Abstract

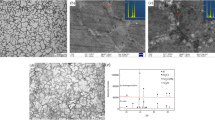

The developed dislocation structure that forms during cryorolling of a D16 alloy is found to be retained after short-term heating to 200°C. At higher temperatures, it undergoes recovery and recrystallization with the formation and growth of nanograins. Rolling intensify the decomposition of a preliminarily supersaturated aluminum solid solution, proving the alloy high-strength after artificial aging at a lower temperature and a shorter time as compared to a conventional T6 temper.

Similar content being viewed by others

References

P. A. Khaimovich, “Cryogenic Deformation during Uniform Compression,” Vopr. Atomnoi Nauki i Tekhniki, No. 4, 28–34 (2006).

E. Ma, “Eight Routes to Improve the Tensile Ductility of Bulk Nanostructured Metals and Alloys,” JOM, April, 49–53 (2006).

R. A. Andrievskii and A. M. Glezer, “Strength of Nanostructures,” Usp. Fiz. Nauk 174(4), 337–358 (2009).

J. Yin, J. Lu, H. Ma, and P. Zhang, “Nanostructural Formation of the Grained Aluminum Alloy by Severe Plastic Deformation at Cryogenic Temperature,” J. Mater. Sci. 39, 2851–2854 (2004).

Y. S. Ii, N. R. Tao, and K. Lu, “Microstractural Evolution and Nanostructure Formation in Copper during Dynamic Plastic Deformation at Cryogenic Temperatures,” Acta Mater. 56, 230–241 (2008).

V. A. Moskalenko and A. R. Smirnov, “Nanocrystalline Titanium Produced by a Cryomechanical Method: Microstructure and Mechanical Properties,” Fiz. Nizk. Temp. 35(11), 1160–1164 (2009).

T. N. Kon’kova, S. Yu. Mironov, and A. V. Korznikov, “Effect of Cryogenic Rolling on the Microstructure and Mechanical Properties of Copper,” Uprochnyayushchie Tekhnologii i Pokrytiya, No. 9, 40–47 (2009).

S. K. Panigrahi and R. Jayaganthan, “Comparative Study on Mechanical Properties of Al 7075 Alloy Processed by Rolling at Cryogenic Temperature and Room Temperature,” Mat. Sci. Forum. 584–586, 734–740 (2008).

S. Cheng, Y. H. Zhao, Y. T. Zhu, and E. Ma, “Optimizing the Strength and Ductility of Fine Structured 2024 Al Alloy by Nano-precipitation,” Acta Mater. 55, 5822–5832 (2007).

Y. B. Lee, D. H. Shin, K.-T Park, and W. J. Nam, “Effect of Annealing Temperature on Microstructures and Mechanical Properties of a 5083 Al Alloy Deformed at Cryogenic Temperature,” Scpirta Mater. 51, 355–359 (2004).

Y.-H. Zhao, X.-Zh. Liao, Sh. Cheng, and E. Ma, “Simultaneously Increasing the Ductility and Strength of Nanostractured Alloys,” Advanced Materials. 18, 2280–2283 (2006).

T. Shanmugasundaram, B. S. Murty, and V. Subramanya Sarma, “Development of Ultrafine Grained High Strength Al-Cu Alloy by Cryorolling,” Scripta Mater. 54, 2013–2017 (2006).

Z. N. Archakova, G. A. Balkhontsev, I. G. Basova, et al., Structure and Properties of Semiproducts Made of Aluminum Alloys (Metallurgiya, Moscow, 1984) [in Russian].

R. Z. Valiev and I. V. Aleksandrov, Bulk Nanostructured Materials: Production, Structure, and Properties (Akademkniga, Moscow, 2007) [in Russian].

H. R. Song, Y. S. Kim, and W. J. Nam, “Mechanical Properties of Ultrafine Grained 5052 Al Alloy Produced by Accumulative Roll-Bonding and Cryogenic Rolling,” Metals and Materials International. 12(1), 7–12 (2006).

V. M. Segal, V. I. Reznikov, V. I. Kopylov, et al., Processes of Plastic Structure Formation in Metals (Navuka i Tekhnika, MInsk, 1994) [in Russian].

M. Murayama, Z. Horita, and K. Hono, “Microstructure of Two-phase Al-1.7 at % Cu Alloy Deformed by Equal-channel Angular Pressing,” Acta mater. 49, 21–29 (2001).

Y. Huang and P. B. Prangnell, “The Effect of Cryogenic Temperature and Change in Deformation Mode on the Limiting Grain Size in a Severely Deformed Dilute Aluminium Alloy,” Acta Mater. 56, 1619–1632 (2008).

G. Sha, Y. B. Wang, X. Z. Liao, et al., “Influence of Equal-channel Angular Pressing on Precipitation in an Al-Zn-Mg-Cu Alloy,” Acta Mater. 57, 3123–3132 (2009).

J. K. Kim, H. G. Jeong, S. I. Hong, et al., “Effect of Aging Treatment on Heavily Deformed Microstracture of a 6061 Aluminum Alloy after Equal-channel Angular Pressing,” Scripta Mater. 45, 901–907 (2001).

W. J. Kim, C. S. Chung, D. S. Ma, et al., “Optimization of Strength and Ductility of 2024 Al by Equal Channel Angular Pressing (ECAP) and Post-ECAP Aging,” Scripta Mater. 49, 333–338 (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.V. Markushev, E.V. Avtokratova, I.Ya. Kazakulov, S.V. Krymsky, M.Yu. Mochalova, M.Yu. Murashkin, O.Sh. Sitdikov, 2010, published in Deformatsiya i Razrushenie Materialov, 2010, No. 4, pp. 36–41.

Rights and permissions

About this article

Cite this article

Markushev, M.V., Avtokratova, E.V., Kazakulov, I.Y. et al. Microstructure and properties of an aluminum D16 alloy subjected to cryogenic rolling. Russ. Metall. 2011, 364–369 (2011). https://doi.org/10.1134/S0036029511040136

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029511040136