Abstract

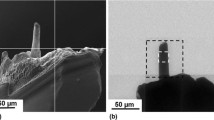

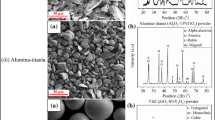

Thermally sprayed deposits have layered structure composed of individual splats. The individual splats have quenching microstructure of quasi-stable preferred fine grains. However, this fine-grained microstructure of the deposits is usually not reflected by improved performance of the deposits because a layered structure with two-dimensional voids occurs between lamellar interfaces.

The microstructure of the thermal spray deposits with the emphasis on the layer structural parameters is reviewed. Conventionally, one of the most common quantitative parameters used to characterize the microstructure of the thermally sprayed deposits is the porosity, measured by different methods. However, it is illustrated that the relationships between properties and porosity for bulk porous materials processed by conventional processes cannot be applied to thermally sprayed deposits owing to the two-dimensional characteristics of voids. The total porosity in the deposits is not meaningful from the viewpoint of prediction of the deposit properties. An idealized structural model and related parameters, instead of porosity, are proposed to characterize quantitatively the microstructure of the thermally sprayed deposit. The relationships between the properties and the structural parameters are presented for the plasma-sprayed ceramic deposits based on the proposed microstructure model. The properties include the Young’s modulus, fracture toughness, erosion resistance, and thermal conductivity of the plasma sprayed ceramic deposits. The correlations of theoretical relationships with reported experimental data are discussed.

An agreement of theoretical with observed values suggests that the lamellar structure of the deposit with limited interface bonding is the dominant factor controlling the performance of the deposit.

Similar content being viewed by others

References

C.-J. Li, A. Ohmori, and R. McPherson: “The Relationship Between Microstructure and Young’s Modulus of Thermally Sprayed Ceramic Coatings,” J. Mater. Sci., 1997, 32, pp. 997–1004.

S. Kuroda and T.W. Clyne: “The Quenching Stress in Thermally Sprayed Coatings,” Thin Solid Films, 1991, 200, pp. 49–66.

R.W. Rice: “Microstructure Dependence of Mechanical Behavior of Ceramics, Properties and Microstructure” in Treatise on Materials Science and Technology, R.K. MacCrone, ed., Academic Press, New York, 1977, 11, p. 199.

L. Pawlowski: The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, New York, 1995, p. 193.

C.-J. Li, Y. He, and A. Ohmori: “Characterization of the Microstructure of Thermally Sprayed Coating” in Proceedings of 15th ITSC, C. Coddet, ed., ASM International, Materials Park, OH, 1988, pp. 717–22.

S. Kuroda: “Properties and Characterization of Thermal Sprayed Coatings—A Review of Recent Research Progress” in Proceedings of 15th ITSC, C. Coddet, ed., ASM International, Materials Park, OH, 1988, pp. 539–50.

A. Ohmori and C.-J. Li: “Quantitative Characterization of the Structure of Plasma Sprayed Al2O3 Coating by Using Copper Electroplating,” Thin Solid Films, 1991, 201, pp. 241–52.

A. Ohmori, C.-J. Li, and Y. Arata: “Influence of Plasma Spray Conditions on the Structure of Al2O3 Coatings,” Trans. Jpn. Weld. Res. Inst., 1990, 19, pp. 259–70.

A. Ohmori, C.-J. Li, and Y. Arata: “Structure of Plasma-Sprayed Alumina Coatings Revealed by Using Copper Electroplating” in Thermal Spray Coating, Properties, Processes and Applications, T.F. Bernecki, ed., ASM International, Materials Park, OH, 1992, pp. 105–13.

S.T. Bluni and A.R. Marder: “The Use of Quantitative Image Analysis for the Characterization of a Thermal Spray Coating” in Thermal Spray Coating, Properties, Processes and Applications, T.F. Bernecki, ed., ASM International, Materials Park, OH, 1992, pp. 89–96.

M.F. Smith, D.T. McGuffi, J.A. Henfling, and W.B. Lenling: “A Comparison of Techniques for the Metallographic Preparation of Thermal Sprayed Samples” in Thermal Spray Coating, Properties, Processes and Applications, T.F. Bernecki, ed., ASM International, Materials Park, OH, 1992, pp. 97–104.

J. Karthikeyan, A.K. Sinha, and A.R. Biswas: “Impregnation of Thermally Sprayed Coatings for Microstructural Studies,” J. Therm. Spray. Technol., 1996, 5, pp. 74–78.

O.J. Whittmore: “Mercury Porosimetry of Ceramics,” Powder Technol., 1981, 29, pp. 167–75.

M. Vardelle and J.L. Besson: “γ-Alumina Obtained by Arc Plasma Spraying: A Study of the Optimization of Spraying Conditions,” Ceram. Int., 1981, 7, pp. 48–54.

S. Uematsu, S. Amada, T. Senda, and S. Sato: “On Pore Structure of Plasma-Sprayed Films” in Proceedings of International Symposium on Advanced Thermal Spraying Technology and Allied Coatings (ATTAC’88), Japan High Temperature Society, Osaka, Japan, 1988, pp. 379–83.

R. McPherson: “The Microstructure of Thermally Sprayed Coatings” in Proceedings of International Symposium on Advanced Thermal Spraying Technology and Allied Coatings (ATTAC’88), Japan High Temperature Society, Osaka, Japan, 1988, pp. 25–30.

S. Kuroda: “Evaluation of the Pore Structure in Plasma-Sprayed Coatings” in Advances in Inorganic Films and Coatings, P. Vincenzini, ed., Techna, 1995, pp. 373–80.

J. Ilavsky, A.J. Allen, G.G. Long, S. Krueger, H. Herman, C.C. Berndt, and A.N. Goland: “Anisotropy of the Surfaces of Pores in Plasma Sprayed Alumina Deposits, Thermal Spraying: Current Status and Future Trends” in Proceedings of 14th ITSC, A. Ohmori, ed., Japan High Temperature Society, Osaka, 1995, pp. 483–88.

J. Ilavsky, J. Pisacka, P. Chraska, and N. Margandant, et al.: “Microstructure-Wear and Corrosion Relationships for Thermally Sprayed Metallic Deposits” in Thermal Spray: Surface Engineering via Applied Research, C.C. Berndt, ed., ASM International, Materials Park, OH, 2000, pp. 449–54.

H.D. Steffens and U. Fischer: “Correlation Between Microstructure and Physical Properties of Plasma Sprayed Zirconia Coatings” in Proceedings of 2nd National Thermal Spray Conference, ASM International, Materials Park, OH, 1989, pp. 167–73.

A.L. Loeb: “Thermal Conductivity: VIII, A Theory of Thermal Conductivity of Porous Materials,” J. Am. Ceram. Soc., 1954, 37(2), pp. 96–99.

J. Francl and W.D. Kingery: “Thermal Conductivity: IX, Experimental Investigation of Effect of Porosity on Thermal Conductivity,” J. Am. Ceram. Soc., 1954, 37(2), pp. 99–107.

R. McPherson: “A Model for the Thermal Conductivity of Plasma-Sprayed Ceramic Coatings,” Thin Solid Films, 1984, 112, pp. 89–95.

G. Neuer, H.-D. Steffens, W. Brandl, Z. Babiak, and R. Brandt: “Some Aspects of Properties Design of Plasma-Sprayed Thermal Barrier Coatings,” Powder Metall. Int., 1991, 23(2), pp. 108–11.

C.C. Berndt and R. McPherson: “A Fracture Mechanics Approach to the Adhesion of Flame and Plasma Sprayed Coatings” in Proceedings of the 9th International Thermal Spraying Conference, Nederland Inst. Voor Lastetechnik, Hague, 1980, pp. 310–16.

L.W. Crane, C.L. Johnston, and D.H. James: “Effect of Processing Parameters on the Shear Adhesion Strength of Arc Sprayed Deposits” in Proceedings of the 10th International Thermal Spraying Conference, German Welding Society, Essen, Germany, 1983, pp. 46–50.

R. McPherson and B.V. Shafer: “Interlamellar Contact Within Plasma-Sprayed Coatings,” Thin Solid Films, 1982, 97, pp. 201–04.

Y. Arata, A. Ohmori, and C.-J. Li: “Study on the Structure of Plasma Sprayed Ceramic Coating by Using Copper Electroplating” in Proceedings of International Symposium on Advanced Thermal Spraying Technology and Allied Coatings (ATTAC’88), Japan High Temperature Society, Osaka, Japan, 1988, pp. 205–10.

C.-J. Li, A. Ohmori, and Y. Arata: “Effect of Spray Methods on the Lamellar Structure of Al2O3 Coatings” in Thermal Spray, Current Status and Future Trends, A. Ohmori, ed., Japan High Temperature Society, Osaka, Japan, 1995, pp. 501–06.

C.-J. Li and A. Ohmori: “The Lamellar Structure of a Detonation Gun Sprayed Al2O3 Coating” Surf. Coat. Technol., 1996, 82, pp. 254–58.

R. McPherson and P. Cheang: “Microstructural Analysis of Ni-Al Plasma Sprayed Coatings” in Proceedings of 12th ITSC, British Welding Society, 1989, p. 17–1.

C. Takahashi and T. Senda: “On Pore Structure of Plasma-Sprayed Films” in Thermal Spray, Current Status and Future Trends, A. Ohmori, ed., Japan High Temperature Society, Osaka, Japan, 1995, pp. 921–26.

S. Kuroda, T. Dendo, and S. Kitahara: “Quenching Stress in Plasma Sprayed Coatings and Its Correlation With the Deposit Microstructure,” J Therm Spray Technol., 1995, 4(1), pp. 75–84.

S. Kuroda and S. Kitahara: “Effect of Spray Conditions on the Pore Structure and Quenching Stress in Plasma Sprayed Coatings” in Thermal Spray, Current Status and Future Trends, A. Ohmori, ed., Japan High Temperature Society, Osaka, Japan, 1995, pp. 489–94.

S. Boire-Lavigne, C. Moreau, and R.G. Saint-Jacques: “The Relationship Between the Microstructure and Thermal Diffusivity of Plasma-Sprayed Tungsten Coatings,” J. Therm. Spray Technol., 1995, 4(3), pp. 261–67.

P. Bengtsson and T. Johannesson: “Characterization of Microstructural Defects in Plasma-Sprayed Thermal Barrier Coatings,” J. Therm. Spray Technol., 1995, 4(3), pp. 245–51.

J.P. Sauer, T. Leonhardt, and A.R. Geary: “The Effect of Mounting Technique on the Microstructure of Thermal Barrier Coatings” in Thermal Spray: A United Forum for Scientific and Technological Advances, C.C. Berndt, ed., ASM International, Materials Park, OH, 1997, pp. 959–64.

H. Nakahira, N. Nomura, K. Miyajima, and Y. Harada: “Improvement of the Properties of Thermal Spray Ceramic Coatings by Chemically Densifying Method,” J. Jpn. High Temp. Soc., 1992, 18, pp. 307–13 (in Japanese).

A. Vardelle, M. Vadelle, R. McPherson, and P. Fauchais: “Study of the Influence of Particle Temperature and Velocity Distribution Within a Plasma Jet Coating Formation” in Proceedings of the 9th International Thermal Spraying Conference, Nederland Inst. Voor Lastetechnik, Hague, The Netherlands, 1980, pp. 155–61.

M. Vardelle, A. Vardelle, and P. Fauchais: “Study of Trajectories and Temperatures of Powders in a D.C. Plasma Jet—Correlation With Alumina Sprayed Coatings” in Proceedings of the 10th International Thermal Spraying Conference, German Welding Society, Essen, Germany, 1983, pp. 88–92

Y. Arata, A. Ohmori, and C.-J. Li: “Characteristics of Metal Electroplating to Plasma Sprayed Ceramic Coatings,” Trans. Jpn. Weld. Res. Inst., 1987, 16, pp. 259–65.

L. Bianchi, F. Blein, P. Lucchese, M. Vardelle, A. Vardelle, and P. Fauchais: “Effect of Particle and Substrate Temperature on Alumina and Zirconia Splat Formation” in Proceedings of 5th NTSC. C.C. Berndt and S. Sampath, ed., ASM International. Materials Park, OH, 1994, pp. 569–74.

M. Fukumoto, S. Katoh, and I. Okane: “Splat Behavior of Plasma Sprayed Particles on Flat Substrate Surface” in Proceedings of 14th International Thermal Spray Conference, A. Ohmori, ed., Japan High Temperature Society, Osaka, Japan, 1995, pp. 353–58.

C.-J. Li, J.-L. Li, and W.-B. Wang: “The Effect of Substrate Preheating and Surface Organic Covering on Splat Formation” in Proceedings of 15th ITSC, C. Coddet, ed., ASM International, Materials Park, OH, 1988, pp. 483–80.

A. Ohmori and C.-J. Li: “The Structure of Thermally Sprayed Ceramic Coatings and Its Dominant Effect on the Coating Properties” in Plasma Spraying, Theory and Applications, S. Surayanarayanan, ed., World Scientific Publishing Co., Singapore, 1993, pp. 179–200.

J. Francel and W.D. Kingrey: “Thermal Conductivity: IV, Apparatus for Determining Thermal Conductivity by a Comparative Method, J. Am. Ceram. Soc., 1954, 37, p. 80.

Thermo-physical Properties Research Center, Data Book, 1966, 3

Data Book of Japanese Society of Mechanical Engineering: Heat Transfer, 4th Edition, The Japan Society of Mechanical Engineering, Tokyo, 1986.

Thermal Spray Handbook, Japan Thermal Spraying Society, Tokyo, 1984 (in Japanese).

H. Nakahira, K. Tani, K. Miyajima, and Y. Harada: “Anisotropy of Thermally Sprayed Coatings” in Proceedings of 13th ITSC, C.C. Berndt, ed., ASM International, Materials Park, OH, 1992, pp. 1011–18.

N.N. Ault: “Characteristics of Refractory Oxide Coatings Produced by Flame-Spraying,” J. Am. Ceram. Soc., 1957, 40, pp. 69–74.

D. Matejka and B. Benko: Plasma Spraying of Metallic and Ceramic Materials, John Wiley, New York, 1989, p. 51.

F.P. Bowden and D. Tabor: Friction and Lubrication of Solids, Oxford University Press, New York, 1964, p. 25.

C.-J. Li, A. Ohmori, and R. McPherson: “A Microstructural Model for the Elastic Behavior of Plasma Sprayed Ceramic Coatings” in Proceedings of Austceram’92, M.J. Bannister, ed., Melbourne, 1992, The Australian Ceramic Society, pp. 816–21.

R. McPherson and P. Cheang: “Elastic Anisotropy of APS Alumina Coatings and Its Relationship to Microstructure” in High Performance of Ceramic Films and Coatings, P. Vincenzini, ed., Elsevier, Amsterdam, 1991, pp. 277–90.

S.-H. Leigh and C.C. Berndt: “Modelling of Elastic Constants of Plasma Spray Deposits with Ellipsoid-Shaped Voids,” Acta Mater., 1999, 47(5), pp. 1575–86.

I. Sevostianov and M. Kachanov: “Modelling of the Anisotropic Elastic Properties of Plasma-Sprayed Coatings in Relation to Their Microstructure,” Acta Mater., 2000, 48, pp. 1361–70.

R.B. Lawn and T.W. Wilshaw: Fracture of Brittle Solids, Cambridge University Press, New York, 1977, p. 65.

C.-J. Li: “Study on the Characterization of the Microstructure and Properties of Plasma-Sprayed Ceramic Coatings,” Ph.D. Thesis, Osaka University, Japan, 1989.

L.A. Simpson: in Fracture Mechanics, R.C. Bradt, et al., ed., Plenum, New York, 1974, p. 567.

C.-J. Li, W.-Z. Wang, and Y. He: “Study of Toughness of Plasma Sprayed Al2O3 Coatings Using a Tapered Double Cantilever Beam Method,” J. Amer. Ceram. Soc., to be published.

A. Arata, A. Ohmori, and C.-J. Li: “Basic Study on Properties of Plasma Sprayed Ceramic Coatings,” Trans. Jpn. Weld. Res. Inst., 1986, 15, pp. 339–48.

C.-J. Li, A. Ohmori, and Y. Arata: “Evaluation of the Lamellar Bonding of Ceramic Coating by Particle Erosive Test” in Thermal Spray, Current Status and Future Trends, A. Ohmori, ed., Japan High Temperature Society, Osaka, Japan, 1995, pp. 967–72.

Y. Arata, A. Ohmori, and C.-J. Li: “Fundamental Properties of the ACTJP (Arata Coating Test with Jet Particles)” in Proceedings of 1st National Thermal Spray Conference, ASM International, Materials Park, OH, 1988, pp. 79–83.

Author information

Authors and Affiliations

Additional information

An erratum to this article is available at http://dx.doi.org/10.1361/105996303770348410.

Rights and permissions

About this article

Cite this article

Li, C.J., Ohmori, A. Relationships between the microstructure and properties of thermally sprayed deposits. J Therm Spray Tech 11, 365–374 (2002). https://doi.org/10.1361/105996302770348754

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996302770348754