Abstract

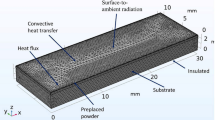

A physical and mathematical model has been proposed for computing the thermal state and shape of the individual deposited track at the laser powder cladding. A three-dimensional statement of the two-phase problem of Stefan type with curved moving boundaries is considered. One of the boundaries is the melting-crystallization boundary, and the other is the boundary of the deposited layer, where the conservation laws are written from the condition of the inflow of the additional mass and energy. To describe the track shape the equation of kinematic compatibility of the points of a surface is used, the motion of which occurs at the expense of the mass of powder particles supplied to the radiation spot. An explicit finite difference scheme on a rectangular nonuniform grid is used for numerical solution of equations. The computations are carried out by through computation without an explicit identification of curved boundaries by using a modification of the immersed boundary method. The computational results are presented for the thermal state and the shape of the surface of the forming individual track depending on physical parameters: the substrate initial temperature, laser radiation intensity, scanning speed, powder feeding rate, etc.

Similar content being viewed by others

References

A.G. Grigoryants, I.N. Shiganov, and A.I. Misyurov, Technological Processes of Laser Treatment, Bauman Moscow State Techn. School, Moscow, 2006.

V.Ya. Panchenko, V.S. Golubev, V.V. Vasiltsov, A.N. Gryazev, V.D. Dubrov, A.A. Karabutov, V.S. Mayorov, and A.N. Safonov, Laser technologies of Materials Treatment, in V.Ya. Panchenko (Ed.), Advanced Problems of Fundamental Research and Applied Developments, Fizmatlit, Moscow, 2009.

U. de Oliveira, V. Ocelik, and J.Th.M. de Hosson, Analysis of coaxial laser cladding processing conditions, Surface & Coating Technology, 2005, Vol. 197, No. 2–3, P. 127–136.

D. Novichenko, L. Thivillon, Ph. Bertrand, and I. Smurov, Carbide-reinforced metal matrix composite by direct metal deposition, Physics Procedia, 2010, Vol. 5, No. 1, P. 369–377.

S. Wen and Y.C. Shin, Modeling of the off-axis high power diode laser cladding process, J. Heat Transfer, 2011, Vol. 133, No. 3, P. 031007 (10).

X. He and J. Mazumder, Transport phenomena during direct metal deposition, J. Appl. Phys., 2007, Vol. 101, No. 5, P. 053113 (9).

C. Lalas, K. Tsirbas, K. Salonitis, and G. Chryssolouris, An analytical model of the laser clad geometry, Int. J. Adv. Manuf. Technol., 2007, Vol. 32, Nos. 1–2, P. 34–41.

V.A. Sudnik, V.A. Erofeev, D. Radai, M. Bek, and M. Kern, Computer modeling of laser cladding of powder coatings, in: Proc. III Inter. Sci. Techn. Conf., Laser Techn. And Means of Their Realization, St. Petersburg, 2000, P. 50–57.

S. Wen and Y.C. Shin, Modeling of transport phenomena during the coaxial laser direct deposition process, J. Appl. Phys., 2010, Vol. 108, No. 4, P. 044908 (9).

O.B. Kovalev, A.V. Zaitsev, D. Novichenko, and I. Smurov, Theoretical and experimental investigation of gas flows, powder transport and heating in coaxial laser Direct Metal Deposition (DMD) process, J. Thermal Spray Technology, 2011, Vol. 20, No. 3, P. 465–478.

A.A. Samarskii and V.D. Moseenko, An efficient scheme for the through computation in a many dimensional Stefan problem, USSR Comput. Math. and Math. Phys., 1965, Vol. 5, No. 5, P. 43–58.

W.D. Bennon and F.P. Incropera, A continuum model for momentum, heat and species transport in binary solidliquid phase change systems. I. Model formulation, Int. J. Heat and Mass Transfer, 1987, Vol. 30, No. 10, P. 2161–2170.

V.V. Semak, B. Damkroger, and S. Kempka, Temporal evolution of the temperature field in the beam interaction zone during laser material processing, J. Phys. D: Appl. Phys., 1999, Vol. 32, No. 15, P. 1819–1825.

V.V. Vinnikov and D.L. Reviznikov, Cartesian grids methods for numerical solution of Navier — Stokes equations in domains with curvilinear boundaries, Matem. modelirovanie, 2005, Vol. 17, No. 8, P. 15–30.

P.N. Vabishchevich, Method of Fictitious Domains in Mathematical Physics Problems, Moscow State Univ., Moscow, 1991.

Y.H. Tseng and J.H. Ferziger, A ghost-cell immersed boundary method for flow in complex geometry, J. Comput. Phys., 2003, Vol. 192, P. 593–623.

A.A. Samarskii, The Theory of Difference Schemes, CRC Press, 2001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bedenko, D.V., Kovalev, O.B. Modelling of heat and mass transfer in the laser cladding during direct metal deposition. Thermophys. Aeromech. 20, 251–261 (2013). https://doi.org/10.1134/S086986431302011X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S086986431302011X