Abstract

Cardanol novolac (CDN) was synthesized by the reaction of cardanol (CD) and paraformaldehyde in the presence of oxalic acid. The prepolymerized compounds of CD/4,4′-bismaleimidediphenylmethane (BMI) and CDN/BMI with CD/maleimide unit ratios 1/2, 1/4 and 1/6 at 200 °C were finally compression-molded at 250 °C for 5 h to produce cured CD/BMI (cCD/BMI) and cured CDN/BMI (cCDN/BMI) resins. Although the proton nuclear magnetic resonance (1H-NMR) and Fourier transform infrared spectroscopy (FTIR) analyses of the model reaction product of CD and N-phenylmaleimide (PMI) at 200 °C for 8 h suggested the occurrence of the ene reaction and subsequent Diels–Alder reaction, the FTIR analysis of cCD/BMI and cCDN/BMI suggested the occurrence of the ene reaction and addition copolymerization. The cCD/BMI and cCDN/BMI with CD/maleimide ratio lower than 1/2 did not show glass transition until 300 °C and had a 5% weight loss temperature higher than 450 °C. The cCD/BMI and cCDN/BMI with CD/maleimide ratio 1/4 showed the most balanced flexural properties (flexural strength 60–80 MPa, flexural modulus 2.0–2.5 GPa).

Similar content being viewed by others

Introduction

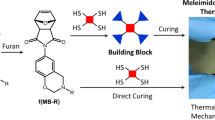

In recent years, renewable resources-derived polymers (bio-based polymers) are attracting a great deal of attention because of the advantages of these polymers, such as conservation of limited petroleum resources, possible biodegradability and the control of carbon dioxide emissions that lead to global warming.1, 2, 3, 4 Most recently, much focus is being placed on bio-based thermosetting resins, such as epoxy resins, phenol resins, unsaturated polyester resins and their composites, because these materials are hard to be recycled owing to the infusible and insoluble properties.5, 6, 7, 8, 9 Petroleum-based thermosetting bismaleimide resins are used as the matrix resins for multilayer printed circuit boards and advanced composite materials in the aerospace industry.10, 11, 12, 13, 14, 15 For example, a commercial thermosetting bismaleimide resin, Matrimid 5292 (Ciba Geigy, Basel, Switzerland), based on 2,2′-diallybisphenol A (DABA)/4,4′-bismaleimidediphenylmethane (BMI) is one of the leading matrix resins in carbon fiber composites for advanced aerospace application.13 The Fourier transform infrared spectroscopy (FTIR) analysis of the cured DABA/BMI resin has shown that a stepwise ene reaction and subsequent chain polymerization in addition to an etherification reaction occur for DABA/BMI.14, 15 We had already reported the thermal and mechanical properties of the BMI cured with drying oil such as dehydrated castor oil and tung oil.16, 17 Cardanol (CD) is a promising bio-based feedstock, which is obtained from anacardic acid, the main component of cashew nutshell liquid, a by-product of cashew nut processing. CD is a phenol meta-substituted with a long unsaturated hydrocarbon chain (C15H31−2x: x=degree of unsaturation; 0–3, average x≅2.1),18, 19 which is expected to undergo the ene reaction and subsequent Diels–Alder reaction with BMI (Figure 1). There have been many reports in the literature on the utilization of CD to phenol resins20, 21, 22 and epoxy resins.22, 23, 24, 25 However, there are only a few reports on the application of CD by use of the reactivity of the unsaturated hydrocarbon chain.26 To the best of our knowledge, the curing reaction of CD and maleimide has not yet been reported. Herein, the thermal and mechanical properties of the CD and CD novolac (CDN) cured with BMI are investigated. The curing mechanism is elucidated by the proton nuclear magnetic resonance (1H-NMR) and FTIR analyses of the model reaction products of CD and N-phenylmaleimide (PMI) and the FTIR analysis of the cured CD/BMI (cCD/BMI) and cured CDN/BMI (cCDN/BMI) resins.

Experimental procedure

Materials

CD was kindly supplied from Cashew Company (Saitama, Japan). Paraformaldehyde and oxalic acid dihydrate were purchased from Wako Pure Chemical Industries (Osaka, Japan) and Kanto Chemical (Tokyo, Japan), respectively. BMI was purchased from Tokyo Kasei Kogyo (Tokyo, Japan). All the commercially available reagents were used without further purification.

Synthesis of CDN

The molecular weight of CD (300.2), calculated from the chemical formula C21H36−2xO (average degree of unsaturation x=2.14 determined by 1H-NMR method) was used for the calculation of the feed amount of CD. A mixture of CD 30.0 g (0.100 mol), paraformaldehyde 1.82 g (CH2O unit: 0.0606 mol) and oxalic acid dehydrate 0.900 g (7.13 mmol) was reacted at 120 °C for 6 h. After chloroform (300 ml) was added to the reaction mixture, the solution was washed with water, and dried with sodium sulfate. The chloroform solution was filtered, and then concentrated in vacuo at 200 °C to produce CDN 27.3 g in 89% yield.

Preparation of the cured materials of CD and BMI

A mixture of CD 13.7 g (45.6 mmol) and BMI 16.3 g (maleimide unit: 91.2 mmol) was stirred at 200 °C for ca. 4 h to produce a gelatinous material. The obtained compound was compression-molded at 200 °C/5 MPa for 1 h, 220 °C/5 MPa for 2 h and finally 250 °C/5 MPa for 5 h to produce the cCD/BMI with CD/maleimide ratio of 1/2 (cCD/BMI 1/2). In a manner similar to the preparation of cCD/BMI 1/2, the cured resins of cCD/BMI with the CD/maleimide ratios of 1/4 and 1/6 (cCD/BMI 1/4 and cCD/BMI 1/6) were also prepared.

Preparation of the cured materials of CDN and BMI

Weight per CD equivalent of CDN (307.4), which was calculated from the number of phenolic units (p=2.52) of CND evaluated from 1H-NMR analysis and the molecular weight (675.4) of CDN calculated from the chemical formula C22p−1H(36−2x)pOp, were used for the calculation of the feed amount of CDN. The parameter, n of CDN shown in Figure 1, is expressed by the equation, n=p−2. A mixture of CDN 13.8 g (CD unit: 44.9 mmol) and BMI 16.1 g (maleimide unit: 89.9 mmol) was stirred at 200 °C for ca. 0.5 h to produce a gelatinous material. The compound that was obtained was compression-molded at 200 °C/5 MPa for 1 h, 220 °C/5 MPa for 2 h, and finally 250 °C/5 MPa for 5 h to produce the cCDN/BMI with CD/maleimide ratio of 1/2 (cCDN/BMI 1/2). In a manner similar to the preparation of cCDN/BMI 1/2, the cured resins of CDN/BMI with CD/maleimide ratios of 1/4 and 1/6 (cCDN/BMI 1/4 and cCDN/BMI 1/6) were also prepared.

Model reactions of CD and PMI

A mixture of CD 0.928 g (3.09 mmol) and PMI 1.07 g (6.18 mmol) was stirred at 200 °C for 8 h to give a model reaction product of CD/PMI with CD/maleimide unit ratio of 1/2 (cCD/PMI 1/2). The reaction mixture was used for the 1H-NMR and FTIR measurements. Similarly, cCD/PMI 1/4 and cCD/PMI 1/6 were also prepared.

Measurements

1H-NMR spectra were recorded on a Bruker AV-400 (400 MHz) (Madison, WI, USA) using CDCl3 as a solvent. FTIR spectra were measured on an FTIR 8100 spectrometer (Shimadzu, Kyoto, Japan) by the KBr or attenuated total reflectance methods. The temperature at which 5% weight loss occurred was measured on a thermogravimetric analyzer TGA7 (Perkin-Elmer Japan, Yokohama, Japan) in a nitrogen atmosphere at a heating rate of 20 °C min−1. The morphology of the cured resins was observed by field emission-scanning electron microscopy (FE-SEM), using a Hitachi S-4700 machine (Hitachi High-Technologies, Tokyo, Japan). All samples were fractured after immersion in liquid nitrogen for about 10 min. The fracture surfaces were sputter coated with gold to provide enhanced conductivity. Dynamic mechanical analysis of the rectangular plates (40 × 6 × 2 mm3) was performed on a Rheolograph Solid instrument (Toyo Seiki, Tokyo, Japan) under air atmosphere with a chuck distance of 20 mm, a frequency of 1 Hz and a heating rate of 2 °C min−1, based on ISO 6721-4:1994 (Plastics-Determination of dynamic mechanical properties, Part 4: Tensile vibration—Non-resonance method). Flexural testing of the rectangular specimen (70 × 10 × 2 mm3) was performed using an Autograph AG-1 (Shimadzu) based on the standard method for testing the flexural properties of plastics (JIS K7171: 2008 (ISO 178: 2001)). The span length was 30 mm, and the testing speed was 10 mm min−1. Five specimens were tested for each set of samples, and the mean values were calculated.

Results and discussion

Characterization of CD and CDN

Figure 2a shows the 1H-NMR spectrum of the used CD in CDCl3. The 1H signals at 7.21 (m, 1H), 6.83 (m, 1H) and 6.72 p.p.m. (m, 2H) are assigned to the protons, H-b, H-c and H-a,d attached to the benzene ring of CD, respectively. As is shown in Figure 1, CD is known to contain cis, cis, cis-pentadeca-8,11,14-trienyl, cis, cis-pentadeca-8,11-dienyl, cis-pentadec-8-enyl and pentadecyl moieties, whose fractions are expressed by f3, f2, f1 and f0, respectively. The 1H signals at 5.10 p.p.m. (m, 0.833H) are assigned to H-l of the terminal vinyl group of the triene moiety. If it is assumed that the terminal vinyl group is contained only for the triene moiety, the fraction of the triene moiety (f3) is evaluated to be 0.417 from the equation, 0.833H/2H. The 1H signal due to H−k of the triene moiety was observed at 5.90 p.p.m. (m), which partly overlapped with the phenolic hydroxy proton signal at 5.78 p.p.m. The latter hydroxy proton signal often shifted to another region and sometimes disappeared from the measurement at a different concentration. The 1H signals at 5.45 p.p.m. (m, H-i, 3.439H) are related to the cis-olefin protons of the triene, diene and monoene moieties. The degree of unsaturation (x) of CD is calculated to be 2.14 from the equation, x=3.439H/2H+0.833H/2H. Also, the following equation (1) is obtained from the equations, x=3f3+2f2+f1 and f3=0.417:

The 1H signals of allylic position (H-h) of the triene, diene and monoene moieties were observed at 2.16 p.p.m. (bs, 3.372H), whose proton number is expressed by 2f3+4f2+4f1. Therefore, the following equation is derived:

From Equations (1) and (2), f2 and f1 are calculated to be 0.254 and 0.381, respectively. The 1H signals of terminal methyl groups for the diene, monoene and pentadecyl moieties are observed at 0.98 p.p.m. (bm, 1.879H), whose proton number is expressed by 3f2+3f1+3f0. Although f0 is calculated to be −0.009 from Equation (3), it is estimated to be 0 after considering the error of this analysis.

Therefore, (f3+f2+f1+f0) is calculated to be 1.052 in this 1H-NMR analysis. However, it should be 1, the values of f3, f2, f1 and f0 are compensated to be 0.397, 0.241, 0.362 and 0, respectively, after considering the error of this analysis. Their values are fairly in good agreement with the reported values (0.41, 0.22, 0.34 and 0.02) measured by chromatography.18

CDN was synthesized as a brown viscose liquid by the reaction of CD and paraformaldehyde in the presence of oxalic acid at the feed molar ratio of CD/CH2O 1.65/1. Theoretical number of phenolic units (p) is 2.54 based on the equation, p/(p−1)=1.65 for the addition–condensation reaction. Figure 2b shows the 1H-NMR spectrum of CDN in CDCl3. Benzylic methylene protons (Ph-CH2-Ph) and aromatic protons (Ar-H) were observed at 3.88 p.p.m. (m) and 7.2–6.6 p.p.m. (m), respectively. In this case, phenolic hydroxy protons were not observed. From the ratio of [Ph-CH2-Ph]/[Ar-H]=(2p−2)/(2p+2)=0.4326, p is calculated to be 2.52, which is in good agreement with the theoretical value (2.54). As the number of unsaturated carbon chains of CDN is more than two, crosslinked structure can be formed even if the CD unit reacts with maleimide unit of BMI at the ratio of 1/1. In the case of the reaction of CD and BMI, the polymer network would not be formed if the stoichiometric ratio of maleimide/CD was 1/1.

Model reaction of CD and PMI

The model reactions of CD/PMI with molar ratios of 1/2, 1/4 and 1/6 at 200°C for 8 h were carried out to elucidate the curing mechanism of cCD/BMI or cCDN/BMI. Figure 3 shows the 1H-NMR spectra of cCD/PMI 1/2 and cCD/PMI 1/6 in CDCl3. The olefinic protons of PMI at 6.85 p.p.m. (s) completely disappeared for cCD/PMI 1/2, and new 1H signals were observed at the regions of 6.2–5.2 p.p.m. (H-k) and 3.7–2.7 p.p.m. (H-j). The former proton signals are reasonably assigned to olefinic protons, and the latter ones to methylene or methine protons adjacent to carbonyl or vinyl groups. The 1H signals due to the original cis-olefin moiety (H-i) decreased with increasing amount of PMI. In the case of CD/PMI 1/6, the facts that the 1H signals (H-i) was very weak and that broad aliphatic 1H signals appeared at lower than 3.7 p.p.m. increased as is shown in Figure 3b, indicating the occurrence of addition copolymerization of the original cis-olefin moieties and PMI. Also, the appearance of broad 1H signals around 4 p.p.m. suggests the occurrence of homopolymerization of PMI.27 However, the fact that the olefinic proton signal of maleimide moieties is observed at 6.85 p.p.m. for cCD/PMI 1/6 indicates that excess PMI remains at the reaction temperature of 200 °C. The probable reaction mechanism of CD and PMI elucidated from the 1H-NMR is shown in Figure 4. Thus, the ene reaction of the terminal allyl group of the pentadeca-8,11,14-triene moiety and PMI generates the cis, cis, trans-pentadeca-8,11,13-triene moiety (Equation (4)). Subsequently, the formed conjugated diene moiety undergoes a Diels–Alder reaction with PMI to produce cyclohexene moiety (Equation (5)). When the trans-olefin generated by the ene reaction of isolated cis-olefin and PMI is not conjugated with another cis-olefin, the subsequent Diels–Alder reaction does not occur (Equation (6)). It is also considered that addition copolymerization of the olefins originated from CD and PMI and the homopolymerization of PMI occur in addition to the ene and Diels–Alder reactions.

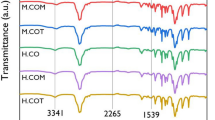

The FTIR spectra of the model reaction products were analyzed to verify the reaction mechanism elucidated by 1H-NMR for cCD/PMI (Figure 5). The analysis of the C–H out-of-plane bending absorptions of alkenes is effective to identify their substitution manner and cis–trans isomerism. For example, it is known that cis-disubstituted RHC=CHR and trans-disubstituted RHC=CRH show the absorption peaks at 730–665 cm−1 (strong) and 980–960 cm−1 (strong), respectively.28 It is also known that vinyl RHC=CH2 shows the absorption peaks at 995–985 cm−1 (strong) and 915–905 cm−1 (strong).29 The C–H out-of-plane bending absorption peak of cis-disubstituted RHC=CHR for CD was observed at 719 cm−1. Also, the C–H out-of-plane bending absorption peaks of the terminal vinyl group for CD were observed at 991 and 910 cm−1. In the FTIR spectra of cCD/PMI 1/2 and cCD/PMI 1/6, the absorption peaks related to cis-RHC=CHR and vinyl RHC=CH2 observed for CD considerably diminished, and new absorption peaks around 968 cm−1 related to the trans-RHC=CRH unit formed by the ene reaction appeared. Also, another new absorption peak at 733 cm−1 related to cis-RHC=CHR of the cyclohexene moiety formed by the ene reaction and subsequent Diels–Alder reaction. Although the absorption peak at 832 cm−1 related maleimide group disappeared for cCD/PMI 1/2, this peak was observed for cCD/PMI 1/6. The result obtained from the FTIR analysis is in good agreement with that elucidated from the 1H-NMR analysis.

Curing reactions of CD/BMI and CDN/BMI

The mixture of CD and BMI with the unit ratio of CD/maleimide 1/2–1/6 gelled during the prepolymerization at 200 °C for 4 h, indicating the progress of crosslinking reaction. Similarly, the mixture of CDN and BMI gelled during the prepolymerization at 200 °C for 0.5 h. The obtained compounds of CD/BMI and CDN/BMI were compression-molded finally at 250 °C for 5 h. Figure 6 shows FE-SEM images of the fractured surface of cCD/BMIs and cCDN/BMIs. All the cured resins of CD/BMI and CDN/BMI did not show any phase separation, indicating that CD and CDN copolymerized with BMI. To verify the curing mechanism estimated from the model reaction, FTIR analysis of cCDN/BMI was performed. Figure 7 shows the FTIR spectra of CDN, cCDN/BMI 1/2, cCDN/BMI 1/6 and BMI over the range between 2000 and 700 cm−1. The C–H out-of-plane bending absorption peak of cis-disubstituted RHC=CHR was observed at 719 cm−1 for CDN in a manner similar to CD. Also, the C–H out-of-plane bending absorption peaks of terminal vinyl group for CDN were observed at 991 and 910 cm−1. The absorption peaks related to the cis-RHC=CHR and vinyl RHC=CH2 observed for CDN almost disappeared for cCDN/BMI 1/2 and cCDN/BMI 1/6 and new broad absorption peaks around 960–980 cm−1 related to trans-RHC=CRH were observed, indicating the occurrence of the ene reaction. Although the absorption peak related to the cyclohexene moiety generated by the Diels–Alder reaction was clearly observed at 733 cm−1 for cCD/PMI, the peak at a near wavenumber region (738 cm−1) was very weak for cCDN/BMI 1/2 and cCDN/BMI 1/6. There is a possibility that retro-Diels–Alder reaction and subsequent addition copolymerization occurred at the curing temperature of 250 °C, or that Diels–Alder reaction itself is prevented by a steric hindrance by use of BMI instead of PMI and the olefinic moieties of CDN directly copolymerized with BMI. Figure 8 shows the comparison of FTIR spectra of CD/PMI 1/4 and CDN/BMI 1/4 prepolymerized at 200 °C for 8 h. In contrast to the fact that the prepolymerized CD/PMI showed a clear peak at 733 cm−1 based on a cyclohexene moiety, the prepolymerized CDN/BMI showed no absorption peak at a similar wavenumber region, except for the peaks based on the unreacted BMI. A similar trend was observed for CDN/BMI 1/2 and CDN/BMI 1/4 prepolymerized at 200 °C for 8 h. These results strongly support that the Diels–Alder reaction is highly hindered in the case of the reaction of CDN and BMI. Although we did not show the FTIR spectra of cCD/BMI 1/2 and cCD/BMI 1/6, their spectra were very similar to those of cCDN/BMI 1/2 and cCDN/BMI 1/6, respectively, indicating that the ene reaction and addition copolymerization similarly occurred for cCD/BMIs. Regarding the effect of steric hindrance on Diels–Alder reaction, it is reported that the Diels–Alder reaction did not occur but the ene reaction and subsequent addition copolymerization occurred in the reaction of DABA/PMI or DABA/BMI, whereas the model reaction of 2-allylphenol and PMI produced the ene and subsequent Diels–Alder adducts.14, 15, 29

Thermal and mechanical properties of cCD/BMI and cCDN/BMI

Figures 9 and 10 show dynamic mechanical analysis curves of cCD/BMIs and cCDN/BMIs cured at 250 °C, respectively. The cCD/BMI 1/2 and cCDN/BMI 1/2 showed clear tan δ peak temperature corresponding to glass transition temperature (Tg) at 141.7 and 158.0 °C, respectively. The storage modulus (E′) for cCD/BMI 1/2 and cCDN/BMI 1/2 considerably dropped at around the Tg. However, clear glass transition and decline of E′ were not identified until 300–350 °C for the cured resins with a higher BMI content than cCD/BMI 1/2 and cCDN/BMI 1/2, indicating highly crosslinked maleimide resins with superior heat resistance are obtained.

Figure 11 shows thermogravimetric analysis curves of cCD/BMI and cCDN/BMI cured resins. The 5% weight loss temperature increased with increasing BMI content, and all the cured resins except cCD/BMI 1/2 showed an excellent 5% weight loss temperature higher than 450 °C. When the cured resins with the same unit ratio of CD /maleimide are compared, cCDN/BMI had a higher 5% weight loss temperature than cCD/BMI did.

Figure 12 shows flexural properties of cCD/BMIs and cCDN/BMIs. There were little differences in flexural strength and modulus between the cCD/BMI and cCDN/BMI with the same unit ratio, suggesting that polymer network is formed for both the cured resins by the reaction at the stoichiometric ratio of maleimide/CD more than two. When the unit ratio is 1/4, the highest flexural strength and modulus were attained for both the resin systems, except that cCDN/BMI 1/4 showed a lower flexural strength than cCDN/BMI 1/2 did. These results suggest that the introduction of a succinimide moiety with a higher fraction during the addition copolymerization contributes to the improvement of the thermal and flexural properties. The fact that flexural strength and modulus of cCD/BMI 1/6 and cCDN/BMI 1/6 were lower than those of the corresponding 1/4 samples may be attributed to the brittle character of homopolymerized BMI component and/or some delamination between succinimide-rich and -poor components. Regarding the comparison with already developed petroleum-based bismaleimide resins, the flexural strength and modulus (78.0 MPa and 2.22 GPa) of cCD/BMI 1/4 were lower than the reported values (172 MPa and 4.21 GPa) of cured DABA/BMI with the molar ratio of 1/1 cured at 250 °C for 6 h.11 Although the occurrence of the ene reaction and vinyl copolymerzation is estimated for both the bismaleimide resin systems, the fact that the unsaturated chain (C15) of CD is much longer than those (C3) of DABA should be attributed to the difference of the flexural properties.

Conclusions

CDN (p=2.52) was synthesized by the reaction of CD (x=2.14) and paraformaldehyde. The prepolymerized compounds of CDN/BMI and CD/BMI with CD/maleimide ratios 1/2, 1/4 and 1/6 at 200 °C were finally compression-molded at 250 °C for 5 h to produce cCDN/BMI and cCD/BMI, respectively. The FE-SEM analysis revealed that homogeneous cured resins without phase separation were obtained for cCD/BMI and cCDN/BMI. Although the 1H-NMR and FTIR analyses of the model reaction product of CD and PMI at 200 °C for 8 h suggested the occurrence of the ene reaction and subsequent Diels–Alder reaction, the FTIR analysis of cCD/BMI and cCDN/BMI suggested the occurrence of the ene reaction and addition copolymerization. The cCDN/BMI and cCD/BMI with CD/maleimide ratio lower than 1/2 did not show glass transition until 300 °C and had a 5% weight loss temperature higher than 450 °C. The cCDN/BMI and cCD/BMI with CD/maleimide ratio 1/4 showed the most balanced flexural properties (flexural strength 60–80 MPa, flexural modulus 2.0–2.5 GPa).

References

Sun, X. S. in Bio-Based Polymers and Composites eds Wool R. P., Sun X. S., Ch. 1, 1–14 (Elsevier, New York, 2005).

Kaplan, D. L in Biopolymers from Renewable Resources ed. Kaplan D. L., Ch.1, 1-29 (Springer, Berlin (1998).

Yu, L., Petinakis, S., Dean, K., Bilyk, A. & Wu, D. Green polymeric blends and composites from renewable resources. Macromol. Symp. 249/250, 535–539 (2007).

Yu, L., Dean, K. & Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 31, 576–602 (2006).

Ronda, J. C., Lligadas, G., Galià, M. & Cádiz, V. A renewable approach to thermosetting resins. React. Funct. Polym. (advance online publication 24/2012).

Kim, J. R. & Sharma, S. The development and comparison of bio-thermoset plastics from epoxidized plant oils. Ind. Crop. Prod. 36, 485–499 (2012).

Raquez, J. M., Deléglise, M., Lacrampe, M. F. & Krawczak, P. Thermosetting (Bio)materials derived from renewable resources: a critical review. Prog. Polym. Sci. 35, 487–509 (2010).

Effendi, A., Gerhauser, H. & Bridgwater, A. V. Production of renewable phenolic resins by thermochemical conversion of biomass: a review. Renew. Sustain. Energy Rev. 12, 2092–2116 (2008).

Wool, R. P. in Bio-Based Polymers and Composites (eds. Wool R. P., Sun X. S., Ch 7, 202–255 (Elsevier, New York (2005).

Nair, C. P. R. Advances in addition-cure phenolic resins. Prog. Polym. Sci. 29, 401–498 (2004).

Hopewell, J. L., George, G. A. & Hill, D. J. T. Quantitative analysis of bismaleimide–diamine thermosets using near infrared spectroscopy. Polymer (Guildf) 41, 8221–8229 (2000).

Chaplin, A., Hamerton, I., Herman, H., Mudhar, A. K. & Shaw, S. J. Studying water uptake effect in resins based on cyanate ester/bismalemide blends. Polymer (Guildf) 41, 3945–3956 (2000).

King, J. J., Chaudhari, M. & Zahir, S. A new bismaleimide system for high performance applications. 29th SAMPE Symposium 29, 392–403 (1984).

Morgan, R. J., Shin, E. E., Rosenberg, B. & Jurek, A. Characterization of the cure reactions of bismaleimide composite matrices. Polymer (Guildf) 38, 639–646 (1997).

Rozenberg, B. A., Dzhavadyan, E. A., Morgan, R. & Shin, E. High-performance bismaleimide matrices: cure kinetics and mechanism. Polym. Adv. Technol. 13, 837–844 (2002).

Hirayama, K., Irie, T., Teramoto, N. & Shibata, M. High performance bio-based thermosetting resins composed of dehydrated castor oil and bismaleimide. J. Appl. Polym. Sci. 114, 1033–1039 (2009).

Shibata, M., Teramoto, N. & Nakamura, Y. High performance bio-based thermosetting resins composed of tung oil and bismaleimide. J. Appl. Polym. Sci. 119, 896–901 (2011).

Chiellini, E., Chiellini, F. & Cinelli, P. in Degradable Polymers: Principles and Applications ed. Scott G., Ch. 7, 192–194 (Springer, Berlin (2003).

Roy, D. R., Basu, P. K., Raghunathan, P. & Eswaran, S. V. Cashew nut shell liquid-based tailor-made novolac resins: polymer morphology quantitatation by 1-D and 2-D NMR techniques and performance evaluation. J. Appl. Polym. Sci. 89, 1959–1965 (2003).

Yadav, R., Devi, A., Tripathi, G. & Srivastava, D. Optimization of the process variables for the synthesis of cardanol-based novolac-type phenolic resin using response surface methodology. Eur. Polym. J. 43, 3531–3537 (2007).

Santos, R. S. S., Souza, A. A., Paoli, M. A. & Souza, C. M. L. Cardanol–formaldehyde thermoset composites reinforced with buriti fibers: preparation and characterization. Composites Part A 41, 1123–1129 (2010).

Devi, A. & Srivastava, D. Studies on the blends of cardanol-based epoxidized novolac type phenolic resin and carboxyl-terminated polybutadiene (CTPB), I. Mater. Sci. Eng. A 458, 336–347 (2007).

Kim, Y. H., An, E. S., Park, S. Y. & Song, B. K. Enzymatic epoxidation and polymerization of cardanol obtained from a renewable resource and curing of epoxide-containing polycardanol. J. Mol. Catal. B 45, 39–44 (2007).

Campaner, P., D’Amico, D., Longo, L., Stifani, C. & Tarzia, A. Cardanol-based novolac resins as curing agents of epoxy resins. J. Appl. Polym. Sci. 114, 3585–3591 (2009).

Yadav, R. & Srivastava, D. Synthesis and properties of cardanol-based epoxidized novolac resins modified with carboxyl-terminated butadiene–acrrylonitrile copolymer. J. Appl. Polym. Sci. 114, 1670–1681 (2009).

Bai, W., Xiao, X., Chen, Q., Xu, Y., Zheng, S. & Lin, J. Synthesis and characterization of cross-linked polymer from cardanol by solvent-free grinding polymerization. Prog. Org. Coat. 75, 184–189 (2012).

Lu, Y., Sun, W. & Shen, Z. Polymerization of N-phenylmaleimide with a rare-earth coordination catalyst. J. Appl. Polym. Sci. 96, 979–982 (2005).

Silverstein, R. M., Webster, F. X. & Kiemle, D. J. Spectrometric Identification of Organic Compounds. 7th edn, Vol. 125 (Wiley, Hoboken, (2005).

Shibahara, S., Yamamoto, T., Yamaji, T., Motoyoshiya, J. & Hayashi, S. Thermal reactions of N-phenylmaleimide and mono- or di-functional allylphenols. Polym. J. 30, 404–409 (1998).

Acknowledgements

We thank Dr Naozumi Teramoto of our department for the helpful suggestions and measuring 1H-NMR spectra. We are also grateful to Mr Ryusuke Osada of Material Analysis Center of our university for assisting in FE-SEM measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Shibata, M., Itakura, Y. & Watanabe, H. Bio-based thermosetting resins composed of cardanol novolac and bismaleimide. Polym J 45, 758–765 (2013). https://doi.org/10.1038/pj.2012.195

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.195

Keywords

This article is cited by

-

Production of epoxidized cardanol–based vinyl ester resins with cinnamic acid for eco-friendly coating materials

Emergent Materials (2022)

-

Synthesis and properties of phosphorus-containing cardanol-based acrylates for flame-retardant UV/EB-cured coatings

Journal of Coatings Technology and Research (2021)

-

Synthesis and properties of UV-curable cardanol-based acrylate oligomers with cyclotriphosphazene core

Journal of Coatings Technology and Research (2019)

-

Cardanol Polymerization Under Acid Conditions By Addition And Condensation Reactions

Journal of Polymers and the Environment (2018)

-

Green polymer chemistry: the biomimetic oxidative polymerization of cardanol for a synthetic approach to ‘artificial urushi’

Polymer Journal (2017)