Abstract

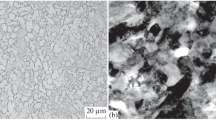

The work presents the results of recent studies of nanostructured titanium and its alloy of the grade VT-6 (Ti-6Al-4V), in which we managed, using the methods of severe plastic deformation (SPD), to obtain ultra-fine-grained (UFG) states and form other nanostructured elements as nanodispersed particles of secondary phases, nonequilibrium grain boundaries, and dislocation substructures. Special attention was paid to equal-channel angular pressing (ECAP) and its modifications in combination with thermal and thermomechanical treatments, which enable one to obtain UFG alloys in the form of elongated rods. The peculiarities of grinding the microstructure in titanium and binary alloy VT-6 in dependence on the deformation technological setup have been established. The principles of nanostructuring to enhance strength, plasticity, and fatigue life have been suggested. The results of studies of the mechanical properties of the UFG VT-6 alloy have demonstrated the high efficiency of its application in the manufacture of articles with enhanced service parameters on the example of compressor blades of a gas-turbine engine (GTE). The possibilities of scaling the ECAP process to implement the commercial manufacture of the new material have been examined.

Similar content being viewed by others

References

B. A. Kolachev, I. S. Pol’kin, and V. D. Talalaev, Titanium Alloys Produced in Different Countries: Handbook (VILS, Moscow, 2000) [in Russian].

B. A. Kolachev, V. I. Elagin, and V. A. Livanov, Metal Science and Thermal Processing of Non-Ferrous Metals and Alloys (MISIS, Moscow, 2001) [in Russian].

A. I. Igolkin, “Titanium in medicine,” Titan, No. 1, 86 (1993).

S. G. Glazunov, S. F. Vazhenin, G. D. Zyukov-Batyrev, and Ya. L. Ratner, Titanium Application in National Economy (Tekhnika, Kiev, 1975) [in Russian].

H. Gleiter, “Nanocrystalline materials,” Progr. Mater. Sci. 33, 223–315 (1989).

R. Z. Valiev and I. V. Aleksandrov, Nanostructured Materials Produced by Intensive Plastic Deformation (Logos, Moscow, 2000) [in Russian].

A. I. Gusev and A. A. Rempel’, Nanocrystalline Materials (Fizmatlit, Moscow, 2000) [in Russian].

R. A. Andrievskii and A. V. Ragulya, Nanostructured Materials (Academia, Moscow, 2005) [in Russian].

N. I. Noskova and R. R. Mulyukov, Submicrocrystalline and Nanocrystalline Metals and Alloys (Ural Branch RAS, Yekaterinburg, 2003) [in Russian].

M. I. Alymov, Powder Metallurgy for Nanocrystalline Materials (Nauka, Moscow, 2007) [in Russian].

R. Z. Valiev, Yu. Estrin, Z. Horita, T. G. Langdon, M. J. Zehetbauer and Y. T. Zhu, “Producing bulk ultrafine-grained materials by severe plastic deformation,” J. Organ. Mater. 58,(4), 33–39 (2006).

R. Z. Valiev and I. V. Aleksandrov, Bulk Nanostructured Metallic Materials: Manufacturing, Structure and Properties (Akademkniga, Moscow) [in Russian].

R. Valiev and T. Langdon, “The art and science of tailoring materials by nanostructuring for advanced properties using SPD techniques,” Adv. Eng. Mater. 12(8), 677–691 (2010).

A. A. Popov, I. Yu. Pyshmintsev, S. L. Demakov, A. G. Illarionov, T. C. Lowe, and R. Z. Valiev, “Structural and mechanical properties of nanocristalline titanium processed by severe deformation processing,” Scripta Mater. 37, 1089–1094 (1997).

Yu. R. Kolobov, O. A. Kashin, E. E. Sagymbaev, E. F. Dudarev, L. S. Bushnev, G. P. Grabovetskaya, G. P. Pochivalova, N. V. Girsova, and V. V. Stolyarov, “Structure, mechanical and electrochemical properties of ultra-fine titanium,” Izv. Vyssh. Uchebn. Zaved. Fiz., No. 1, 77–85 (2000).

A. V. Sergueeva, V. V. Stolyarov, R. Z. Valiev, and A. K. Mukherjee, “Advanced mechanical properties of pure titanium with ultrafine grained structure,” Scripta Mater., No. 45, 747–752 (2001).

G. A. Salishchev, S. V. Zherebtsov, and R. M. Galeyev, “Evolution of microstructure and mechanical behavior of titanium, during warm multiple deformation,” in Proc. “Ultrafine Grained Materials II”, Ed. by T. Zhu, T. G. Langdon, R. S. Mishra, S. L. Semiatin, M. J. Saran, and T. C. Lowe (2002), pp. 123–131.

G. A. Salishchev, O. R. Valiakhmetov, R. M. Galeev, and S. P. Malysheva, “The way to form submicrocrystalline structure in titanium under plastic deformation and its effect onto mechanical properties,” Metally, No. 4, 86 (1996).

V. V. Stolyarov, L. O. Shestakova, A. I. Zharikov, V. V. Latysh, R. Z. Valiev, Y. T. Zhu, and T. C. Lowe, “Mechanical properties of nanostructured titanium alloys processed using severe plastic deformation,” in Proc. 9th Int. Conf. Titanium-99 (Nauka, 2001), Vol. 1, p. 466.

S. V. Zherebtsov, P. M. Galleev, O. R. Valiakhmetov, et al., “The way to form submicrocrystalline structure in titanium alloys by means of intensive plastic deformation,” Kuznechno-Shtamp. Proizv., No. 7, 17–22 (1999).

V. V. Stolyarov, Y. T. Zhu, I. V. Alexandrov, T. C. Lowe, and R. Z. Valiev, “Influence of ECAP routes on the microstructure and properties of pure Ti,” Mater. Sci. Eng. A 299, 59 (2001).

G. I. Raab and R. Z. Valiev, “Equal channel angular pressing according to “Konform” scheme for long-size nanostructured titanium half-products,” Kuznechno-Shtamp. Proizv. Obrab. Met. Davleniem, No. 1, 21–27 (2008).

R. Z. Valiev, G. I. Raab, D. V. Gunderov, and M. Yu. Murashkin, “Intensive plastic deformation methods for producing bulk nanostructured metals and alloys,” Kuznechno-Shtamp. Proizv., Obrab. Met. Davleniem, No. 11, 5–12 (2008).

V. V. Stolyarov, Y. T. Zhu, I. V. Alexandrov, T. C. Lowe, and R. Z. Valiev, “Grain refinement and properties of pure Ti processed by warm ECAP and cold rolling,” Mater. Sci. Eng. A 343, 43–50 (2003).

G. Kh. Sadikova, V. V. Latysh, I. P. Semenova, and R. Z. Valiev, “Effect of intensive plastic deformation and thermomechanical processing onto titanium structure and properties,” Metalloved. Term. Obrab. Met., No. 11(605), 31–34 (2005).

I. P. Semenova, A. V. Polyakov, G. I. Raab, T. C. Lowe, and R. Z. Valiev, “Enhanced fatigue properties of ultrafine-grained Ti rods processed by ECAP-Conform November,” J. Mater. Sci. 47(22), 7777–7781 (2012).

S. Zherebtsov, G. Salishchev, R. Galeyev, and K. Maekawa, “Mechanical properties of Ti-6Al-4V titanium alloy with submicrocrystalline structure produced by severe plastic deformation,” Mater. Trans. 46(9), 2020–2025 (2005).

L. R. Saitova, H. W. Hoeppel, M. Goeken, I. P. Semenova, and R. Z. Valiev, “Cyclic deformation behavior and fatigue lives of ultrafine-grained Ti-6Al-4V ELI alloy for medical use,” Int. J. Fatigue, No. 31, 322–331 (2009).

I. P. Semenova, “Strength and increased fatigue properties of ultra-fine titanium half-products produced by means of intensive plastic deformation,” Metally, No. 5, 87–94 (2010).

N. A. Amirkhanova, R. Z. Valiev, E. Yu. Chernyaeva, E. B. Yakushina, and I. P. Semenova, “Corrosion behavior of titanium materials with ultrafine structure,” Metally, No. 3, 101–107 (2010).

Y. G. Ko, W. S. Jung, D. H. Shin, and C. S. Lee, “Effects of temperature and initial microstructure on the equal channel angular pressing of Ti-6Al-4V alloy,” Scripta Mater. 48, 197–202 (2003).

I. P. Semenova, L. R. Saitova, G. I. Raab, and R. Z. Valiev, “Equal channel angular pressing influence on the Ti-6Al-4V alloy structure and mechanical behavior,” Mater. Sci. Eng. A 387–389, 805–808 (2004).

L. R. Saitova, I. P. Semenova, G. I. Raab, and R. Z. Valiev, “Intensive plastic deformation effect onto mechanical behavior and structure of Ti-6Al-4V alloy,” Deform. Razrush. Mater., No. 3, 27–30 (2005).

I. P. Semenova, L. R. Saitova, R. K. Islamgaliev, T. V. Dotsenko, A. R. Kil’mametov, S. L. Demakov, and R. Z. Valiev, “Evolution of VT6 alloy structure under equal channel pressing,” Fiz. Met. Metalloved. 100(1), 1–8 (2005).

S. L. Demakov, O. A. Elkina, A. G. Illarionov, M. S. Karabanalov, A. A. Popov, I. P. Semenova, L. R. Saitova, and N. V. Shchetnikov, “Effect of rolling deformation conditions onto ultra-fine structure formation in two-phase alloy produced by intensive plastic deformation,” Fiz. Met. Metalloved. 105(6), 638–646 (2008).

S. V. Zherebtsov, G. A. Salishchev, R. M. Galeyev, O. R. Valiakhmetov, S. Yu. Mironov, and S. L. Semiatin, “Production of submicrocrystalline structure in large-scale Ti-6Al-4V billet by warm severe deformation processing,” Scripta Mater. 51, 1147–1151 (2004).

G. A. Salishchev, R. M. Galeyev, O. R. Valiakhmetov, R. V. Safiulin, R. Y. Lutfullin, O. N. Senkov, F. H. Froes, and O. A. Kaibyshev, “Development of Ti-6Al-4V sheet with low temperature superplastic properties,” J. Mater. Processing Tech., No. 16, 265–268 (2001).

V. V. Latysh, G. H. Salimgareeva, I. P. Semenova, I. V. Kandarov, Y. T. Zhu, T. C. Lowe, and R. Z. Valiev, “Microstructure and properties of Ti rods produced by multi-step SPD,” Mater. Sci. Forum 503–504, 763–768 (2006).

E. B. Yakushina, I. P. Semenova, and R. Z. Valiev, “Nanostructured titanium for biomedical application,” Tsvetnye Metally, No. 7, 81–83 (2010).

R. Z. Valiev, I. P. Semenova, V. V. Latysh, A. V. Shcherbakov, and E. B. Yakushina, “Nanostructured titanium for biomedical applications: new developments and challenges for commercialization,” Nanotech. Russ. 3(9–10), 593 (2008).

T. Zhu, Y. R. Kolobov, G. P. Grabovetskaya, V. V. Stolyarov, N. V. Girsova, and R. Z. Valiev, “Microstructure and mechanical properties of ultrafine-grained Ti foil processed by equal-channel angular pressing and cold rolling,” J. Mater. Res. 18(4), 1011–1016 (2003).

L. R. Saitova, I. P. Semenova, G. I. Raab, and R. Z. Valiev, “The way to rise mechanical properties of Ti-6Al-4V alloy by using equal channel angular pressing and further plastic deformation,” Fiz. Tekhn. Vys. Davlenii 14(4), 19–24 (Donetsk, 2004).

I. P. Semenova, L. R. Saitova, G. I. Raab, A. I. Korshunov, Y. T. Zhu, T. C. Lowe, and R. Z. Valiev, “Microstructural features and mechanical properties of the Ti-6Al-4V ELI alloy processed by severe plastic deformation,” Mater. Sci. Forum 503–504, 757–762 (2006).

I. P. Semenova, E. B. Yakushina, V. V. Nurgaleeva, and R. Z. Valiev, “Nanostructuring of Ti-alloys by SPD processing to achieve superior fatigue properties,” Int. Joint Mater. Res. (Form. Z. Metallk.) 100, 1691–1696 (2009).

Y. T. Zhu and X. Z. Liao, “Nanostructured materials: retaining ductility,” Nature Mater. 3, 351 (2004).

R. Z. Valiev, A. V. Sergueeva, and A. K. Mukherjee, “Effect annealing behavior of nanostructured SPD titanium,” Scripta Mater. 49, 669 (2003).

I. P. Semenova, G. H. Salimgareeva, G. Da Costa, W. Lefebvre, and R. Z. Valiev, “Enhanced strength and ductility of ultra-fine grained Ti processed by severe plastic deformation,” Adv. Eng. Mater. 12(8), 803–807 (2010).

A. Yu. Vinogradov and S. Hashimoto, “Fatigue of ultrafine materials produced by equal channel angular pressing,” Metally, No. 1, 51–62 (2004).

A. Y. Vinogradov, V. V. Stolyarov, S. Hashimoto, and R. Z. Valiev, “Cyclic behavior of ultrafine-grain titanium produced by severe plastic deformation,” Mater. Sci. Eng. A 318, 163–173 (2001).

V. V. Stolyarov, I. V. Alexandrov, Yu. R. Kolobov, M. Zhu, Y. Zhu, and T. Lowe, Proc. 7th Int. Fatigue Congr. Fatigue’99 (Beijing, 1999), Vol. 3, pp. 1345–1351.

L. Kunz P. Lukas, and M. Sloboda, “Fatigue strength, microstructural stability and strain localization in ultrafine-grained copper,” Mater. Sci. Eng. A 424(1–2), 97–104 (2006).

M. Grabski, Fine-Structure Superplasticity in Metals (Silesian Press, Katowice 1973).

A. V. Sergueeva, V. V. Stolyarov, R. Z. Valiev, and A. K. Mukherjee, “Superplastic behavior of ultra-fine grained Ti-6Al-4V alloy,” Mater. Sci. Eng. A 323, 318–325 (2002).

I. P. Semenova, L. R. Saitova, G. I. Raab, and R. Z. Valiev, “Superplasticity behavior of ultra-fine Ti-6Al-4V alloy produced by intensive plastic deformation,” Fiz. Tekhn. Vys. Davlenii 16(4), 84–89 (Donetsk, 2006).

A. V. Botkin, A. Shayakhmetov, I. P. Semenova, G. I. Raab, R. Z. Valiev, and S. P. Pavlinich, “The way to simulate and estimate analytically the isothermal stamping force parameters for blade made of VT6 alloy,” Kuznechno-Shtamp. Proizv. Obrab. Met. Davleniem, No. 11, 43–48 (2008).

I. P. Semenova, V. V. Polyakova, R. R. Valiev, G. I. Raab, and N. F. Izmailova, “Microstructure and properties of gas turbine engine compressor blades made by volumetric stamping from ultra-fine VT6 alloy,” Fiz. Tekhn. Vys. Davlenii, No. 4, 86–96 (2011).

F. Z. Utyashev and G. I. Raab, “Scale factor effect onto grain refining under intensive plastic deformation,” Kuznechno-Shtamp. Proizv., Obrab. Met. Davleniem, No. 11, 13–20 (2008).

G. I. Raab and F. Z. Utyashev, “Development of SPD technologies of production line for rod-shaped semi-products out of nanostructured titanium for medical application,” Mater. Sci. Forum, Nos. 667–669, 1159–1164 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.P. Semenova, G.I. Raab, R.Z. Valiev, 2014, published in Rossiiskie Nanotekhnologii, 2014, Vol. 9, Nos. 5–6.

Rights and permissions

About this article

Cite this article

Semenova, I.P., Raab, G.I. & Valiev, R.Z. Nanostructured titanium alloys: New developments and application prospects. Nanotechnol Russia 9, 311–324 (2014). https://doi.org/10.1134/S199507801403015X

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S199507801403015X