Abstract

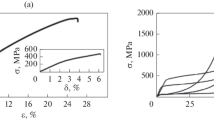

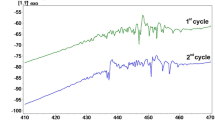

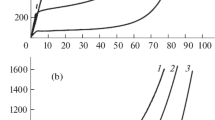

It was found that deformation by the uniaxial compression scheme (while measuring mechanical properties under isothermal conditions) at 600–800°C leads to a significant refinement of the grain structure, which increases the strength and ductility of Cu–13.95 wt % Al–3.98 wt % Ni alloy, experiencing thermoelastic martensitic transformation and related shape memory effects. The structural and phase composition features were studied using scanning and transmission electron microscopy and X-ray diffraction.

Similar content being viewed by others

REFERENCES

K. Ootsuka, K. Simidzu, Yu. Sudzuki, Yu. Sekiguti, Ts. Tadaki, T. Khomma, and S. Miyadzaki, in Shape Memory Effects in Alloys, Ed. by J. Perkins (Plenum, New York, 1975; Metallurgiya, Moscow, 1990).

Materials with Shape Memory Effect, Ed. by V. A. Likhachev (NIIKh SPbGU, St. Petersburg, 1997–1998) [in Russian].

S. A. Pul’nev, V. I. Nikolaev, G. A. Malygin, S. L. Kuz’min, V. V. Shpeizman, and S. P. Nikanorov, Tech. Phys. 51, 1004 (2006).

L. A. Matlakhova, E. C. Pereira, A. N. Matlakhov, S. N. Monteiro, and R. Toledo, Mater. Charact. 59, 1630 (2008).

V. I. Nikolaev, P. N. Yakushev, G. A. Malygin, A. I. Averkin, A. V. Chikiryaka, and S. A. Pulnev, Tech. Phys. Lett. 40, 123 (2014).

R. Dasgupta, J. Mater. Res. 29, 1681 (2014).

V. G. Pushin, A. I. Lotkov, Yu. R. Kolobov, R. Z. Valiev, E. F. Dudarev, N. N. Kuranova, A. P. Dyupin, D. V. Gunderov, and G. P. Bakach, Phys. Met. Metallogr. 106, 520 (2008).

U. Sari and T. Kirindi, Mater. Charact. 59, 920 (2008).

A. Creuziger and W. C. Crone, Mater. Sci. Eng., A 498, 404 (2008).

Z. Wang, X. F. Liu, and J. X. Xie, Prog. Natur. Sci.: Mater. Int. 21, 368 (2011).

Z. Wang, X. F. Liu, and J. X. Xie, Mater. Sci. Eng., A 532, 536 (2012).

G. Lojen, M. Cojic, and I. Anzel, J. Alloy Compd. 580, 497 (2013).

P. Sedlak, H. Seiner, M. Landa, V. Novák, P. Šittner, and L. I. Manosa, Acta Mater. 53, 3643 (2005).

V. N. Khachin, S. A. Muslov, V. G. Pushin, and Yu. I. Chumlyakov, Sov. Phys. Dokl. 32, 606 (1987).

P. Rodriguez and G. Guenin, Mater. Sci. Eng., A 129, 273 (1990).

H. Fu, S. Song, L. Zhuo, Z. Zhang, and J. Xie, Mater. Sci. Eng., A 650, 218 (2016).

A. V. Lukyanov, V. G. Pushin, N. N. Kuranova, A. E. Svirid, A. N. Uksusnikov, Yu. M. Ustyugov, and D. V. Gunderov, Phys. Met. Metallogr. 119, 374 (2018).

A. E. Svirid, N. N. Kuranova, A. V. Luk’yanov, V. V. Makarov, N. V. Nikolaeva, V. G. Pushin, and A. N. Uksusnikov, Russ. Phys. J. 61, 1681 (2018).

V. G. Pushin, V. V. Stolyarov, R. Z. Valiev, N. I. Kourov, N. N. Kuranova, E. A. Prokofiev, and L. I. Yurchenko, Ann. Chim. Sci. Mater. 27, 77 (2002).

V. G. Pushin, V. V. Stolyarov, R. Z. Valiev, T. C. Lowe, and Y. T. Zhu, Mater. Sci. Eng., A 410, 386 (2005).

Funding

This work was financially supported by state assignment no. АААА-А18-118020190116-6 (“Structure“) of the Institute of Metal Physics, Ural Branch, Russian Academy of Sciences, and the joint laboratory of the Institute of Metal Physics and Ural Federal University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by A. Bannov

Rights and permissions

About this article

Cite this article

Svirid, A.E., Pushin, V.G., Kuranova, N.N. et al. The Effect of Plastification of Cu–14Al–4Ni Alloy with the Shape Memory Effect in High-Temperature Isothermal Precipitation. Tech. Phys. Lett. 46, 118–121 (2020). https://doi.org/10.1134/S1063785020020145

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785020020145