Abstract

The magnetic NiFe2O4 nanoparticles have been synthesized and used as adsorbents for removal of an azo dye, Eriochrome black-T (EBT) from aqueous solution. The NiFe2O4 nanoparticles were characterized by scanning electron microscope (SEM), Transmission electron microscope (TEM), X-ray diffraction (XRD) and Fourier transform infrared spectra (FTIR). The adsorption studies were carried out under various parameters, such as pH, adsorbent dosage, contact time and initial dye concentration. The experimental results show that the percentage of adsorption increases with an increase in the adsorbent dosage. The maximum adsorption occurred at the pH value of 6.0. The equilibrium uptake was increased with an increase in the initial dye concentration in solution. Adsorption kinetic data were properly fitted with the pseudo-second-order kinetic model. The experimental isotherms data were analyzed using Langmuir and Freundlich isotherm equations. The best fit was obtained by the Langmuir model with high correlation coefficients (R2 = 0.9733) with a maximum monolayer adsorption capacity of 47.0 m g/g.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

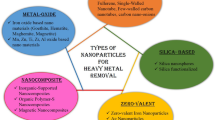

Organic dyes are widely used in various fields and seriously induce water pollution. Most of the industrial dyes are toxic, carcinogenic, and teratogen [1]. Moreover, they are very stable to light, temperature and microbial attack, making them recalcitrant compounds. From an environmental point of view, the removal of synthetic dyes is of great concern. Among several chemical and physical methods, adsorption process is one of the effective techniques that have been successfully employed for color removal from wastewater [2]. In recent years, magnetic nanoparticles have attracted much attention because of their unique magnetic properties and widespread application in different fields such as mineral separation magnetic storage devices, catalysis, magnetic refrigeration system, heat transfer application in drug delivery system, magnetic resonance imaging (MRI), cancer therapy, and magnetic cell separation [3]-[7]. Magnetic separation has been gradually regarded as a rapid and effective technique for separating magnetic particles [8],[9]. It has been used for many applications in biochemistry, cell biology, analytical chemistry, mining, and environmental technology [10]. The advantages of this separation technology are that the harmful ingredients together with the magnetic particles can be eliminated from the polluted system by a simple magnetic field. The application of magnetic nanoparticles in waste water treatment is becoming an interesting area of research. Nanoparticle exhibit good adsorption efficiency especially due to higher surface area and greater active sites for interaction with metallic species and dyes and can easily be synthesized; several researches have used it as an adsorbent [11]-[19]. Among the various magnetic nanoparticles, most of them inevitably have the drawback of small adsorption capacity, and especially inefficient regeneration of the adsorbents, which limits their practical application. Ni ferrites with general formula (AB2O4) are one of the most versatile magnetic materials as they have high saturation magnetization, high Curie temperature, chemical stability and relatively high permeability [20]. In the present paper, NiFe2O4 magnetic nanoparticles have been used for removal of Eriochrome black-T (EBT) which is used for dyeing silk, wool, nylon multifibers after pretreatment with chromium salts. Pure EBT is also used as an indicator in complexometric titrations for determination of Ca2+, Mg2+ and Zn2+ ions and for biological staining. This dye is hazardous as such and its degradation products like Naphtaquinone are still more carcinogenic. A literature survey showed that only few papers have raised the removal of EBT [2],[21]-[26]. Therefore we became interested to develop NiFe2O4 as an efficient and low-cost adsorbent for removing this azo dye from aqueous solution.

Experimental

Materials and methods

All chemicals were obtained commercially and were used as received. Double distilled water was used throughout. X-ray diffraction analysis was carried out using a XRD model Siemens D-5000 diffractometer with Cu Kα radiation (γ = 1.5406 A°) at room temperature. Surface morphology and particle size were studied by scanning electron microscopy (SEM) using a Hitachi S-4800 SEM instrument. Transmission electron microscope (TEM) observation was performed using Hitachi H-7650 microscope at 80 KV. FT-IR spectra were determined as KBr pellets on a Bruker model 470 spectrophotometer.

Preparation of the NiFe2O4

The solution of metallic salts FeCl3 (160 mL, 1 M) and NiCl2 (40 mL, 1 M) was poured as quickly as possible into the boiling alkaline solution [NaOH (1000 mL, 1 M)] under vigorous stirring. Then the solution was cooled and continuously stirred for 90 min. The resulting precipitate was then purified by a four times repeated centrifugation (4000-6000 rpm, 20 min) and decantation.

Adsorption experiments

The experiments were carried out in conical flasks at room temperature. 40 mL of organic dye solution of known initial concentration was shaked with different mass magnetic composites and different reaction conditions on a shaker at 250 rpm. The initial pH value of the dye solutions were adjusted with 0.1 mol L-1 HNO3 or 0.1 mol L-1 NaOH solution using a pH meter. After magnetic separation using an external magnet, the equilibrium dye concentrations were determined from UV-vis absorbance characteristic with the calibration curve method at the maximum of absorbance (double beam UV/vis spectrophotometer, Shimadzu, Tokyo, Japan; Model 1601; Table 1).All experiments were performed at room temperature (25 ± 1°C). The studied ranges of the experimental variables were as follows: dye concentration (10, 20, 30, 40, 50, 60, 70 mg/L), initial pH of solution (2, 4, 6, 8, 10), adsorbent dosage (0.01, 0.02, 0.05, 0.1, 0.2 g) and contact time (5, 10, 15, 20, 30 min).

Results and discussion

Characterization of NiFe2O4 magnetic nanoparticles

NiFe2O4 nanocrystallites were prepared according to the reported procedure by R. Massart with slight modifications: fine particles are precipitated in an alkaline solution [27]. NiFe2O4 nanocrystallites were characterized by FT-IR (Figure 1), XRD (Figure 2) TEM (Figure 3) and SEM (Figure 4). The FT-IR spectrum of NiFe2O4 (Figure 1) exhibits strong bands in the low-frequency region (1000-500 cm-1 ) due to iron oxide skeleton, which is in agreement with the magnetite spectrum. The peak at 1633 cm-1 showed the existence of Fe - O and the peak at 3446 cm-1 implied the existence of residual hydroxyl groups [28]-[30]. To confirm the Ni ferrite formation in the synthesized magnetic nanoparticles, the XRD spectrum of the sample was studied. The XRD pattern of the (Figure 2) indicates that these nanoparticles have spinel structure, with all major peaks matching the standard pattern of bulk NiFe2O4 (JCPDS 10-325). The TEM and SEM photographs of the sample are illustrated in Figure 3 and Figure 4 respectively. Both the SEM and TEM images demonstrate that the prepared magnetic nanoparticles are spherical, narrowly distributed, and well dispersed, with average size of less than 50 nm in the diameter.

Adsorption and removal of dye from aqueous solution

The effect of contact time on the amount of EBT adsorbed was investigated at 10 mg L-1 initial concentration of dye. It can be observed from Figure 5 that with the increase of contact time, the percentage adsorptions also increased. Minimum adsorption was 66.8% for time 5 minutes to maximum adsorption value 86.7% for the time 10 minutes. The adsorption characteristic indicated a rapid uptake of the dye. The adsorption rate however decreased to a constant value with increase in contact time because of all available sites was covered and no active site available for binding.

The dye removal percentage was calculated as follows [1]:

where C0 and Ct (mg L-1) are the concentration of dye in the solution at initial and equilibrium time, respectively.

The effect of pH on adsorption of dyes was investigated in Figure 6 from pH 2 to 10. Solution pH may affect both aqueous chemistry and surface binding sites of the adsorbent [31]. Removal of EBT increases with increasing pH and a maximum value was found at pH 6.0. The observed trend can be explained by effect of the surface charge of adsorbent. The hydroxyl groups on NiFe2O4 as revealed by FT-IR spectrum (Figure 1, peak at 3446.54 cm-1) play a dominant role in the EBT adsorption. Depending on the solution pH, the adsorbent surface undergoes protonation or deprotonation [32] as shown by the Equation (2):

At pH < 7, -Ni-Fe-O-H2+ is the dominant species. These species having high positive charge density make the negative charged dye (EBT) adsorption favorable due to electrostatic attraction. However, at pH > 7, -Ni- Fe-OH is the dominant species in NiFe2O4. Such deprotonated species undergo electrostatic repulsion for negative charged dye. This causes decreased dye adsorption [17].

The effect of variation in the adsorbent amount on the process adsorption of EBT was studied, with different adsorbent amount in the range of 0.01-0.2 g. The results obtained are shown in Figure 7. From Figure 7, it is observed that as the adsorbent dose increases, the percentage removal also increase, until it reaches a saturation point, where the increase in adsorbent dose does not change the percentage removal. An increase in adsorption rate with adsorbent dosage can be attributed to increased surface area and the availability of more adsorption sites [17]. The best removal of EBT is at about 91 %, using an adsorbent dosage of 0.05 g in 10 mg L-1 EBT solution.

The maximum adsorption capacities at 298 K in the concentration range studied are 32.41 mg g -1 for EBT (Figure 8). The amount of dye adsorbed (Qe) was calculated using the Equation (3) [33]:

where C0 and Ce are the initial and equilibrium concentrations of dye (mg L-1), m is the mass of NiFe2O4 nanoparticles (g), and V is the volume of solution (L).

It is obvious from the data that adsorption capacity of EBT dye increases (Figure 8), but the percent removal of EBT decreases with the increase in initial concentration, suggesting that the adsorption of EBT on to NiFe2O4 is highly dependent on initial dye concentration. Because, the total number of available adsorption sites is fixed for a given adsorbent dose.

Adsorption isotherms

Isotherms study can describe how an adsorbate interacts with adsorbent. The experimental data were correlated by Langmuir and Freundlich models. The related linear equations are shown in Equations (4) and (5) respectively:

where qe = the amount of dye adsorbed per unit mass at equilibrium (mg/g); qm = the maximum amount of adsorbent that can be adsorbed per unit mass adsorbent (mg/g); Ce = concentration of adsorbent (in the solution at equilibrium (mg/l); ka = adsorption equilibrium constant.

A plot ofversusgives a straight line, with a slope ofand intercept.

Freundlich equation:

where Ce (mg/ L) and qe (mg/g) are the equilibrium concentration of adsorbent in the solution and the amount of adsorbent adsorbed at equilibrium respectively; KF (mg1-(1/n) L1/n g-1) and n are the Freundlich constant which show the adsorption capacity for the adsorbent and adsorption intensity, respectively.

A plot of log q e versus log Ce gives a straight line of slope 1/n and intercept log KF.

Ifthen the adsorption is favorable. Ifthe adsorption bond becomes weak and unfavorable adsorption occurs.

At first, we correlated the adsorption data at different initial concentrations of EBT in terms of the Langmuir isotherm (Equation (4)). Furthermore, we examined the data according to the Freundlich isotherm (Equation (5)). The calculated parameters of the Langmuir and Freundlich models are given in Table 2. The comparison of correlation coefficients (R2) of the linearized form of both equations indicates that the Langmuir model yields a better fit for the experimental equilibrium adsorption data than the Freundlich model. This suggests the monolayer coverage of the surface of NiFe2O4 nanoparticles by EBT molecules.

The maximum adsorption capacity is compared in Table 3 with the data reported by other authors for EBT adsorption.

Adsorption kinetics

In this study, pseudo-first-order and pseudo-second-order kinetics model were applied to examine the controlling mechanism of EBT adsorption from aqueous solutions. Adsorption equilibrium was reached in 10 min (Figure 5). The linear form of the pseudo first-order model and pseudo second-order kinetics model can be described as shown in Equations (6) and (7) respectively:

where, qe and qt are the adsorption capacities at equilibrium and at time t (min) respectively. k1 (min-1) and k2 (g/(mg.min)) are the pseudo first-order and pseudo second-order rate constants respectively [34]. The equilibrium experimental results were not well fitted with the pseudo first-order model (Table 2). The values of qe and k2 can be calculated from the slope and intercept of the plot of t/qt versus t (figure was not shown). The results listed in Table 1 show that the correlation coefficient is very high (R2 = 0.9962). Furthermore, the calculated equilibrium adsorption capacity was consistent with the experimental result. This result suggested that the kinetics data were better described with a pseudo second-order kinetics model.

Conclusion

NiFe2O4 magnetic nanoparticles with average size less than 50 nm in the diameter have been synthesized for removal of an azo dye from water. The prepared magnetic nanoparticles can be well dispersed in the aqueous solution and easily separated from the solution using an external magnet after adsorption. The adsorption capacity for EBT in the concentration range studied is 32.41 mg g-1. The process of purifying water pollution presented here is clean and safe using the magnetic nanoparticles. Therefore, this adsorbent was found to be useful and valuable for controlling water pollution due to dyes.

References

Qadri S, Ganoe A, Haik Y: Removal and recovery of acridine orange from solutions by use of magnetic anoparticles. J Hazard Mater 2009, 169: 318–323. 10.1016/j.jhazmat.2009.03.103

Barka N, Abdennouri M, Makhfouk ME: Removal of Methylene Blue and Eriochrome Black T from aqueous solutions by biosorption on Scolymus hispanicus L.: Kinetics, equilibrium and thermodynamics. J Taiwan Inst Chem E 2011, 42: 320–326. 10.1016/j.jtice.2010.07.004

Liu Z, Wang H, Lu Q, Du G, Peng L, Du Y, Zhang S, Yao K: Synthesis and characterization of ultrafine well-dispersed magnetic nanoparticles. J Mag Mag Mater 2004, 283: 258–262. 10.1016/j.jmmm.2004.05.031

Sharma Y, Srivastava V: Separation of Ni (II) ions from aqueous solutions by magnetic nanoparticles. J Chem Eng Data 2009, 55: 1441–1442. 10.1021/je900619d

Chang YC, Chen DH: Adsorption Kinetics and Thermodynamics of Acid Dyes on a Carboxymethylated Chitosan-Conjugated Magnetic Nano-Adsorbent. Macro Bios 2005, 5: 254–261. 10.1002/mabi.200400153

Teja AS, Koh P-Y: Synthesis, properties, and applications of magnetic iron oxide nanoparticles. Prog Cryst Growth Ch 2009, 55: 22–45. 10.1016/j.pcrysgrow.2008.08.003

Zhou J, Wu W, Caruntu D, Yu M, Martin A, Chen J, O'Connor C, Zhou W: Synthesis of porous magnetic hollow silica nanospheres for nanomedicine application. J Phys Chem C 2007, 111: 17473–17477. 10.1021/jp074123i

Kaminski MD, Nunez L: Extractant-coated magnetic particles for cobalt and nickel recovery from acidic solution. J Magn Magn Mater 1999, 194: 31–36. 10.1016/S0304-8853(98)00579-4

Oliveira LCA, Rios RV, Fabris JD, Sapag K, Garg VK, Lago RM: Clay-iron oxide magnetic composites for the adsorption of contaminants in water. Appl Clay Sci 2003, 22: 169–177. 10.1016/S0169-1317(02)00156-4

Ebner AD, Ritter JA, Ploehn HJ: Magnetic hetero-flocculation of paramagnetic colloidal particles. Sep Purif Technol 2000, 225: 39–46.

Mak SY, Chen DH: Binding and Sulfonation of Poly (acrylic acid) on Iron Oxide Nanoparticles: a Novel, Magnetic, Strong Acid Cation Nano-Adsorbent. Macromol Rapid Comm 2005, 26: 1567–1571. 10.1002/marc.200500397

Panneerselvam P, Morad N, Tan KA: Magnetic nanoparticle (Fe3O4) impregnated onto tea waste for the removal of nickel (II) from aqueous solution. J Hazard Mater 2011, 186: 160–168. 10.1016/j.jhazmat.2010.10.102

Hritcu D, Popa MI, Popa N, Badescu V, Balan V: Preparation and characterization of magnetic chitosan nanospheres. Turk J Chem 2009, 33: 785–796.

Bazrafshan E, Kord Mostafapour F, Rahdar S, Mahvi AM: Equilibrium and thermodynamics studies for decolorization of Reactive Black 5 (RB5) by adsorption onto MWCNTs. Desal Water Treat 2014, 1-11. doi:10.1080/19443994.2014.895778, in press.

Bazrafshan E, Zarei AA, Nadi H, Zazouli MA: Adsorptive removal of Methyl Orange and Reactive Red 198 by Moringa peregrina ash. Indian J Chem Technol 2014, 21: 105–113.

Bazrafshan E, Ahmadabadi M, Mahvi AH: Reactive Red-120 removal by activated carbon obtained from cumin herb wastes. Fresenius Environ Bull 2013, 22: 584–590.

Bazrafshan E, Kord Mostafapoor F, Mahvi AH: Decolorisation of Reactive Red (120) dye by using single-walled carbon nanotubes in aqueous solutions. J Chem 2013, doi:10.1155/2013/938374.

Nitayaphat W, Jintakosol T: Removal of Silver (I) from Aqueous Solutions by Chitosan/Carbon Nanotube Nanocomposite Beads. Adv Mater Res 2014, 893: 166–169. 10.4028/www.scientific.net/AMR.893.166

Revathi G, Ramalingam S, Subramaniam P: Assessment of the Adsorption Kinetics and Equilibrium for the Potential Removal of Direct Yellow-12 Dye Using Jatropha CurcusL. Activated Carbon. Chem Sci Trans 2014, 3: 93–106.

Goldman A: Modern ferrite technology. Springer, New York; 2006.

Dave P, Kaur S, Khosla E: Removal of Eriochrome black-T by adsorption on to eucalyptus bark using green technology. Indian J Chem Techn 2011, 18: 53–60.

Hailei W, Ping L, Guosheng L, Xin L, Jianming Y: Rapid biodecolourization of eriochrome black T wastewater by bioaugmented aerobic granules cultivated through a specific method. Enzyme Microb Tech 2010, 47: 37–43. 10.1016/j.enzmictec.2010.03.011

Bedoui A, Ahmadi M, Bensalah N, Gadri A: Comparative study of Eriochrome black T treatment by BDD-anodic oxidation and Fenton process. Chem Eng J 2009, 146: 98–104. 10.1016/j.cej.2008.05.029

Malakootian M, Fatehizadeh A: Color removal from water by coagulation/caustic soda and lime. Iran J Environ Health Sci Eng 2010, 7: 267–272.

de Luna MDG, Flores ED, Genuino DAD, Futalan CM, Wan M-W: Adsorption of Eriochrome Black T (EBT) dye using activated carbon prepared from waste rice hulls-Optimization, isotherm and kinetic studies. J Taiwan Inst Chem Engin 2013, 44: 646–653. 10.1016/j.jtice.2013.01.010

Dong K, Qiu F, Guo X, Xu J, Yang D, He K: Adsorption Behavior of Azo Dye Eriochrome Black-T from Aqueous Solution by β-Cyclodextrins/Polyurethane Foam. Mater Polym Plast Techn Engin 2013, 52: 452–460. 10.1080/03602559.2012.748805

Zins D, Cabuil V, Massart R: New aqueous magnetic fluids. J Mol Liq 1999, 83: 217–232. 10.1016/S0167-7322(99)00087-2

Zhang Z, Duan H, Li S, Lin Y: Assembly of magnetic nanospheres into one-dimensional nanostructured carbon hybrid materials. Langmuir 2010, 26: 6676–6680. 10.1021/la904010y

Sun X, Li Y: Colloidal Carbon Spheres and Their Core/Shell Structures with Noble-Metal Nanoparticles. Angew Chem Int Edit 2004, 43: 597–601. 10.1002/anie.200352386

Pol VG, Daemen LL, Vogel S, Chertkov G: Solvent-Free Fabrication of Ferromagnetic Fe3O4 Octahedra. Indust Eng Chem Res 2009, 49: 920–924. 10.1021/ie9011062

Ai L, Huang H, Chen Z, Wei X, Jiang J: Activated carbon/CoFe 2O4 composites: Facile synthesis, magnetic performance and their potential application for the removal of malachite green from water. Chem Eng J 2010, 156: 243–249. 10.1016/j.cej.2009.08.028

Krika F, Azzouz N, Ncibi MC: Adsorptive removal of cadmium from aqueous solution by cork biomass: Equilibrium, dynamic and thermodynamic studies. Arab J Chem 2011, doi:10.1016/j.arabjc.2011.12.013.

Qu S, Huang F, Yu S, Chen G, Kong J: Magnetic removal of dyes from aqueous solution using multi-walled carbon nanotubes filled with Fe2O3 particles. J Hazard Mater 2008, 160: 643–647. 10.1016/j.jhazmat.2008.03.037

Ho YS: Review of second-order models for adsorption systems. J Hazard Mater 2006, 136: 681–689. 10.1016/j.jhazmat.2005.12.043

Acknowledgments

The authors acknowledge the Islamic Azad University-Bandar Abbas and Kerman Branches for financial support of this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

AA, is a MSc student and this manuscript was written based on her thesis results. She carried out all the lab works (experiments and nanoparticles synthesis) under the guidance of FM and MK and wrote initial manuscript. MK also contributed in analyzing of data. FM, is the supervisor of the thesis and supervised the methods and the project. He wrote the original research plan of the project and edited the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Moeinpour, F., Alimoradi, A. & Kazemi, M. Efficient removal of Eriochrome black-T from aqueous solution using NiFe2O4 magnetic nanoparticles. J Environ Health Sci Engineer 12, 112 (2014). https://doi.org/10.1186/s40201-014-0112-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40201-014-0112-8