Abstract

Because of their disordered atomic structure, amorphous metals (termed metallic glasses) have fundamentally different deformation mechanisms compared with polycrystalline metals. These different mechanisms give metallic glasses high strength, but the extent to which they affect other macroscopic deformation properties is uncertain. For example, the nature of the plastic-yield criterion is a point of contention, with some studies reporting yield behaviour roughly in line with that of polycrystalline metals, and others indicating strong fundamental differences. In particular, it is unclear whether pressure- or normal stress-dependence needs to be included in the plastic-yield criterion of metallic glasses, and how such a dependence could arise from their disordered structure1,2,3,4. In this work we provide an atomic-level explanation for pressure-dependent yield in amorphous metals, based on an elementary unit of deformation. This simple model compares favourably with new atomistic simulations of metallic glasses, as well as existing experimental data.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Lewandowski, J.J. & Lowhaphandu, P. Effects of hydrostatic pressure on the flow and fracture of a bulk amorphous metal. Phil. Mag. A 82, 3427–3441 ( 2002).

Zhang, Z.F., Eckert, J. & Schultz, L. Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glasses. Acta Mater. 51, 1167–1179 ( 2003).

Flores, K.M. & Dauskardt, R.H. Mean stress effects on flow localization and failure in a bulk metallic glass. Acta Mater. 49, 2527–2537 ( 2001).

Lowhaphandu, P., Montgomery, S.L. & Lewandowski, J.J. Effects of superimposed hydrostatic pressure on flow and fracture of a Zr-Ti-Ni-Cu-Be bulk amorphous alloy. Scripta Mater. 41, 19–24 ( 1999).

Bulatov, V.V., Richmond, O. & Glazov, M.V. An atomistic dislocation mechanism of pressure-dependent plastic flow in aluminum. Acta Mater. 47, 3507–3514 ( 1999).

Courtney, T.H. Mechanical Behaviour of Materials (McGraw-Hill, New York, 1990).

Mukai, T., Nieh, T.G., Kawamura, Y., Inoue, A. & Higashi, K. Effect of strain rate on compressive behaviour of a Pd40Ni40P20 bulk metallic glass. Intermetall. 10, 1071–1077 ( 2002).

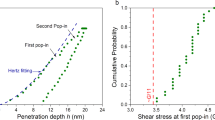

Vaidyanathan, R., Dao, M., Ravichandran, G. & Suresh, S. Study of mechanical deformation in bulk metallic glass through instrumented indentation. Acta Mater. 49, 3781–3789 ( 2001).

Argon, A.S. Plastic deformation in metallic glasses. Acta Metall. 27, 47–58 ( 1979).

Spaepen, F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Metall. 25, 407–415 ( 1977).

Eastgate, L.O., Langer, J.S. & Pechenik, L. Dynamics of large-scale plastic deformation and the necking instability in amorphous solids. Phys. Rev. Lett. 90, 045506 ( 2003).

Kim, J.-J., Choi, Y., Suresh, S. & Argon, A.S. Nanocrystallization during nanoindentation of a bulk amorphous metal alloy at room temperature. Science 295, 654–657 ( 2002).

Born, M. & Huang, K. Dynamical Theory of Crystal Lattices (Claredon, Oxford, UK, 1954).

Kobayashi, S., Maeda, K. & Takeuchi, S. Computer simulation of deformation of amorphous Cu57Zr43 . Acta Metall. 28, 1641–1652 ( 1980).

Falk, M.L. & Langer, J.S. Dynamics of viscoplastic deformation in amorphous solids. Phys. Rev. E 57, 7192–7205 ( 1998).

Falk, M.L. Molecular-dynamics study of ductile and brittle fracture in model noncrystalline solids. Phys. Rev. B 60, 7062–7070 ( 1999).

Argon, A.S. & Kuo, H.Y. Plastic flow in a disordered bubble raft (an analog of a metallic glass). Mater. Sci. Eng. 39, 101–109 ( 1979).

Lund, A.C. & Schuh, C.A. Atomistic simulation of strain-induced amorphization. Appl. Phys. Lett. 82, 2017–2019 ( 2003).

Lacks, D.J. Energy landscape and the non-newtonian viscosity of liquids and glasses. Phys. Rev. Lett. 87, 225502 ( 2001).

Gagnon, G., Patton, J. & Lacks, D.J. Energy landscape view of fracture and avalanches in disordered materials. Phys. Rev. E 64, 051508 ( 2001).

Schiotz, J., Vegge, T., Tolla, F.D.D. & Jacobsen, K.W. Atomic-scale simulations of the mechanical deformation of nanocrystalline metals. Phys. Rev. B 60, 11971–11983 ( 1999).

Rottler, J. & Robbins, M.O. Yield conditions for deformation of amorphous polymer glasses. Phys. Rev. E 64, 051801 ( 2001).

Donovan, P.E. A yield criterion for Pd40Ni40P20 metallic glass. Acta Mater. 37, 445–456 ( 1989).

Fan, C., Ott, R.T. & Hufnagel, T.C. Metallic glass matrix composite with precipitated ductile reinforcement. Appl. Phys. Lett. 81, 1020–1022 ( 2002).

Hays, C.C., Kim, C.P. & Johnson, W.L. Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glass containing in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 84, 2901–2904 ( 2000).

Nieh, T.G. & Wadsworth, J. Hall-Petch relation in nanocrystalline solids. Scripta Metall. Mater. 25, 955–958 ( 1991).

Yamakov, V., Wolf, D., Phillpot, S.R., Mukherjee, A.K. & Gleiter, H. Dislocation processes in the deformation of nanocrystalline aluminium by molecular-dynamics simulation. Nature Mater. 1, 1–4 ( 2002).

Acknowledgements

This work was partially supported by the Defense University Research Initiative on NanoTechnology (DURINT) on damage and failure resistant nanostructured materials, which is funded at the Massachusetts Institute of Technology by the US Office of Naval Research, Grant No. N00014-01-1-0808.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Schuh, C., Lund, A. Atomistic basis for the plastic yield criterion of metallic glass. Nature Mater 2, 449–452 (2003). https://doi.org/10.1038/nmat918

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat918

This article is cited by

-

Vortex Evolution Behavior in Self-Assembly of Flow Units in Metallic Glasses

Acta Mechanica Solida Sinica (2023)

-

High-strength and malleable dual-phase nanostructured Ta-based metallic glass via atomic manufacturing

Science China Materials (2023)

-

Extra plasticity governed by shear band deflection in gradient metallic glasses

Nature Communications (2022)

-

Hypocrystalline ceramic aerogels for thermal insulation at extreme conditions

Nature (2022)

-

Research progress on cutting machining simulation technology of metallic glasses

The International Journal of Advanced Manufacturing Technology (2022)