Abstract

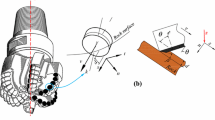

Conical bits are very common in excavation of soft to medium rocks in a great deal of mining and construction applications. Bit rotation allows the conical bits to maintain their tip shape and allows them to work more efficiently for extended period of time. This paper discusses the importance of bit rotation and the research work of measuring bit rotation and the impact of various parameters on this phenomenon. To find the relevant factors contributing to bit rotation, a few dominant parameters such as bit type, cut spacing, depth of cut, attack angle, and skew angle were considered. The paper described full scale linear cutting tests which were performed at Kennametal rock cutting lab in Latrobe PA. This linear cutting test is a prototype experiment to verify the direct measurement of bit rotation, to evaluate the impact of related parameters before performing rotary cutting tests. This paper offers the review of the linear cutting test results and outlines the observed bit rotation during experiments and their practical implications.

Similar content being viewed by others

References

Hurt, K.G. and Evans, I., Point Attack Tools: An Evaluation of Function and Use for Rock Cutting, The Mining Engineer, 1981, no. 5, pp. 673–675.

Yilmaz, N.G., Yurdakul, M., and Goktan, R.M., Prediction of Radial Bit Cutting Force in High-Strength Rocks Using Multiple Linear Regression Analysis, International Journal of Rock Mechanics and Mining Science, 2007, vol. 44, pp. 962–970.

Goktan, R.M. and Gunes, N., A Semi-Empirical Approach to Cutting Force Prediction for Point-Attack Picks, Journal of the Southern African Institute of Mining and Metallurgy, 2005, vol. 105, pp. 257–263.

Roxborough, F.F. and Sen, G.C., Breaking Coal and Rock, Australasian Coal Mining Practice, Australia Institute of Mining and Metallurgy (imprint), 1986, pp. 130–147.

Nishimatsu, Y., The Mechanics of Rock Cutting, International Journal of Rock Mechanics and Mining Science Geomechanics Abstract, 1972, no. 9, pp. 261–270.

Roxborough, F.F. and Pedroncelli, E.J., A Practical Evaluation of Some Coal-Cutting Theories Using a Continuous Miner, The Mining Engineer, 1982, pp. 145–155.

Saouma, V. and Kleinosky, M., Finite Element Simulation of Rock Cutting: A Fracture Mechanics Approach, Proc. 25th U.S. Symp. Rock Mechanics (USRMS), Evanston, IL, 1984.

Bilgin, N., Demircin, M.A., Copur, H., Balci, C., Tuncdemir, H., and Akcin, N., Dominant Rock Properties Affecting the Performance of Conical Picks and the Comparison of Some Experimental and Theoretical Results, International Journal of Rock Mechanics and Mining Science, 2006, vol. 43, pp. 139–156.

Tiryaki, B., Evaluation of the Indirect Measures of Rock Brittleness and Fracture Toughness in Rock Cutting, The Journal of Southern African Institute of Mining and Metallurgy, 2006, vol. 106, pp. 409–423.

Goktan, R.M. and Yilmaz, N.G., A New Methodology for the Analysis of the Relationship between Rock Brittleness Index and Drag Pick Cutting Efficiency, Journal of the Southern African Institute of Mining and Metallurgy, 2005, vol. 105, pp. 727–733.

Bilgin, N., Dincer, T., and Copur, H., The Performance Prediction of Impact Hammers from Schmidt Hammer Rebound Values in Istanbul Metro Tunnel Drivages, Tunnelling and Underground Space Technology, 2002, vol. 17, pp. 237–247.

Roxborough, F.F. and Phillips, H.R., Rock Excavation by Disk Cutter, International Journal of Rock Mechanics and Mining Sciences, 1975, vol. 12, pp. 361–366.

Teale, R., The Concept of Specific Energy in Rock Drilling, International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstract, 1965, 2, pp. 57–73.

Hekimoglu, O.Z., Investigations into Performance of Point-Attack and Radial-Type Rock- and Coal-Cutting Picks, Transactions of the Institution of Mining and Metallurgy Section A: Mining Industry, 1998, vol. 107, A55–A59.

Deketh, H.J.R., Wear of Rock Cutting Tools: Laboratory Experiments on the Abrasivity of Rock, A.A. Balkema/Rotterdam/Brookfields, 1995.

Asbury, B., Ozdemir, L., and Rozgonyi, T.G., Frustum Bit Technology for Continuous Miner and Roadheader Applications, Proc. 6th Int. Symp. Mine Mechanization and Automation, South African Institute of Mining and Metallurgy, 2001.

Eunhye Kim, Jamal Rostami, and Chad Swope, Measurement of Conical Bit Rotation, Proc. 23nd Symp. U.S. Rock Mechanics, Asheville, NC, 2009, ARMA 09-027.

Achanti, V.B. and Khair. A.W., Bit Geometry Effects on Failure Characteristics of Rock, The Mining Engineering, 2000, vol. 52, no. 6, pp. 101–107.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Kim, E., Rostami, J. & Swope, C. Full scale linear cutting experiment to examine conical bit rotation. J Min Sci 48, 882–895 (2012). https://doi.org/10.1134/S1062739148050139

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1062739148050139