Abstract

The observation of a stimulated emission at interband transitions in monocrystalline n-InN layers under optical pumping is reported. The spectral position of the stimulated emission changes over a range of 1.64 to 1.9 μm with variations of free electron concentration in InN layers from 2·1019 cm−3 to 3·1017 cm−3. The main necessary conditions for achieving the stimulated emission from epitaxial InN layers are defined. In the best quality samples, a threshold excitation power density is obtained to be as low as 400 W/cm2 at T = 8 K and the stimulated emission is observed up to 215 K. In this way, the feasibility of InN-based lasers as well as the potentials of crystalline indium nitride as a promising photonic material are demonstrated.

Similar content being viewed by others

Introduction

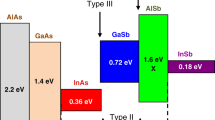

The interest in indium nitride is mainly due to its narrow band gap (about 0.7 eV)1,2, which makes InN a promising material for application in a wide class of optoelectronic devices. With interband optical transitions falling into the 1.5–1.9 μm range, it can supplement the much better studied GaN and AlN and significantly expand possible device applications of III-nitride compounds to the whole spectral range, from UV to near-IR3,4. Due to a low effective mass and high electron mobility in InN films, the realization of both optoelectronic and logic components seems feasible; the fabrication of lasers and optical amplifiers for the 1.5–1.9 μm spectral range based on crystalline InN or InGaN compounds would open up exciting prospects for application in communication technologies.

InN growth technology has proven to be the most difficult of all III-nitrides. The first problem in InN epitaxy is the lack of lattice-matched substrates, which results in a dislocation density of at least 109 cm−2 in the InN layers. The second problem is the thermal decomposition of InN, which occurs at temperatures above 470 °C. Low growth temperature strongly limits the selection of possible sources of active nitrogen. These factors lead to a high concentration of defects, including electrically active ones5,6. As a result, the obtained epitaxial InN is usually a degenerate semiconductor material with an electron concentration of more than 3·1017 cm−3. The above-mentioned technological problems hamper the study of InN properties. Despite this, considerable progress in device applications of epitaxial InN has been demonstrated recently, including the fabrication of infrared photodetectors7, thin-film transistors8, photovoltaic converters9, and a number of terahertz-range devices10,11. One of the possible ways to overcome the lattice mismatch problem is the formation of InN-based low-dimensional structures: nanowires, quantum dots, and quantum “pyramids”12,13,14. It has been shown that the equilibrium concentration of free carriers in nanowire structures can be reduced to ~1013 cm−3 15. The development of near-IR light emitters, photovoltaic devices and infrared photodetectors based on low-dimensional InN structures is the subject of intense study.

Further advances towards practical applications of InN in communication technologies require the fabrication of lasers and optical amplifiers for the 1.5–2 μm spectral range, and the key step in this direction would be the achievement of stimulated emission from crystalline InN. However, to date, stimulated emission from InN has only been demonstrated for a very specific sample, with InN nanobelts grown on a Si(100) substrate16. The stimulated emission was observed in a wavelength range of 1.6–1.7 μm under optical pumping at low temperature (20 K) with a threshold excitation power density as high as 75 kW/cm2. Despite a demonstration of lasing, no further development has followed, in contrast to the intense study of visible-range InGaN nanowire lasers17,18. As for planar epitaxial InN structures, to our knowledge, no report on the stimulated emission has been published so far. On the other hand, rather pure n-InN/GaN/AlN/Al2O3 planar structures with an equilibrium carrier concentration in the InN layer down to 3∙1017 cm−3 exhibited intense photoluminescence (PL) corresponding to interband transitions in a degenerate direct-gap material19,20. The external quantum efficiency of the spontaneous emission as high as 10% at T = 4.2 K was demonstrated, with a moderate temperature quenching up to the room temperature21. Light-emitting diodes based on n-InN/p-GaN/Al2O3 and n-InN/p-NiO/p-Si heterostructures emitting in the range 1.55–1.6 μm have been obtained22,23.

In spite of the sophisticated and demanding growth technique, we consider InN a typical direct-band semiconductor and a promising material for the development of near-IR light-emitting devices. We confirm this by the observation of stimulated emission from crystalline epitaxial InN layers in n-InN/GaN/AlN/Al2O3 planar waveguide structures under optical pumping. Based on the results of the study of a large number of InN structures with different crystal quality, thickness, composition, growth morphology, and carrier concentration, we determine the necessary conditions for achieving stimulated emission in InN structures.

Results

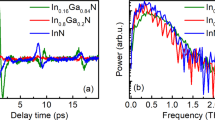

In order to obtain stimulated emission and to study the conditions for its realization in the planar InN layers, a series of monocrystalline InN samples were grown by plasma-assisted molecular-beam epitaxy (PA MBE) on (0001) sapphire substrates. The details of the growth procedure can be found in the Method section, supplementary materials and elsewhere24. To expand the range of the parameters of InN structures that affect the implementation and characteristics of stimulated emission, we have also studied the structures grown earlier at Cornell University. The detailed studies of this series of structures have been previously carried out by several scientific groups, including studies of the temperature and power dependencies of the photoluminescence spectra under CW optical pumping2,21,25 and time-resolved transmission measurements26,27. We should note that to our knowledge, no attempts were made in previous studies to obtain stimulated emission in InN structures similar to those studied in this work, including PL studies under pulsed optical pumping28,29. The samples obtained in IPM RAS and at Cornell University are marked in the text by the prefixes “IPM” and “GS”, respectively.

All samples under study were grown by PA MBE method on c-Al2O3 substrates. Prior to the deposition of the InN layer a buffer consisting of AlN and GaN layers was deposited onto the sapphire substrate (Fig. 1a). The thickness of GaN/AlN buffer layer was ~1 μm for IPM samples (Fig. 1) and ~0.3 μm for GS samples. Using a GaN/AlN buffer allows partial compensation of the lattice mismatch between InN and Al2O3. Due to a significant difference in the refractive indices of the active InN layer (n = 2.9), the buffer GaN and AlN layers (n = 2.3 and 2.1, respectively) and c-Al2O3 substrate (n = 1.74) an asymmetric planar waveguide was formed in the grown structures. The parameters of the InN layer and GaN/AlN buffer in all investigated samples provided strong (>90%) confinement of the fundamental TE0 mode in the active InN layer (see Fig. 1b for the calculated mode profile). Optically pumped planar waveguide provides the confinement of the guided light modes in the active layer and eliminates the need to form a resonator for the study of amplification and lasing conditions30. The thickness of InN layers was varied in the range 0.5–1.1 μm in the IPM structures, and in the range 1.1–12 μm in the GS structures.

InN structures were investigated by a wide range of the experimental methods in order to reveal the conditions affecting the achievement of stimulated emission in epitaxial InN layers (see section Methods). The performed studies made it possible to determine the morphology of the structures, the roughness of their surfaces, the concentration of the impurity atoms and free charge carriers, the dislocation density, and the presence or absence of the metallic In clusters. In this work, we have analyzed InN layers with the thickness from 0.5 to 12 µm, having both planar and three-dimensional nanopillar structure (see supplementary materials), with the dislocation density in the range 1010–1011 cm−2 and the electron concentration from 3∙1017 to 3∙1019 cm−3. According to X-ray diffraction all investigated InN layers were unstrained within the limits of measurement errors. The roughness of the sample surface increased with the thickness of the InN layer with root-mean-square surface roughness values varying from ≤10 nm for the 1 μm thick layers to ≤30 nm, for the layers thicker than 5 μm. The samples under study had an arbitrary shape with the maximal size from 3 to 10 mm. The parameters of some investigated structures are presented in Table 1.

The emission spectra were studied under optical excitation using both a continuous wave (CW) laser (up to 500 mW at the wavelength of 0.8 μm) and an optical parametric oscillator, tunable in the spectral range 0.45 to 2.3 μm (up to 3 mJ in 10 ns pulses with a repetition rate of 10 Hz). The emitted radiation was collected from the surface or from the edge of the sample. In case of pulsed excitation, we tuned the pump wavelength in order to achieve uniform excitation of the whole active layer for samples with rather thick InN layers. Taking into account that the intrinsic absorption coefficient of InN exceeds 104 cm−1 for the incident light with the wavelength shorter than 1.7 μm, samples with ~ 1 μm thick InN layers were considered optimal for the implementation of stimulated emission. For further details, see the Methods and supplementary materials.

The obtained InN/GaN/AlN/Al2O3 structures demonstrated intense spontaneous PL from the InN layers under CW optical pumping. Figure 2 (curve 1) shows the PL spectrum of the sample IPM80 at T = 78 K. The position of the PL peak originated from the band-to-band transitions in InN depended on the concentration of free electrons in the InN layer and demonstrated a blue-shift of the PL maximum for the samples with higher electron concentration in accordance with the change of the Fermi level in a degenerate semiconductor. The low-energy part of the spontaneous emission band, observed in the PL spectra below the band gap energy of bulk InN (<700 meV), was related to the radiative transitions from the conduction band to the localized acceptor states21. Under CW excitation, the pump power dependence of the spontaneous PL intensity was sublinear for all samples under study.

Emission spectra of the sample IPM80 at T = 78 K. 1 – CW excitation (λex = 800 nm, 1 W/cm2); 2 – pulsed excitation (λex = 1300 nm, 80 kW/cm2). Insets: (a) transition from spontaneous to stimulated emission near the threshold power density; (b) dependence of the integral emission intensity on the pump power density.

Under pulsed excitation, a relatively narrow line (FWHM = 16 meV) arose near the maximum of the spontaneous emission peak at pump power densities above the threshold value (~60 kW/cm2 at T = 78 K for the sample IPM80, see Fig. 2). The intensity of this line demonstrated a superlinear dependence on the pump power (inset 2 in Fig. 2), which clearly indicated a realization of stimulated emission at the interband transitions in strongly degenerate InN with electron concentration 1019 cm−3. It should be noted that the use of a planar waveguide without special processing of the facets for the formation of laser cavity mirrors, and the arbitrary shape of the samples resulted in the observation of lasing in a single-pass regime30.

The samples grown in CU had substantially lower electron concentration (see Table 1 and Method section), which led to a strong red shift of the spontaneous emission band and the stimulated emission line (Fig. 3). Figure 4 and Table 1 summarize the results on stimulated emission obtained for all InN samples studied. It can be seen that the change in the concentration of equilibrium electrons in the InN layer from 2∙1019 to 3.6∙1017 cm−3 is accompanied by a shift of the stimulated emission line from 1.64 μm (755 meV) to 1.89 μm (655 meV) and by a substantial narrowing of this line (from 23 meV FWHM down to 2 meV). Besides that, we observed a substantial decrease in the stimulated emission threshold in the structures with lower electron concentration. For the sample GS2042, the estimated threshold at Т = 78 K was Pth ~6 kW/cm2 (see inset in Fig. 3), i.e. an order of magnitude lower than in the sample IPM80. This is seemingly caused by a decrease in the non-radiative recombination rate for more pure samples, which is confirmed by a substantial increase in the spontaneous emission intensity in these samples. At T = 8 K we estimated a threshold pump power density for the sample GS2042 as low as Pth = 400 W/cm2. For all CU samples with low electron concentration, Pth was less than 1 kW/cm2, which corresponds to an injection current density of <1 kA/cm2 in case of electrical pumping. As shown in Fig. 5, at elevated temperatures, the stimulated emission threshold increased exponentially with a characteristic temperature of T0 ≈ 30 K, which is a limiting factor for high-temperature laser operation. However, for the sample GS2060 with the most pure InN layer, stimulated emission was observed up to 215 K. It should be noted that the threshold of stimulated emission in the obtained planar structures was more than an order of magnitude lower than the previously reported value for the samples with InN nanobelts16.

Stimulated emission spectra obtained for different InN samples (see Table 1 for details). All spectra have been measured at T = 78 K with excitation power density slightly above the stimulated emission threshold.

Discussion

The conditions for optical amplification and stimulated emission can be obtained using the following equation:30,31

where I is the output emission intensity in an edge-emission geometry, ISp is the spontaneous luminescence intensity, l is the length of the excited stripe, g is the optical gain coefficient and α is the total losses coefficient including absorption and scattering losses. Consequently, a superlinear dependence of I(l) for gl > 1 is a direct indication of gain and the presence of stimulated emission. Note that the parameters g and l are determined by the experimental conditions and the intrinsic properties of the active medium, while absorption and scattering losses pertain to deviations from the properties of a homogeneous crystalline layer with a smooth interface. Comparison of the results obtained for a number of planar InN structures made it possible to identify some factors that are essential for the realization of the stimulated emission. The experiment in an edge-emission geometry provided the conditions for obtaining stimulated emission. The power of the pulsed excitation of the active waveguide (in our case this was a planar waveguide, see Fig. 1) was sufficient to create a population inversion and to provide the gain that exceeded the total absorption and scattering losses in a series of InN samples (see Table 1).

At T = 78 K, we observed stimulated emission in n-InN/GaN/AlN/Al2O3 samples with a thickness of the active InN layer of 0.65–12 μm, with a free electron concentration ≤2∙1019 cm−3 and with a threading dislocation density <6∙1010 cm−2. As follows from the obtained results, the concentration of free electrons was the most important factor that determines the threshold and temperature dependence of the stimulated emission. In IR light-emitting structures based on degenerate semiconductors, the processes of intraband free carrier absorption are intensified, which leads to an increase in absorption losses, preventing the implementation of lasing. Lower electron concentration resulted in a significant decrease of the threshold power density (see Table 1) and in a higher lasing temperature. The reduction in the electron concentration can be achieved by the growth of thick InN layers20, which leads to a decrease in the dislocation density and, as a result, in the concentration of dislocation-related electrically active centers (see samples GS2050, GS2060, GS2054). Besides that, the concentration of free electrons is strongly affected by the amount of residual impurities in the InN layer. Secondary-ion mass spectrometry (SIMS) analysis had shown that the InN layer grown in CU and characterized by lower concentration of equilibrium electrons as compared with IPM samples, also had a lower concentration of residual impurities, primarily oxygen and carbon (see Supplementary Fig. S5) Interstitial carbon and substitutional oxygen atoms act as donors and can contribute to n-type conductivity of InN32,33.

Despite the revealed strong influence of the concentration of equilibrium electrons on the parameters of stimulated emission, an analysis of all the samples studied showed that a low electron concentration is not a sufficient condition for the realization of stimulated emission in InN layers. The results of studying a large number of structures close in geometry and the concentration of free carriers indicate the contribution of scattering processes to total optical losses. It is well known that in semiconductor crystalline waveguides scattering loss may originate from poor crystallinity, mixed growth phases, incorrect stoichiometry or interface roughness34. For instance, stimulated emission was not observed in the sample IPM34 (see Table 1), which had one of the lowest values of dislocation density and electron concentration in the InN layer among the IPM samples. The scanning electron microscopy showed that a three-dimensional nanopillar-like growth of InN layer has been realized in the sample IPM34 (see supplementary materials) instead of the formation of a continuous planar InN layer as it was observed for the rest of the samples. In this case, strong light scattering in the active InN layer should lead to an increase of optical losses hindering stimulated emission.

Stimulated emission was also not observed in the sample GS2054 despite the lowest dislocation density (1010 cm−2) and a low electron concentration (3·1017 cm−3). We have found a factor that can be responsible for the suppression of lasing in this sample. The X-ray diffraction analysis has shown a presence of the metallic In phase. A pronounced peak originating from metallic indium can be seen in the corresponding ω-2θ curve (see Fig. 6). For the samples grown under metal-rich conditions, the formation of metallic In clusters in the InN layer may result in an increase of the radiation scattering. Inclusions of the metallic phase can serve as centers of nonradiative recombination thus also hampering the implementation of lasing.

Thus, along with the low electron concentration and low dislocation density, the basic conditions for the realization of stimulated emission in planar InN structures include the homogeneity of the active InN layer, the absence of the metallic In phase and the low density of the absorption and nonradiative recombination centers. Apart from the optimization of the growth process for InN layers, one can expect further improvement of the lasing characteristics of InN by means of the formation of appropriate waveguide structures and laser cavities.

In summary, stimulated emission at direct band-to-band transitions in crystalline n-InN was obtained under optical excitation. For the best quality samples, the stimulated emission threshold was as low as 400 W/cm2 at T = 8 K and 6 kW/cm2 at T = 78 K, and stimulated emission was observed up to 215 K. For epitaxial n-InN films with an equilibrium electron concentration over a range of n = 3.6∙1017–2∙1019 cm−3, the emission wavelength varied in the range λ = 1.64–1.9 μm. Thus, the feasibility of InN-based laser is demonstrated. In thus way, crystalline indium nitride appears to be a promising photonic material for the realization of a new generation of InN laser structures, active waveguides, microcavities and photonic crystals.

Methods

Samples

Samples from the Institute for Physics of Microstructures (IPM RAS) and Cornell University were grown using the PA MBE technique. InN layers were obtained on GaN/AlN buffer layer (~1 μm for IPM samples and ~ 0.3 μm for Cornell University samples) on c-Al2O3 substrates. According to atomic-force microscopy study of test structures the root-mean-square surface roughness of the GaN/AlN buffers was less than 1 nm. The total dislocation density in GaN buffers evaluated from X-ray diffraction analysis was in a range (1.5–3.5)∙1010 cm−2.

The growth of InN layers was carried out at different growth conditions which resulted in a difference of their structural, electrical and optical properties. According to X-ray diffraction all investigated InN layers were unstrained within the limits of measurement errors. The InN layers had the thickness varying from 0.5 to 12 µm, both with planar and three-dimensional nanopillar structure (see supplementary materials), and with the dislocation density in the range (1–10)·1010 cm−2 both for IPM and Cornell University samples. However, InN layers obtained in Cornell University demonstrated lower electron concentration varying from 3∙1017 to 1.4∙1018 cm−3, while in IPM samples it varied from 7∙1018 to 3∙1019 cm−3. This difference could be attributed to a much higher concentration of impurities in the IPM samples (more than order of magnitude for O and C impurities) according to the secondary ion mass spectroscopy (SIMS) (see Fig. S5 in supplementary materials).

Samples characterization

The surface of the test structures with a GaN/AlN buffer layer and the investigated InN layer were characterized by atomic force microscopy (AFM) using an NTEGRA Prima microscope and by scanning electron microscopy (SEM) using a Carl Zeiss Supra 50VP microscope. The latter was also used to obtain the cross-sectional images of the samples. X-ray diffraction analysis were performed using a Bruker D8 Discover diffractometer. The half-widths of (0004) and (10–12) reflections were analyzed in order to evaluate the density of screw and edge dislocations in InN layers. The half-width of (0004) reflection from investigated InN layers was varied in range 0.14°–0,76° and the half-width of (10–12) reflection in range 0.27°–0.86°. The total dislocation density was calculated using the technique reported by Moram and Vickers35. The photoluminescence (PL) spectra were studied using a Nd:YAG-laser with a wavelength of 532 nm, a grating spectrometer Acton 2300i and an OMA-V photodetector based on a linear InGaAs-photodiode array. Measurements of the reflection and transmission spectra were carried out using a Bruker IFS 125 HR Fourier spectrometer. The above mentioned optical spectroscopy methods together with Hall measurements were used to determine the equilibrium electron concentration in InN layers. The secondary ion mass spectroscopy (SIMS) analysis was performed using a TOF.SIMS-5 system with a time-of-flight mass analyzer. For further details, see supplementary materials.

Emission measurements

We used a standard experimental setup for photoluminescence (PL) studies (see Supplementary Fig. S4). The emission spectra were studied under optical excitation using both a continuous wave (CW) laser (up to 500 mW at a wavelength of 0.8 μm) and an optical parametric oscillator, tunable in the spectral range 0.45 to 2.3 μm (up to 3 mJ in 10 ns pulses with a repetition rate of 10 Hz). The pump beam was focused on the surface of the sample using a cylindrical lens into a stripe 200 μm wide and up to 10 mm long. The emitted radiation was collected from the sample surface in the case of CW excitation, or from the edge of the sample while studying emission under pulse exitation, dispersed using a grating spectrometer (Princeton Instruments Acton 2300i), and detected using an InGaAs-based linear diode array detector OMA-V (sensitivity range 0.8–2.1 μm). Depending on the sample under study, a Ge wafer or a low-pass optical filter were used to filter out the scattered pumping radiation. Most measurements were performed at liquid nitrogen (LN) temperature, with the sample placed into LN Dewar vessel; for temperature-dependent studies, we used a helium closed-cycle refrigerator.

Data availability

Any additional supporting information may be available from the corresponding author upon request.

References

Davydov, V. et al. Band Gap of Hexagonal InN and InGaN. Alloys. Phys. Status Solidi B 234, 787 (2002).

Wu, J. et al. Temperature dependence of the fundamental band gap of InN. J. Appl. Phys. 94, 4457 (2003).

Mi, Z. & Zhao, S. Extending group-III nitrides to the infrared: Recent advances in InN. Phys. Status Solidi B 252, 1050 (2015).

Nanishi, Y. Nobel Prize in Physics: The birth of the blue LED. Nat. Photonics 8, 884 (2014).

Lu, H. et al. Improvement on epitaxial grown of InN by migration enhanced epitaxy. Appl. Phys. Lett. 77, 2548 (2000).

Piper, L. F. J., Veal, T. D., McConville, C. F., Lu, H. & Schaff, W. J. Origin of the n -type conductivity of InN: The role of positively charged dislocations. Appl.Phys. Lett. 88, 252109 (2006).

Hsu, L.-H. et al. InN-based heterojunction photodetector with extended infrared response. Opt. Express 23, 31150 (2015).

Lye, K. S., Kobayashi, A., Ueno, K., Ohta, J. & Fujioka, H. InN thin-film transistors fabricated on polymer sheets using pulsed sputtering deposition at room temperature. Appl. Phys Lett. 109, 032106 (2016).

Yamamoto, A., Islam, M. R., Kang, T.-T. & Hashimoto, A. Recent advances in InN-based solar cells: Status and challenges in InGaN and InAlN solar cells. Phys. Status Solidi C 7, 1309 (2010).

Ascazubi, R., Wilke, I., Denniston, K., Lu, H. & Schaff, W. J. Terahertz emission by InN. Appl. Phys.Lett. 84, 4810 (2004).

Liu, H. et al. Ultrastrong Terahertz Emission from InN Nanopyramids on Single Crystal ZnO Substrates. Adv. Opt. Mater. 5, 1700178 (2017).

Zhao, S., Nguyen, H. P. T., Kibria, M. G. & Mi, Z. III-Nitride nanowireoptoelectronics. Prog. Quantum Electron. 44, 14 (2015).

Zhao, S. & Mi, Z. Chapter Eight - InN Nanowires: Epitaxial Growth, Characterization, and Device Applications. Semicond. Semimetals. 96, 267 (2017).

Sun, W., Tan, C.-K. & Tansu, N. Ultra-Broadband Optical Gain in III-Nitride Digital Alloys. Sci. Rep. 7, 6671 (2017).

Zhao, S. et al. Probing the electrical transport properties of intrinsic InN nanowires. Appl. Phys. Lett. 102, 073102 (2013).

Hu, M.-S. et al. Infrared lasing in InN nanobelts. Appl. Phys. Lett. 90, 123109 (2007).

Bhattacharya, P., Hazari, A., Jahangir, S., Guo, W. & Frost, T. III-Nitride Electrically Pumped Visible and Near-Infrared Nanowire Lasers on (001)Silicon. Semicond. Semimetals 96, 385 (2017).

Arafin, S., Liu, X. & Mi, Z. Review of recent progress of III-nitride nanowire lasers. J. Nanophotonics 7, 074599 (2013).

Lu, H. et al. Effect of an AlN buffer layer on the epitaxial growth of InN by molecular-beam epitaxy. Appl.Phys. Lett. 79, 1489 (2001).

Lu, H. et al. Growth of Thick InN by Molecular Beam Epitaxy. Mat. Res. Soc. Symp. Proc. 743, L4.10.1 (2003).

Klochikhin, A. A. et al. Acceptor states in the photoluminescence spectra of n-InN. Phys. Rev. B 71, 195207 (2005).

Wu, G.-G. et al. Near infrared electroluminescence from n-InN/p-GaN light-emitting diodes. Appl. Phys. Lett. 100, 103504 (2012).

Zhao, Y. et al. Near infrared light-emitting diodes based on n-InN/p-NiO/p-Si heterojunction. J. Lumin. 173, 1 (2016).

Lobanov, D. N. et al. Features of InN Growth by Nitrogen-Plasma-Assisted MBE at Different Ratios of Fluxes of Group-III and -V Elements. Semiconductors 50, 261 (2016).

Klochikhin, A. et al. Photoluminescence of n-InN with low electron concentrations. Phys. Status Solidi A 203, 50 (2006).

Fu, S. P., Chen, Y. F. & Tan, K. Recombination mechanism of photoluminescence in InN epilayers. Solid State Commun. 137, 203 (2006).

Chen, F., Cartwright, A. N., Lu, H. & Schaff, W. J. Time-resolved spectroscopy of recombination and relaxation dynamics in InN. Appl. Phys. Lett. 83, 4984 (2003).

Intartaglia, R. et al. Radiative and nonradiative recombination processes in InN films grown by metal organic chemical vapor deposition. Appl.Phys. Lett. 86, 142104 (2005).

Mohanta, A., Jang, D.-J., Lin, G.-T., Lin, Y.-T. & Tu, L. W. Carrier recombination dynamics in Si doped InN thin films. J. Appl. Phys. 110, 023703 (2011).

Shaklee, K. L. & Leheny, R. F. Direct determination of optical gain in semiconductor crystals. Appl. Phys. Lett. 18, 475 (1971).

Dingle, R., Shaklee, K. L., Leheny, R. F. & Zetierstrom, R. B. Stimulated emission and laser action in Gallium Nitride. Appl. Phys. Lett. 19, 5 (1971).

Lyons, J. L. & Janotti, A. & Van de Walle, C.G. Effects of carbon on the electrical and optical properties of InN, GaN, and AlN. Phys. Rev. B 89, 035204 (2014).

Duan, X. M. & Stampf, C. Defect complexes and cluster doping of InN: First-principles investigations. Phys. Rev. B 79, 035207 (2009).

Grivas, C. Optically pumped planar waveguide lasers, Part I: Fundamentals and fabrication techniques. Progress in Quantum Electronics. 45-46, 3 (2016).

Moram, M. A. & Vickers, M. E. X-ray diffraction of III-nitrides. Rep. Prog. Phys. 72, 036502 (2009).

Acknowledgements

The authors would like to thank Dr. H. Lu and Prof. W.J. Schaff (Cornell University, USA) for the loan of InN samples and Dr. M.N. Drozdov (IPM RAS) for SIMS measurements. This work was financially supported by the Russian Foundation for Basic Research (grant #16–29–03374 and #18-02-00711).

Author information

Authors and Affiliations

Contributions

B.A.A. conceived the project. D.N.L. and A.V.N. performed the epitaxial growth of the samples studied, P.A.B., V. Yu. D. and L.V.K. carried out preliminary sample characterization, A.N.Y., K.E.K. and L.V.K. conducted photoluminescence studies, and E.V.S. performed the SEM studies. B.A.A. and Z.F.K. supervised the project. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Andreev, B.A., Kudryavtsev, K.E., Yablonskiy, A.N. et al. Towards the indium nitride laser: obtaining infrared stimulated emission from planar monocrystalline InN structures. Sci Rep 8, 9454 (2018). https://doi.org/10.1038/s41598-018-27911-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-27911-2

This article is cited by

-

Strong tribo-piezoelectric effect in bilayer indium nitride (InN)

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.