Abstract

Herein we report superior dye-adsorption performance for flower-like nanostructure composed of two dimensional (2D) MoS2 nanosheets by a facile hydrothermal method, more prominent adsorption of cationic dye compared with anodic dye indicates the dye adsorption performance strongly depends on surface charge of MoS2 nanosheets. The adsorption mechanism of dye is analyzed, the kinetic data of dye adsorption fit well with the pseudo-second-order model, meanwhile adsorption capability at different equilibrium concentrations follows Langmuir model, indicating the favorability and feasibility of dye adsorption. The regenerable property for MoS2 with full adsorption of dye molecules by using alkaline solution were demonstrated, showing the feasibility of reuse for the MoS2, which is promising in its practical water treatment application.

Similar content being viewed by others

Introduction

During the past decade, organic dye is serious water pollutant which generally present in different industrial fields, such as leather goods, cosmetics, textile, paper, etc.1,2,3,4. Most of them are highly dissolved in aqueous solution and quite toxic, which can cause serious damage to the environment and human beings. Therefore, various techniques for the removal of dye have been developed, such as precipitation5, photocatalysis6,7,8 and adsorption9,10. Nowadays, photocatalysis has received widespread attention, but the photocatalysts may cause secondary pollutants in aqueous solution during the chemical reaction11,12. Hence, adsorption technique deserves extensive investigation due to its low consumption of energy, simple operation, high efficiency, low cost as well as the wide suitability for diverse dyes13,14. As most common adsorbents, polymer microspheres, mesoporous SiO2, and activated carbon were synthesized to study their adsorption properties15,16,17. Though activated carbon is widely used as an excellent adsorbent due to its large surface area and high adsorption capacity18,19, its high cost and regeneration difficulties restricted its application seriously. Therefore, it is necessary to develop low cost and regenerable adsorbents to meet the requirements of actual application.

Recently, two dimensional (2D) materials which own large surface areas and abundant active sites have been one of the most extensively studied materials20,21. As a typical representative, graphene oxide and its derivatives are considered as ideal adsorbents for the treatment of organic dye, heavy metal, and bisphenol from the water, etc.22,23,24. However, the synthetic method of graphene oxide involves in the strong acid/oxidant consumption, and its production efficiency is very low25. Recently, molybdenum disulfide (MoS2) has attracted particular attention in electronics, photonics, and optoelectronics applications, including hydrogen evolution reaction26, field-effect transistor27, and photodetectors28, due to its unique physical, optical and electrical properties. Moreover, MoS2 can be easily synthesized on a large scale with low cost, such as hydrothermal, chemical vapor deposition methods29,30. As a typical 2D material, MoS2 should be an ideal adsorbent. However, the report about its environmental remediation is scarce, hence it is of significant interest to examine the role and mechanism of dye adsorption based on MoS2 in detail.

Herein, flower-like MoS2 nanosheets was fabricated by a simple hydrothermal process, and then annealed in Ar atmosphere at 400 °C to improve the crystallinity and remove the organic linkers on the surface. The study showed that the prepared MoS2 owned superior dye (Rhodamine B, Methylene Blue, Methyl Orange) adsorption behavior. Furthermore, dye adsorption performance and adsorption mechanism are evidenced by a series of different dye adsorption experiments. Interestingly, after being washed by the solution of PH = 14, the MoS2 samples recover its superior adsorption ability, exhibiting its regenerable property.

Results

Characterization of MoS2 samples

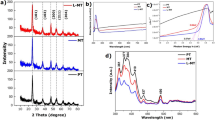

The scanning electron microscopy (SEM) and transmission electron microscopy (TEM) images of MoS2 architecture annealed in Ar atmosphere at 400 °C are displayed in Fig. 1. Figure 1a,b shows the average size of the MoS2 nanostructure is ~200 nm, and such three dimensional flower-like structure owns the large surface area, which is significantly beneficial to the effective adsorption. In Fig. 1d, the high-resolution TEM (HRTEM) image shows that the distinguished lattice spacing is 0.62 nm, which corresponds to the (002) plane of MoS2. Moreover, the crystal fringes of (002) plane along the curled edge may indicate the formation of 3–8 layered MoS231. Figure 2 shows the X-ray diffraction (XRD) pattern and Raman spectrum of the MoS2. From Fig. 2a, all the diffraction peaks can be indexed to hexagonal MoS2 phase (JCPDS card No. 37–1492). The peaks at 12.0°, 33.5°, 39.7° and 59.2° can be ascribed to (002), (110), (103) and (110) planes of MoS2, respectively. As shown in Fig. 2b, two characteristic Raman active modes of  and A1g are located at 377 cm−1 and 402 cm−1, which associate with the vibration of sulfides in the out-of-plane direction32. The big discrepancy between

and A1g are located at 377 cm−1 and 402 cm−1, which associate with the vibration of sulfides in the out-of-plane direction32. The big discrepancy between  and A1g means the formation of relatively thick MoS2 layer, which is accordance with the HRTEM results.

and A1g means the formation of relatively thick MoS2 layer, which is accordance with the HRTEM results.

In general, large surface area which provides more active sites is helpful to the diffusion of dye molecules, consequently improving the adsorption capacity during the dye removal process33. Herein, the N2 adsorption-desorption isotherms and the corresponding Barratt-Joyner-Halenda (BJH) adsorption curve for the obtained MoS2 were displayed in Fig. 3. The samples show the type V sorption isotherm with a H3 hysteresis loop, indicating the presence of well-developed mesoporous structure and irregular pores in the samples34. The pore size of MoS2 calculated by the BJH method ranges from 5 to 20 nm with a broad distribution (inset in Fig. 3). The Brunauer-Emmett-Teller (BET) analysis reveals the surface area (SBET) of 63.9 m2/g, total pore volume (VT) of 0.31 cm3/g, and average pore width (D) of 19.5 nm, as shown in Table 1. A relatively high specific surface area (~64 m2 g−1) of MoS2 can provide more adsorption sites, and the relatively large pore size might facilitate the diffusion of dye molecules.

Discussion

As shown in Fig. 4, firstly 20 mg MoS2 was taken to confirm the adsorption capability, almost 100% dyes (Rhodamine B (RhB) and Methylene Blue (MB)) were removed within 10 min in our experiment. However, in order to facilitate to investigate the kinetics and isotherms measurements in different industrial dyes (RhB, MB and Methyl Orange (MO)), 10 mg MoS2 samples were chosen to slow down the adsorption process. The concentration values of RhB, MB and MO were taken from absorbance at 550 nm, 663 nm, and 464 nm, respectively35,36,37. All the experiments were carried in the dark. Figure 5a–c show the changes of UV-vis absorption spectra after MoS2 was added into dye solution, which correspond to the decrease of dye concentration in the solution. Clearly the adsorption process can be divided into two stages in Fig. 5d: the adsorption is very fast due to the high initial dye concentration and unoccupied active adsorption sites at first, then followed by a slow stage, adsorption equilibrium reached. Clearly, the adsorption efficiencies for RhB and MB can achieve almost 100% within 3 h. The color of solution before and after the MoS2 adsorption changed from purple, blue to transparency, indicating high adsorption capacity of MoS2. In comparison, the adsorption ability of MO is relatively weak, just about 60% of MO was adsorbed within 3 h.

To explore the reason why there is huge adsorption difference between cationic and anodic dye, the zeta-potential and FTIR were carried out to study the surface property of MoS2. Figure 6a shows that the obtained MoS2 has negative surface charge above pH 3, and the zeta potential increases towards alkaline PH, which indicates the abundant acidic sites on MoS2 nanosheets38. The functional group (-OH, -COOH) maybe responsible for the surface negative charge, which is evidenced by FT-IR spectrum in Fig. 7. Based on above analysis, electrostatic adsorption could be the main factor to selectively adsorb positive charged dye such as RhB, MB compared with negative charged dye MO. Figure 6b shows the schematic diagram for the adsorption of cationic dye RhB, indicating that the obtained MoS2 can be superior adsorbent for industrial dye, especially for cationic dye.

In terms of the super-high adsorption capability for cationic dyes, RhB and MB were selected as the indicant reagents to examine the adsorption mechanism of MoS2 samples. Herein, the kinetics of these two dye adsorption on MoS2 were analyzed by pseudo-first-order model (Eq. 1) and pseudo-second-order model (Eq. 2)39,40:

where qt denotes the adsorbed amount at any time t, qe denotes the adsorbed amount at equilibrium. k1 and k2 denote the rate constant of pseudo-first-order model, pseudo-second-order model, and intra-particle diffusion model, respectively. The fitting results of the models are all shown in Fig. 8a and b, and the calculated data are displayed in Table 2. qe value calculated by the pseudo-first-order model is significantly smaller than the experimental qe, and the low values of correlation coefficient (R2) of pseudo-first-order model, suggesting the model is not fit to the adsorption process. In contrast, the almost same calculated qe with experimental qe, and the high values of R2 (>98%) make pseudo-second-order model be more applicable, which implied that the overall rate of the adsorption process was controlled by chemisorption41,42.

The Langmuir (Eq. 3) and Freundlich isotherm adsorption model (Eq. 4) were used to further determine the adsorption capability of RhB and MB at different equilibrium concentrations43,44.

where qe is the adsorbed amount of dye at the equilibrium concentration, Ce is the equilibrium solute concentration, Qm is the maximum adsorption capacity and KL is the equilibrium constant of Langmuir. Kf and 1/n are Freundlich constants related to adsorption capacity and adsorption intensity.

Figure 8c and d show the fitting results of the Langmuir isotherm adsorption model, and Freundlich isotherm adsorption model. All the values of isotherm constants are given in Table 2. The R2 values obtained for Langmuir isotherm adsorption model are greater than that of Freundlich isotherm adsorption model, suggesting that the Langmuir isotherm adsorption model is perfectly fit for adsorption equilibrium of RhB, MB on the MoS2 samples.

The basic assumption of Langmuir model is that only one dye molecule could be adsorbed on each adsorption site, and monolayer could form on the surface of the adsorbent, indicating the inter-molecular force and adsorption site decrease with the distance5. Hence, the surface of MoS2 may have identical adsorption activity, thus providing monolayer dye coverage for MoS2 in our experiment. Langmuir dimensionless separation factor RL to determine the favorability and feasibility of adsorption is given in eq. 5:

RL indicates the shape of the isotherm, 0 < RL < 1 represent favorable adsorption process and RL > 1 represent the unfavorable adsorption45,46. As shown in Table 2, all the values of RL are between 0 and 1, suggesting that dye adsorption on the MoS2 samples is favorable.

The adsorption process is mainly controlled by two factors: (1) film diffusion, (2) intra-particle (surface or pore) diffusion47. And intra-particle diffusion kinetic model was used to determine the rate-controlling step of adsorption based on the Weber–Morris equation (eq. 6).

where ki is the intra-particle diffusion rate constant for adsorption at stage, and C is the intercept that represents the boundary layer thickness47. In Fig. 8e, the linearized plots of the adsorption amount versus the square root of time were obtained. The straight lines pass through the origin, indicating intra-particle diffusion processes plays a determinative effect in controlling the rate of adsorption. Three different intra-particle diffusion rate constants for the stepwise adsorption influence the rate-limiting steps, as listed in Table 2. The adsorption process can be explained based on the above analysis as follows: (1) The steep slope k1 represents the fast adsorption process because of the electrostatic interaction between MoS2 and the dye molecules; (2) The slope k2 is more gradual, reflecting the dye molecules diffuse into the inner structure of the adsorbent, which is a slowly diffusing process. (3) The flat slope k3 is attributed to the adsorption process at equilibrium, where the free path of the MoS2 molecules in the pore becomes narrow, and the molecules may also be blocked.

Interestingly, Fig. 9 shows that the adsorption efficiency of RhB for MoS2 with full adsorption of RhB molecules washed with alkaline solution is higher than that for MoS2 washed with de-ionized water, meaning that the MoS2 adsorbents with full adsorption of RhB molecules can be reused easily using different PH alkaline agents to wash, and then the regenerated adsorbents were utilized again to adsorb dye. When PH = 14 alkaline solution was applied, the removal efficiency still remained 83.9% in comparison the efficiency of pure MoS2 is 98.5%, meaning that the adsorption ability can be easily recovered by alkaline solution. According to the zeta potential, the excellent desorption performance at alkaline solution can be attributed that excessive OH− ions compete with the activated adsorption sites of the cationic RhB molecules, leading to the desorption of RhB from MoS2 through ions exchange48. It is confirmed that the feasibility of reuse for the MoS2 with full adsorption of RhB molecules by using alkaline solution, which is applicable in its practical water treatment applications.

Conclusions

In summary, the flower-like MoS2 nanosheets have been synthesized successfully by a simple hydrothermal process, which have superior ability to adsorb various dyes and organic pollutants, especially cationic dyes. The obtained MoS2 samples own the negative zeta potential, resulting in superior adsorption of cationic dye compared with anodic dye, indicating the dye adsorption performance of MoS2 strongly depends on their surface charge. The adsorption mechanism of dye is analyzed, the kinetic data of dye adsorption fit well with the pseudo-second-order model, meanwhile adsorption capability at different equilibrium concentrations follows Langmuir model, indicating the favorability and feasibility of dye adsorption. The excellent reused ability of MoS2 has also been confirmed. As a result, the as-synthesized MoS2 are promising materials suitable for high-performance pollutant scavenger for water treatment.

Methods

Synthesis of MoS2

Typically, 0.23 g of Na2MoO4·2H2O (Sinopharm Chemical Reagent Corp.) and 0.8 g of L-cysteine (Sinopharm Chemical Reagent Corp.) were dissolved in 60 mL of deionized (DI) water after stirring for 40 min at room temperature. And then the solution was transferred into a 100 mL Teflon-lined stainless steel autoclave. The autoclave was sealed tightly and heated at 200 °C for 24 h and cooled naturally after the reaction. After cooling naturally, the black precipitates were collected by centrifugation, washed with DI water and ethanol three times, respectively. The samples were dried in vacuum oven at 60 °C for 10 h, and then were annealed in a conventional tube furnace at 400 °C for 2 h in Ar atmosphere.

Adsorption experiments

All adsorption experiments were carried out in dark and at room temperature. At first, 20 mg MoS2 samples were added into 60 mL of the RhB, MB solution with initial concentration of 10 mg/L to confirm the adsorption capability. For the kinetic experiments, 10 mg of MoS2 was added to 60 mL of RhB, MB, MO solution with initial concentration of 10 mg/L, then 4 mL of the suspension was taken out at certain time intervals (0–180 min). MoS2 samples were separated from the suspension via centrifugation. The measurements of dye concentration were carried out by the Agilent 8453 UV–vis spectrophotometer. For adsorption isotherm measurement, 10 mg of MoS2 samples were added to 60 mL of RhB, MB and MO solution with desired concentration (10, 15, 20, 30, 40, 50 and 60 mg/L), then the suspension was stirred for 24 h. For the readsorption experiment, 10 mg MoS2 samples with full adsorption of RhB molecules washed by different PH were added to 60 mL 10 mg/l RhB solution. The measurements of RhB, MB and MO were analyzed at the absorbance of 550 nm, 663 nm and 464 nm, respectively.

Materials characterization

The morphology and composition of the sample were determined by field-emission scanning electron microscopy (FESEM, JSM-6701F), and high-resolution transmission electron microscopy (TECNAI G2 S-TWIN), and X-ray diffraction using Cu Kα radiation (XRD, Bruker D8-A25). The Fourier transformed infrared (FT-IR) spectra and Raman spectra were characterized on Nexus 470 FT-IR spectrometer and Spex 403 Raman spectrometer. The surface area and pore size distribution were performed by nitrogen adsorption-desorption method at 77 K (Micromeritics Tristar ASAP 3000). The ζ-potentials were determined on a Zetasizer Nano (ZS90).

Additional Information

How to cite this article: Han, S. et al. Superior Adsorption and Regenerable Dye Adsorbent Based on Flower-Like Molybdenum Disulfide Nanostructure. Sci. Rep. 7, 43599; doi: 10.1038/srep43599 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Change history

03 August 2017

A correction has been published and is appended to both the HTML and PDF versions of this paper. The error has not been fixed in the paper.

References

Han, F. et al. Tailored titanium dioxide photocatalysts for the degradation of organic dyes in wastewater treatment: a review. Appl. Catal. A: Gen. 359, 25–40 (2009).

Chen, H., Zhao, J., Wu, J. & Dai, G. Isotherm, thermodynamic, kinetics and adsorption mechanism studies of methyl orange by surfactant modified silkworm exuviae. J. Hazard. Mater. 192, 246–254 (2011).

Liu, F. et al. Liu Native defects in ZnO: effect on dye adsorption and photocatalytic degradation. J. Phys. Chem. C 117, 12218–12228 (2013).

Zhao, J., Ren, W. & Cheng, H. M. Graphene sponge for efficient and repeatable adsorption and desorption of water contaminations. J. Mater. Chem. 22, 20197–20202 (2012).

Toor, M. & Jin, B. Adsorption characteristics, isotherm, kinetics, and diffusion of modified natural bentonite for removing diazo dye. Chem. Eng. J. 187, 79–88 (2012).

Ma, X. C., Dai, Y., Yu, L. & Huang, B. B. Energy transfer in plasmonic photocatalytic composites. Light-Sci. Appl. 5, e16017 (2016).

Han, S. C. et al. One-Step Hydrothermal Synthesis of 2D Hexagonal Nanoplates of α-Fe2O3/Graphene Composites with Enhanced Photocatalytic Activity. Adv. Funct. Mater. 24, 5719–5727 (2014).

Cheng, H. F., Huang, B. B. & Dai, Y. Engineering BiOX(X=Cl, Br, I) nanostructures for highly efficient photocatalytic applications. Nanoscale 6, 2009–2026 (2014).

Li, Y. et al. Comparative study of methylene blue dye adsorption onto activated carbon, graphene oxide, and carbon nanotubes. Chem. Eng. Res. Des. 91, 361–368 (2013).

Zhu, J., Wang, Y., Liu, J. & Zhang, Y. Facile One-Pot Synthesis of Novel Spherical Zeolite–Reduced Graphene Oxide Composites for Cationic Dye Adsorption. Ind. Eng. Chem. Res. 53, 13711–13717 (2014).

Han, S. C. et al. Efficient Self-Assembly Synthesis of Uniform CdS Spherical Nanoparticles-Au Nanoparticles Hybrids with Enhanced Photoactivity. Adv. Funct. Mater. 24, 3725–3733 (2014).

Chen, Z., Liu, S. Q., Yang, M. Q. & Xu, Y. J. Synthesis of Uniform CdS Nanospheres/Graphene Hybrid Nanocomposites and Their Application as Visible Light Photocatalyst for Selective Reduction of Nitro Organics in Water. ACS Appl. Mater. Interfaces 5, 4309–4319 (2013).

Yang, D. J. et al. Titanate nanofibers as intelligent absorbents for the removal of radioactive ions from water. Adv. Mater. 20, 2777–2781 (2008).

Lee, C. K. et al. Application of titanate nanotubes for dyes adsorptive removal from aqueous solution. J. Hazard. Mater. 148, 756–760 (2007).

Nomura, A. & Jones, C. W. Amine-functionalized porous silicas as adsorbents for aldehyde abatement. ACS Appl. Mater. Interfaces 5, 5569–5577 (2013).

Pal, S. et al. Carboxymethyl tamarind-g-poly (acrylamide)/silica: a high performance hybrid nanocomposite for adsorption of methylene blue dye. Ind. Eng. Chem. Res. 51, 15546–15556 (2012).

Lu, Y. et al. Effects of matrix and functional groups on tylosin adsorption onto resins and carbon nanotubes. Water Air Soil Poll. 224, 1372 (2013).

Valix, M., Cheung, W. & McKay, G. Roles of the textural and surface chemical properties of activated carbon in the adsorption of acid blue dye. Langmuir 22, 4574–4582 (2006).

Xiao, J. D. et al. Magnetic porous carbons with high adsorption capacity synthesized by a microwave-enhanced high temperature ionothermal method from a Fe-based metal-organic framework. Carbon 59, 372–382 (2013).

Butler, S. Z. et al. Progress, challenges, and opportunities in two-dimensional materials beyond graphene. ACS Nano 7, 2898–2926 (2013).

Geim, A. K. & Novoselov, K. S. The rise of graphene. Nature Mater. 6, 183–191 (2007).

Mi, X. et al. Preparation of graphene oxide aerogel and its adsorption for Cu2+ ions. Carbon 50, 4856–4864 (2012).

Travlou, N. A., Kyzas, G. Z., Lazaridis, N. K. & Deliyanni, E. A. Functionalization of graphite oxide with magnetic chitosan for the preparation of a nanocomposite dye adsorbent. Langmuir 29, 1657–1668 (2013).

Xu, J., Wang, L. & Zhu, Y. Econtamination of bisphenol A from aqueous solution by graphene adsorption. Langmuir 28, 8418–8425 (2012).

Hummers Jr., W. S. & Offeman, R. E. Preparation of graphitic oxide. J. Am. Chem. Soc. 80, 1339–1339 (1958).

Li, Y. et al. MoS2 nanoparticles grown on graphene: an advanced catalyst for the hydrogen evolution reaction. J. Am. Chem. Soc. 133, 7296–7299 (2011).

Yin, Z. et al. Single-layer MoS2 phototransistors. ACS Nano 6, 74–80 (2011).

Yu, S. H. et al. Dye-sensitized MoS2 photodetector with enhanced spectral photoresponse. ACS Nano 8, 8285–8291 (2014).

Chang, K. & Chen, W. L-cysteine-assisted synthesis of layered MoS2/graphene composites with excellent electrochemical performances for lithium ion batteries. ACS Nano 5, 4720–4728 (2011).

Zhang, W. et al. High-Gain Phototransistors Based on a CVD MoS2 Monolayer. Adv. Mater. 25, 3456–3461 (2013).

Xu, X., Hu, J., Yin, Z. & Xu, C. Photoanode Current of Large-Area MoS2 Ultrathin Nanosheets with Vertically Mesh-Shaped Structure on Indium Tin Oxide. ACS Appl. Mater. Interfaces 6, 5983–5987 (2014).

Najmaei, S., Liu, Z., Ajayan, P. & Lou, J. Thermal effects on the characteristic Raman spectrum of molybdenum disulfide (MoS2) of varying thicknesses. Appl. Phys. Lett. 100, 013106 (2012).

Zhu, H. et al. Preparation, characterization and adsorption properties of chitosan modified magnetic graphitized multi-walled carbon nanotubes for highly effective removal of a carcinogenic dye from aqueous solution. Appl. Surf. Sci. 285, 865–873 (2013).

Zhi, Y., Li, Y., Zhang, Q. & Wang, H. ZnO nanoparticles immobilized on flaky layered double hydroxides as photocatalysts with enhanced adsorptivity for removal of acid red G. Langmuir 26, 15546–15553 (2010).

Zhao, H., Song, X. & Zeng, H. 3D white graphene foam scavengers: vesicant-assisted foaming boosts the gram-level yield and forms hierarchical pores for superstrong pollutant removal applications. NPG Asia Mater. 7, e168 (2015).

Zhao, L. et al. One-Step Solvothermal Synthesis of a Carbon@ TiO2 Dyade Structure Effectively Promoting Visible-Light Photocatalysis. Adv. Mater. 22, 3317–3321 (2010).

Wu, H. B., Hng, H. H. & Lou, X. W. D. Direct synthesis of anatase TiO2 nanowires with enhanced photocatalytic activity. Adv. Mater. 24, 2567–2571 (2012).

Lian, G. et al. Boron nitride ultrathin fibrous nanonets: One-step synthesis and applications for ultrafast adsorption for water treatment and selective filtration of nanoparticles. ACS Appl. Mater. Interfaces 5, 12773–12778 (2013).

Yagub, M. T., Sen, T. K., Afroze, S. & Ang, H. M. Dye and its removal from aqueous solution by adsorption: a review. Adv. Colloid Interface 209, 172–184 (2014).

Mittal, A. et al. Adsorption of hazardous dye crystal violet from wastewater by waste materials. J. Colloid Interf. Sci. 343, 463–473 (2010).

Hameed, B., Ahmad, A. & Latiff, K. Adsorption of basic dye (methylene blue) onto activated carbon prepared from rattan sawdust. Dyes Pigments 75, 143–149 (2007).

Wang, R., Cai, X. & Shen, F. TiO2 hollow microspheres with mesoporous surface: Superior adsorption performance for dye removal. Appl. Surf. Sci. 305, 352–358 (2014).

Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 40, 1361–1403 (1918).

Freundlich, H. Over the adsorption in solution. J. Phys. Chem. 57, e470 (1906).

Hou, X. et al. Magnetic and high rate adsorption properties of porous Mn1− xZnxFe2O4 (0 x 0.8) adsorbents. J. Colloid Interf. Sci. 353, 524–529 (2011).

Zeng, S. et al. Magnetically separable Ni0.6Fe2.4O4 nanoparticles as an effective adsorbent for dye removal: Synthesis and study on the kinetic and thermodynamic behaviors for dye adsorption. Chem. Eng. J. 258, 218–228 (2014).

Hwang, K. J. et al. Dye adsorption mechanisms in TiO2 films, and their effects on the photodynamic and photovoltaic properties in dye-sensitized solar cells. Phys. Chem. Chem. Phys. 17, 21974–21981 (2015).

Zhang, H. et al. Preparation of magnetic composite hollow microsphere and its adsorption capacity for basic dyes. Ind. Eng. Chem. Res. 52, 16902–16910 (2013).

Acknowledgements

The work was supported by the National Natural Science Foundation of China (Grant Nos 51471051 and 51372040), Science and Technology Commission of Shanghai Municipality (15520720700 and 13NM1400300), Shanghai Sailing Program (17YF1412700), Shanghai Shu Guang Project (12SG01), and the Programs for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning Part of the experimental work have been carried out in Fudan Nanofabrication Laboratory.

Author information

Authors and Affiliations

Contributions

H.S.C., L.K.R., H.L.F. and Z.Y.F. conceived the experiments, analyzed the results and performed characterization. T. F. and Y. P. P.helped with collected and analysis the data. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Han, S., Liu, K., Hu, L. et al. Superior Adsorption and Regenerable Dye Adsorbent Based on Flower-Like Molybdenum Disulfide Nanostructure. Sci Rep 7, 43599 (2017). https://doi.org/10.1038/srep43599

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep43599

This article is cited by

-

Recent advances and perspectives of molybdenum disulfide and molybdenum disulfide based nanocomposites for adsorption and photocatalytic degradation of organic dyes: a review

Journal of Materials Science (2024)

-

Efficient adsorption and photocatalytic degradation of textile dye from metal ion-substituted ferrite for environmental remediation

International Journal of Environmental Science and Technology (2024)

-

Enantioseparation and quantitative determination of ibuprofen using vancomycin-mediated capillary electrophoresis combined with molybdenum disulfide-assisted dispersive solid-phase extraction: optimization using experimental design

Journal of the Iranian Chemical Society (2020)

-

Comparative approach towards the adsorption of Reactive Black 5 and methylene blue by n-layer graphene oxide and its amino-functionalized derivative

Adsorption (2020)

-

Synthesis of MoOx nanostructures with the assistance of polymeric surfactants for dye removal from water

Korean Journal of Chemical Engineering (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.