Abstract

Study design:

Test development for a device that could prevent both brain and spinal cord injuries during motorcycling and horseback riding.

Objective:

The objective of this study was to develop a method and test a concept device that could protect against both spinal cord (SCI) and brain injuries (BI).

Setting:

St Louis, Missouri, USA.

Methods:

A Hybrid III dummy (that is, head, neck and torso) was used as a pendulum bob during three test conditions: (1) no protection, (2) standard motorcycle helmet and (3) SCI and BI test structure (SCIBITS). Triaxial accelerometers, a C1 force transducer and a video system were used to collect data as the dummy axially impacted a rigid barrier at speeds ranging from 10 to 605 cm s−1. SCIBITS consisted of a fused fiberglass thoracic jacket/head shield unit. Separation between the dummy head and the head shield permitted freedom of head movement within safe limits as impact forces to the head shield were transferred from the head and neck to the upper thorax. The BI threshold was 200–300 g, and the SCI threshold was 3010 N.

Results:

The SCIBITS protected against spinal cord injury, whereas the motorcycle helmet did not. The helmet protected against BI and the SCIBITS provided partial protection.

Conclusions:

The experiments describe the efficacy of an impact testing system utilizing an instrumented dummy suspended as a pendulum bob. The equipment will facilitate the design and construction of a functional device for protection against both SCI and BI in relation to both motorcycling and horseback riding.

Similar content being viewed by others

Introduction

Methods are well established for the testing of helmets designed to protect against brain injury (BI).1, 2, 3 The helmet and a metal headform (ISO/DIN 6220–1983 J, mass=4.3 kg, Mg headform) are dropped from 1.8 m onto an anvil. The drop height of 1.8 m assures impact speed of 6.0 m s−1±3%. The acceleration of the center of gravity in the headform at impact is measured with an accelerometer. For the equestrian standard, the impact at the center of gravity of the headform must not exceed the threshold of 300 g.1 For one component of the motorcycle standard, the impact at the center of gravity of the headform must not exceed the 200 g threshold.2, 3 Other conditions and specifications vary according to the specific test, but the essential criterion is attainment of a 6.0 m s−1 (600 cm s−1) impact speed without exceeding the specified threshold value.

Methods are well established in the automobile industry for the study of spinal cord injury (SCI), especially from whiplash injuries.4, 5 Crash dummies instrumented with accelerometers and force measuring devices are placed in an automobile that impacts with a barrier. Thresholds for BI and SCI have been established,4, 5 but there are no established methods for testing the high-speed risks of motorcycling and horseback riding.

We have patented a device to protect against both SCI and BI (SCIBID).6 Key concepts of SCIBID for brain protection include: (1) direct relief of head impact provided by the head shield of the SCIBID mounted upon the thoracic jacket, (2) compression of the plastic foam lining in the head shield of the SCIBID provides supplementary relief equivalent to that of the conventional helmet and (3) skull movement upon the spine is limited by the head shield's movement constraints in all directions. For spinal cord protection they include: (1) excessive bending of the cervical spine is prevented by the head shield's constraint of head movement in all directions, (2) axial compression of the cervical spine is restricted by the transfer of impact load from the head shield of the SCIBID to the thoracic jacket, and (3) compression of the plastic foam lining in the head shield of the SCIBID provides supplementary relief equivalent to that of the helmet. Comfortable range of vision and safe range of voluntary head motion are provided by the 2–3 cm separation between the head and the head shield of the SCIBID.

The long-term goal of our research was to develop a comfortable, fitted apparatus that prevents against both BI and SCI (Figure 1). The purpose of this investigation was to develop methods of testing devices that offer protection from BI and SCI.

Methods

This study involved four components: (1) method of impact, (2) selection of injury threshold limits, (3) conditions of testing and (4) collection of data from an initial test structure.

Method of impact

Neither the helmet drop test nor the whiplash tests were an appropriate method of testing.1, 2, 3, 4, 5 The helmet drop tests only require a metal headform. The current investigation required impacts with both head and torso. Although the whiplash tests included the head and torso, the whiplash mechanism of injury was not typical for motorcycle and equestrian SCI. Ultimately, we chose modification of methods employing a Hybrid III dummy wearing a bicycle helmet crashing into a concrete slab.7, 8

Our impact target was a square steel plate (61 cm × 61 cm × 79 mm) welded to a frame, hinged to steel I-beams and anchored it to the concrete floor (Figure 2). Our human model was an instrumented Hybrid III 50th percentile male dummy (First Technology, Plymouth, MI, USA). For impact testing, the dummy served as the bob of a pendulum; three cords attached a support frame to the dummy arm receptacles and spine (Figures 2 and 3). Specified drop heights provided a wide range of impact speeds including those of standard American Society for Testing and Materials (ASTM) helmet drop testing. For this preliminary evaluation, only direct axial impact was tested.

Selection of injury threshold limits

The 300–200 g (g is acceleration due to gravity) range was used as the BI threshold at a speed of 600 cm s−1. The 300 g value was chosen based on the standard ASTM equestrian helmet threshold for BI1 The 200 g value was derived from one component of the standard ASTM motorcycle helmet threshold.2, 3 There are no current standards for protection against spinal cord injury; we set an empirical threshold value of 3010 N (675 lb) at a speed of 600 cm s−1 to indicate a compressive cervical spine injury.9, 10

Conditions of testing

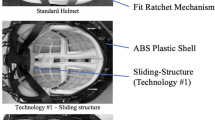

Three different testing challenges were compared: (1) unprotected head, (2) head protected by a motorcycle helmet (Bell Helmets, Zephyr model, full face coverage, DOT approved) and (3) head and neck protected by a sturdy one-piece vest, fiberglass jacket and head shield, reinforced at key load-bearing sites with steel rods and plates (SCI and BI test structure, SCIBITS) (Figure 4). Here, 2–3 cm separated the dummy head and the inside of the shield. The plastic foam shield lining, identical to that of the standard helmet, was not provided as it was not considered necessary for this initial comparative evaluation of testing instrumentation.

Data collection from test structure

Three types of instrumentation were used: (1) triaxial accelerometer, (2) neck transducer and (3) video motion capture. The accelerometer was used in the injury threshold assessment for BI; the neck transducer was used for SCI. The video motion capture system determined the impact speed. A triaxial accelerometer (no. 356B21; PCB Corp., DePew, NY, USA, rated at 500 g) was placed at the center of gravity of the head similar to the procedure used for the ASTM testing.1, 2, 3 A six degree of freedom neck transducer (6 DOF force/moment from FTSS, no. F-205) was fixed at the C1 vertebra in the Hybrid III neck according to the manufacturer's specifications. Reflective surface markers were placed on the dummy's head, trunk and support frame, and the barrier. They were also placed on the motorcycle helmet and SCIBITS. A single video motion capture marker on the support frame was used to calculate the impact speed. The three-dimensional marker locations were established by a six-camera Motion Analysis video system.

The testing routine was to raise the dummy to the desired elevation for predetermined impact speed. Data collection began just prior to release of the dummy and continued for about 2 s after barrier impact. Video data were collected at 500 Hz; accelerometer and neck transducer data at 5000 Hz, using the acquisition program EVaRT (5.4) from Motion Analysis Corp. and an internal National Instruments 64 channel A/D board, capable of 12-bit resolution (NI model 482A16). All data were time synchronized by the data collection computer.

The same test methods were used for the bare head control, motorcycle helmet and SCIBITS. In total, 1–5 trials were conducted at different speeds up to ∼600 cm s−1. A helmet was used multiple times when speeds were below that at which the helmet could be damaged (that is, 200 cm s−1), but only once when the speed would damage the helmet. Eight new helmets were used during the testing. The SCIBITS was used multiple times at different speeds, but only once for the maximum speed of ∼600 cm s−1.

Accelerometer, force and video data were transferred to Excel spreadsheets. Relative to SCIs, maximum forces for each condition and speed were plotted on the same figure in addition to the threshold value. For BI, the vector sum of each triaxial accelerometer was calculated for each test. Maximum accelerometer results for each condition and each speed were plotted on the same figure in addition to the threshold range. Best fit curves (for example, linear or power) were applied to the data.

Results

The pendulum method achieved consistent dummy impact speeds. Data were successfully collected for the three different conditions at various speeds ranging from 10 to 605 cm s−1.

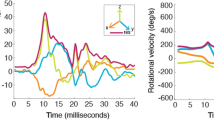

For SCI protection, impact to the bare head produced neck compression values that exceeded the injury threshold at speeds slightly less than 200 cm s−1 (Figure 5). Similar results for the helmeted head indicated that the compression of the cervical spine exceeded the injury threshold at speeds slightly greater than 200 cm s−1. However, with the SCIBITS, even at a speed of 605 cm s−1 the compression in the neck (275 N or 61.7 lb) was well below the injury threshold limit.

The results for BI protection indicated that the bare head condition exceeded the motorcycle injury threshold at a speed of about 230 cm s−1 (Figure 6). The SCIBITS exceeded the 200 g BI threshold at about 500 cm s−1, but not that for 300 g at 605 cm s−1. The motorcycle helmet protected the head from exceeding the injury thresholds at speeds up to 550 cm s−1. The fact that the load cell in the neck could not exceed 13 377 N (3000 lb) without damage prevented us from testing speeds greater than 550 cm s−1 with the unprotected neck (that is, bare head and helmet).

Speed vs impact acceleration (g) for bare head, helmet and shield tests to investigate the potential for head injury. The threshold for head injury was 300 g for equestrian helmets and 200 g for motorcycle helmets. Note that the head shield was not lined with Styrofoam identical to that of the helmet. Power/linear in the legend refers to the curve fitting method.

Discussion

The purpose of this investigation was to develop methods of testing devices that offer protection from BI and SCI. A number of limitations exist with the study. They fall into two categories: data collection methods and SCIBID design.

Our data collection impact speeds (maximum of 605 cm s−1) were low compared with actual traumatic impact conditions. Richter et al.11 have reported motorcycle impact crash speeds of 55 km h−1 (1528 cm s−1), more than twice the speed used in the present investigation. Speeds of race horses can exceed 47 km h−1 (1305 cm s−1), also more than twice the testing speed.12 Our reference point was the maximum speed and injury threshold required for the helmet drop test as it was believed that mimicking the helmet drop test wherever possible was most prudent in the eventual development of a standardized method of testing.

Another methodological issue is the biofidelity of the Hybrid III dummy. The Hybrid III dummy is a model designed and built to simulate the actual human body during impact conditions. It is made of various metals, rubber and other components that are meant to substitute for human structures. Patents have been issued (for example, for the neck) and upgrades are continuously being made to improve biofidelity.13, 14 It is presently the best available model for the actual human body during impact conditions. Although it is certainly desirable to have the most current test model that simulates the human body, when it comes to a standardized method, it is quite difficult to continually account for upgrades. An excellent example is with the helmet drop test where a magnesium headform is used to simulate the human head. Head models (for example, Hybrid III dummy) currently exist that are more biofidelic than the magnesium headform, yet it remains the standard by which all helmets are tested.

A third limitation of this method is the absence of load quantification to the torso. Our primary effort was to quantify loads at the head and neck to demonstrate the load transfer concept. We considered load quantification to the structures that bore these transferred loads (for example, sternum, clavicle and ribs) to be secondary. Future work using force sensors on the torso as well as finite element analysis computer models will be performed to gain an accurate force distribution profile, and an estimate of the potential extent of injuries. However, our premise is that injuries below the neck are less likely to produce the degree of permanent disability associated with brain and spinal cord lesions.

Relative to SCIBITS limitations, it is clear that the SCIBITS (Figure 4) is not something that can be worn by a human. Our SCIBITS was designed as a test structure to be used as part of the development of the testing methods. It was designed to withstand multiple impacts without being damaged. Thus, it was constructed of rigid fiberglass and steel members welded and riveted together and tightly fitted to the Hybrid III dummy. In fact, it was quite surprising to see that it was broken at key sites (for example, the shoulders) at the 600 cm s−1 speed. Breathing, mobility, fit, appearance, comfort and so on are all part of our future work where we will be able to use the methods developed in the current project to experimentally test protective efficacy.

Relative to the method of impact, Hodgson et al.7, 8 used a concrete barrier for impact with Hybrid III dummy wearing bicycle helmets to investigate their sliding friction characteristics. Our 79-mm-thick steel plate withstood the impact of the dummy up to the greatest speed of 605 cm s−1 (Figure 2). The pendulum technique permitted controlled and reproducible speeds that were confirmed with the video motion capture system. Unlike the helmet drop tests where only a metal headform is used to test impacts to the head, our pendulum method allowed for testing of both the head and neck by including the neck and torso of the Hybrid III dummy.

Relative to the selection of injury threshold limits, we used the same standard threshold limits for head protection that have been previously established (that is, 200–300 g at 600 cm s−1).1, 2, 3 As threshold standards for neck injury do not exist, it seemed logical to continue with the speed of 600 cm s−1 and then use the previously reported compression injury value of 3010 N (675 lb).9, 10 The speed threshold combination is new to the body of knowledge.

Relative to the conditions of testing, the testing of unprotected head, head protected by a motorcycle helmet, and head and neck protected by the SCIBITS were necessary to demonstrate the efficacy of the protective equipment. Tests with the unprotected head show the impact conditions that would sustain BI and SCI injuries. Tests with the helmeted head reveal the protective effect for BI but not for SCI. The results support previous work indicating no difference in the number of SCIs between helmeted and unhelmeted motorcyclist crash survivors.15 Tests with the SCIBITS demonstrate protection against both BI and SCI. Ultimately, the future standards will not include tests with the unprotected head, and only tests for the head and neck protective mechanisms.

The SCIBITS permitted demonstration of the effectiveness of the basic BI and SCI protective concept.6 The concept is to transfer the impact load from the head shield to the trunk via the structural members connecting the head shield with the vest. This transfer of load eliminates or reduces the impact load seen by the head and neck. Future SCIBIDs will be designed, similar to helmets, for protection of a single impact event, thus requiring a less rigid structure. They will be designed as a comfortable, wearable, scalable apparatus that will fit more than the Hybrid III dummy (Figure 1).

The instrumented pendulum arrangement was found to be reliable and convenient for future development of the SCIBID. The force transducer in the neck was able to quantify the impact loads and demonstrate the protective effect under the three test conditions. The accelerometer data were used to assess the efficacy of the device for preventing BI in the same way as in the helmet drop tests. Future studies with non-axial orientations of the dummy in relation to the impact barrier will permit further investigation of impact loads to the head, neck, shoulder and trunk regions.

References

American Society for Testing and Materials. ASTM F1163-01. Standard Specification for Protective Headgear Used in Horse Sports and Horseback Riding. ASTM International: West Conshohocken, PA, 2001.

American Society for Testing and Materials. ASTM F1446-01a. Standard Test Methods for Equipment and Procedures Used in Evaluating the Performance Characteristics of Protective Headgear. ASTM International: West Conshohocken, PA, 2001.

FMVSS 218 Federal Motor Vehicle Safety Standard (FMVSS) known as FMVSS 218 (49CFR571.218). Code of Federal Regulations, Title 49;5: 2001.

Bostrom O, Haland Y, Fredriksson R, Svensson M, Mellander H . A Sled tests procedure proposal to evaluate the risk of neck injury in low speed rear impacts using a new neck injury criterion (NIC). 16th ESV Conference; 1–4 June 1998; Windsor, Canada.

Kleinberger M, Sun E, Eppinger R, Kuppa S, Saul R . Development of Improved Injury Criteria for the Assessment of Advanced Automotive Restraint Systems, NHTSA Docket 98-4405-9 Washington, DC: US Department of Transportation, 1998.

Landau WM . Brain and spinal cord protector. US patent no. 5 715 541. 1998.

Hodgson VR . Skid Tests on a Select Group of Bicycle Helmets to Determine their Head–Neck Protective Characteristics. Lansing, MI: Michigan Department of Public Health, 1991.

Hodgson VR . Impact, Skid, and Retention Tests on a Representative Group of Bicycle Helmets to Determine their Head–Neck Protective Characteristics. Lansing, MI: Michigan Department of Public Health, 1990.

Allen BL, Ferguson Jr RL, Lehmann TR, O'Brien RP . A mechanistic classification of closed, indirect fractures and dislocations of the lower cervical spine. Spine 1982; 7: 1–27.

Yoganandan N, Sances Jr A, Maiman DJ, Myklebust JB, Pech P, Larson SJ . Experimental spinal injuries with vertical impact. Spine 1986; 11: 855–860.

Richter M, Dietmar O, Lehmann U, Chinn B, Schuller E, Doyle D et al. Head injury mechanisms in helmet-protected motorcyclists: prospective multicenter study. J Trauma Inj Infect Crit Care 2001; 51: 949–958.

Pinchbeck GL, Clegg PD, Proudman CJ, Morgan KL, French NP . Case–control study to investigate risk factors for horse falls in hurdle racing in England and Wales. Vet Rec 2003; 152: 583–587.

Richards MK . Biofidelic manikin neck. US patent no. 5 122 692 1992.

First Technology Safety Systems Website at http://ftss.com/pcat/h3-50m.cfm.

O'Connor PJ . Motorcycle helmets and spinal cord injury: helmet usage and type. Traffic Inj Prev 2005; 6: 60–66.

Acknowledgements

We acknowledge support from the Missouri Spinal Cord Injuries Research Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Engsberg, J., Standeven, J., Shurtleff, T. et al. Spinal cord and brain injury protection: testing concept for a protective device. Spinal Cord 47, 634–639 (2009). https://doi.org/10.1038/sc.2009.1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/sc.2009.1

Keywords

This article is cited by

-

Evaluation of the Fall Protection of Type I Industrial Helmets

Annals of Biomedical Engineering (2022)