Abstract

Platinum oxide nanoparticles were prepared by a simple hydrothermal route and chemical reduction using carbohydrates (fructose and sucrose) as the reducing and stabilizing agents. In comparison with other metals, platinum oxide has less environmental pollution. Therefore, Pt is considered an appropriate candidate to deal with environmental pathogens. The crystallite size of these nanoparticles was evaluated from X-ray diffraction, atomic force microscopy, and transmission electron microscopy (TEM) and was found to be 10 nm, which is the demonstration of EM bright field and transmission electron microscopy. The effect of carbohydrates on the morphology of the nanoparticles was studied using TEM. The nanoparticles were administered to the Pseudomonas stutzeri and Lactobacillus cultures, and the incubation was done at 37°C for 24 h. The nanocomposites exhibited interesting inhibitory as well as bactericidal activity against P. stutzeri and Lactobacillus species. Incorporation of nanoparticles also increased the thermal stability of the carbohydrates. The results of this paper showed that carbohydrates can serve as a carrier for platinum oxide nanoparticles, and nanocomposites can have potential biological applications.

Similar content being viewed by others

Background

Metal nanoparticles have different properties from those of bulk metal because of their small sizes, and thus, these materials can be employed in various photoelectronic, catalytic, magnetic, sensor, and biomedical applications [1–3]. In particular, Pt is known to inactivate microbes by interacting with their enzymes, proteins, or DNA to restrain cell proliferation or cell division [4]. Among all, capping ligands play a vital role in transforming the spherical or triangular-shaped nanoparticles to nanodevices or nanosensors of any desired shape [5]. Much of the recent research efforts have focused on developing new strategies to fabricate nanoconstructs with carbohydrates [6, 7] as capping ligands because of their potential applications in the design and development of nanoscale devices and nanosensors for biomedical applications [8]. Carbohydrates contain many hydroxyl and carbonyl groups; these groups offer sugar-coated nanoparticle, a unique H-bonding capabilities in constructing supramolecular architecture. Upon surface coating with nanoparticles, they provide attractive nanoconstruction abilities for building smart nanomaterials. For example, nanowires of platinum or tellurium have been constructed from glucose-stabilized platinum nanoparticles or starch-stabilized tellurium nanoparticles [9–12]. Current strategies for carbohydrate functionalization of Pt nanoparticles utilize thiol-tailored sugars as synthons [12–15]. Quinti and coworkers have developed a ‘green’ method to synthesize and stabilize carbohydrate-Pt nanocomposites in starch matrix using glucose as the reducing agent [16].

In this work, we developed an easy method to produce platinum oxide composites with homogeneous size distribution and then these materials were stabilized with sucrose. These stabilized nanoparticles were then used as the antimicrobial agents against Pseudomonas stutzeri and Lactobacillus cultures in further experiments.

Methods

The sucrose was supplied by Fibrocel - Produtos Biotecnológicos Ltda. (Ibiporã, Brazil). Platinum oxide and other reagents were commercially purchased from Sigma-Aldrich Corporation (St. Louis, MO, USA) and used as received. Aqueous solutions and bacterial suspensions were prepared using distilled deionized sterile water. Agar, tryptone, and yeast extract of BactoTM, used for the microbiological culture media, were purchased from Himedia (Mumbai, India). The P. stutzeri and Lactobacillus strains were taken from the Central Laboratory of Pathology, Yazd. All reagents were of analytical grade and used without further purification.

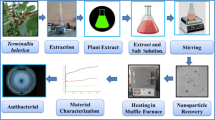

Syntheses of carbohydrate-stabilized platinum oxide nanoparticles

In a typical experiment, 1.7 g (1.0 × 10−2 mol) of platinum oxide (Sigma-Aldrich, 99.9+ %) was dissolved in 100 mL of deionized water. Then, the solution platinum oxide was precipitated with 0.62 g (1.55 × 10−2 mol) of sodium hydroxide (Sigma-Aldrich, 99+ %). An obtained precipitate of platinum oxide was filtered and dissolved in 100 mL of aqueous ammonia (0.4% w/w, 2.3 × 10−2 mol) until a transparent solution of platinum-ammonium complex was formed. Next, 2.5 g (8.9 × 10−3 mol) of oleic acid (Sigma-Aldrich, 99 + %) was added dropwise into the obtained complex, and the resulting solution was gently stirred for 2 h at room temperature until the complete homogeneity of the reaction mixture was achieved. Finally, 2 g (1.11 × 10−2 mol) of glucose was added to the mixture at room temperature with gentle stirring. The reduction process of silver complex solution (in quartz glass) was initiated with UV-irradiation (UV MILTON ROY Company, Ivyland, PA, USA; Spectrum 21). UV treatment was carried out for 8 h under vigorous stirring without additional heating. An UV lamp (k = 365 nm, 35 W) was used as light source to stimulate the reduction process. After 8 h of irradiation, the transparent dispersion obtained oleic acid-stabilized platinum oxide nanoparticles (platinum oxide concentration = 10 mg mL−1). The synthesis of platinum oxide NPs was also successfully conducted with the final Pt concentrations in the range of 0.1% to 2%.

The TEM (H987 - Philips, Amsterdam, The Netherlands) images of the Pt oxide nanoparticles were taken by the following method: at first, a solution of Pt oxide was prepared and diluted 100 times with 50% ethanol. A drop of this diluted solution was added to fomvar/carbon-coated grids (400 meshes) and, after drying, viewed under the TEM (Brazilian Synchroton Light Laboratory, Sao Paulo, Brazil), operating at 80 kV.

XRD (U234 - Philips) patterns were obtained in a Siemens Kristalloflex diffractometer (Siemens, Knoxville, TN, USA) using nickel filtered CuKα radiation from 4° to 70° (2θ angle) as shown in Figure 1. TG (STA 409 - Netzsch (Selb, Germany)) was conducted using dried samples in SDT 2960 device from TA Instruments (New Castle, DE, USA). Samples were heated in open alumina pans from 40°C to 600°C, under an oxidant atmosphere (O2), using flux of 50 mL/min, at a heating rate of 10°C/min. The Pt oxide content of the BC/Pt composites was estimated from the residue at 600°C.

Antibacterial properties of carbohydrate-stabilized platinum oxide nanoparticles

The antimicrobial activity of sucrose-modified Pt oxide nanoparticles was investigated against P. stutzeri and Lactobacillus. The following solution and media were prepared to study the antimicrobial activity: (a) NaCl aqueous solution (2.7 g of NaCl dissolved in 300 mL of distilled water), sterilized by autoclaving at 120°C for 20 min; (b) culture medium (Luria-Bertani (LB)) containing 1.0-g NaCl, 1.0-g tryptone, 0.5-g yeast extract of BactoTM, and 100-mL distilled water, sterilized by autoclaving at 120°C for 20 min; and (c) solid LB medium, used to prepare petri dishes containing 3-g NaCl, 3-g tryptone, 1.5-g yeast extract of BactoTM, 4.5-g agar, and 300-mL distilled water. The solid LB medium was sterilized by autoclaving at 120°C for 20 min.

An aliquot (100 μL) of the bacterial suspension prepared previously was transferred to a test tube with 9.9 mL of lysogenic broth medium (LB) and homogenized. This tube contained a concentration of 107 cells mL−1. This bacterial suspension was diluted in a saline solution to obtain a suspension containing about 105 cells mL−1. Aliquots of 1,000 μL of the suspension containing about 105 cells mL−1 were transferred to sterile test tubes containing the samples. The test tubes were incubated in a stirring incubator at 37°C and stirred at 120 rpm for 24 h. After incubation, the content of the tubes was transferred to four Erlenmeyer flasks filled with 50 mL of sterile NaCl aqueous solution at 0.9%. An aliquot (100 μL) of the content of each Erlenmeyer flask was transferred to a microtube filled with 900 μL of sterile NaCl aqueous solution. The microtubes were then vortexes. This dilution sequence was repeated four times to obtain four dilutions. Aliquots (100 μL) of these dilutions were then spread on a nutrient agar plate and incubated at 37°C for 24 h; after which, the colony-forming units were counted, and the average was taken from the three plates corresponding to a particular sample. The antibacterial activity of the carbohydrate-Pt nanocomposites impregnated in bacterial cellulose was determined at different concentrations (103, 104, 105, 106, and 107 cells mL−1). The experiments were carried out in triplicate. Statistical analysis was performed using Student's t-test, and the percentage reduction in bacterial count was calculated by the following equation:

Results and discussion

Pt oxide nanoparticles could be successfully synthesized in the sucrose matrix. The reduction was fastest in the case of sucrose followed by waxy corn and soluble starch while stability of nanoparticles followed the order soluble starch > waxy corn starch > sucrose (data not shown). Thus, the size and molecular weight were important for stabilization of the nanoparticles.

Figure 1a shows the TEM image of Pt oxide nanoparticles alone. Figure 1b shows the TEM image of Pt oxide modified with sucrose. The sucrose reduction occurred only after heating at 80°C for 4 h. This is required because the more hydrolyzed the carbohydrate the better its ability to act as a reducing agent. UV-visible illumination was used to enhance the reduction capacity of sucrose where it is hydrolyzed, and the hydrolyzed products then reduce the metal. The time taken for reduction is also very short (30 s).

UV–vis absorption spectrum of carbohydrate-stabilized Pt oxide nanoparticles in aqueous solution was recorded after sufficient dilution as demonstrated in Figure 2. The characteristic absorption peak due to the surface-plasmon resonance of Pt colloids was observed within the range of 415 to 425 nm.

Although the exact mechanism of the formation of the nanostructures is difficult to know, we think that the simple structure of sucrose could serve as a directing template for the growth of Pt nanoparticles. Figure 3 demonstrates the simulated XRD patterns of sucrose-stabilized Pt oxide nanoparticles. All Bragg's reflections representing b111N, b200N, b220N, and b311N planes of FCC crystal structures due to metallic Pt are observed. About 7% of Pt is present in nanocomposites, and oxygen comes from the surrounding organic matter.

Figure 4 shows the atomic force microscopic image of the sucrose-stabilized Pt oxide nanoparticles. The carbohydrate-stabilized aqueous solution of Pt oxide nanoparticles exhibited antibacterial activity against P. stutzeri and Lactobacillus bacteria even at concentrations as low as 0.049 mg/L. The photographs in Figures 5 and 6 clearly show the zone of inhibition for carbohydrate-Pt nanocomposites against P. stutzeri and Lactobacillus, respectively. Similar results were obtained against Staphylococcus aureus (data not shown).

The digital photographs in Figure 5a,b represents MIC and MBC tests in Pt oxide-sucrose nanocomposite against P. stutzeri, respectively. This figure specifies that MIC/MBC rate is about 0/5.

On the other hand, Figure 6a,b shows the same parameters against Lactobacillus strain. The effectiveness of sucrose nanocomposites was proven to be highly effective. Therefore, it could be concluded that Pt oxide nanoparticles could be released through aqueous carbohydrate solutions owing to the stable dispersion at molecular level and the slow diffusion from the stabilizing medium.

Platinum oxide nanoparticles were obtained by a green approach using sucrose as a reducing as well as stabilizing agent [17–19]. The nanoparticles exhibited interesting morphology when synthesized under hydrothermal conditions in the matrix of sucrose-rich medium. These nanocomposites exhibited high thermal stability as well as bactericidal effect against P. stutzeri and Lactobacillus. Thus, carbohydrates can serve as a carrier for platinum oxide nanoparticles, and nanocomposites can have potential biological applications [20–22].

Conclusion

The present study reveals the characteristics of antibacterial effect of carbohydrate-stabilized platinum oxide nanoparticles. Given the fact that the nanocomposition of platinum oxide can be used in biomedicine product, nanofilters consequently contained more antibacterial active sites than other antibacterial agents.

References

Shevchenko EV, Talapin DV, Kotov NA, O'Brien S, Murray CB: Structural diversity in binary nanoparticle superlattices. Nature 2006, 439: 55–59. 10.1038/nature04414

Wang X, Zhuang J, Peng Q, Li YD: A general strategy for nanocrystal synthesis. Nature 2005, 437: 121–124. 10.1038/nature03968

Portney NG, Singh K, Chaudhary S, Destito G, Schneemann A, Manchester M, Ozkan M: Organic and inorganic nanoparticle hybrids. Langmuir 2005, 21: 2098–2103. 10.1021/la047525f

Maye MM, Lim IIS, Luo J, Rab Z, Rabinovich D, Liu TB, Zhong CJ: Mediator-template assembly of nanoparticles. J. Am. Chem. Soc. 2005, 127: 1519–1529. 10.1021/ja044408y

Chane-Ching JY, Cobo F, Aubert D, Harvey HG, Airiau M, Corma A: A general method for the synthesis of nanostructured large-surface-area materials through the self-assembly of functionalized nanoparticles. Chem. Eur. J. 2005, 11: 979–987. 10.1002/chem.200400535

Kim BS, Hong DJ, Bae J, Lee M: Controlled self-assembly of carbohydrate conjugate rod-coil amphiphiles for supramolecular multivalent ligands. J. Am. Chem. Soc. 2005, 127: 16333–16337. 10.1021/ja055999a

Barrientos AG, de la Fuente JM, Rojas TC, Fernandez A, Penades S: Gold glyconanoparticles: synthetic polyvalent ligands mimicking glycocalyx-like surfaces as tools for glycobiological studies. Chem. Eur. J. 2003, 9: 1909–1921. 10.1002/chem.200204544

Rojas TC, de la Fuente JM, Barrientos AG, Penades S, Ponsonnet L, Fernandez A: Gold glyconanoparticles as building blocks for nanomaterials design. Adv. Mater. 2002, 14: 585–588. 10.1002/1521-4095(20020418)14:8<585::AID-ADMA585>3.0.CO;2-W

Zand AM, H Khani P, Imani S, Rezaei M, Rezaei-Zarchi S: Determining the antibacterial effect of ZnO nanoparticle against the pathogenic bacterium, Shigella dysenteriae (type 1). International Journal of Nano Dimension (IJND) 2010,1(4):279–285.

Reynolds AJ, Haines AH, Russell DA: Gold glyconanoparticles for mimics and measurement of metal ion mediated carbohydrate-carbohydrate interactions. Langmuir 2006, 22: 1156–1163. 10.1021/la052261y

Halkes KM, de Carvalho SA, Elizabeth C, Maliaars P, Gerwig GJ, Kamerling JP: Facile method for the preparation of gold glyconanoparticles from free oligosaccharides and their applicability in carbohydrate-protein interaction studies. Eur. J. Org. Chem. 2005, 12: 3650–3659.

De la Fuente JM, Eaton P, Barrientos AG, Menendez M, Penades S: Thermodynamic evidence for Ca2 + −mediated self-aggregation of Lewis X gold glyconanoparticles. A model for cell adhesion via carbohydrate-carbohydrate interaction. J. Am. Chem. Soc. 2005, 127: 6192–6197. 10.1021/ja0431354

de la Fuente JM, Barrientos AG, Rojas TC, Rojo J, Canada J, Fernandez A, Penades S: Gold glyconanoparticles as water-soluble polyvalent models to study carbohydrate interactions. Angew. Chem. Int. Ed. 2001, 40: 2258–2261.

Ipe BI, Yoosaf K, Thomas KG: Functionalized gold nanoparticles as phosphorescent nanomaterials and sensors. J. Am. Chem. Soc. 2006, 128: 1907–1913. 10.1021/ja054347j

Perez JM, Josephson L, Weissleder R: Use of magnetic nanoparticles as nanosensors to probe for molecular interactions. Chem. Bio. Chem. 2004, 5: 261–264.

Quinti L, Weissleder R, Tung CH: A fluorescent nanosensor for apoptotic cells. Nano. Lett. 2006, 6: 488–490. 10.1021/nl0524694

Imani S, Zagari Z, Rezaei-Zarchi S, Zand AM, Dorodiyan , Bariabarghoyi H, Lotfi F: Antibacterial effect of CrO and CoFe2O4 nanoparticles upon Staphylococcus aureus. 2011, 3: 119–125.

de la Fuente JM, Penades S: Types, synthesis and applications in glycoscience, biomedicine and material science. Biochim. Biophys. Acta 2006, 1760: 636–651. 10.1016/j.bbagen.2005.12.001

Lu QY, Gao F, Komarneni S: A green chemical approach to the synthesis of tellurium nanowires. Langmuir 2005, 21: 6002–6005. 10.1021/la050594p

Liu JC, Qin G, Ravindran P, Ikushima Y: Facile “green” synthesis, characterization, and catalytic function of β-d-glucose-stabilized Au nanocrystals. Chem. Eur. J. 2006, 12: 2131. 10.1002/chem.200500925

Raghuraman K, Katti KK, Barbour LJ, Pillarsetty N, Barnes CL, Katti KV: Characterization of supramolecular (H2O) 18 water morphology and water–methanol (H2O) 15(CH3OH) 3 clusters in a novel phosphorus functionalized trimeric amino acid host. J. Am. Chem. Soc. 2003, 125: 6955–6961. 10.1021/ja034682c

Raghuraman K, Pillarsetty N, Volkert WA, Barnes C, Jurisson S, Katti KV: Exceptional kinetic propensity of hydroxymethyl phosphanes toward Rh(III) stabilization in water. J. Am. Chem. Soc. 2002, 124: 7276–7277. 10.1021/ja025987e

Acknowledgments

The authors greatly appreciate the financial support from Payame Noor University, Yazd and Imam Houssein University for running the present project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

SRZ and ZZ designed and synthesized the carbohydrate-stabilized platinum oxide nanoparticles, guided the contact angle analysis, and prepared the manuscript. AMZ and SI facilitated and made the antibacterial and biological samples, guided the contact angle analysis, and prepared the manuscript. MS participated in the SEM analysis and prepared the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Rezaei-Zarchi, S., Imani, S., mohammad Zand, A. et al. Study of bactericidal properties of carbohydrate-stabilized platinum oxide nanoparticles. Int Nano Lett 2, 21 (2012). https://doi.org/10.1186/2228-5326-2-21

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5326-2-21