about the specific deformation mechanisms. Here we use large-scale molecular-dynamics simulations to elucidate this intricate interplay during room-temperature plastic deformation of model nanocrystalline Al microstructures. We demonstrate that, in contrast to coarse-grained Al, mechanical twinning may play an important role in the deformation behaviour of nanocrystalline Al. Our results illustrate that this type of simulation has now advanced to a level where it provides a powerful new tool for elucidating and quantifying–in a degree of detail not possible experimentally–the atomic-level mechanisms controlling the complex dislocation and grain-boundary processes in heavily deformed materials with a submicrometre grain size.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Koch, C.C. & Suryanarayana, C. in Microstructure and Properties of Materials Vol. 2 (ed. Li, J. C. M.) Ch. 6 380–385 (World Scientific, Singapore, 2000).

Karch, J., Birringer, R. & Gleiter, H. Ceramics ductile at low-temperature. Nature 330, 556–558 (1987).

McFadden, S.X., Mishra, R.S., Valiev, R.Z., Zhilyaev, A.P. & Mukherjee, A.K. Low-temperature superplasticity in nanostructured nickel and metal alloys. Nature 398, 684–686 (1999).

Kim, B.N., Hiraga, K., Morita, K. & Sakka, Y. A high-strain-rate superplastic ceramic. Nature 413, 288–291 (2001).

Siegel, R.W. Mechanical properties of nanophase materials. Mater. Sci. Forum 235–238, 851–860 (1997).

Morris, D.G. & Morris, M.A. Hardness, strength, ductility and toughness of nanocrystalline materials. Mater. Sci. Forum 235–238, 861–872 (1997).

Nesladek, P. & Veprek, S. Superhard nanocrystalline composites with hardness of diamond. Phys. Status Solidi A 177, 53–62 (2000).

Yip, S. Nanocrystals—the strongest size. Nature 391, 532–533 (1998).

Yamakov, V., Wolf, D., Salazar, M., Phillpot, S.R., & Gleiter, H. Length-scale effects in the nucleation of extended lattice dislocations in nanocrystalline Al by molecular-dynamics simulation. Acta Mater. 49, 2713–2722 (2001).

Ercolessi, F. & Adams, J.B. Interatomic potentials from 1st-principle calculations – the force-matching method. Europhys. Lett. 26, 583–588 (1994).

Noonan, J.R. & Davis, H.L. Truncation-induced multilayer relaxation of the Al(110) surface. Phys. Rev. B 29, 4349–4355 (1984).

Schiotz, J., DiTolla, F.D. & Jacobsen, K.W. Softening of nanocrystalline metals at very small grain sizes. Nature 391, 561–563 (1998).

Schiotz, J., Vegge, T., DiTolla, F.D. & Jacobsen, K.W. Atomic-scale simulations of the mechanical deformation of nanocrystalline metals. Phys. Rev. B 60, 11971–11983 (1999).

Swygenhoven, H.V., Spaczer, M., Caro, A. & Farkas, D. Competing plastic deformation mechanisms in nanophase metals. Phys. Rev. B 60, 22–25 (1999).

Weertman, J. & Weertman, J.R. Elementary Dislocation Theory (Oxford Univ. Press, New York, 1992).

Jonsson, H. & Andersen, H.C. Icosahedral ordering in the Lennard-Jones liquid and glass. Phys. Rev. Lett. 60, 2295–2298 (1988).

El-Danaf, E., Kalindi, S.R. & Doherty, R. Influence of grain size and stacking-fault energy on deformation twinning. Metall. Mater. Trans. A 30, 1223–1233 (1999).

Ungar, T., Ott, S., Sanders, P.G., Borbely, A. & Weertman, J.R. Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis. Acta Mater. 46, 3693–3699 (1998).

Gleiter, H. in Progress in Materials Science, Chalmers Anniversary Volume (eds Christian, J. W., Haasen, P. & Massalski, T. B.) 172 (Pergamon, Oxford, 1981).

Hirth, J.P. & Hoagland, R.G. Extrinsically dissociated dislocations in simulated aluminium. Phil. Mag. A 78, 529–532 (1998).

Hirth, J.P. & Lothe, J. Theory of Dislocations Ch. 10-3 (Wiley, New York, 1992).

Zhou, S.J., Preston, D.L., Lomdahl, P.S. & Beazley, D.M. Large-scale molecular dynamics simulations of dislocation intersection in copper. Science 279, 1525–1527 (1998).

Bulatov, V., Abraham, F.F., Kubin, L., Devincre, B. & Yip, S. Connecting atomistic and mesoscale simulations of crystal plasticity. Nature 391, 669–672 (1998).

Gouldstone, A., Koh, H.-J., Zeng, K.-Y., Giannakopoulos, A.E. & Suresh, S. Discrete and continuous deformation during nanoindentation of thin films. Acta Mater. 48, 2277–2295 (2000).

Gouldstone, A., Van Vliet, K.J. & Suresh, S. Simulation of defect nucleation in a crystal. Nature 411, 656 (2001).

Yamakov, V., Wolf, D., Phillpot S.R. & Gleiter, H. Grain-boundary diffusion creep in nanocrystalline palladium by molecular-dynamics simulation. Acta Mater. 50, 61–73 (2002).

Coble, R.L. A model for boundary-diffusion controlled creep in polycrystalline materials. J. Appl. Phys. 34, 1679–1682 (1963).

Keblinski, P., Phillpot, S.R., Wolf, D. & Gleiter, H. Self-diffusion in high-angle fcc-metal grain boundaries by molecular-dynamics simulation. Phil. Mag. A 79, 2735–2761 (1999).

Keblinski, P., Phillpot, S.R., Wolf, D. & Gleiter, H. Thermodynamic criterion for the stability of amorphous intergranular films in covalent materials. Phys. Rev. Lett. 77, 2965–2968 (1996).

Wolf, D. in The Encyclopedia of Materials: Science and Technology (ed. Cahn, R.) 3597–3609 (Elsevier, Amsterdam, 2001).

Parrinello, M. & Rahman, A. Polymorphic transitions in single crystals: A new molecular dynamics method. J. Appl. Phys. 52, 7182–7190 (1981).

Melchionna, S., Ciccotti, G. & Holian, B.L. Hoover NPT dynamics for systems varying in shape and size. Mol. Phys. 78, 533–544 (1993).

Acknowledgements

V.Y.,D.W. and S.R.P.P. are supported by the US Department of Energy, Basic Energy Sciences-Materials Science under contract W-31-109-Eng-38. V.Y. also thanks the DOE/BES Computational Materials Science Network (CMSN) for support. A.K.M. acknowledges support from the National science Foundation-Division of Materials Research. We are grateful for computer time on the Cray-3E at the John-von-Neumann Institut for Computing in Jülich, Germany, and on the Chiba City Linux cluster at Argonne National Laboratory.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

41563_2002_BFnmat700_MOESM1_ESM.mov

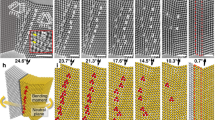

Movie S1. A movie of the full simulation of deformation of nanocrystalline Al with grains of 45 nm in diameter perfect-crystal atoms as being either in a local hcp (red atoms) or fcc (MOV 5193 kb)

Rights and permissions

About this article

Cite this article

Yamakov, V., Wolf, D., Phillpot, S. et al. Dislocation processes in the deformation of nanocrystalline aluminium by molecular-dynamics simulation. Nature Mater 1, 45–49 (2002). https://doi.org/10.1038/nmat700

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat700

This article is cited by

-

Atomic-scale observation of nucleation- and growth-controlled deformation twinning in body-centered cubic nanocrystals

Nature Communications (2024)

-

Revealing the strengthening contribution of stacking faults, dislocations and grain boundaries in severely deformed LPBF AlSi10Mg alloy

Scientific Reports (2023)

-

Plastic Deformation in Aluminum Columnar Nanograins

JOM (2023)

-

Influence mechanisms of tool geometry parameters on surface quality and subsurface damage in polycrystalline NiFeCr superalloys

The International Journal of Advanced Manufacturing Technology (2023)

-

Evidence of twinning-induced plasticity (TWIP) and ultrahigh hardness in additively-manufactured near-eutectic Ni–Nb

Journal of Materials Science (2023)