Abstract

Highlighted by the safe operation and stable performances, titanium oxides (TiO2) are deemed as promising candidates for next generation lithium-ion batteries (LIBs). However, the pervasively low capacity is casting shadow on desirable electrochemical behaviors and obscuring their practical applications. In this work, we reported a unique template-assisted and two-step atomic layer deposition (ALD) method to achieve TiO2@Fe2O3 core-shell nanotube arrays with hollow interior and double-wall coating. The as-prepared architecture combines both merits of the high specific capacity of Fe2O3 and structural stability of TiO2 backbone. Owing to the nanotubular structural advantages integrating facile strain relaxation as well as rapid ion and electron transport, the TiO2@Fe2O3 nanotube arrays with a high mass loading of Fe2O3 attained desirable capacity of ~520 mA h g−1, exhibiting both good rate capability under uprated current density of 10 A g−1 and especially enhanced cycle stability (~450 mA h g−1 after 600 cycles), outclassing most reported TiO2@metal oxide composites. The results not only provide a new avenue for hybrid core-shell nanotube formation, but also offer an insight for rational design of advanced electrode materials for LIBs.

Similar content being viewed by others

Introduction

Lithium-ion batteries (LIBs) have been regarding as predominant power sources due to their excellent power-energy reliability, long cycle life and environmental benignity1,2,3. However, to date, their performance still lags behind the development of emerging applications, such as electric vehicles and multifunctional portable electronics, which still remains as the major hurdle for its large scale implementation in the future. As a vital part of LIBs, anode materials cast great influence on overall performance and need to be equipped with higher capacity, better rate capability and outstanding cycle ability4,5. In this sense, conventional graphite electrodes are trapped in low specific capacity (372 mA h g−1, as well as other issues, such as inferior power delivery and potential safety hazards resulted from low operating voltage (below 0. 2 V versus Li/Li+)6,7. Nano-scaled metal oxides (SnO2, TiO2, Fe2O3, Fe3O4, etc.) hold great promise as available alternative anode materials8,9, exhibiting relatively high specific capacity, nontoxicity, high corrosion resistance, low-cost processing and simplicity of syntheses10,11.

Amongst all, TiO2-based materials attracted a lot of attention and stimulated extensive researches based on their excellent merits serving as LIBs anodes. TiO2 possesses safe and stable working plateau potential (about 1.5–1.75 V versus Li/Li+) without intense decomposition of electrolyte. Furthermore, taking advantage of favorable crystallographic characteristics and surface activity with negligible volume change during charging/discharging processes, TiO2 material shows good structural stability, stable voltage output and long lifespan12,13,14. Nevertheless, it is regretted that TiO2 only delivers a low theoretical capacity (only 335 mA h g−1), which is even inferior to graphite15,16. On the other hand, as an another family member of transition metal oxides, Fe2O3 is endowed a theoretical capacity as high as 1005 mA h g−1, showing great prospect towards high energy anodes11. Frustratingly, accompanying the multi-electron reaction, concomitant repeating formation of metal and Li2O matrix will lead to dramatic volume variation and finally result in electrode pulverization and drastic capacity fading17,18. Apparently, the complementary features of these two oxides allow artful design of corresponding hybrid structures and lead to large numbers of delicate fabrication focusing TiO2 and Fe2O3 smart nanostructures15,19.

It is acknowledged that hybrid TiO2 with high-capacity metal oxides or carbon matrix is an efficient route to improve the electrochemical performance20,21,22. Till now, various nanostructured TiO2/Fe2O3 composites are taken up into anode materials23,24,25, showing improvement on capacity as well as upgrading on cycling stability. However, in most cases, the hybrid structures usually deliver unsatisfying performance than expected, especially for deficient rate ability and low capacity, which are mainly ascribed to insufficient contact at interfaces, large share of carbon constituent as conductive and stuffed component with long transport distance. As summarized, most literatures on TiO2@metal oxides as anodes for LIBs, e.g. TiO2@MnO2 nanowire array, TiO2@Fe2O3 nanorod array, and TiO2@Co3O4 nanobelt array, were normally tested at low current densities under 2.0 A/g, and exhibited depressing capacities below 300 mA h g−1 once the current density reaches over 1.6 A/g25. Moreover, uncontrollable synthesis makes it hard to achieve optimal balance in the synergistic effect. Herein, we present a binder-additive-free TiO2/Fe2O3 core-shell nanotubular arrays as high performance electrode through a unique method combining hydrothermal and stepwise atomic layer deposition (ALD). First of all, this 3D nanotubular architecture leads to a much larger surface area with adequate electrolyte penetration and direct 1D pathway for electron transport with also neighboring space to accommodate volumetric change of electrode materials3,26,27. Compared with traditional array structure, this core-shell nanotube design is further vested with friendly interface between components along with continuously intimate contact, more efficient ion and electron transport within hollow arrays as well as double-side area for high loading of Fe2O328,29. Particularly, ADL facilitates facile construction of Fe2O3/TiO2 interface and controllable loading to investigate synergistic effects30,31. With the optimal effect of Fe2O3 coating, hybrid electrode exhibits outstanding electrochemical performance with especially outstanding cycle stability (~450 mA h g−1 after 600 cycles) and superb rate capability (up to 10 A g−1 charging), demonstrating great potential as excellent anode alternative for high performance LIBs.

Results

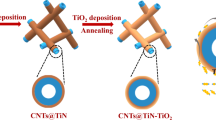

The fabrication process of hollow TiO2@Fe2O3 core/shell nanotube arrays on Ti foil substrates is illustrated in Fig. 1. The sacrificial template of Co2(OH)2CO3 nanowire arrays were firstly synthesized on Ti foils through a hydrothermal reaction. TiO2 was uniformly deposited on the surface of the nanowire arrays, followed by etching of Co2(OH)2CO3 templates. Finally, an outmost layer of Fe2O3 was uniformly grown intimately onto the double-side of TiO2 nanotube architectures with thickness (mass) controllable synthesis precisely regulated by ALD cycles.

The overall crystal structure and phase purity of three samples were characterized by XRD. Shown in Fig. 2a, it is clear that one set of diffraction peaks located at 25.2°, 38.5°, 48.0°, 55.0° and 82.6° correspond to (101), (112), (200), (211) and (224) planes of anatase TiO2 (JCPDS no. 21-1272). Additionally, two diffraction peaks at 35.6° and 77.7° with weaker intensity are indexed to (110) and (306) planes of hexagonal α-Fe2O3 (JCPDS no. 33-0664). Accordingly, Fe2O3 proportions are calculated as 25.1 wt%, 33.6 wt% and 44.6 wt% for TiO2@Fe2O3 samples by increasing ALD cycles to 200, 600 and 1000 cycles, which is in good accordance with the evolution of diffraction intensity in XRD and Raman spectra (Figure S1). Except for patterns of Ti foil substrate, no impurity peaks were observed in the XRD patterns, affirming the existence of bi-phase oxide crystal structures for the active materials without any by-products.

Field emission scanning electron microscopy (FESEM) was utilized to investigate morphological evolution of bare TiO2 to TiO2@Fe2O3 samples (Figure S2a–d). The pure TiO2 material exhibits dense and uniform nanotube arrays without agglomeration of large particles, laying good foundation for high mass loading of active materials. After coating of Fe2O3 onto the surface, these randomly oriented nanotube arrays of TiO2@Fe2O3-600 across each other to form a highly interconnected network (Fig. 2b), which is favorable for the electron conduction across the whole electrode32,33. Under higher magnification in Fig. 2c, hollow interiors are discerned for these nanotubes. Even after coating of ALD cycles, the tubular architecture could still be maintained, which is clearly shown from open-ended nanotubes. These open structures with inside perforative channels are conductive to the electrolyte infiltration and will largely benefit ion migration during electrochemical process34. The overall cross-section image of TiO2@Fe2O3-600 manifests array length of micron order with perfect attachment and connection to Ti substrate (Fig. 2d).

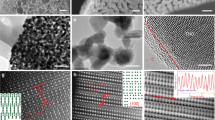

More detailed texture and structure are revealed by transmission electron microscopy (TEM) and schematic illustration of one single TiO2@Fe2O3 nanotube (Fig. 3a), identified with characteristic hollow of the nanotube and with diameter of around 100 nm (Fig. 3b). Further enlarged at the edge in Fig. 3c, high-resolution TEM (HRTEM) images focusing on the hetero-junction region display two distinct sets of lattice fringe spacing as 0.27 and 0.35 nm, matching well with the (104) plane of the hexagonal α-Fe2O3 and the (101) plane of the anatase TiO2, respectively. Corresponding selected area electronic diffraction (SAED, Fig. 3d) pattern further confirms the coherent existence of well-crystallized TiO2 and Fe2O3 structures, suggesting the success building of intimate interaction at the interface. The obviously spotted diffraction rings are in well correspondence with (110) and (211) planes of α-Fe2O3, together with the (211) and (200) planes of anatase TiO2, which is consistent with the XRD analysis. Moreover, element mapping of Fig. 3f–i derived from dark-field SEM (Fig. 3e) confirms that all the elements are homogeneously dispersed within the overall nanotube. It is noted that distributions of Fe and O confirm a wrapped picture around the element of Ti, providing another evidence for the Fe2O3-coated core-shell structure.

To determine the chemical compositions and surface bond states of the obtained materials, XPS test was conducted on the representative TiO2@Fe2O3-600 sample. From a wide survey scan in Fig. 4a, peaks of C 1 s, O 1 s, Ti 2p and Fe 2p were detected, which is accordance with the EDS measurement (Figure S3). The C1s peak originates from adventitious carbon25. High resolution spectrum of Fe 2p is comprised of two distinct peaks around 711 eV and 724.5 eV (Fig. 4b), which correspond well to the Fe 2p3/2 and 2p1/2 with satellite lines. The spectrum is consistent with the characteristic of Fe3+ in α-Fe2O324,25,35, indicating no reductive component consisting of Fe2+ were generated within ALD process. As shown in Fig. 4c, the binding energy of Ti 2P1/2 and Ti 2P3/2 core levels are observed at approximately 458.9 and 464.6 eV with ~6.3 eV peak splitting, confirming TiIV state in the anatase TiO223,25. The spectrum of O1s core level is shown in Fig. 4d, where binding energy peaks at 531.4 and 533.1 eV possibly originate from bonded hydroxyl groups and surface absorbent, respectively36,37. As for the broad peak centered at 529.9 eV, it is attributed to metal-bonding in both oxides.

The cyclic voltammetry (CV) was carried out firstly to explore the electrochemical behavior of the binary oxides structure, while the representative curve is shown in Fig. 5a. During the cathodic scan process, each of the TiO2@Fe2O3 arrays exhibits three reduction peaks around 1.75 V, 1.4 V and 0.8 V. The first peak is ascribed to the phase transition from tetragonal TiO2 to orthorhombic LixTiO223, which is consistent with the behavior of bare TiO2. The second peak is associated with the formation of cubic Li2Fe2O338. The third peak reflects the complete reduction from Fe2+ to Fe0 as well as generation of amorphous Li2O39. For the anodic scan, oxidized peaks centered around 1.5–2.5 V correspond to the successively reversible process, including oxidation of Fe0 to Fe3+, delithiation of LixTiO2 as well as conversion of Li2O. To investigate the influence of mass balance, TiO2 with different amount of Fe2O3 coating were synthesized and systematically studied. Figure S4 describes the discharge-charge curves for the first cycle at a current density of 0.1 A g−1 (0.005–3 V vs. Li/Li+), wherein the similar voltage plateaus consistent with CV scans are identified (Figure S5). For the bare TiO2 nanotubes, the initial discharge and charge capacities are limited to 307 and 173 mA h g−1, respectively. By contrast, TiO2@Fe2O3 composites exhibited noticeable improvement. As for TiO2@Fe2O3 samples, the charge capacity raises along with the amount of Fe2O3 coating. When it comes to TiO2@Fe2O3-1000, the initial discharge and charge capacities can reach up to 878 and 590 mA h g−1, with the irreversible capacity loss cut down from 43.7% to 32.8%, which is ascribed to good electrochemical reversibility of in situ generated metal nanoparticles. Considering the benign and intimate connection, it is reasonable that the Fe0 nanoparticles produced at the interface between TiO2 and Fe2O3 can advance the reversibility of reactions and further result in a high reversible capacity. The TiO2@Fe2O3 hybrid electrodes all show higher capacity than bare TiO2 nanotube electrode owing to the introduction of high-capacity Fe2O3. Particularly shown in Fig. 5c, the TiO2@Fe2O3-600 electrode maintains a high capacity delivery of 436 mA h g−1 even after 600 cycles with above 87% capacity retention, which are clearly distinguished from previous reported hybrid TiO2-Fe2O3 materials operated less than 200 cycles23,24,25,40. Furthermore, the coulombic efficiency rapidly increases and stays at a high level of around 100% in the subsequent cycles. As revealed in Figure S6, the morphology and texture of the nanotube architecture maintains well after 20 discharging/charging cycles.

(a) CV curves of pristine TiO2 and TiO2@Fe2O3-600 samples at a scan rate of 0.5 mV/s (0.005–3 V). (b) Rate performance at multiple current densities from 0.1 A/g to 10 A/g then back to 0.1 A/g. (c) Capacity vs. cycle number plots and corresponding coulombic efficiency of the TiO2@Fe2O3-600 at a current density of 0.1 A g−1.

For comprehensive understanding of electrochemical performance, rate capability tests were conducted with different current densities from 0.1 A g−1 to 10 A g−1 (Fig. 5b). It is encouraging that TiO2@Fe2O3-600 sample exhibits outstanding rate performances, with high capacity of ~390 and ~330 mA h g−1 even at uprated 5 and 10 A g−1, which is more than three-fold of bare TiO2 electrodes. Energy storage devices could be served at large currents is highly required for realistic circumstance, while those reported TiO2/Fe2O3 composites are always operated under current densities of 1.6 A g−123,24,25. Such outstanding rate capability of the TiO2@Fe2O3 core- shell nanotube arrays benefits from the unique 1D tubular structure with fast kinetics established from hollow interior. By contrast, although TiO2@Fe2O3-1000 sample demonstrates attracting capacity at a low rate of 0.1 A g−1, it drops sharply with escalating currents and is much inferior to TiO2@Fe2O3-600 above the current density of 0.3 A g−1.

Discussion

Overall, high capacity of Fe2O3 component elevates the holistic lithium storage, while its instability is compensated by the robust scaffold of TiO2 nanotubes. These complementary properties may lead to trade-off wherein optimal content are critical yet still need to be precisely studied. Taking advantage of the precisely controllable ALD method, it is found herein that excessive loading of Fe2O3 will lead to unfavorable attachment with TiO2, thus impair the structural stability and electrical conductivity of entire composite along with cycling, though high capacity is obtained at a higher mass loading. With a proper mass loading of 33.6 wt%, TiO2@Fe2O3-600 achieve favorable contact with TiO2 substrate while still maintains considerable lithium storage sites, beneficial for the superb fast-stable energy storage balance, which can be regarded as general guidance for materials design of TiO2-based binary oxides. Furthermore, after returning to the initial current density of 0.1 A g−1, all samples recover back to the original capacity, confirming that the robustness of TiO2 arrays matrix in hybrid electrode materials even under high rates circumstance.

To prove the 1D advantage and further understand the optimal Fe2O3-TiO2 balance, the electrochemical impedance spectra are conductive to illuminate kinetics difference (Figure S7). The TiO2@ Fe2O3-600 manifests the fastest ion diffusion than other hybrid materials judging from Warburg impedance values (Zw), demonstrating the efficient ion diffusion within this optimized thickness of coating-wall. It is mentioned that 1D nanotube structure is profitable for the fast kinetics by improving the electrolyte infiltration as well as shorten ion and electron immigration distance, also offering high loading of electrochemical-active sites through double sides coating and mitigation against the volume change of Fe2O3. Also, optimum mass loading endows TiO2@Fe2O3-600 with the best complementary effect for superb and more stable electrochemical performances.

In this work, binder-additive-free TiO2@Fe2O3 nanotube arrays with double-wall coating are prepared through hydrothermal and controllable ALD methods. In addition to the traditional advantages of 1D structure such as fast transport and good electrolyte contact, the rational design of hollow TiO2 tube provides a robust backbone to efficiently hold structural stability and the introduction of double-wall Fe2O3 coating largely enhance overall energy storage. Particularly, taking advantage of this precisely controllable ALD, an optimal proportion is found to desirably maximize the complementary effects within components, which offers deeper understanding on merits of this binary oxide design. As a result, the hybrid electrode delivers outstanding electrochemical performance in terms of high reversible capacity (520 mA h g−1 at 100 mA g−1) over three-fold of bare TiO2 electrodes and especially long term stability of >87% capacity retention after 600 cycles as well as superb rate capability that could be reversibly operated even at uprated 10 A g−1. The presented synthetic techniques of thin-films arrayed electrode are readily extended to other alternative multi-components electrode and are promising for fabricating micro-scale energy storage devices in the future.

Methods

Synthesis of Co2(OH)2CO3 nanowire arrays on Ti substrates

Co2(OH)2CO3 nanowire arrays were prepared through a simple hydrothermal method. Briefly, 0.6 g Co(NO3)·6H2O, 0.15 g NH4F and 0.6 g CO(NH2)2 were dissolved in 70 mL water under magnetic stirring to form homogeneous solution. After cleaning by successive sonication in ethanol, acetone and deionized water, Ti foil substrate was immerged in the above solution and placed into Teflon-lined stainless steel autoclaves. The autoclave was heated at 105 °C for 5 h and then allowed to cool down to room temperature naturally. Then obtained foil was softly rinsed with DI water several times and dried in air at 80 °C.

Synthesis of hollow TiO2@Fe2O3 core/shell nanotube arrays

Firstly, TiO2 was deposited on the as-prepared Co2(OH)2CO3 nanowires using a hot wall ALD system with TiCl4 and H2O as the Ti and O precursors. Deposition was conducted at 400 °C while flow rates of TiCl4 and H2O were set as 0.6 cm3/pulse and 0.5 cm3/pulse, respectively. The processing pressures were ~40 Pa in the deposition steps and 27 Pa in the pump-down steps. Then, the products were immersed into 0.6 M HCl solution for 12 h. Co2(OH)2CO3 was therein removed and hollow TiO2 nanotube arrays were obtained. Coating Fe2O3 to form final core shell structure was realized through further ALD process with water and homoleptic dinuclear irontert-butoxide complex (Fe2(OtBu)6) as Fe and O precursors, respectively. Controllable syntheses were achieved via different coating loops wherein three samples with 200, 600 and 1000 cycles were conducted at 150 °C, respectively under the same conditions, which are denoted as TiO2@Fe2O3-200, TiO2@Fe2O3-600, TiO2@Fe2O3-1000, respectively.

Materials characterization

The phase purity and crystal structure of products were characterized by X-ray powder diffraction (XRD, Bruker-AXS D8 Advance, Cu Kα radiation, λ = 0.15418 nm). Morphologies and structures were examined using a field-emission scanning electron microscope (FESEM, Quant 250FEG) equipped with energy dispersive spectrometer (EDS) function, a transmission electron microscope (TEM, FEI Philips CM300 UT/FEG) and a high-resolution transmission electron microscope (HRTEM, JEOL JEM-2010) with energy-dispersive X-ray spectroscopy (EDS). The chemical bonds were analyzed through X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi).

Electrochemical Measurements

Electrochemical measurements were carried out on Swagelok cells, assembled in an Ar-filled glove box at room temperature. Pure lithium foils were used as both the counter/reference electrodes and the Ti substrate supported TiO2 or TiO2@Fe2O3 (with Fe2O3 coating deposition of different cycles) were firstly cut into small pieces with the size of 0.5 ∗ 0.5 cm and then directly used as the working electrodes without extra binders or conductive additives. 1 M solution of LiPF6 in ethylene carbonate and diethyl carbonate (EC/DEC = 1:1 v/v) was used as the electrolyte. The galvanostatic charge-discharge measurements were performed on LANDCT2001A battery test system at different current densities from 0.1 A g−1 to 10 A g−1 with a cut-off voltage window of 0.005–3 V. Cyclic voltammograms (CV) were measured at a scan rate of 0.5 mV/s with the same voltage range. Electrochemical impedance spectroscopy (EIS) measurements were recorded in the frequency range of 100 kHz to 10 mHz, with an AC amplitude of 5 mV. Both CV and EIS were conducted on a CHI660D electrochemical workstation.

Additional Information

How to cite this article: Zhong, Y. et al. Controllable Synthesis of TiO2@Fe2O3 Core-Shell Nanotube Arrays with Double-Wall Coating as Superb Lithium-Ion Battery Anodes. Sci. Rep. 7, 40927; doi: 10.1038/srep40927 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Bruce, P. G., Scrosati, B. & Tarascon, J. M. Nanomaterials for rechargeable lithium batteries. Angew. Chem. Int. Ed. 47, 2930–2946 (2008).

Zhong, Y., Yang, M., Zhou, X. & Zhou, Z. Structural design for anodes of lithium-ion batteries: emerging horizons from materials to electrodes. Mater. Horiz. 2, 553–566 (2015).

Goodenough, J. B. & Kim, Y. Challenges for Rechargeable Li Batteries. Chem. Mater. 22, 587–603 (2010).

Wang, Y., Li, H., He, P., Hosono, E. & Zhou, H. Nano active materials for lithium-ion batteries. Nanoscale 2, 1294–1305 (2010).

Wu, H. & Cui, Y. Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today 7, 414–429 (2012).

Scrosati, B. & Garche, J. Lithium batteries: Status, prospects and future. J. Power Sources 195, 2419–2430 (2010).

Guo, X. L. et al. Engineering of three dimensional (3-D) diatom@TiO2@MnO2 composites with enhanced supercapacitor performance. Electrochim. Acta 190, 159–167 (2016).

Li, F. et al. Low-cost high-performance asymmetric supercapacitors based on Co2AlO4@MnO2 nanosheets and Fe3O4 nanoflakes. J. Mater. Chem. A 4, 2096–2104 (2016).

Reddy, M. V., Subba Rao, G. V. & Chowdari, B. V. Metal oxides and oxysalts as anode materials for Li ion batteries. Chem. Rev. 113, 5364–5457 (2013).

Zhang, L., Wu, H. B. & Lou, X. W. D. Iron-Oxide-Based Advanced Anode Materials for Lithium-Ion Batteries. Adv. Energy Mater. 4, 1300958 (2014).

Zhang, Y., Tang, Y., Li, W. & Chen, X. Nanostructured TiO2-based Anode Materials for High-performance Rechargeable Lithium-ion Batteries. ChemNanoMat 2, 764–775 (2016).

Ren, H. et al. Multishelled TiO2 hollow microspheres as anodes with superior reversible capacity for lithium ion batteries. Nano. Lett. 14, 6679–6684 (2014).

Ren, Y. et al. Nanoparticulate TiO2(B): an anode for lithium-ion batteries. Angew. Chem. Int. Ed. 51, 2164–2167 (2012).

Gao, L., Hu, H., Li, G., Zhu, Q. & Yu, Y. Hierarchical 3D TiO2@Fe2O3 nanoframework arrays as high-performance anode materials. Nanoscale 6, 6463–6467 (2014).

Wang, N., Yue, J., Chen, L., Qian, Y. & Yang, J. Hydrogenated TiO2 Branches Coated Mn3O4 Nanorods as an Advanced Anode Material for Lithium Ion Batteries. ACS Appl. Mater. Interfaces 7, 10348–10355 (2015).

Gao, X.-P. & Yang, H.-X. Multi-electron reaction materials for high energy density batteries. Energy Environ. Sci. 3, 174–189 (2010).

Wu, Z.-S. et al. Graphene/metal oxide composite electrode materials for energy storage. Nano Energy 1, 107–131 (2012).

Wang, B. et al. Porous Co3O4 nanowires derived from long Co(CO3)0.5(OH)·0.11H2O nanowires with improved supercapacitive properties. Nanoscale 4, 2145–2149 (2012).

Yan, Y., Li, B., Guo, W., Pang, H. & Xue, H. Vanadium based materials as electrode materials for high performance supercapacitors. J. Power Sources 329, 148–169 (2016).

Zhou, L. et al. Morphology-controlled construction of hierarchical hollow hybrid SnO2@TiO2 nanocapsules with outstanding lithium storage. Sci. Rep. 5, 15252 (2015).

Zheng, P., Liu, T., Su, Y., Zhang, L. & Guo, S. TiO2 nanotubes wrapped with reduced graphene oxide as a high-performance anode material for lithium-ion batteries. Sci. Rep. 6, 36580 (2016).

Luo, Y. et al. Seed-assisted synthesis of highly ordered TiO2@α-Fe2O3 core/shell arrays on carbon textiles for lithium-ion battery applications. Energy Environ. Sci. 5, 6559 (2012).

Luo, J. et al. Rationally Designed Hierarchical TiO2@Fe2O3 Hollow Nanostructures for Improved Lithium Ion Storage. Adv. Energy Mater 3, 737–743 (2013).

Xia, H. et al. Hierarchical TiO2-B nanowire@α-Fe2O3 nanothorn core-branch arrays as superior electrodes for lithium-ion microbatteries. Nano Res 7, 1797–1808 (2014).

Wang, J., Du, N., Zhang, H., Yu, J. & Yang, D. Large-Scale Synthesis of SnO2 Nanotube Arrays as High-Performance Anode Materials of Li-Ion Batteries. J. Phys. Chem. C 115, 11302–11305 (2011).

Wang, Y., Xia, H., Lu, L. & Lin, J. Excellent performance in lithium-ion battery anodes: rational synthesis of Co(CO3)0.5(OH)0.11H2O nanobelt array and its conversion into mesoporous and single-crystal Co3O4 . ACS Nano 4, 1425–1432 (2010).

Tang, Y. et al. Mechanical force-driven growth of elongated bending TiO2-based nanotubular materials for ultrafast rechargeable lithium ion batteries. Adv. Mater. 26, 6111–6118 (2014).

Su, L., Jing, Y. & Zhou, Z. Li ion battery materials with core-shell nanostructures. Nanoscale 3, 3967–3983 (2011).

George, S. M. Atomic layer deposition: an overview. Chem. Rev. 110, 111–131 (2010).

Memarzadeh Lotfabad, E. et al. ALD TiO2 coated silicon nanowires for lithium ion battery anodes with enhanced cycling stability and coulombic efficiency. Phys. Chem. Chem. Phys. 15, 13646–13657 (2013).

Li, Y., Tan, B. & Wu, Y. Mesoporous Co3O4 nanowire arrays for lithium ion batteries with high capacity and rate capability. Nano. Lett. 8, 265–270 (2008).

Xia, X. et al. High-quality metal oxide core/shell nanowire arrays on conductive substrates for electrochemical energy storage. ACS Nano 6, 5531–5538 (2012).

Liu, J., Song, K., van Aken, P. A., Maier, J. & Yu, Y. Self-supported Li4Ti5O12-C nanotube arrays as high-rate and long-life anode materials for flexible Li-ion batteries. Nano. Lett. 14, 2597–2603 (2014).

Yao, X. et al. Porous hematite (α-Fe2O3) nanorods as an anode material with enhanced rate capability in lithium-ion batteries. Electrochem. Commun. 13, 1439–1442 (2011).

Yang, Z. et al. Synthesis of uniform TiO2@carbon composite nanofibers as anode for lithium ion batteries with enhanced electrochemical performance. J. Mater. Chem. 22, 5848 (2012).

Dupin, J.-C., Gonbeau, D., Vinatier, P. & Levasseur, A. Systematic XPS studies of metal oxides, hydroxides and peroxides. Phys. Chem. Chem. Phys. 2, 1319–1324 (2000).

Jain, G., Balasubramanian, M. & Xu, J. J. Structural studies of lithium intercalation in a nanocrystalline α-Fe2O3 compound. Chem. Mater. 18, 423–434 (2006).

Chen, S., Bao, P. & Wang, G. Synthesis of Fe2O3-CNT-graphene hybrid materials with an open three-dimensional nanostructure for high capacity lithium storage. Nano Energy 2, 425–434 (2013).

Li, L., Zhang, J. & Zhu, Q. A novel fractional crystallization route to porous TiO2-Fe2O3 composites: large scale preparation and high performances as a photocatalyst and Li-ion battery anode. Dalton Trans. 45, 2888–2896 (2016).

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 51572129, U1407106), International S&T Cooperation Program of China (No. 2016YFE0111500), QingLan Project of Jiangsu Province, A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), and the Fundamental Research Funds for the Central Universities (No. 30915011204).

Author information

Authors and Affiliations

Contributions

H.X. and Y.Z. designed project and carried out data analyses. Y.M., Q.G., and J.L. performed the materials characterization. Y.W. participated in analyzing the results. M.Y. wrote the manuscript. All authors reviewed and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhong, Y., Ma, Y., Guo, Q. et al. Controllable Synthesis of TiO2@Fe2O3 Core-Shell Nanotube Arrays with Double-Wall Coating as Superb Lithium-Ion Battery Anodes. Sci Rep 7, 40927 (2017). https://doi.org/10.1038/srep40927

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep40927

This article is cited by

-

Self-cleaning and photocatalytic properties of eco-friendly clay-based facing bricks from industrial and natural wastes

Environmental Science and Pollution Research (2023)

-

Hydrogenated titanium dioxide modified core–shell structure Fe3O4@NiO for lithium-ion battery anode material

Ionics (2023)

-

Hierarchical Fe2O3 hexagonal nanoplatelets anchored on SnO2 nanofibers for high-performance asymmetric supercapacitor device

Scientific Reports (2022)

-

Facile synthesis of monodispersed α-Fe2O3 cubes as a high-performance anode material for lithium-ion batteries

Ionics (2021)

-

Free-standing transition metal oxide electrode architectures for electrochemical energy storage

Journal of Materials Science (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.