Abstract

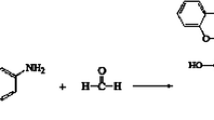

Boron carbide powder (B4C) was added into phenol-formaldehyde (PF) resin to increase the high temperatural bond strength of PF resin. Using the modified PF resin silicon carbide block could be bonded satisfactorily even treated at 700–800°C, and its bond strength was higher than 20 MPa. The thermal modification mechanism was investigated by scanning electron microscopy, energy dispersive X-Ray, and pyrolysis gas chromatography spectrum coupled with a mass spectrum. The results indicate that B4C can increase the heat resistance of PF resin efficiently. B4C can not only seize some active groups of the resin matrix including phenolic hydroxyl and methylol, but also can hold the main components of some volatiles such as CO, H2O, phenol, and its derivations in the resin matrix by chemical reactions. At the same time, the reaction product boron oxide closes and mends the microcracks for its satisfactory wettability and adhesive capacity. In consequence, the efficient components escaping from the resin matrix can be sharply reduced. A relative intact skeleton of the resin is obtained, and its bond strength and thermal stability are remarkably elevated.

Similar content being viewed by others

References

Jiang, H.Y, Wang, J.G, Wu S.Q., et al., Polym. Degrad. Stabil., 2012, vol. 97, p. 1527.

Zhang, Y, Zhao, X., and Cheng, X., J. Wuhan Univ. Technol.-Mater. Sci. Ed., 2012, vol., p. 1077.

You, L.J, Xu, S, Ma, W., et al., Langmuir, 2012, vol. 28, p. 10565.

Hu, J., Situ, Y., et al., J. Wuhan Univ. Technol.-Mater. Sci. Ed., 2008, vol. 23, p. 431.

Wang, T.M., Hou, K.H., Chang, Y.T., et al., Mater. Design, 2010, vol. 31, p. 4296.

Lv, J., Mo, Y., and Pan. L., Adv. Mate. Res., 2010, vol. 87, p. 58.

Yun, R.P, Filip, P., and Lu, Y.F., Tribol. Int., 2010, vol. 43, p. 2010.

Szczurek, A. Jurewicz, K., Amaral-Labat, G., et al., Carbon, 2010, vol. 48, p. 3874.

Wei, W., Hu, H., Qin G., et al., Carbon, 2004, vol. 42, p. 679.

Gun’ko, V., Bogatyrov, V., Oranska, O., et al., Appl. Surf. Sci., 2013, vol. 264, p. 707.

Abdalla, M.O., Ludwick, A., and Mitchell, T., Polymer, 2003, vol. 44, p. 7353.

Bijwe, J,, Majumdar, N., and Satapathy, B., Wear, 2005, vol. 259, p. 1068.

Wang, M., Wei, L., and Zhao, T., Eur. Polym. J., 2005, vol. 41, p. 903.

Sharif, M.A. and Sueyoshi, H., J. Ceram. Soc. Jpn., 2008, vol. 116, p. 807.

Mirski, R., Dziurka, D., and Jkcka, J., J. Appl. Polym. Sci., 2008, vol. 107, pp. 3358.

Wang, M., Leitch, M., and Xu, C., Eur. Polym. J., 2009, vol. 45, p. 3380.

Matsuzawa, T., Mase, K., and Inoue, S., J. Appl. Polym. Sci., 2009, vol. 112, p. 3748.

Park, B.D., and Kadla, J.F., Thermochim. Acta, 2012.

Neelamana, I.K., Thomas, S., and Parameswaranpillai, J., J. Appl. Polym. Sci., 2013, vol. 130, p. 239.

Reghunadhan Nair, C.P., Prog. Polym. Sci., 2004, vol. 29, p. 401.

Trick, K.A. and Saliba, T.E., Carbon, 1995, vol. 33, pp. 1509.

Sobera, M, and Hetper. J., J. Chromato. A, 2003, vol. 993, pp. 131–135.

Ozaki, J., Ohizumi, W., and Oya, A., Carbon, 2000, vol. 38, pp. 1515.

Jiang, H.Y., Wang, J.G,, Duan, Z.C., and Li, F., Front.Mater. Sci. China, 2007, vol. 1, p. 35.

Ogawa, I., Yamamoto, T., Hagio, T., et al., J. Ceramic Soc. Jpn., 1986, vol. 94, p. 409.

Steiner, H., 2005, J.Nucl. Mater., vol. 345, p. 75.

Sheehan, J.E., 1989, Carbon, vol. 27, p. 709.

McKee, D.W,, Spiro, C.L., and Lamby, E., J Carbon, 1984, vol. 22, p. 507.

Liu, Y., Gao, J., and Zhang, R., Polym. Degrad. Stabil., 2002, vol. 77, p. 495.

Benson, S.W., Cruickshank, F.R., Golden, D.M., et al., Chem. Rev., 1969, vol. 69, p. 279.

Chase, M.W., Davies, C.A., Downey, J.R., et al., J. Phys. Chem. Ref. Data, 1985, vol. 14, p. 1.

Author information

Authors and Affiliations

Corresponding author

Additional information

The text was submitted by authors in English.

Rights and permissions

About this article

Cite this article

Jiang, H., Wang, J., Wu, S. et al. Study on the property of boron carbide-modified phenol-formaldehyde resin for silicon carbide bonding. Russ J Appl Chem 87, 904–908 (2014). https://doi.org/10.1134/S1070427214070106

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427214070106