Abstract

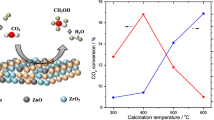

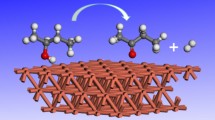

Considered three options for the synthesis of a catalyst by the precipitation method, the Cu/SiO2 catalysts prepared by varying the precipitation procedure and calcination temperature for the dehydrogenation of methanol was investigated. When the CuO/SiO2 catalyst precursors were prepared by the addition of a copper nitrate aqueous solution into an ammonia aqueous solution (reverse precipitation) and co-current flow addition of both aqueous solutions, after reduction with gaseous hydrogen, small-sized metallic copper nanocrystallites were formed in the reduced Cu/SiO2 catalysts as compared to those prepared by the addition of an ammonia aqueous solution into a copper nitrate aqueous solution (direct precipitation). The reduced Cu/SiO2 catalysts prepared by the reverse precipitation method with relatively lower acidity and basicity exhibited higher catalytic activity for the formation of methyl formate in methanol dehydrogenation. The reduced Cu/SiO2 catalysts prepared by the calcination at a lower temperature exhibited higher catalytic activity for the formation of methyl formate. The surface metallic Cu0 and Cu+ species catalyzed the methanol dehydrogenation to methyl formate, meanwhile the surface Cu+ cations enhanced the decomposition of the resultant methyl formate to CO and H2.

Similar content being viewed by others

REFERENCES

Huang, C., Wen, J., Sun, Y., Zhang, M., Bao, Y., Zhang, Y., Liang, L., Fu, M., Wu, J., Ye, D., and Chen, L., Chem. Eng. J., 2019, vol. 374, pp. 221–230. https://doi.org/10.1016/j.cej.2019.05.123

Du, H., Ma, X., Yan, P., Jiang, M., Zhao, Z., and Zhang, Z.C., Fuel Process. Technol., 2019, vol. 193, pp. 221–231. https://doi.org/10.1016/j.fuproc.2019.05.003

Zhang, D., Yin, H., Ge, C., Xue, J., Jiang, T., Yu, L., and Shen, Y., J. Ind. Eng. Chem., 2009, vol. 15, pp. 537–543. https://doi.org/10.1016/j.jiec.2009.01.010

Zhang, D., Yin, H., Xue, J., Ge, C., Jiang, T., Yu, L., and Shen, Y., Ind. Eng. Chem. Res., 2009, vol. 48, pp. 11220–11224. https://doi.org/10.1021/ie9013875

Ferrah, D., Haines, A.R., Galhenage, R.P., Bruce, J.P., Babore, A.D., Hunt, A., Waluyo, I., and Hemminger, J.C., ACS Catal., 2019, vol. 9, pp. 6783−6802. https://doi.org/10.1021/acscatal.9b01419

Lu, Z., Yin, H., Wang, A., Hu, J., Xue, W., Yin, H., and Liu, S., J. Ind. Eng. Chem., 2016, vol. 37, pp. 208–215. https://doi.org/10.1016/j.jiec.2016.03.028

Yang, H., Chen, Y., Cui, X., Wang, G., Cen, Y., Deng, T., Yan, W., Gao, J., Zhu, S., Olsbye, U., Wang, J., and Fan, W., Angew. Chem., 2018, vol. 130, pp. 1854–1858. https://doi.org/10.1002/anie.201710605

Salaeva, A.A., Salaev, M.A., Vodyankina, O.V., and Mamontov, G.V., Appl. Catal. A., 2019, vol. 581, pp. 82–90. https://doi.org/10.1016/j.apcata.2019.05.018

Yin, H., Yin, H., Wang, A., Shen, L., Liu, Y., and Zheng, Y., J. Nanosci. Nanotechnol., 2017, vol. 17, pp. 1255–1266. https://doi.org/10.1166/jnn.2017.12573

Park, J., Cho, J., Lee, Y., Park, M.J., and Lee, W.B., Ind. Eng. Chem. Res., 2019, vol. 58, pp. 8663–8673. https://doi.org/10.1021/acs.iecr.9b01254

Sitthisa, S., Sooknoi, T., Ma, Y., Balbuena, P.B., and Resasco, D.E., J. Catal., 2011, vol. 277, pp. 1–13. https://doi.org/10.1016/j.jcat.2010.10.005

Indu, B., Ernst, W.R., and Gelbaum, L.T., Ind. Eng. Chem. Res., 1993, vol. 32, pp. 981–985. https://doi.org/10.1021/ie00017a031

He, L., Liu, H., Xiao, C., and Kou, Y., Green Chem., 2008, vol. 10, pp. 619–622. https://doi.org/10.1039/B804459G

Ai, M., J. Catal., 1982, vol. 77, pp. 279–288. https://doi.org/10.1016/0021-9517(82)90168-3

Shelepova, E.V., Ilina, L.Y., and Vedyagin, A.A., Catal. Today, 2019, vol. 331, pp. 35–42. https://doi.org/10.1016/j.cattod.2017.11.023

Matsuda, T., Yogo, K., Pantawong, C., and Kikuchi, E., Appl. Catal. A., 1995, vol. 126, pp. 177–186. https://doi.org/10.1016/0926-860X(95)00041-0

Lu, Z., Gao, D., Yin, H., Wang, A., and Liu, S., J. Ind. Eng. Chem., 2015, vol. 31, pp. 301–308. https://doi.org/10.1016/j.jiec.2015.07.002

Shelepova, E.V., Vedyagin, A.A., Ilina, L.Y., Nizovskii, A.I., and Tsyrulnikov, P.G., Appl. Surf. Sci., 2017, vol. 409, pp. 291–295. https://doi.org/10.1016/j.apsusc.2017.02.220

Zhang, R., Sun, Y., and Peng, S., Fuel, 2002, vol. 81, pp. 1619–1624. https://doi.org/10.1016/S0016-2361(02)00085-6

Minyukova, T.P., Simentsova, I.I., Khasin, A.V., Shtertser, N.V., Baronskaya, N.A., Khassin, A.A., and Yurieva, T.M., Appl. Catal. A., 2002, vol. 237, pp. 171–180. https://doi.org/10.1016/S0926-860X(02)00328-9

Guerreiro, E.D., Gorriz, O.F., Larsen, G., and Arrúa, L.A., Appl. Catal. A., 2000, vol. 204, pp. 33–48. https://doi.org/10.1016/S0926-860X(00)00507-X

Guo, Y., Lu, G., Mo, X., and Wang, Y., Catal. Lett., 2005, vol. 99, pp. 105–108. https://doi.org/10.1007/s10562-004-0783-3

Kipnis, M.A., Volnina, E.A., Belostotskii, I.A., and Levin, I.S., Kinet. Catal., 2020, vol. 61, pp. 145‒154. https://doi.org/10.1134/S0023158420010024

Zhong, J., Yang, X., Wu, Z., Liang, B., Huang, Y., and Zhang, T., Chem. Soc. Rev., 2020, vol. 49, pp. 1385–1413. https://doi.org/10.1039/C9CS00614A

Minyukova, T.P., Khasin, A.V., Khassin, A.A., Shtertser, N.V., Simentsova, I.I., and Yurieva, T.M., Catal. Ind., 2016, vol. 8, pp. 293‒299. https://doi.org/10.1134/S2070050416040073

Xue, W., Yin, H., Lu, Z., Wang, A., Liu, S., and Shen, L., J. Nanosci. Nanotechnol., 2018, vol. 18, pp. 3362–3372. https://doi.org/10.1166/jnn.2018.14706

Yin, H., Zhang, C., Yin, H., Gao, D., Shen, L., and Wang, A., Chem. Eng. J., 2016, vol. 288, pp. 332–343. https://doi.org/10.1016/j.cej.2015.12.010

Wang, A., Zhang, M., Yin, H., Liu, S., Liu, M., and Hu, T., RSC Adv., 2018, vol. 8, pp. 19317–19325. https://doi.org/10.1039/C8RA03125H

Dai, W.L., Sun, Q., Deng, J.F., Wu, D., and Sun, Y.H., Appl. Surf. Sci., 2001, vol. 177, pp. 172–179. https://doi.org/10.1016/S0169-4332(01)00229-X

Aravinda, C.L., Bera, P., Jayaram, V., Sharma, A.K., and Mayanna, S.M., Mater. Res. Bull., 2002, vol. 37, pp. 397–405. https://doi.org/10.1016/S0025-5408(01)00821-2

Deutsch, K.L., and Shanks, B.H., Appl. Catal. A., 2012, vol. 447–448, pp. 144–150. https://doi.org/10.1016/j.apcata.2012.09.047

Sun, K., Lu, W., Qiu, F., Liu, S., and Xu, X., Appl. Catal. A., 2003, vol. 252, pp. 243–249. https://doi.org/10.1016/S0926-860X(03)00466-6

ACKNOWLEDGMENTS

This work was financially supported by the Jiangsu Science and Technology Department, China (FZ20180919).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors state that they have no conflict of interest to be disclosed in the present communication.

Rights and permissions

About this article

Cite this article

Wang, A.L., Ye, C.L., Jia, X.Y. et al. Methanol Dehydrogenation to Methyl Formate Catalyzed by Cu/SiO2 Catalysts: Impact of Precipitation Procedure and Calcination Temperature. Russ J Appl Chem 94, 1302–1312 (2021). https://doi.org/10.1134/S1070427221090135

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427221090135