Abstract

Purpose

The question of resource scarcity and emerging pressure of environmental legislations has brought a new challenge for the manufacturing industry. On the one hand, there is a huge population that demands a large quantity of commodities; on the other hand, these demands have to be met by minimum resources and pollution. Resource conservative manufacturing (ResCoM) is a proposed holistic concept to manage these challenges. The successful implementation of this concept requires cross functional collaboration among relevant fields, and among them, closed loop supply chain is an essential domain. The paper aims to highlight some misconceptions concerning the closed loop supply chain, to discuss different challenges, and in addition, to show how the proposed concept deals with those challenges through analysis of key performance indicators (KPI).

Methods

The work presented in this paper is mainly based on the literature review. The analysis of performance of the closed loop supply chain is done using system dynamics, and the Stella software has been used to do the simulation.

Findings

The results of the simulation depict that in ResCoM; the performance of the closed loop supply chain is much enhanced in terms of supply, demand, and other uncertainties involved. The results may particularly be interesting for industries involved in remanufacturing, researchers in the field of closed loop supply chain, and other relevant areas.

Originality

The paper presented a novel research concept called ResCoM which is supported by system dynamics models of the closed loop supply chain to demonstrate the behavior of KPI in the closed loop supply chain.

Similar content being viewed by others

Background

Due to worldwide population boost, economic growth, and increase in standards of living, current reserves of natural resources are proven to be insufficient, and the Earth’s ecosystems are facing increasing threat. The current growth indicates that the worldwide population will be doubled by 2072 [1]. This double population size will result in a fivefold increase in the gross domestic product (GDP) per capita, with a tenfold increase in resource consumption and waste generation [2]. By contributing 30.7% to the total world GDP and employing a 0.7 billion workforce worldwide (estimated in 2010) [3], the manufacturing industry serves as one of the main driving forces in economic growth. Indeed, the manufacturing industry is consuming resources and generating waste on a large scale at the same time.

It is estimated that if the current consumption rate continues and recycle rate remains the same, then there will be no iron ore left for consumption in the next century [4–6]. Besides, the manufacturing industry is one of the largest contributors to waste generation. In 2008, approximately 363 million tons of solid waste (account for 14% of the total waste) was generated by the manufacturing industry in the EU-27 [7]. In addition to this, through the extended producer responsibility regulation, manufacturers are now fully or partially accountable for End-of-Life (EoL) products that are sold in the market. The problem has become more serious with an increase in tax and restriction on the landfill of solid waste.

Moreover, in the fast-growing and evolving consumer market, products seldom reach EoL when a consumer decides to shift to the next generation of products. In those cases, products end up in scrap yards although they retain some values. Recovering only material from a product when it could be possible to recover other values is not the best practice both from a manufacturing and an environmental point of view.

To summarize, manufacturing industries have to grow in the same proportion as the market demands with limited resources, higher-energy efficiency, and lower emission and wastes. The manufacturing industry needs solutions that can solve entirely, or partially, all the problems. Resource conservative manufacturing (ResCoM) is a novel holistic concept which deals with the conservation of resources through the product’s multiple life cycle [8]. ResCoM is defined as follows:

" A strategic model which emphasizes conservation of resources through product’s multiple life cycle by product design, incorporating supply chain and business model and by integrating OEMs, consumers and other relevant stakeholders. Resources conservative manufacturing system seeks to optimize material and energy usage in manufacturing, use phase and end of use and value recovery from the product at the end of life. "

ResCoM proposes to design products in a way that can sustain a number of predefined life cycles. At the end of each predefined life cycle, products are returned to the original equipment manufacturer (OEM) or to the authorized third party; upon return, remanufacturing or other EoL strategies, such as recycling and landfilling, are undertaken. Remanufactured products are then redistributed through the ResCoM closed loop supply chain using the ResCoM business model. As multiple life cycles require the same product to come back and forth in several occasions, a robust closed loop supply chain is vital.

The main objectives of this research are as follows:

-

To introduce a novel concept named as ResCoM,

-

To demonstrate how key performance indicators (KPI) such as rate (production, assembly, shipment, order), delivery delay, level of inventory, backlog, and capacity (production and assembly) in the closed loop supply chain are affected under variable quantity of product flow at variable times, [9, 10], and

-

To show how adoption of ResCoM concept improves the robustness of the closed loop supply chain.

Closed loop supply chain: a state-of-the-art review

Designing and managing supply chains to ensure collection of used products (usually addressed as ‘core’) are two of the essentials for products’ multiple life cycles. A supply chain of this kind is usually addressed as a reverse supply chain or closed loop supply chain. A significant difference can be observed when defining these two terms. It is appropriate to address the chain of core collection as the reverse supply chain, if the following conditions are fulfilled:

-

The recovered cores do not enter the main stream of the forward supply chain.

-

The recovered contents of the original products used by other firms to manufacture products serve a different purpose [11, 12].

It should be noted that core collection activities can only be referred to as a closed loop supply chain if the following conditions are fulfilled:

-

The core is collected by the OEM or the third party remanufacturer that acts as the supplier to the OEM.

-

The core enters (and is used) in the main stream of a manufacturing forward material flow.

-

The remanufactured product is sold in the same way as the new one, i.e., the remanufactured product is not considered as a different product variant, and order and supply is not handled separately.

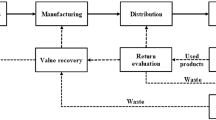

Figure 1a,b,c describes the material flow in different types of supply chains.

The ideal closed loop supply chain, which is essential for the success of the product’s multiple life cycle, is shown in Figure 1a. By clarifying the existing misconceptions, the closed loop supply chain management can be defined as follows [13]:

" The design, control, and operation of a system to maximize value creation over the entire life cycle of a product with dynamic recovery of value from different types and volumes of returns over time. "

In the remanufacturing system, the core acts as raw material, and seamless operation of the system entirely depends on the efficiency of the core collection. It becomes especially challenging as the core is not supplied by one or a few suppliers in a periodic and systematic manner. Instead, the suppliers of the core are the end consumers who own one or a few products and return those products whenever they need or want. In addition to this, the consumers’ geographic locations could be anywhere on the globe. The supply chain becomes further complicated with product variety, return time, quality of the core, product life cycle, technology life cycle, cost of collection, and so on.

Guide and Van [13] have put together the past 15 years’ research development in the closed loop supply chain which provides an overview of relevant research areas, and Lundmark et al. [14] have presented a literature review pointing out industrial challenges within the remanufacturing system. Researchers who have worked with the closed loop supply chain have more or less acknowledged the problem of uncertainty related to timing and quantity of the returned core, quality of the core, and mismatch between the supply and demand of the core and remanufactured product. This problem was mentioned in the early research done by Thierry et al. [15], and the most recent work presented by Guide and Van [13] indicates that the problem still exists. Along the way, these problems have been brought up by several authors; among them, the contributions of Gungor and Gupta [16], Seitz and Peattie [17], and Toffel [18] are worth mentioning. By reviewing several relevant research, the underlying reasons of uncertainty have been identified as follows:

-

The return of the core occurs for different reasons in different periods of time [19, 20].

-

A product’s EoL is the result of the complex relationships between age and pattern of use (user conditions, user interactions, levels of service and maintenance, etc.) [21].

-

Some products never return as the products move out of the region where legislative or other obligations are not valid and return is not economically feasible.

-

The product’s information is lost; thus, the core collection from the product is done manually on the basis of trial and error, which often causes destruction of cores. Freiberger et al. [22] have given an example of difficulties in testing and remanufacturing of electronic and mechatronic vehicle components due to lack of information.

-

Remanufacturing is treated as a separate business; therefore, demand and supply is tackled independently.

However, with the increase in interest to conserve resources, efforts to minimize the uncertainties in core collection are also getting attention. To ensure flawless core returns, some sort of agreement between OEMs, consumers, and remanufacturers is needed. There are several business models that have been adopted by the pioneering OEMs in remanufacturing. Östlin et al. [20] have discussed some of the relationships and core acquisition strategies often used by the OEMs. Kumar and Malegeant [25] pointed out that strategic alliance between the OEMs and eco-non-profit organizations in the collection process not only helps to acquire cores at EoL/end of use (EoU), but also creates value for the firm. Among all these, the most commonly used business models for core collection are ownership-based and buyback. However, from the publication of Lifset and Lindhqvist [26], it is understood that the ownership-based business model is not straightforward, and its success depends upon careful analysis of the profit and loss. In other words, the ownership-based business model is not always feasible. Buyback is not as efficient as it is supposed to be if the consumers are not concerned and motivated.

Moreover, this solves half of the problem. It is true that these kinds of business models bring a certain level of certainty to the timing of the core returns, but uncertainty related to the quality of the core remains unsolved [8–11]. At the same time, the above-mentioned business models aim to bring cores back at the EoL/EoU, at which point, value recovery becomes extremely difficult. It is also important to consider the consumer’s perception about newness of the product as it influences return of the core. Most of the business models may fail to fulfill its purpose if the consumers have a negative attitude towards the remanufactured product. The rest of the business models may fail if the customers wish to change brand or manufacturer.

System dynamics and its application in closed loop supply chain

System dynamics is a method to enhance learning in the complex system which is grounded in the theory of nonlinear dynamics and feedback control developed in mathematics, physics, and engineering. Basically, the dynamic tendency of any complex system is the result of a system’s internal structures, feedback mechanism, and causal relationships among factors that are active in the system [27]. System dynamics was introduced by Jay Wright Forrester and developed at MIT in the mid 1950s. Since then, system dynamics has been applied to a wide range of issues in social, economic, and engineering sciences.

Ilgin and Gupta [28] concluded that the application of simulation, stochastic programming, robust optimization, and sensitivity and scenario analyses has become quite popular in research due to a high degree of uncertainty involved in reverse logistics. They have also mentioned that more studies are needed to better control the effects of uncertainties in the closed loop supply chain. System dynamics is one of such modeling and simulation method which is widely used in the management of production systems, especially in the supply chain (forward) for about five decades. An overview of the frame of the research that applied system dynamics in the supply chain is presented by Angerhofer and Angelides [29], Georgiadis and Vlachos [30], and Vlachos et al. [31]. The trend of using system dynamics in the analysis of the closed loop supply chain is relatively new but growing; at the same time, Kumar and Yamaoka [32] mentioned the lack of system dynamics research in studying the closed loop supply chain. Nevertheless, fair progress has been made in this respect.

Georgiadis and Vlachos [30] studied the long-term behavior of reverse supply chains with product recovery under the influence of various ecological awarenesses. Later, Vlachos et al. [31] examined capacity planning policies of a single product’s forward and reverse supply chain transient flows due to market, technological, and regulatory parameters. Georgiadis et al. [33] and Georgiadis and Efstratios [34] developed models of system dynamics to study the closed loop supply chain with remanufacturing both for single-product and two-product types under two alternative scenarios which incorporate a dynamic capacity modeling approach.

In a recent work, Qingli et al. [35] continued the work of Vlachos et al. [31], to some extent, and added the bullwhip effect into their studies. Similar modeling has been done by Schröter and Spengler [36], but their focus was product recovery to obtain spare parts for equipment, when the original equipment is no longer produced. Poles and Cheong [37] modeled the closed loop supply chain to determine factors that influence the return of cores and concluded that customer behavior and the level of service agreement improve control over returns, thus, reducing uncertainty in remanufacturing systems.

The research mentioned above focused mainly on operational issues of the closed loop supply chain. Besiou et al. [38] argued that even though system dynamics has been applied to various environmental problems, business policy, and strategy, few strategic sustainability problems in the closed loop supply chain are reported. Nevertheless, Georgiadis and Besiou [39] combined strategies of environmental sustainability with operational issues of the closed loop supply chain to study their interaction and understand their impact on the environment. In an earlier research, Georgiadis and Besiou [40] examined the impact of innovation and ecological motivation to study the long-term behavior of the closed loop supply chain which can be used as a strategic tool.

These are only few of the publications; besides these, there are a large number of publications available. Apart from applying system dynamics, linear programming models for the closed loop supply chain network design are quite popular among researchers. The review of mathematical models using linear programming has not been included in this paper. The authors recommend the work of Özkir and Basligil [41] for an overview of research done to design the closed loop supply chain network using the linear programming approach.

Critical review of the state-of-the-art

There is a misconception concerning the closed loop supply chain. Supply chains designed to collect cores and developed to sell remanufactured products in a secondary market (bypassing the OEMs) are not necessarily closed. Apart from this fact, it is an established truth that the main problem of the closed loop supply chain is the uncertainty in timing of core return and the quality of the returned cores. A fundamental but rarely discussed truth is that most of the researchers suggest implementing the closed loop supply chain concept where the product, or the business model, is not designed for it.

The scope of applying system dynamics in the closed loop supply chain is large compare to what had been done so far. System dynamics has been applied in both operational and strategic issues of the closed loop supply chain. However, studying and analyzing the performance (or behavior of KPI) of the closed loop supply chain under the influence of uncertain quantity and quality of returned core in unpredictable intervals using system dynamics had not been the main focus of the research up to this point. The influence of the uncertainty in strategic resources such as inventory, capacity, backlog, and demand in the closed loop supply chain had not been extensively covered in most research.

ResCoM: a new paradigm of manufacturing

According to the definition presented in the ‘Background’ section, ResCoM is a holistic approach that provides a complete solution to maximize resource conservation and minimize waste. ResCoM is built upon the concept of the product’s multiple life cycle.

The concept of product life cycle can simply be explained as follows: the life cycle of a product (that contains more than one part) is generally equal to the life cycle of the component that has the shortest life. For example, a product consists of three components X, Y, and Z, and each has the designed life of 1, 2, and 3 years, respectively. Basically, the product will reach its EoL when one of the components fails. Considering that other factors do not affect the component’s life, component ‘X’ will fail at the age of one, and eventually, the product will be discarded. It is to be noted that components ‘Y’ and ‘Z’ have equal and twice as many remaining lives compared with X, respectively. If the entire product is discarded, the potential recoverable values are lost. Instead, if component X can be replaced or upgraded at the age of 1 year and component X is replaced or upgraded again along with Y at the age of 2 years, then the product can sustain three life cycles. Alternatively, the ideal case is to design a product that contains components that have the same duration of life. Of course, in reality, it is not as straightforward as it has been explained. It is important to highlight that the life cycle of a product/component is not time-dependent, which means that the time when a product/component will reach its EoL is not exactly deterministic. The life cycle duration of a product is the result of a complex relationship mainly between age, operating conditions, service, and maintenances during the life cycle and the user locations. It is not possible to determine the exact interval of each life cycle. Therefore, ResCoM proposes to develop a robust design method to reduce the uncertainty in predicting the EoL and to integrate life cycle-monitoring devices to monitor the physical/functional condition of critical components.

In ResCoM, the product is named as resource conservative product (RCP) which is used as a ‘brand’ name. Each life cycle of RCP is labeled with a resource conservation level (RCL). The concept is illustrated in Figure 2a. In principle, RCL0 refers to a new RCP that contains only new components, and it is at the start of its first life cycle, having several life cycles ahead. Components at a certain level are called RCL i (where i = 0, 1, 2…) components, such as RCL0 components, RCL1 components, and so on. At the end of life cycle 1 (i.e., end-of-resource conservation level 0 (EoRCL0)), when the desired performance reaches the minimum allowable, the product is recalled, upgrading and replacement of complements are done, and remanufacturing is performed. RCL1, which is the beginning of the second life cycle, contains new components of RCL0 and upgraded components of RCL0 and may contain some new components. This approach continues until the product finishes its predetermined number of life cycles. At the end of each life cycle, the product is restored to the desired performance level. This so far explains the life cycle at the product or subassembly level. The life cycle of the component is slightly different and is illustrated in Figure 2b.

Let us assume that a product is assembled with three components represented by X, Y, and Z and that their performance index over time is shown in Figure 2b with red, blue, and green curves, respectively. In this particular case, the life cycle (i.e., three life cycles) of the product is determined based on the component which has the longest design life, i.e., component Z. At RCL0, the product contains three new components. At EoRCL0, component X reaches the minimum allowable performance, which is then replaced with a similar component. It means that at RCL1, the product will have two RCL0 components and one new component and so on.

So far, the core concept of ResCoM and product’s multiple life cycle has been briefly presented. Readers are referred to the work of Asif [8] for further details.

Among the many dimensions of ResCoM research framework, the closed loop supply is an essential element. The innovative approach of managing the closed loop product system in ResCoM is further elaborated in the following sections.

ResCoM closed loop supply chain

As discussed in the preceding section, in the product’s multiple life cycle approach, the product will return at several occasions and will go through remanufacturing. To facilitate this, the closed loop supply chain is required. The operational effectiveness of a supply chain mostly depends on the smooth flow of material both in forward and reverse directions without constraining the planned capacity of the manufacturing processes. It means that the manufacturing system for RCL0 products and the manufacturing systems for RCL1 to RCL i should not be over- or under-capacitated. To ensure this, the expected quantity of the product to be manufactured at RCL0 and RCL1 to RCL i needs to be known. As the RCL0 product refers to a newly manufactured product and follows a standard manufacturing forward supply chain, it is relatively simple to plan. On the other hand, RCL1 to RCL i manufacturing significantly depends on the availability of the products (cores) from their previous life cycles. Availability of the returned products and scrap rate of the returned products are the main obstacles to the success of the closed loop supply chain. In ResCoM, the problem of product availability is solved through product design, estimation of life cycle duration, and the number of life cycle and business model. In ResCoM, the quantity and the timing of the product return are predictable within a certain confidence interval. However, the other problem with the quality of the returned product is not entirely solved but minimized to a large extent.

In the conventional approach, it is estimated that the scrap rate of returned product can be anything from 15% to 85%. The reasons for this large variation are mainly due to age, operating conditions of product, and quality of service that the product receives during the life cycle. In ResCoM, the age of the returned product is known, and the service of the product is managed and controlled by the OEM (or authorized service provider). This means that in normal circumstance, the quality of the returned products is known within a certain confidence interval. The functional condition of critical components in the products will be monitored during operation; if there is any deviation in the desired performance, the product will be recalled earlier. In this way, currently perceived scrap rate can certainly be reduced, which eventually can create a robust closed loop supply chain with minimum uncertainty.

There are other issues, such as designing the network, planning and controlling the logistics, and production at RCL1 to RCL i , which are also related to the success of the closed loop supply chain. These issues are greatly influenced by the types of product, size, and periphery of the market. As the concept is presented in a generic context and does not refer to any specific product, discussion around these issues is not within the scope of the research at this point.

ResCoM business model

The ResCoM approach is not well fitted with the ordinary sell-buy-sell business model. It requires a model that goes beyond the conventional business model and establishes a strong relationship among OEMs, consumers, and third parties (if the OEM decides to outsource RCL1 to RCL i production). Based on the concept of RCP brand and RCL labeling, the business model of resource conservative manufacturing is illustrated in Figure 3. In this model, the RCP production at RCL0 and RCL i are separate functions of the same enterprise. However, RCL i production can be outsourced by the OEM only if the entire process is controlled by the OEM. In the ResCoM business model, consumers are part of the manufacturing system and mostly responsible for returning the product at the end of each life cycle. As mentioned earlier, consumers are still reluctant towards secondhand products. Therefore, at the beginning, the business model suggests a dedicated RCP reselling unit, which will act as the bridge between the consumer and OEM or third party suppliers. The basis of their relationship and the interest of each stakeholder are determined mainly based on the product type, number of returns, arrangement of returns, and way of reselling. Besides, the RCP reselling unit will also be engaged in promoting RCL1 to RCL i product adoption as a social and moral responsibility. Once the business model is established and consumers become comfortable with the product’s multiple life cycle and consider product returning as part of their social responsibility, the RCP reselling unit will be abolished. The ordinary product distribution unit will take over both RCL0 and RCL i product selling.

The modeling approach and the models of supply chains

The models that are presented in this paper retain different objectives than the publications mentioned in the ‘System dynamics and its application in closed loop supply chain’ section. The main purpose of the modeling is to study and analyze the performance of the closed loop supply chain. Therefore, the model does not propose any solution; instead, the model is used to understand the behavior of KPI of the closed loop supply chain in conventional and in the proposed ResCoM context. The models are used to analyze the robustness of the conventional forward supply chain in the settings of the conventional closed loop supply chain and compare it to the proposed one by ResCoM. The aim of the modeling is to see how the KPI in the closed loop supply chain vary with time in different settings. In addition, the aim is to understand the main drivers affecting the KPI as well as the end results, and the behaviors of the strategic resources. Two models have been built, and four different analyses have been made. The behavior of KPI has been analyzed for the following:

-

1.

Conventional forward supply chain.

-

2.

Conventional reverse supply chain.

-

3.

Forward supply chain when reverse supply chain is combined, i.e., the conventional closed loop supply chain.

-

4.

Closed loop supply chain proposed by ResCoM.

The models have been built in three steps. In the first step, forward and reverse supply chains have been modeled without any dependency. In the second step, forward and reverse supply chains have been combined, i.e., the closed loop supply chain where the forward supply chain is influenced by the reverse supply chain. In the third step, the model has been built as how ResCoM proposes. In the following sections, the structure of these models is described. The supply chain is modeled with inventory control mechanism, capacity acquisition, demand backlog, and demand forecasting. The performance of the supply chain is analyzed in respect to the level of inventories, backlogs, rates (production, assembly, shipment, etc.), and delays. The causal structures of the feedback loops used in the models are shown in Figure 4.

Regardless of which model settings are discussed, the performance indicators, drivers, end results, and strategic resources have the same structure and relationships. For example, the end result order (rate) directly influences the strategic resource backlog. The end result is driven by the delivery delay ratio which is influenced by delivery delay. Delivery delay is influenced by the shipment (rate).

Similarly, in case of capacity acquisition loop, the end result is the change in the capacity of the system. This end result is driven by the pressure to expand capacity, which causes the strategic resource capacity to fall or rise. This is directly influenced by the delivery delay.

Finally, in case of inventory, the end result is the desired production rate which is driven by inventory gap and backlog gap. The gaps are influenced by the strategic resource backlog, expected demand, and the inventory itself which are influenced by the delivery delay.

Mathematical formulation

The main mathematical formulations used in the modeling are shown in Additional file 1. However, depending on where in the models these concepts are used, the notation to define the flows, stocks and variables are named accordingly. For detail mathematical formulation of each section in the model the readers are referred to the work of Asif [8].

Forward supply chain

The forward supply chain has been modeled with the sectors named as production capacity, assembly capacity, production work in progress (WIP) inventory, assembly WIP inventory, finished product inventory, production backlog, assembly backlog, sales backlog, and demand forecasting.a The stock and flow diagram of the forward supply chain is shown in Figure 5. The following assumptions have been made:

-

The models are built for a single product.

-

Production starting capacity is infinite.

-

Shipment of product is only constrained by availability of product in the finished product inventory.

-

Order placed by the consumers is constant.

In the forward supply chain sector, the stock of production WIP inventory is accumulated at the desired production rate, and the inventory moved to the next step (assembly WIP inventory) at the production rate. The production rate can be determined in four ways as follows:

-

Available production WIP inventory starts to move to the next stage after minimum production delay.

-

Available production WIP inventory starts to move to the next stage as much as the current production capacity allows.

-

Available production WIP inventory starts to move to the next stage at a rate that can bring the production backlog to the desired level.

-

Available production WIP inventory starts to move to bring the assembly WIP inventory at the desired level.

Current production capacity is an accumulative value of the difference between the desired and current production capacity over time. If the ratio of actual and planned production delay becomes larger, then that would create a pressure to expand capacity. This pressure causes the desired capacity to rise after a predefined delay.

Similarly, in the sales backlog sector, the expected demand is an accumulative value of the difference between the expected demand and sales order rate over time. It is to be noted that the expected demand represents information, not the physical product. If the ratio of actual and planned distribution delay becomes larger, then that would cause a drop in the order rate. This causes the expected demand to fall. However, the expected demand does not rise or fall immediately but after a predefined delay. It is important to note that in the model, normal order that is placed by the consumers has been considered as the order rate in all steps, i.e., shipment, assembly, and production in the forward supply chain.

As mentioned earlier, in the production backlog sector, the production order rate is considered the same as the normal order placed by the consumers. ‘ This rate causes the production backlog to rise, and backlog decreases with the rate of production order fulfillment rate, which is basically the production rate (it also reduces production WIP inventory). The backlog and the rate at which the order is fulfilled determine the actual production delay. The ratio between planned and actual production delay would cause the order to fall if the ratio becomes greater than one. Similar to the expected demand, production backlog also represents information, not physical product.

In addition, the production WIP inventory sector is used to estimate the desired production WIP inventory and desired production backlog. Based on the expected demand and how much inventory to keep, the desired production WIP inventory is estimated. Similarly, based on expected demand and planned production delay, the desired production backlog is determined. Desired production start rate is estimated based on the gap between the desired and actual inventory and the gap between the desired and actual backlog.

Exactly the same stock and flow structure follows in the assembly WIP inventory and finished product inventory as of production WIP inventory. The assembly capacity, assembly backlog, assembly WIP inventory, sales backlog, and finished product inventory sectors have exactly the same flow and stock structure as the production part of the model.

Behavior of key performance indicators

At the beginning of simulation, the production WIP inventory is much less than the desired value, causing a high production backlog which results in the actual production delay to rise. As soon as the desired backlog becomes equal to the actual level, the actual production delay becomes equal to the planned production delay. For the desired production backlog to become equal to the production backlog, the production WIP inventory level has to rise, and at the same time, the rate at which product is moved to the next stage (assembly WIP inventory) also has to rise. The stock of inventory and the backlog are increased with the rate at which products are piling up into the inventory, and the rate of order placed. The inflow and outflow of the inventory and backlog are affected by all other feedback loops that are connected with it. Similarly, with the rise of the actual production delay, the capacity side of the model gets alarmed, causing the desired production capacity to rise, which eventually results in the current production capacity to adjust. As soon as everything else becomes stabilized, the current production capacity also stabilizes. These behaviors are illustrated in the graphs in Figures 6, 7, and 8.

Exactly the same behavior and the same dependency are evident, i.e., after an initial shock, the KPI become balanced, in case of assembly and distribution in the forward supply chain. Therefore, detailed graphical illustration is avoided.

Reverse supply chain

The reverse supply chain consists of sectors namely reverse supply chain, remanufacturable product inventory, remanufactured product demand forecasting, and remanufactured product backlog. The stock and flow diagram of the reverse supply chain is shown in Figure 9.

The reverse supply chain sector consists of the EoL product inventory where products accumulate at EoL through three aging chains named as product in use 1, 2, and 3. Aging is deterministic; however, the rate at which the product reaches at EoL or to the succeeding stages of product in use is probabilistic. It is assumed that the probability of failure increases with age. Products move from EoL product inventory to collected EoL product inventory after some predefined delay. Products in collected EoL product inventory are then inspected, (inspection rates 1 and 2) and depending on their physical and functional conditions, products are stored either in remanufacturable product inventory or in non-remanufacturable product inventory. The physical and functional conditions of returned products are denoted by the functionality factor, which is probabilistic and generates any random values between 0.1 and 1. The assumptions made here are as follows:

-

There is no capacity constrain in the reverse supply chain.

-

The rate, i.e., shipment rate of manufactured products, at which product is supplied to the next stage is only constrained by the availability of collected EoL product inventory and remanufacturable product inventory or the desired shipment rate of remanufactured product.

-

Each product reaching EoL creates a demand, and order is placed immediately.

The stock and flow structure used in the sectors remanufactured product backlog, remanufactured product demand forecasting, and remanufactured product inventory has the same structure as the backlogs, demand forecasting, and inventory sectors described in the forward supply chain in the previous section.

Behavior of key performance indicators

Behavior of KPI in the reverse supply chain is not the same as that in KPI in the forward supply chain. The main reason for inconsistency in the behavior is the random variables that determine different rates in the model. Besides, in the reverse supply chain model, the demand is considered to be more than the supply. This causes the planned and actual distribution delay, inventory, backlog, and shipment rates never to balance. This hypothesis is a well-known fact in the reverse supply chain. The behavior of KPI is illustrated in the graphs in Figures 10 and 11.

From the above graphs, it can be concluded that the reverse supply chain is unstable in nature. The uncertainty of core arriving time, quantity, and quality causes the feedback loops to suffer. This kind of behavior limits the possibility to create a robust policy. The decision makers usually cannot identify key drivers within the system that can improve the system’s performance in such situations.

Conventional closed loop supply chain

In the conventional closed loop supply chain, the above-mentioned two models have been kept the same with two distinct differences. Firstly, remanufacturable product inventory has been connected to the assembly WIP inventory, i.e., products accumulated in the remanufacturable product inventory move to the assembly WIP inventory at the shipment rate of manufactured product. Secondly, the order rate of remanufactured product has been added in the sectors production backlog, assembly backlog, and sales backlog in the forward supply chain. The changes are shown in the model with ‘green’-colored flows and connections in Figure 12. The main assumptions made here are as follows:

-

Both remanufactured and newly manufactured products are sold through the same channel.

-

All remanufactured products are as good as the newly manufactured products and can substitute the need for production.

-

The market becomes larger as soon as the firm decides to remanufacture products.

-

All remanufacturable products are remanufactured without any delay. It means that the shipment delay for remanufactured product is not constrained by other factors such as delay in capacity acquisition and delay in order processing.

Behavior of key performance indicators

The behavior of KPI in production (forward supply chain) of the conventional closed loop supply chain is shown in Figures 13, 14, and 15.

Two distinct differences are evident in the behavior of KPI in case of production in the conventional closed loop supply chain compared with the forward supply chain discussed in the ‘Forward supply chain’ section:

-

The graphs are not balancing.

-

The graphs continuously fluctuate.

In case of other parts of the forward supply chain in the conventional closed loop supply chain scenario, i.e., assembly and distribution exhibit balancing but fluctuating characteristics. The reason of graphs in production not balancing in the closed loop supply chain (both in conventional and ResCoM scenarios) has been mentioned in the ‘Discussion’ section.

The reverse part of the supply chain in conventional closed loop supply chain shows similar behavior pattern as shown in Figure 10 and Figure 11.

Closed loop supply chain in ResCoM

The closed loop supply chain in ResCoM has a slightly different structure than the conventional closed loop supply chain. As in ResCoM, the time of product return is predetermined; the aging chain does not exist in the model. The only delay to accumulate products from product in use 1 to EoL product inventory is predefined. In addition to this, all products are assumed to be returned; therefore, there is no random variation in the EoL ratio. Moreover, the functionality factor that determines inspection rates 1 and 2 is assumed to be quite high (90% of the products are remanufacturable) and constant. This assumption is in line with the argument made in the ‘ResCoM a new paradigm of manufacturing’ section, i.e., in the proposed ResCoM approach, the quality of returned products is known (high) to some extent, and almost all of them can be used further (if designed for multiple life cycle). The assumptions made in the models discussed above are valid, and no new assumptions are made. The stock and flow diagram of the reverse part of the ResCoM proposed closed loop supply chain is shown in Figure 16. The stock and flow diagram of the forward part of the closed loop supply chain proposed by ResCoM remains the same as in Figure 12.

Behavior of key performance indicators

The behavior of KPI in the forward part in the ResCoM proposed closed loop supply chain is shown in Figures 17, 18, and 19.

The behavior of KPI in the reverse part of the ResCoM proposed closed loop supply chain scenario shows a significant difference compared with that in the conventional closed loop supply chain scenario shown in the ‘Reverse supply chain’ section. These behaviors are shown in Figures 20 and 21.

Results and discussion

Simulation results

The simulation results have been presented in terms of performance of the supply chain in three different settings. The trend (graphs) of the KPI such as level of inventories, backlogs, rates, and delays are shown in respective sections. The trends clearly depict that the reverse supply chain faces uncertainty due to the availability of cores and the quality of returned cores. The forward supply chain becomes unstable when the reverse supply chain is combined, i.e., the conventional closed loop supply chain. The forward supply chain becomes stable again if the resource ResCoM approach is adopted.

The feedback loop that exists within the dynamics of the supply chain helps decision makers to take actions that are sustainable over time. The simulation helps to understand to what extent the policy is robust and the drivers that affect robustness of the current policy. In the case of the forward supply chain, this is particularly true and is validated through the model once again. However, in the case of the closed loop supply chain, the conventional supply chain management policies cannot be applied or it is not possible to create a robust policy. Industries that use the reverse supply chain or closed loop supply chain cannot manage their supply chain with traditional thinking and well-established policies. Industries that are planning to incorporate the reverse supply chain with their forward supply chain should, from these models, gain insight that as soon as two supply chains are combined, their policies (that have been in place and working well) will be disturbed, and the robustness will not be within manageable limits. Nevertheless, if the concept of ResCoM is adopted, the closed loop supply chain will behave more or less similarly as how the conventional forward supply chain usually behaves.

Model testing

The models were tested through the initialization of the model in a balanced equilibrium. It means that all stocks in the system remain unchanged despite the variation of time, requiring their inflow and outflow to be equal. The part of the model with random variables could not be initialized as it is; in this case, random variables were replaced by constant values. Initialization confirms that there is no discrepancy in the equations or in the feedback loops.

The models were tested using the extreme condition test [27], where extreme input values were assigned concurrently. The reverse part did not fulfill the condition of the extreme test due to the random variables used in the reverse supply chain.

The simulation time has been extended to test if the model causes any reaction. In this case, the trends (graphs) of KPI remain more or less steady despite the largely varied simulation duration.

Discussion

The models that have been presented are generic models, which do not depict any specific type of product or industry. The boundaries of the models are quite broad; therefore, there is a lack in details in many cases. The input data of the models are fabricated but correspond to the reality. In the models, some random variables are used, which do not comply with the system dynamics principles as Sterman describes randomness as a measure of our ignorance, not intrinsic to the system. In this particular case, randomness could not have been avoided as no research has been found that describes these phenomena otherwise; the span of the analysis is relatively shorter than what system dynamics usually suggests, and finally, there is a lack of empirical data.

The model raised at least two questions related to dynamics of policy and performance of supply chain. This is the first question: when remanufactured products enter (in rate of nondeterministic number) the forward supply chain and the production rate adjusts itself, what are the dynamics and feedback loops acting on it? This explains the behavior (non-balancing trends) of KPI in the production part in the forward supply chain after combining the reverse supply chain with the forward supply chain. The other question is as follows: when a firm decides to enter the remanufacturing (new) market, how do the dynamics of the supply and demand and market share become balanced and what are the feedback loops that cause it to balance? At the same time, it has been realized that environmental benefits, change in societal perception, and level of natural resource conservation are needed to be incorporated in the model to make it complete.

The purpose of the modeling has been different from what is usually expected from system dynamics modeling. Through modeling, it has been shown how the policy and its leverage get affected when there is large uncertainty in any part of the supply chain. Therefore, the descriptions and arguments that are built around the models may not be as they would have been in the case of a conventional system dynamics model.

Referring to the question that usually emerges while choosing between continuous and discrete event simulations, the main factor in deciding which modeling tool to use is the level of aggregation sufficient for a particular object at hand [42]. Morecroft [43] has proven that similar results can be obtained using both system dynamics and discrete event simulation. However, system dynamics is particularly useful in demonstrating the complex dynamic relations of factors that are essential to manage a supply chain. It also helps to visualize the feedback loops and how they influence each other in a supply chain. Moreover, it gives management a base for decision making i.e., in a supply chain, in what degree of freedom one has to change different variables. As the objective of modeling has been to demonstrate performance of the supply chain in different settings and how they influence each other in terms of behavior, no other tool can fulfill the purpose as explicitly as the system dynamics did.

Apart from the modeling, the research presented in this paper tried to collect and summarize the research done in the closed loop supply chain. Moreover, this work attempted to clarify the misconceptions and problems related to the closed loop supply chain. A novel concept, ResCoM, is presented to show the relevance of the research work with the state-of-the-art research. Finally, through KPI analysis of the closed loop supply chain, it is proven that the closed loop supply chain faces less uncertainty in terms of the supply and demand of products in ResCoM. As a by-product of this research, knowledge base has been created in the field of system dynamics applied in supply chain management.

Conclusions

Based on the review and analysis of the research in the area of closed loop supply chains, it is evident that the prevailing approach to close the loop for product multiple life cycle or remanufacturing is inherent to business thinking and models used for open loop manufacturing. The classic challenges of the closed loop supply chain, i.e., uncertain product returns, create serious problems for the multiple life cycle approach. Only the business thinking unique to closing the loop can solve this problem.

Moreover, it has been observed that isolated research in the areas of product design, closed loop supply chain, and business model has progressed, but the fundamental problems are still unique in the conventional approach. We proposed an alternative approach, which is partially described in this work, called ResCoM. The essential features of the proposed ResCoM model are as follows:

-

Products designed for multiple life cycles with predefined life,

-

Integration of forward (RCL0 production) and reverse (RCL i production) manufacturing functions into a single enterprise, and

-

Customer integration as a business function of the enterprise

will ensure enhanced visibility of the products during their entire life cycle as regards to the quality, quantity, and timing of their return to the remanufacturing function; this visibility will minimize the uncertainties in product returns. This work also concludes that for advancement in developing successful product multiple life cycle, the current approach of research on isolated problems and implementation of its results in the industry is inefficient. The ResCoM concept requires a framework for a system level approach integrating four major functions of the manufacturing enterprise: product design and development, supply chain design and management, marketing and consumer behavior, and manufacturing and remanufacturing technologies should be integrated to form a unified research platform.

By reviewing and analyzing the research in the area of closed loop supply chain in stochastic environment, this work concludes that system dynamics has been applied in both operational and strategic issues of the closed loop supply chain. However, there is a need for further research as closed loop supply chain deals with complex issues. Using system dynamics, different researchers have described different phenomena of the closed loop supply chain which are important in creating the knowledge base. Models presented in this paper used system dynamics to demonstrate the robustness of the closed loop supply chain by analyzing the performance in conventional and in the ResCoM proposed approach. Through analysis of the behavior of KPI, it can be concluded that the ResCoM proposed closed loop is much more robust in terms of operations and faces less uncertainty. It is important for the policymakers to understand the behavior of KPI in order to set a robust policy. The behavior of KPI in ResCoM also shows that robust policies can be adopted in this approach as the uncertainty is minimized.

Methods

The methodological approach taken for this research can be best described as the cyclic process explained by Leedy and Ormrod [44] which includes the following:

-

Problem identification and setting the research goal,

-

Subdividing the problem to smaller elements,

-

Introducing hypotheses that might lead to the solution,

-

Gathering data and information that the hypotheses and problem lead to,

-

Presenting the data in the form of a result to show that the problem has been solved, the question has been answer, or the result support or do not support the hypotheses, and

-

Finally, validation and verification of the results.

While research methodology is a systematic way to do research, methods of research is just the means for conduction of research [45]. The research methodology remains the same throughout the research, while methods can be different at different stages of research. As the research presented in this paper is in conceptual stage, and it is a small part of the ResCoM research paradigm, therefore, all the steps of the cyclic process described above may not be obvious at first glance.

The foundation of the research presented in this paper is mainly based on literature review. Some knowledge and experiences gathered by the authors by attending international conferences have also been reflected in this work. This is to say that the original problem formulation was measured and analyzed against the literature in the topic, and this led to the final problem form. These foundations have motivated the authors to describe by simulation the widely spoken problem of the closed loop supply chain, i.e., uncertainty in quantity and quality and arrival time of core. System dynamics principle has been used to model the closed loop supply chains, and the Stella software has been used to visually demonstrate the behavior of KPI in different scenarios. Finally, the results of simulation have been presented in the form of behavioral comparison of KPI in conventional and ResCoM proposed closed loop supply chain settings. However, no real data has been used to run the simulation as the objective of the modeling was to highlight the particular behavior of the KPI, not to simply quantify them.

Endnotes

aWords written in italics from this point forward are the terms used in the simulation models.

Authors’ information

FMAA is a PhD student at the Department of Production Engineering, KTH Royal Institute of Technology, Sweden. He has been awarded the Technology Licentiate degree in September 2011. Apart from his Licentiate thesis, he has published articles for the Proceeding of Swedish production Symposium, DAAAM Baltic, and DAAAM international conferences. CB is a full professor of Business and Public Management at the Department of International Studies, University of Palermo (Italy) where he is also the scientific coordinator of the CED4 System Dynamics Group. He is the director of the masters degree course on “Managing business growth through system dynamics and accounting models: a strategic control perspective” and of the international PhD program on “Model based public planning, policy design, and management”. He is also the associate editor of the System Dynamics Review. His main research and consulting areas are related to small business growth management, entrepreneurial learning, startup, matching system dynamics with accounting models, dynamic scenario planning, dynamic balanced scorecards, business process analysis, and performance management. AR is a researcher and assistant professor at the Department of Production Engineering, KTH the Royal Institute of Technology, Sweden. He has been working in different manufacturing industries until he joined KTH in 2010. His research emphasis has been the analysis and control of machining system dynamics and extending his expertise towards sustainable manufacturing. He is the author of many scholarly articles published in many international journal and highly reputed conference proceedings. He has significant experience in the management of collaborative R&D projects through locally and EC funded projects. CMN is a full professor at the Department of Production Engineering, KTH the Royal Institute of Technology, Sweden. He is the chair of the research division called Machine and Process Technology. Aside from the many publications in different international journal and highly reputed conference proceedings, he has published some books. He has been actively involved in research and teaching since the beginning of his career and had supervised many PhD students.

References

The World Bank: World development indicators. 2011. (2011). Accessed 18 June 2011 http://data.worldbank.org/data-catalog/world-development-indicators/wdi-2011

Kumar V, Bee D, Tumkor S, Shirodkar P, Bettig B, Sutherland J: Towards sustainable “product and material flow” cycles: identifying barriers to achieving product multi-use and zero waste. In ASME 2005 International Mechanical Engineering Congress and Exposition. Orlando, Florida; 2005.

CIA: The World Factbook. (2011). Accessed 18 June 2011 http://www.cia.gov/library/publications/the-world-factbook/geos/xx.html

Jorgenson JD: Mineral commodity summaries. 2011. (2011). Accessed 20 June 2011 http://minerals.usgs.gov/minerals/pubs/mcs/2011/mcs2011.pdf

World Steel Association: World steel in figures. 2011. (2011). Accessed 20 June 2011 http://www.worldsteel.org/media-centre/press-releases/2011/wsif.html

Bureau of Internal Recycling: World steel recycling in figures 2006–2010: steel scrap - a raw material for steelmaking. (2010). Accessed 20 June 2011 http://www.bir.org/assets/Documents/publications/brochures/aFerrousReportFinal2006–2010.pdf

Eurostat European Commission: Energy, transport and environment indicators. . Accessed 20 June 2011 http://epp.eurostat.ec.europa.eu/cache/ITY_OFFPUB/KS-DK-10–001/EN/KS-DK-10–001-EN.PDF

Asif FMA: Resource conservative manufacturing: a new generation of manufacturing. Licentiate thesis, KTH Royal Institute of Technology; 2011.

Akkermans HA, Oorschot KEV: Relevance assumed: a case study of balanced scorecard development using system dynamics. Journal of the Operational Research Society 2005, 56: 931–94. 10.1057/palgrave.jors.2601923

Bianchi C: Enhancing Performance Management and Sustainable Organizational Growth through System Dynamics Modeling. In Systemic Management for Intelligent Organizations: Concepts, Model-Based Approaches, and Applications. Edited by: Groesser SN, Zeier R. Heidelberg: Springer-Publishing; 2012. under process

Asif FMA, Nicolescu CM: Minimizing uncertainty involved in designing the closed-loop supply network for multiple-lifecycle of products. In Annals of DAAAM for 2010 and Proceeding of the 21st International DAAAM Symposium: Intelligent Manufacturing and Automation: Focus on Interdisciplinary Solutions, Zadar Edited by: Katalinic B. 2010.

Hammond D, Beullens P: Closed-loop supply chain network equilibrium under legislation. Eur J Oper Res 2007,183(2):895–908. 10.1016/j.ejor.2006.10.033

Guide VDR, Van Wassenhove LN: The evolution of closed-loop supply chain research. Oper Res 2009,57(1):10–18. 10.1287/opre.1080.0628

Lundmark P, Sundin E, Björkman M: Industrial challenges within the remanufacturing system. In Proceedings of Swedish Production Symposium. Gothenberg; 2009.

Thierry MC, Salomon M, Van Wassenhove L: Strategic issues in product recovery management. Calif Manag Rev 1995,37(2):114–145. 10.2307/41165792

Gungor A, Gupta SM: Issue in environmentally conscious manufacturing and product recovery: a survey. Comput Ind Eng 1999,36(4):811–853. 10.1016/S0360-8352(99)00167-9

Seitz M, Peattie KJ: Meeting the closed-loop challenge: the case of remanufacturing. Calif Manag Rev 2004,46(2):74–79. 10.2307/41166211

Toffel MW: Strategic management of product recovery. Calif Manag Rev 2004,46(2):120–141. 10.2307/41166214

Parlikad AK, McFarlane DD: Recovering value from “End-of-Life” equipment: a case study on the role of product information. Technical report: Centre for Distributed Automation and Control, University of Cambridge; 2004.

Sundin E, Björkman M, Ostlin J: Importance of closed-loop supply chain relationship for product remanufacturing. Int J Prod Econ 2008,115(2):336–348. 10.1016/j.ijpe.2008.02.020

de Brito MP, Dekker R: A framework for reverse logistics. Rotterdam: Erasmus Research Institute of Management; 2003.

Freiberger S, Albrecht M, Käufl J: Reverse engineering technologies for remanufacturing of automotive systems communicating via CAN bus. Journal of Remanufacturing 2011, 1: 6. 10.1186/2210-4690-1-6

Kerr W, Ryan C: Eco-efficiency gains from remanufacturing a case study of photocopier remanufacturing at Fuji Xerox Australia. J Clean Prod 2001,9(1):75–81. 10.1016/S0959-6526(00)00032-9

Sundin E, Bras B: Making functional sales environmentally and economically beneficial through product remanufacturing. J Clean Prod 2005,13(9):913–925. 10.1016/j.jclepro.2004.04.006

Kumar S, Malegeant P: Strategic alliance in a closed-loop supply chain: a case of manufacturer and eco-non-profit organization. Technovation 2006,26(10):1127–1135. 10.1016/j.technovation.2005.08.002

Lifset R, Lindhqvist T: Does leasing improve end of product life management? J Ind Ecol 1999,3(4):10–13. 10.1162/108819899569647

Sterman JD: Business Dynamics: Systems Thinking and Modeling for a Complex World. Boston: McGraw-Hill/Irwin; 2000.

Ilgin MA, Gupta SM: Environmentally conscious manufacturing and product recovery (ECMPRO): a review of the state of the art. J Environ Manage 2010,91(3):563–591. 10.1016/j.jenvman.2009.09.037

Angerhofer BJ, Angelides MC: System dynamics modelling in supply chain management: research review. In Proceedings of the 32nd Conference on Winter Simulation. Orlando; 2000.

Georgiadis P, Vlachos D: The effect of environmental parameters on product recovery. Eur J Oper Res 2003,157(2):449–464.

Vlachos D, Georgiadis P, Iakovou E: A system dynamics model for dynamic capacity planning of remanufacturing in closed-loop supply chains. Comput Oper Res 2007,34(2):367–394. 10.1016/j.cor.2005.03.005

Kumar S, Yamaoka T: System dynamics study of the Japanese automotive industry closed loop supply chain. J Manuf Technol Manag 2007,18(2):115–138. 10.1108/17410380710722854

Georgiadis P, Vlachos D, Tagaras G: The impact of product lifecycle on capacity planning of closed-loop supply chains with remanufacturing. Prod Oper Manag 2006, 15: 514–527.

Georgiadis P, Athanasiou E: The impact of two-product joint lifecycles on capacity planning of remanufacturing networks. European Journal of Operations Research 2010,202(2):420–433. 10.1016/j.ejor.2009.05.022

Qingli D, Hao S, Hui Z: Simulation of remanufacturing in reverse supply chain based on system dynamics. In IEEE, Service Systems and Service Management, 2008 International Conference. Melbourne; 2008.

Schröter M, Spengler T: A system dynamics model for strategic management of spare parts in closed-loop supply chains. In The 23rd International Conference of the System Dynamics Society. Boston; 2005.

Poles R, Cheong F: A system dynamics model for reducing uncertainty in remanufacturing systems. In PACIS 2009 Proceedings. Hyderabad; 2009.

Besiou M, Georgiadis P, Van Wassenhove LN: Official recycling and scavengers: symbiotic or conflicting. European Journal of Operations Research 2012,218(2):563–576. 10.1016/j.ejor.2011.11.030

Georgiadis P, Besiou M: Environmental and economical sustainability of WEEE closed-loop supply chains with recycling: a system dynamics analysis. Int J Adv Manuf Technol 2010, 47: 475–493. 10.1007/s00170-009-2362-7

Georgiadis P, Besiou M: Sustainability in electrical and electronic equipment closed-loop supply chains: a system dynamics approach. J Clean Prod 2008,16(15):1665–1678. 10.1016/j.jclepro.2008.04.019

Özkir V, Basligil H: Modelling product recovery processes in closed loop supply chain network design. Int J Prod Res 2012,50(8):2218–2233. 10.1080/00207543.2011.575092

Semere DT: Configuration design of a high performance and responsive manufacturing system. Doctoral thesis, KTH Royal Institute of Technology; 2005.

Morecroft J: Strategic modelling and business dynamics: a feedback system approach. West Sussex: John Wiley & Sons Ltd.; 2007.

Leedy PD, Ormrod JE: Practical Research Planning and Design. New Jersey: Merrill/Pearson Education, Inc.; 2010.

Kothari CR: Research Methodology: Methods and Techniques. Delhi: New Age International Limited; 2004.

Acknowledgments

The authors acknowledge the financial support received from the Swedish Institute (http://www.si.se) through the project Lifecycle Management and Sustainability in the Baltic Region.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

FMAA contributed in developing the concept of resource conservative manufacturing, carried out the research presented in the paper, did the modeling, and made the draft of the paper. CB contributed in modeling, provided ideas for the modeling approach, and reviewed the modeling part of the research. AR contributed in developing the concept of resource conservative manufacturing, supervised the research, provided ideas for research, and also revised the paper critically for important intellectual content. CMN contributed in developing the concept of resource conservative, supervised the research, revised the paper critically for important intellectual content, and gave the final approval of the version to be published. All authors read and approved the final manuscript.

Electronic supplementary material

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Asif, F.M., Bianchi, C., Rashid, A. et al. Performance analysis of the closed loop supply chain. Jnl Remanufactur 2, 4 (2012). https://doi.org/10.1186/2210-4690-2-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2210-4690-2-4