Abstract

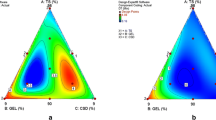

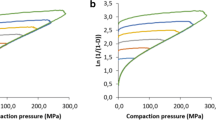

The development of new direct compression excipients should include a comprehensive and rapid determination of deformation properties. The aim of this study was to characterize StarLac, a new coprocessed compound for direct compression based on lactose and maize starch. For this purpose, the effects of the base materials (maize starch and spraydried lactose) were considered and the influence of the spray-drying process was investigated. This was performed by comparing the physical mixture of starch and spray-dried lactose at the same ratio as for StarLac. For analysis of the deformation behavior, the 3-D model and the Walker equation were applied; for verification, the Heckel equation and the pressure time function (a modified Weibull equation) were used. The advantages of StarLac are its good flowability depending on the spray-drying process, an acceptable crushing force due to its lactose content, its rapid disintegration depending on starch, and a brilliant fast release of an active ingredient, such as theophylline monohydrate. The volume-pressure deformation properties of StarLac were dependent on the lactose properties. Only at high maximum relative density (ϱrel,max) did the influence of starch cause a change in these properties. A network-like structure can be observed using scanning electron microscopy pictures. Overall, StarLac deformed plastically with a low portion of elasticity. The physical mixture exhibited a more elastic behavior than StarLac. However, the part of the powder that was irreversibly compressed was much lower than was observed for the single substances. This behavior is caused by an interaction between the components, which in StarLac is prevented by spray drying.

Similar content being viewed by others

References

Picker KM. Soft tableting: A new concept to tablet pressure-sensitive drugs. Pharm Dev Technol. 2004;9(1):107–121.

Picker KM. New Insights in the Process of Tablet Formation: Ways to Explore Soft Tableting. [Habilitationsschrift]. Halle, Germany: Martin-Luther-University Halle-Wittenberg and Görich und Weiershäuser Verlag, Marburg; 2002.

Meggle AG. Technical information at www.meggle-pharma.de/en/products/uebersicht/starlac.

Vromans H, Bolhuis GK, Lerk CF. Studies on tableting properties of lactose. VI. Consolidation and compaction of spray-dried amorphous lactose. Acta Pharm Suec. 1986;23:231–240.

Vromans H, de Boer AH, Bolhuis GK, Lerk CF, Kussendrager KD. Studies on tableting properties of lactose. I. The effect of initial particle size on binding properties and dehydration characteristics of lactose. Acta Pharm Suec. 1985;22:163–172.

Goto K, Sunada H, Danjo K, Yonezawa Y. Pharmacentical evaluation of multipurpose excipients for direct compressed tablet manufacture: comparisons of the capabilities of multipurpose excipients with those in general use. Drug Dev Ind Pharm. 1999;25:869–878.

Bolhuis GK, Chowhan ZT. Lactose. In: Alderborn G, Nyström C, eds. Pharmacentical Powder Compaction Technology. New York, NY: Marcel Dekker. 1996:459–478.

Paronen P, Juslin M. Compressional characteristics of four starches. J Pharm Pharmacol. 1983;35:627–635.

Bos CE, Bolhuis GK, van Doorne H, Lerk CF. Native starch in tablet formulations: properties on compaction. Pharm Weekbl Sc Ed. 1987;9:274–282.

Heckel RW. Density-pressure relationship in powder compaction. Trans Metall Soc AIME. 1961;221:671–675.

Walker EE. The influence of the velocity of compression on the apparent compressibility of powders. Trans Faraday Soc. 1923;19:614–622.

Cooper AR, Eaton LE. Compaction behavior of several ceramic powders. J Am Ceram Soc. 1962;45:97–101.

Kawakita K, Lüdde KH. Some considerations on powder compression equations. Powder Technol. 1971;4:61–68.

Sonnergaard JM. Investigation of a new mathematical model for compression of pharmacential powders. Eur J Pharm Sci. 2001;14:149–157.

Dietrich R, Mielck JB. Parametrisierung des zeitlichen Verlaufs der Verdichtung bei der Tablettierung mit Hilfe der modifizierten Weibull-Funktion: 1. Mitt.: Gedanklicher und experimenteller Ansatz. Pharm Ind. 1984;46:863–869.

Dietrich R, Mielck JB. Parametrisierung des zeitlichen Verlaufs der Verdichtung bei der Tablettierung mit Hilfe der modifizierten Weibull-Funktion: 2.Mitt.: Auswertung und Interpretation der Ergebnisse. Pharm Ind. 1985;47:216–220.

Fraser RDB, Suzuki E. Resolution of overlapping bands, functions for simulating band shapes. Anal Chem. 1969;41:37–39.

Picker KM. The 3-D Model: Comparison of Parameters Obtained From and by Simulating Different Tableting Machines. AAPS Pharm Sci Tech. 2003;4(3):E35.

Kurup TRR, Pilpel N. Compression characteristics of pharmaceutical powder mixtures. Powder Technol. 1978;19:147–155.

Heckel RW. An analysis of powder compaction phenomena. Trans Metall Soc AIME. 1961;221:1001–1008.

Sønnergaard JM. A critical evaluation of the Heckel equation. Int J Pharm. 1999;193:63–71.

Sønnergaard JM. Impact of particle density and initial volume on mathematical compression models. Eur J Pharm Sci. 2000;11:307–315.

Dietrich R, Mielck JB. Eignung der Weibull-Funktion zur Charakterisierung des zeitabhängigen Verformungsverhaltens von Tablettierhilfsstoffen. Acta Pharm Technol. 1985;31:67–76.

Picker KM. Hydrophile Matrixtabletten: Tablettierung und Freisetzung unter besonderer Berücksichtigung der relativen Feuchte während der Herstellung [Dissertation]. Hamburg, Germany: University of Hamburg; 1995.

Picker KM. The 3-D Model: Does Time Plasticity Represent the Influence of Tableting Speed? AAPS Pharm Sci Tech. 2003;4(4):E66.

Armstrong NA, Haines-Nutt RF. Elastic recovery and surface area changes in compacted powders systems. J Pharm Pharmacol. 1972;24(suppl):135P-136P.

Koch HP. Die Technik der Dissolutionsbestimmung (2 Teil). Pharm Acta Helv. 1984;59:130–139.

Kibbe AH, Weller PJ. Lactose. In: Rowe RC, Sheskey PJ, Weller PJ, eds. Handbook of Pharmaceutical Excipients. London, UK: Pharmaceutical Press; 2003:323–332.

Rowley G. Starch. In: Rowe RC, Sheskey PJ, Weller PJ, eds. Handbook of Pharmaceutical Excipient. London, UK: Pharmaceutical Press; 2003:601–608.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published: May 26, 2004

Rights and permissions

About this article

Cite this article

Hauschild, K., Picker, K.M. Evaluation of a new coprocessed compound based on lactose and maize starch for tablet formulation. AAPS J 6, 16 (2004). https://doi.org/10.1208/ps060216

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/ps060216