Abstract

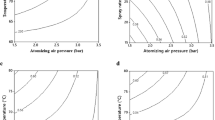

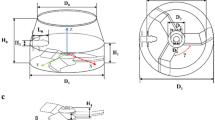

Top-spray fluidized bed granulation with axial fluidization airflow from the bottom of the granulator is well-established in the pharmaceutical industry. The application of swirling airflow for fluidized bed granulation was more recently introduced. This study examined the effects of various process parameters on the granules produced by side-spray fluidized bed with swirling airflow using the central composite and Box–Behnken design of experiment. Influence of the amount of binder solution, spray rate, and distance between spray nozzle and powder bed were initially studied to establish operationally viable values for these parameters. This was followed by an in-depth investigation on the effects of inlet airflow rate, atomizing air pressure and distance between spray nozzle and powder bed on granule properties. It was found that the amount of binder solution had a positive correlation with granule size and percentage of lumps but a negative correlation with size distribution and Hausner ratio of the granules. Binder solution spray rate was also found to affect the granules size. High drug content uniformity was observed in all the batches of granules produced. Both inlet airflow rate and atomizing air pressure were found to correlate negatively with granule size and percentage of lumps but correlate positively with the size distribution of the granule produced. Percentage of fines was found to be significantly affected by inlet airflow rate. Distance between spray nozzle and powder bed generally affected the percentage of lumps.

Similar content being viewed by others

REFERENCES

Schœfer T, Worts O. Control of fluidized bed granulation I. Effects of spray angle, nozzle height and starting materials on granule size and size distribution. Arch Pharm Chem Sci. 1977;5:51–60.

Schœfer T, Worts O. Control of fluidized bed granulation II. Estimation of droplet size of atomized binder solutions. Arch Pharm Chem Sci. 1977;5:178–93.

Schœfer T, Worts O. Control of fluidized bed granulation III. Effects of inlet air temperature and liquid flow rate on granule size and size distribution. Control of moisture content of granules in the drying phase. Arch Pharm Chem Sci. 1978;6:1–13.

Schœfer T, Worts O. Control of fluidized bed granulation IV. Effects of binder solution and atomization on granule size and size distribution. Arch Pharm Chem Sci. 1978;6:14–25.

Schœfer T, Worts O. Control of fluidized bed granulation V. Factors affecting granule growth. Arch Pharm Chem Sci. 1978;6:69–82.

Alkan MH, Yuksel A. Granulation in a fluidized bed. II. Effect of binder amount on the final granules. Drug Dev Ind Pharm. 1986;12(10):1529–43.

Kokubo H, Sunada H. Effect of process variables on the properties and binder distribution of granules prepared in a fluidized bed. Chem Pharm Bull. 1997;45(6):1069–72.

Schaafsma SH, Vonk P, Kossen NWF. Fluid bed agglomeration with a narrow droplet size distribution. Int J Pharm. 2000;193(2):175–87.

Rajniak P, Mancinelli C, Chern RT, Stepanek F, Farber L, Hill BT. Experimental study of wet granulation in fluidized bed: impact of the binder properties on the granule morphology. Int J Pharm. 2007;334(1–2):92–102.

Nienow AW, Rowe PN. Particle growth and coating in gas-fluidized beds. In: Davidson JF, Clift R, Harrison D, editors. Fluidization. 2nd ed. Orlando: Academic; 1985. p. 563–94.

Yilmaz M, Çomakli O, Yapici S. Enhancement of heat transfer by turbulent decaying swirl flow. Energy Convers Manag. 1999;40(13):1365–76.

Algifri AH, Bhardwaj RK, Rao YVN. Heat transfer in turbulent decaying swirl flow in a circular pipe. Int J Heat Mass Transf. 1988;31(8):1563–8.

Özbey M, Söylemez MS. Effect of swirling flow on fluidized bed drying of wheat grains. Energy Convers Manag. 2005;46(9–10):1495–512.

Ritala M, Virtanen S. The effect of binder solution quantity and lactose particle size on granule properties. Acta Pharma Nordica. 1991;3(4):229–34.

Niskanen T, Niskanen M, Yliruusi J, Kristoffersson E. Granulation in instrumented fluidized bed granulator—evaluation of the effects of two independent process variables on granule properties. Acta Pharma Nordica. 1991;3(1):19–24.

Davies WL, Gloor Jr WT. Batch production of pharmaceutical granulations in a fluidized bed. I. Effects of process variables on physical properties of final granulation. J Pharm Sci. 1971;60(12):1869–74.

Rambali B, Baert L, Thone D, Massart DL. Using experimental design to optimize the process parameters in fluidized bed granulation. Drug Dev Ind Pharm. 2001;27(1):47–55.

Arnaud P, Brossard D, Chaumeil JC. Effect of the granulation process on nitrofurantoin granule characteristics. Drug Dev Ind Pharm. 1998;24(1):57–66.

Hausman DS. Comparison of low shear, high shear, and fluid bed granulation during low dose tablet process development. Drug Dev Ind Pharm. 2004;30(3):259–66.

Aulton ME. Drying. In: Aulton ME, editor. Aulton’s pharmaceutics: the design and manufacture of medicines. 3rd ed. New York: Churchill Livingstone; 2007. p. 425–40.

Er DZL, Liew CV, Heng PWS. Layered growth with bottom-spray granulation for spray deposition of drug. Int J Pharm. 2009;377(1–2):16–24.

Loh ZH, Er DZ, Chan LW, Liew CV, Heng PW. Spray granulation for drug formulation. Expert Opin Drug Deliv. 2011;8(12):1645–61.

Liew CV, Er DZL, Heng PWS. Air-dictated bottom spray process: Impact of fluid dynamics on granule growth and morphology. Drug Dev Ind Pharm. 2009;35(7):866–76.

Schaafsma SH, Kossen NWF, Mos MT, Blauw L, Hoffmann AC. Effects and control of humidity and particle mixing in fluid-bed granulation. AICHE J. 1999;45(6):1202–10.

Jager, Bauer. Effects of material motion on agglomeration in the rotary fluidized bed granulator. Drugs Made Ger. 1982;25:61–5.

Kristensen J, Hansen VW. Wet granulation in rotary processor and fluid bed: comparison of granule and tablet properties. AAPS PharmSciTech. 2006;7(1):E1–10.

Esbensen KH, Guyot D, Westad F, Houmøller LP. 16. Introduction to experimental design. Multivariate data analysis—in practice: an introduction to multivariate data analysis and experimental design. 5th ed: Camo Software; 2001.

Myers RH, Montgomery DC. Building empirical model. Response surface methodology: process and product optimization using designed experiments. 2nd ed. New York: Wiley; 2002. p. 17.

Kristensen HG, Holm P, Jaegerskou A, Schaefer T. Granulation in high-speed mixers. 4. Effect of liquid saturation on the agglomeration. Pharm Ind. 1984;46(7):763–7.

Hemati M, Cherif R, Saleh K, Pont V. Fluidized bed coating and granulation: influence of process-related variables and physicochemical properties on the growth kinetics. Powder Technol. 2003;130(1–3):18–34.

Lipps DM, Sakr AM. Characterization of wet granulation process parameters using response surface methodology. 1. Top-spray fluidized bed. J Pharm Sci. 1994;83(7):937–47.

Rankell AS, Scott MW, Lieberman HA, Chow FS, Battista JV. Continuous production of tablet granulations in a fluidized bed. II. J Pharm Sci. 1964;53:320–4.

Wan LSC, Heng PWS, Liew CV. The influence of liquid spray rate and atomizing pressure on the size of spray droplets and spheroids. Int J Pharm. 1995;118(2):213–9.

Pilpel N. The flow properties of magnesia. J Pharm Pharmacol. 1964;16:705–16.

Jones TM, Pilpel N. The flow properties of granular magnesia. J Pharm Pharmacol. 1966;18(2):81–93.

Andersson KM, Bergström L. Friction and adhesion of single spray-dried granules containing a hygroscopic polymeric binder. Powder Technol. 2005;155(2):101–7.

Yilmaz M, Comakli O, Yapici S, Sara ON. Heat transfer and friction characteristics in decaying swirl flow generated by different radial guide vane swirl generators. Energy Convers Manag. 2003;44(2):283–300.

Scott MW, Lieberman HA, Rankell AS, Battista JV. Continuous production of tablet granulations in a fluidized bed. I. J Pharm Sci. 1964;53:314–20.

Lin K, Peck GE. Development of agglomerated talc. I. Evaluation of fluidized bed granulation parameters on the physical properties of agglomerated talc. Drug Dev Ind Pharm. 1995;21(4):447–60.

ACKNOWLEDGMENTS

The authors would like to acknowledge the financial support from GEA-NUS PPRL fund (N-148-000-008-001) and A*STAR SERC grant no. 102 161 0049 (R-148-000-157-305). Wong Poh Mun is a recipient of the National University of Singapore Graduate Research Scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wong, P.M., Chan, L.W. & Heng, P.W.S. Investigation on Side-Spray Fluidized Bed Granulation with Swirling Airflow. AAPS PharmSciTech 14, 211–221 (2013). https://doi.org/10.1208/s12249-012-9906-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-012-9906-0