Abstract

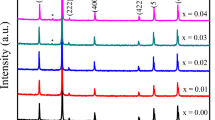

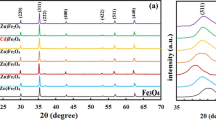

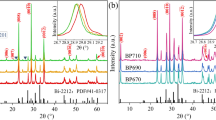

Sintered Nd–Pr–Dy–Fe–B permanent magnets were prepared by a powder blending technique using mixtures consisting of strip-casting alloy (wt %) 24.0 Nd, 6.5 Pr, 0.5 Dy, 1.0 B, 0.2 Al, 65.8 Fe and 2 wt % DyH2 dysprosium hydride. After optimum heat treatment of magnets at 500°C for 1 h, the following hysteretic characteristics were reached: remanence B r = 1.29 T; coercive force j H c = 1309 kA/m; critical field H k = 1220 kA/m; and the maximum energy product (BH)max = 322 kJ/m3. The characteristic peculiarity of the magnets prepared from hydride-containing power mixtures is the stability of hysteretic properties in the course of subsequent stepped annealings or progressive heatings at temperatures of 250–500°C for, in total, more than 20 h. Conditions of low-temperature annealings resulting in the degradation and subsequent restoration of hysteretic properties of magnets are determined. The evolution of the microstructure and phase composition of magnets in the course of heat treatments was studied by X-ray diffraction analysis and scanning electron microscopy, and the correlation between the structural changes and hysteretic properties of magnets is discussed.

Similar content being viewed by others

References

Hiraga, K., Hirabayashi, M., Sagawa, M., and Matsuura, Y., A study of microstructures of grain boundaries in sintered Fe77Nd15B8 permanent magnet by highresolution electron microscopy, Jpn. J. Appl. Phys., 1985, vol. 24, no. 6, pp. 699–703.

Seperhri-Amin, H., Ohkubo, T., and Hono, K., The mechanism of coercivity enhancement by the grain boundary diffusion process of Nd–Fe–B sintered magnets, Acta Mater., 2013, vol. 61, no. 6, pp. 1982–1990.

Straumal, B.B., Kucheev, Yu.O., Yatskovskaya, I.L., Mogilnikova, I.V., Schutz, G., Nekrasov, A.N., and Baretzky, B., Grain boundary wetting in the NdFeBbased hard magnetic alloys, J. Mater. Sci., 2012, vol. 47, no. 24, pp. 8352–8359.

Withey, P.A., Devlin, E.J., Abell, J.S., and Harris, I.R., Ageing effects in Nd(Dy)Fe(Nb)B alloys magnets, J. Magn. Magn. Mater., 1989, vol. 80, no. 1, pp. 67–70.

Lukin, A.A., Kolchugina, N.B., Burkhanov, G.S., Klyueva, N.E., and Skotnicova, K., Role of terbium hydride additions in the formation of microstructure and magnetic properties of sintered Nd–Pr–Dy–Fe–B magnets, Inorg. Mater.: Appl. Res., 2013, vol. 4, no. 3, pp. 256–259.

Tokunada, M., Kogure, H, Endoh, M., and Harada, H., Improvement of thermal stability of Nd–Dy–Fe–Co–B sintered magnets by additions of Al, Nb, and Ge, IEEE Trans. Magn., 1987, vol. 23, no. 5, pp. 2287–2289.

Lukin, A.A., Influence of heat treatment parameters on properties of NdRFeMCoB sintered magnets, J. Iron Steel Res. Int., 2006, vol. 13, supp. 1, pp. 331–335.

Kononenko, A.S., Fedyakin, V.V., Sergeev, V.V., and Vol’skii, A.A., Effect of heat treatment on Hci of Nd–Fe–B permanent magnets, Izv. Akad. Nauk SSSR, Met., 1986, no. 2, pp. 182–184.

Eckert, D., Hinz, D., Handstein, A., and Schneider, J., Thermal ageing and coercivity of sintered Nd–Fe–B magnets, Phys. Status Solidi A, 1987, vol. 101, pp. 563–566.

Lukin, A.A. and Szymura, S., Peculiarities of forming of coercive force by heat treatment processes of sintered Nd–Fe–B type magnets, Arch. Mater. Sci., 2000, vol. 21, no. 1, pp. 21–30.

Lukin, A.A., Influence of heterogeneity of chemical composition and texture on magnetic properties of sintered magnets (Nd, Dy, Tb)–(Fe, Ti)–B, Metally, 1996, no. 2, pp. 131–137.

Menushenkov, V.P. and Savchenko, A.G., Heat treatment, microstructure and coercivity of Nd–Fe–B based sintered magnets, Proc. Russian-Japanese Seminar “Material Research and Metallurgy. Advanced Technologies and Equipment,” Moscow, March 25, 2003, Kozhitov, L.V. Ed. Moscow: Mosk. Gos. Tekh. Univ., 2003, pp. 127–146.

Kim, H.-S., Kim, S.H., Kim, J.W., Lee, Y.J., Kim, D.-G., and Kim, Y.D., Magnetic properties of high coercivity Nd23Dy10Fe64TM2B1 sintered magnets by a convergent heat treatment, Res. Chem. Intermed., 2010, vol. 36, nos. 6–7, pp. 859–866.

Akiya, T., Sasaki, T.T., Ohkubo, T., Une, Y., Sagawa, M., Kato, H., and Hono, K., The origin of the coercivity reduction of Nd–Fe–B sintered magnet annealed below an optimal temperature, J. Magn. Magn. Mater., 2013, vol. 342, pp. 4–10.

Woodcock, T.G., Bittner, F., Mix, T., Mueller, K.-H., Sawatzki, S., and Gutfleisch, O., On the reversible and fully repeatable increase in coercive field of sintered Nd–Fe–B magnets following post sinter annealing, J. Magn. Magn. Mater., 2014, vol. 360, pp. 157–164.

Woodcock, T.G. and Gutfleisch, O., Multi-phase EBSD mapping and local texture analysis in NdFeB synthered magnets, Acta Mater., 2011, vol. 59, pp. 1026–1030.

Matsuura, M., Goto, R., Tezuka, N., and Sugimoto, S., Influence of Nd oxide phase on the coercivity of Nd–Fe–B thin films, Mater. Trans., 2010, vol. 51, pp. 1901–1904.

Vial, F., Joly, F., Nevalainen, E., Sagawa, M., Hiraga, K., and Park, K.T., Improvement of coercivity of sintered NdFeB permanent magnets by heat treatment, J. Magn. Magn. Mater., 2002, vol. 242–245, pp. 1329–1334.

Yan, G., McGuiness, P.J., Farr, J.P.G., and Harris, I.R., Optimization of the processing of Nd–Fe–B with dysprosium addition, J. Alloys Compd., 2010, vol. 491, pp. L20–L24.

Malfliet, A., Cacciamani, G., Lebrun, N., and Rogl, P., Boron–iron–neodymium, in Landolt-Börnstein–Group IV: Physical Chemistry, Vol. 11: Ternary Alloy Systems. Phase Diagrams, Crystallographic and Thermodynamic Data, Subvolume D: Iron Systems, Part 1: Selected Systems from Al–B–Fe to C–Co–Fe, Effenberg, G. and Ilyenko, S., Eds., Berlin: Springer-Verlag, 2008, pp. 482–511.

Koshkidko, Yu.S., Skotnikova, K., Zivotsky, O., Kursa, M., Burkhanov, G.S., Kolchugina, N.B., Lukin, A.A., Dormidontov, A.G., Sitnov, V.V., and Cwik, J., Evolution of the phase composition of (Nd, Pr, Dy)–Fe–B magnets during stepped annealing, Proc. Int. Conf. on Metallurgy and Materials, May 21–23, 2014, Brno, Czech Republic, Tanger, 2015, pp. 1416–1420.

Burkhanov, G.S., Semenova, E.M., Karpenkov, D.Yu., Lukin, A.A., Kolchugina, N.B., Cwik, J., Rogacki, K., Kursa, M., and Skotnicova, K., Application of duplex sintering for improvement of energy parameters of thermostable Pr–Dy–Fe–Co–B–Cu–Al permanent magnets, Perspekt. Mater., 2016, no. 11, pp. 39–47.

Yang, N., Dennis, K.W., McCallum, R.W., Kramer, M.J., Zhang, Y., and Lee, P.L., Role of the Fe on the invar anomaly in R2Fe14B compounds, J. Appl. Phys., 2003, vol. 93, no. 10, pp. 7990–7992.

Andreev, A.V., Deryagin, A.V., Zadvorkin, S.M., and Terent’ev, S.V., Thermal extension and spontaneous magnetostriction of R2Fe14B (R–Y, Nd, Sm) compounds, Sov. Phys. Solid State, 1985, vol. 27, no. 6, pp. 987–989.

Buschow, K.H.J., Invar effect in R2Fe14B compounds (R–La, Ce, Nd, Sm, Gd, Er), J. Less-Common Met., 1986, vol. 118, pp. 349–353.

Andreev, A.V. and Bartashevich, M.I., Spontaneous magnetostriction of Y2(Fe1–xCox)14B single crystals, Fiz. Tverd. Tela, 1990, vol. 32, no. 4, pp. 1140–1143.

Andreev, A.V. and Bartashevich, M.I., Spontaneous magnetostriction of the Y2(Fe1–x)Cox)14B intermetallic compounds, J. Less-Common Met., 1990, vol. 162, pp. 33–37.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © G.S. Burkhanov, N.B. Kolchugina, A.A. Lukin, Yu.S. Koshkidko, J. Cwik, K. Skotnicova, V.V. Sitnov, 2017, published in Fizika i Khimiya Obrabotki Materialov, 2017, No. 5, pp. 44–54.

Rights and permissions

About this article

Cite this article

Burkhanov, G.S., Kolchugina, N.B., Lukin, A.A. et al. Structure and Magnetic Properties of Nd–Fe–B Magnets Prepared from DyH2-Containing Powder Mixtures. Inorg. Mater. Appl. Res. 9, 509–516 (2018). https://doi.org/10.1134/S2075113318030115

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113318030115