Abstract

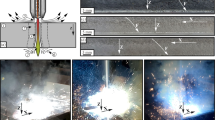

Optical, scanning, and transmission electron microscopy methods, and X-ray diffraction analysis have been used to study the changes in the structure and the microhardness in the surface layer of the Al–Mg (5.8–6.8 wt %) alloy after water jet cutting. The dislocation density, the sizes of coherent scattering regions, and microdistortions have been determined. The transformation of the fine structure has been revealed in the displacement from the alloy volume to the abrasive-waterjet cutting surface.

Similar content being viewed by others

References

A. S. Denisov, “Increasing the efficiency of cutting of working-parts of thick-sheet metals on the base of a discrete supply of abrasive,” Candidate Sci. (Eng.) Dissertation, Mosk. Gos. Tekh. Univ. “STANKIN”, 2014.

V. A. Tarasov and A. N. Polukhin, “Estimation of the geometric parameters of the surface formed during hydro-abrasive treatment,” Vestn. Mosk. Gos. Tekh. Univ. (MGTU), Ser. Mashinostroenie, no. 1, 107–116 (2012).

A. M. Ignatova, M. N. Ignatov, and R. N. Sharitnov, “The classification of the basic elements of the technological system of the waterjet cutting to ensure the accuracy and quality of the cut surface,” Russ. Internet J. Indust. Eng. 3, 17–20 (2015).

V. A. Levko, “Abrasive-extrusion treatment: Contemporary achievements, problems and trends of the development,” Izv. Tomsk. Politekhn. Univ.: Inzhiniring Georesursov 309 (6), 125–129 (2006).

K. I. Mirkin, A Handbook on X-ray Diffraction Analysis of Polycrystal (Fizmatgiz, Moscow, 1961) [in Russian].

S. S. Gorelik, L. N. Rastorguev, and Yu. A. Skakov, X-ray Difraction and Electronographic Analysis of Metals (Gos. Nauchn.-Tekhn. Izd. Chern. Tsvetn. Metall., Moscow, 1963) [in Russian].

L. M. Utevskii, Diffraction Electron Microscopy in Metal Science Metallurgiya, Moscow, 1973) [in Russian].

P. B. Hirsch, A. Howie, R. B. Nicholson, D. W. Pashley, and M. J. Whelan, Electron Microscopy of Thin Crystals (New York: Krieger, 1977), 2nd ed.

V. A. Kolachev, V. A. Livanov, and V. I, Elagin, Metal Science and Heat Treatment of Non-ferrous Metals and Alloys (Metallurgiya, Moscow, 1972) [in Russian].

N. A. Belov, Phase Composition of Industrial and Perspective Aluminum Alloys (MISiS, Moscow, 2010) [in Russian].

V. S. Zolotarevskii and N. A. Belov, Metal Science of Casting Aluminum Alloys (MISiS, Moscow, 2005) [in Russian].

L. I. Kaigorodova, V. M. Zamyatin, and V. I. Popov, “The influence of homogenizing conditions on the structure and properties of an Al–Mg alloy,” Phys. Met. Metallogr. 98, 75–82 (2004).

Metal Science of Aluminum and Its Alloys, Ed. by I. N. Fridlyander, (Metallurgiya, Moscow, 1983) [in Russian].

I. G. Brodova, A. N. Petrova, S. V. Razorenov, and E. V. Shorokhov, “Resistance of submicrocrystalline aluminum alloys to high-rate deformation and fracture after dynamic channel angular pressing,” Phys. Met. Metallogr. 116, 519–527 (2015).

L. I. Kaigorodova, D. Yu. Rasposienko, V. G. Pushin, V. P. Pilyugin, and S. V. Smirnov, “Structure and mechanical properties of aging Al–Li–Cu–Zr–Sc–Ag alloy after severe plastic deformation by high-pressure torsion,” Phys. Met. Metallogr. 116, 346–355 (2015).

L. I. Kaigorodova, D. Yu. Rasposienko, V. G. Pushin, V. P. Pilyugin, and S. V. Smirnov, “Structure of aging Al–Li–Cu–Zr–Sc–Ag alloy after severe plastic deformation and long-term storage,” Phys. Met. Metallogr. 116, 1108–1115 (2015).

A. N. Petrova, I. G. Brodova, and E. V. Shorokhov, “Structural refinement in Al–Mg–Mn alloy by the dynamic channel-angular pressing method,” Perspekt. Mater., no. 12, 72–77 (2015).

A. N. Petrova, H. Radziszewska, L. Kaczmarek, M. Klih, I. G. Brodova, and M. Steglinski, “Influence of megaplastic deformation on the structure and hardness of Al–Cu–Mg alloy after aging,” Phys. Met. Metallogr. 117, 1237–1244 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © T.I. Tabatchikova, N.A. Tereshchenko, I.L. Yakovleva, N.Z. Gudnev, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 9, pp. 924–934.

Rights and permissions

About this article

Cite this article

Tabatchikova, T.I., Tereshchenko, N.A., Yakovleva, I.L. et al. Effect of abrasive water jet on the structure of the surface layer of Al–Mg alloy. Phys. Metals Metallogr. 118, 879–889 (2017). https://doi.org/10.1134/S0031918X17090095

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17090095