Abstract

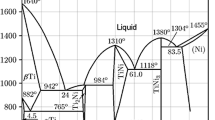

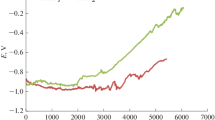

Nanosized refractory titanium, zirconium, and hafnium carbides were manufactured from highly dispersed metal dioxide-carbon starting mixtures at moderate temperatures of 1200°C or lower. The products were characterized by powder X-ray diffraction, elemental analysis, and transmission electron microscopy. The average size of particles (in nanometers) manufactured at 1200°C was as follows: for TiC, 13 ± 4; for ZrC, 17 ± 3; and for HfC, 16 ± 3; the average crystallite size (in nanometers) was as follows: for TiC, 8 ± 2; for ZrC, 5 ± 2; and for HfC, 8 ± 3. Thermodynamic modeling was performed for the synthesis of Group IVB carbides via carbothermal reduction of the corresponding oxides. The results show that in the titanium dioxide-carbon system, for example, titanium monocarbide formation is possible at a temperature as low as 850°C (p = 10−4 MPa). Highly dispersed metal dioxide-carbon starting mixtures were prepared using solgel technology from metal alkoxyacetylacetonates in the presence of a polymeric carbon source.

Similar content being viewed by others

References

Hugh O. Pierson. Handbook of Refractory Carbides and Nitrides. Properties, Characteristics, Processing and Applications (Noyes Publications, Westwood, 1996).

R. Kiffer and F. Benezovskii, Solid Materials (Metallurgiya, Moscow, 1968) [in Russian].

C. Agte and H. Alterthum, Z. Techn. Phys., No. 6, 182 (1930).

V. V. Fesenko and A. S. Bolgar, Vaporization of Refractory Materials (Metallurgiya, Moscow, 1966) [in Russian].

G. V. Samsonov and I. M. Vinitskii, Handbook of Refractory Compounds (Metallurgiya, Moscow, 1976; Plenum Press, New York, 1980).

A. Sayir, J. Mater. Sci. 39, 5995 (2004).

E. Wuchina, M. Opeka, S. Causey, et al., J. Mater. Sci. 39, 5939 (2004).

M. B. Dickerson, P. J. Wurm, JR. Schorr, et al., J. Mater. Sci. 39, 6005 (2004).

M. Fluche, G. E. Hilmas, W. G. Fahrenholtz, and S. E. Landwehr, 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. 2005. Article number 2005.

Qingfeng Tong, Jingli Shi, Yongzhong Song, et al., Carbon 42(12–13), 2495 (2004).

Li Shu-Ping, Li Ke-zhi, Li He-Jun, et al., Mater. Sci. Eng.: A 517(1–2), 61 (2009).

Houbu Li, Litong Zhang, Laifei Cheng, and Yiguang Wang, Ceram. Int. 35(7), 2831 (2009).

Zhen Wang, Shaoming Dong, Xiangyu Zhang, et al., J. Am. Ceram. Soc. 91(10), 3434 (2008).

Emission Properties of Solid Materials: A Handbook, Ed. by A. E. Sheindlin (Energiya, Moscow, 1974) [in Russian].

H. J. Boving and H. E. Hintermann, Tribology Int. 23(2), 129 (1990).

T. Zehnder and J. Patscheider, Surf. Coat. Technol. 133–134, 138 (2000).

G. E. Spriggs, Int. J. Refractory Metals & Hard Mater. 13, 241 (1995).

M. B. Dickerson, P. J. Wurm, J. R. Schorr, et al., J. Mater. Sci. 39, 6005 (2004).

V. E. Ovcharenko and Yu. F. Ivanov, Izv. Tomsk. Politekhn. Univ. 313(2), 114 (2008).

O. N. Dogn, J. A. Hawk, and K. K. Schrems, J. Mater. Eng. Perform. 15(3), 320 (2006).

Jun Zhao, Xunliang Yuan, and Yonghui Zhou, Int. J. Refractory Met. Hard Mater. 28(3), 330 (2010).

P. Bai and Y. Li, Sci. Sintering 41, 35 (2009).

Bingqiang Liu, Chuanzhen Huang, Meilin Gu, et al., Mater. Sci. Eng.: A 460–461, 146 (2007).

M. Hassan, R. S. Rawat, P. Lee, et al., Appl. Phys. A 90, 669 (2008).

L. Tong and R. G. Reddy, J. Miner. 58(4), 62 (2006).

D. E. Grove, U. Gupta, and A. W. Castleman, Jr., ACS Nano 4(1), 49 (2010).

S. Sulaimankulova, E. Omurzak, J. Jasnakunov, et al., J. Cluster Sci. 20, 37 (2009).

L. Tong and R. G. Reddy, Scr. Mater. 52(12), 1253 (2005).

E. Wuchina, M. Opeka, S. Causey, et al., J. Mater. Sci. 39, 5939 (2004).

Y. Leconte, H. Maskrot, N. Herlin-Boime, et al., Glass Phys. Chem 31(4), 510 (2005).

J. W. Brockmeyer, B. E. Williams, and S. Heng, TMS Ann. Meeting, 259 (1998).

N. I. Baklanova, T. M. Zima, A. T. Titov, et al., Inorg. Mater. 44(2), 121 (2008).

Wei Sun, Xiang Xiong, Bai-yun Huang, et al., Carbon 47(14), 3368.

R. Koc and J. S. Folmer, J. Am. Ceram. Soc. 80(4), 952 (1997).

Y. Shin, X. S. Li, W. D. Samuels, et al., Mater. Res. Soc. Symp. Proc. 879E Warrendale. PA. Z10.25. (2005).

H. Preiss, E. Schierhorn, and K.-W. Brzezinka, J. Mater. Sci. 33, 4697 (1998).

M. D. Sacks, Wang Chang-An, Yang Zhaohui, and Jain Anubhav, J. Mater. Sci. 39, 6057 (2004).

H. Preiss, L.-M. Berger, and D. Schultze, J. Eur. Ceram. Soc. 19, 195 (1999).

Jain Anubhav, A Thesis Presented to the Academic Faculty Georgia Institute of Technology. USA (2004).

P. Das Bharat, M. Panneerselvam, and K. J. Rao, J. Solid State Chem. 173(1), 196 (2003).

Ch.-A. Wang and M. D. Sacks, Proceedings of the 27th Annual Cocoa Beach Conference on Advanced Ceramics and Composites, A: Ceramic Engineering and Science, Cocoa Beach, Florida, 2003 (Cocoa Beach, 2003), Vol. 24, No. 3, p. 33.

A. Jain, M. D. Sacks, Ch.-A. Wang, et al., Proceedings of the 27th Annual Cocoa Beach Conference on Advanced Ceramics and Composites, A: Ceramic Engineering and Science, Cocoa Beach, Florida, 2003 (Cocoa Beach, 2003), Vol. 24, No. 3, p. 41.

Yongjie Yan, Zhengren Huang, Xuejian Liu, and Dongliang Jiang, J. Sol-Gel Sci. Technol. 44, 81 (2007).

Haijun Zhang, Faliang Lia, Quanli Jia, Guotian Ye, J. Sol-Gel Sci. Technol. 46, 217 (2008).

V. G. Sevastyanov, R. G. Pavelko, and N. T. Kuznetsov, Khim. Tekhnol., No. 1, 12 (2007).

V. G. Sevastyanov, R. G. Pavelko, Yu. S. Ezhov, and N. T. Kuznetsov, Neorg. Mater. 43(7), 792 (2007).

E. P. Simonenko, V. G. Sevastyanov, V. P. Meshalkin, and N. T. Kuznetsov, Kompozity Nanostruktury, No. 4, 28 (2009).

E. N. Kablov, N. T. Kuznetsov, P. D. Sarkisov, et al., RU Patent No. 2350580 (2009).

E. P. Simonenko, N. A. Ignatov, Yu. S. Ezhov, et al., Proceedings of the 3rd International Scientific and Engineering Conference “Metal Physics and Mechanics of Materials, Nanostructures, and Deformation Processes. METALLDEFORM-2009” (Samara, 2009), p. 146 [in Russian].

N. T. Kuznetsov, V. G. Sevastyanov, E. P. Simonenko, et al., RU Patent No. 2333888 (2008).

V. G. Sevastyanov, E. P. Simonenko, N. A. Ignatov, et al., Neorg. Mater. 46(5), 563 (2010).

E. P. Simonenko, N. P. Simonenko, V. G. Sevastyanov, and N. T. Kuznetsov, Perspektivnye Mater., No. 9A, 35 (2010).

N. T. Kuznetsov, V. G. Sevastyanov, E. P. Simonenko, et al., RU Patent No. 2407705 (2010).

E. P. Simonenko, N. P. Simonenko, V. G. Sevastyanov, and Yu. P. Galaktionov, in Cosmic Challenge of the XXI Century. Novel Materials and Technologies for Rocket and Space Technology (Torus-Press, Moscow, 2007), Vol. 3, p. 71 [in Russian].

M. W. Chase, Jr., J. Phys. Chem. Ref. Data Monogr. 9 (1998).

F. J. Kohl and C. A. Stearns, High Temp. Sci. 6(4), 284 (1974).

M. D. Hack, G. A. R. Maciagan, G. E. Scuseria, and M. S. Gordon, J. Chem. Phys. 104(17), 6628 (1996).

C. W. Bauschlicher and E. M. Siegbahn, Chem. Phys. Lett. 104(4), 331 (1984).

S. Sokolova and A. Luchov, Chem. Phys. Lett. 320(5), 421 (2000).

X. B. Wang, C. F. Ding, and L. S. Wang, J. Phys. Chem. A 101(5), 7699 (1997).

E. K. Storms, The Refractory Carbides (Academic Press, New York, 1967; Atomizdat, Moscow, 1970).

H. J. Schaller, Z. Metallkunde 86, 319 (1995).

S. Jonsson, Z. Metallkunde 87, 703 (1996).

T. C. Wallace, Sr., J. Am. Ceram. Soc. 76, 1409 (1993).

A. Hara, J. Cryst. Growth 51, 164 (1981).

E. Rudy, Planseeber. Pulvermetallurg. 8, 66 (1960).

R. V. Sara, Transact. Metallurg. Soc. AIME 233, 1683 (1965).

L. W. Artjuch, Colloq. Int. Centre Nat. Rech. Sci. (Paris), 277 (1971).

A. I. Gusev and A. A. Rempel’, Dokl. Akad. Nauk 332(6), 717 (1993).

I. Barin, O. Knacke, and O. Kubaschewski, Thermochemical Properties of Inorganic Substances (Springer, Berlin, 1977).

L. V. Gurvich, I. V. Veits, V. A. Medvedev, et al., The Thermodynamic Properties of Individual Compounds: A Handbook, Ed. by V. P. Glushko (Nauka, Moscow, 1978) [in Russian].

L. V. Gurvich and V. S. Iorish, et al., IVTANTERMO. A Thermodynamic Database and Software System for the Personal Computer. User’s Guide (CRC Press, Boca Raton, FL, 1993).

E. Rudy, D. P. Harmon, and C. E. Brukl, Rep. No. AFML-TR-65-2. Contract No. USAF 33(615)-1249. Air Force Mater. Lab., Wright-Patterson Air Force Base, (1965), Part I: Related Binary Systems, Vol. II: Ti-C and Zr-C Systems. Ternary Phase Equilibria in Transition Metal-Boron-Carbon-Silicon Systems.

M. Pajunen and J. Kivilahti, Z. Metallkunde 83(1), 17 (1992).

J. P. Abriata, J. Garces, and R. Versaci, Bull. Alloy Phase Diagrams 7(2), 116, 203 (1986).

P. Stecher, J. Less-Common Met. 5, 78 (1963).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.G. Sevastyanov, E.P. Simonenko, N.A. Ignatov, Yu.S. Ezhov, N.P. Simonenko, N.T. Kuznetsov, 2011, published in Zhurnal Neorganicheskoi Khimii, 2011, Vol. 56, No. 5, pp. 707–719.

Rights and permissions

About this article

Cite this article

Sevastyanov, V.G., Simonenko, E.P., Ignatov, N.A. et al. Low-temperature synthesis of nanodispersed titanium, zirconium, and hafnium carbides. Russ. J. Inorg. Chem. 56, 661–672 (2011). https://doi.org/10.1134/S0036023611050214

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036023611050214