Abstract

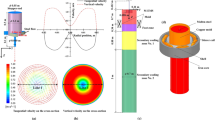

The classic one-dimensional isentropic flow approach is used along with a two-dimensional axisymmetric numerical model to show that the exit Mach number of a cold spray nozzle should be limited due to two factors. To show this, the two-dimensional model is validated with experimental data. Although both models show that the stagnation temperature is an important limiting factor, the one-dimensional approach fails to show how important the shock-particle interactions are at limiting the nozzle Mach number. It is concluded that for an air nozzle spraying solid powder particles, the nozzle Mach number should be set between 1.5 and 3 to limit the negative effects of the high stagnation temperature and of the shock-particle interactions.

Similar content being viewed by others

References

A.P. Alkhimov, A.N. Papyrin, V.F. Dosarev, N.I. Nesterovich, and M.M. Shuspanov: U.S. Patent 5 302 414, 1994.

A.O. Tokarev: “Structure of Aluminum Powder Coatings Prepared by Cold Gas-Dynamic Spraying,” Met. Sci. Heat Treat., 1996, 38(3–4), pp. 136–39.

A.P. Alkhimov, V.F. Kosarev, and A.N. Papyring: “A Method of Cold Gas Dynamic Deposition,” Dokl. Akad. Nauk SSSR, 1990, 315(5), pp. 1062–65.

A.H. Shapiro, The Dynamics and Thermodynamics of Compressible Fluid Flow, Ronald Press, New York, 1953.

R.C. Dykhuizen and M.F. Smith: “Gas Dynamic Principles of Cold Spray,” J. Therm. Spray Technol., 1998, 7(2), pp. 205–12.

D.L. Gilmore, R.C. Dykhuizen, R.A. Neiser, T.J. Roemer, and M.F. Smith: “Particle Velocity and Deposition Efficiency in the Cold Spray Process,” J. Therm. Spray Technol., 1999, 8(4), pp. 576–82.

V. Shukla, G.S. Elliott, and B.H. Kear: “Nanopowder Deposition by Supersonic Rectangular Jet Impingement,” J. Therm. Spray Technol., 2000, 9(3), pp. 394–98.

J. Karthikeyan, C.M. Kay, J. Lindeman, R.S. Lima, and C.C. Berndt: “Cold Spray Processing of Titanium Powder” in Proceedings of the First International Thermal Spray Conference, C.C. Berndt, ed., ASM International, Materials Park, OH, 2000, pp. 255–62.

R.N. Cox and L.F. Crabtree: Elements of Hypersonic Aerodynamics, Academic, New York, 1965.

J.K. Vennard and R.L. Street: Elementary Fluid Mechanics, Wiley, New York, 1982.

C.B. Henderson: “Drag Coefficients of Spheres in Continuum and Rarefied Flows,” AIAA J., 1976, 14, pp. 707–08.

R.P. Benedict: Fundamentals of Temperature, Pressure and Flow Measurements, Wiley, New York, 1984, pp. 339–73.

B. Jodoin, P. Proulx, and Y. Mercadier: “Numerical Study of Supersonic Direct Current Plasma Nozzle Flow,” AIAA J., 1998, 36(4), pp. 578–84.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jodoin, B. Cold spray nozzle mach number limitation. J Therm Spray Tech 11, 496–507 (2002). https://doi.org/10.1361/105996302770348628

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996302770348628