Abstract

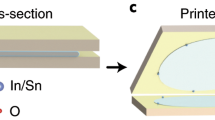

Transparent conducting electrodes are essential components for numerous flexible optoelectronic devices, including touch screens and interactive electronics1,2,3,4. Thin films of indium tin oxide—the prototypical transparent electrode material—demonstrate excellent electronic performances, but film brittleness, low infrared transmittance and low abundance limit suitability for certain industrial applications1,4,5. Alternatives to indium tin oxide have recently been reported and include conducting polymers6, carbon nanotubes7,8,9 and graphene10,11,12. However, although flexibility is greatly improved, the optoelectronic performance of these carbon-based materials is limited by low conductivity8,13. Other examples include metal nanowire-based electrodes14,15,16,17,18,19,20,21,22, which can achieve sheet resistances of less than 10Ω □−1 at 90% transmission because of the high conductivity of the metals. To achieve these performances, however, metal nanowires must be defect-free, have conductivities close to their values in bulk, be as long as possible to minimize the number of wire-to-wire junctions, and exhibit small junction resistance. Here, we present a facile fabrication process that allows us to satisfy all these requirements and fabricate a new kind of transparent conducting electrode that exhibits both superior optoelectronic performances (sheet resistance of ∼2Ω □−1 at 90% transmission) and remarkable mechanical flexibility under both stretching and bending stresses. The electrode is composed of a free-standing metallic nanotrough network and is produced with a process involving electrospinning and metal deposition. We demonstrate the practical suitability of our transparent conducting electrode by fabricating a flexible touch-screen device and a transparent conducting tape.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Fortunato, E., Ginley, D., Hosono, H. & Paine, D. C. Transparent conducting oxides for photovoltaics. Mater. Res. Soc. Bull. 32, 242–247 (2007).

Lipomi, D. J. et al. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nature Nanotech. 6, 788–792 (2011).

Peng, H. L. et al. Topological insulator nanostructures for near-infrared transparent flexible electrodes. Nature Chem. 4, 281–286 (2012).

Kumar, A. & Zhou, C. W. The race to replace tin-doped indium oxide: which material will win? ACS Nano 4, 11–14 (2010).

Tahar, R. B. H., Ban, T., Ohya, Y. & Takahashi, Y. Tin doped indium oxide thin films: electrical properties. J. Appl. Phys. 83, 2631–2645 (1998).

Kirchmeyer, S. & Reuter, K. Scientific importance, properties and growing applications of poly(3,4-ethylenedioxythiophene). J. Mater. Chem. 15, 2077–2088 (2005).

Zhang, M. et al. Strong, transparent, multifunctional, carbon nanotube sheets. Science 309, 1215–1219 (2005).

Hecht, D. S., Hu, L. B. & Irvin, G. Emerging transparent electrodes based on thin films of carbon nanotubes, graphene, and metallic nanostructures. Adv. Mater. 23, 1482–1513 (2011).

Niu, C. M. Carbon nanotube transparent conducting films. Mater. Res. Soc. Bull. 36, 766–773 (2011).

Kim, K. S. et al. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 457, 706–710 (2009).

Bonaccorso, F., Sun, Z., Hasan, T. & Ferrari, A. C. Graphene photonics and optoelectronics. Nature Photon. 4, 611–622 (2010).

Bae, S. et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nature Nanotech. 5, 574–578 (2010).

Hecht, D. S. & Kaner, R. B. Solution-processed transparent electrodes. Mater. Res. Soc. Bull. 36, 749–755 (2011).

De, S. et al. Silver nanowire networks as flexible, transparent, conducting films: extremely high DC to optical conductivity ratios. ACS Nano 3, 1767–1774 (2009).

Garnett, E. C. et al. Self-limited plasmonic welding of silver nanowire junctions. Nature Mater. 11, 241–249 (2012).

Hu, L. B., Wu, H. & Cui, Y. Metal nanogrids, nanowires, and nanofibres for transparent electrodes. Mater. Res. Soc. Bull. 36, 760–765 (2011).

Wu, H. et al. Electrospun metal nanofibre webs as high-performance transparent electrode. Nano Lett. 10, 4242–4248 (2010).

Kang, M. G., Kim, M. S., Kim, J. S. & Guo, L. J. Organic solar cells using nanoimprinted transparent metal electrodes. Adv. Mater. 20, 4408–4413 (2008).

Van de Groep, J. V., Spinelli, P. & Polman, A. Transparent conducting silver nanowire networks. Nano Lett. 12, 3138–3144 (2012).

Leem, D. S. et al. Efficient organic solar cells with solution-processed silver nanowire electrodes. Adv. Mater. 23, 4371–4375 (2011).

Lyons, P. E. et al. High-performance transparent conductors from networks of gold nanowires. J. Phys. Chem. Lett. 2, 3058–3062 (2011).

Scardaci, V., Coull, R., Lyons, P. E. Rickard, D. & Coleman, J. N. Spray deposition of highly transparent, low-resistance networks of silver nanowires over large areas. Small 7, 2621–2628 (2011).

Li, D. & Xia, Y. N. Electrospinning of nanofibres: Reinventing the wheel? Adv. Mater. 16, 1151–1170 (2004).

Kelly, P. J. & Arnell, R. D. Magnetron sputtering: a review of recent developments and applications. Vacuum 56, 159–172 (2000).

Ghosh, D. S. Martinez, L., Giurgola, S., Vergani, P. & Pruneri, V. Widely transparent electrodes based on ultrathin metals. Opt. Lett. 34, 325–327 (2009).

Lipomi, D. J. et al. Electronic properties of transparent conductive films of PEDOT:PSS on stretchable substrates. Chem. Mater. 24, 373–382 (2012).

Lee, J-Y., Connor, S. T., Cui, Y. & Peumans, P. Solution-processed metal nanowire mesh transparent electrodes. Nano Lett. 8, 689–692 (2008).

Sun, Y. G., Gates, B., Mayers, B. & Xia, Y. N. Crystalline silver nanowires by soft solution processing. Nano Lett. 2, 165–168 (2002).

De, S. & Coleman, J. N. The effects of percolation in nanostructured transparent conductors. Mater. Res. Soc. Bull. 36, 774–781 (2011).

Hsu, P. C. et al. Passivation coating on electrospun copper nanofibres for stable transparent electrodes. ACS Nano 6, 5150–5156 (2012).

Acknowledgements

This material is based upon work supported as part of the Center on Nanostructuring for Efficient Energy Conversion (CNEEC) at Stanford University, an Energy Frontier Research Center funded by the US Department of Energy, Office of Science, Office of Basic Energy Sciences under Award Number DE-SC0001060, and the National Basic Research of China (grant no. 2013CB632702).

Author information

Authors and Affiliations

Contributions

H.W. and Y.C. conceived the idea. H.W. and D.K. performed materials fabrication and tests. Z.C.R., Z.F.Y. and S.H.F. designed and carried out the optical simulations. H.W. and D.K. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 14071 kb)

Supplementary movie S1

Supplementary movie S1 (WMV 1314 kb)

Supplementary movie S2

Supplementary movie S2 (WMV 1903 kb)

Supplementary movie S3

Supplementary movie S3 (WMV 2245 kb)

Rights and permissions

About this article

Cite this article

Wu, H., Kong, D., Ruan, Z. et al. A transparent electrode based on a metal nanotrough network. Nature Nanotech 8, 421–425 (2013). https://doi.org/10.1038/nnano.2013.84

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2013.84

This article is cited by

-

Engineered kirigami design of PVDF-Pt core–shell nanofiber network for flexible transparent electrode

Scientific Reports (2023)

-

The high-throughput atomization of polymer solutions for fiber synthesis in a single step aided with corona ionizers

Scientific Reports (2023)

-

Simultaneous fabrication of porous metals and metallic nanowires via atmospheric pressure plasma-assisted electro-dealloying

Science China Technological Sciences (2023)

-

Progress and challenges in wearable electrochromic devices: a review

Journal of Materials Science: Materials in Electronics (2023)

-

Analytical model for large deformation and capacitance of rhomboidal pressure sensors and experimental verification

Acta Mechanica Sinica (2023)