Abstract

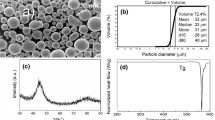

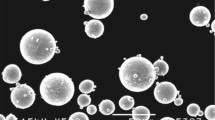

Tantalum (Ta) coatings have been produced using a relatively new process, kinetic spray. Ta starting powders having particle diameters greater than 65 µm are injected into a de Laval-type nozzle, entrained in a supersonic gas stream, and accelerated to high velocities due to drag effects. The particles’ kinetic energy is transformed via plastic deformation into strain and heat on impact with the substrate surface. Particles are not thermally softened or melted, producing relatively low oxide, reduced residual stress, high adhesion and low porosity coatings. Analysis of the mechanical and physical properties of these Ta coatings demonstrated increasing hardness, cohesive adhesion, and decreasing porosity as a function of particle velocity. Comparison between kinetically sprayed coatings and coatings produced using conventional coating methods will be discussed.

Similar content being viewed by others

References

T.H. Van Steenkiste, J.R. Smith, and R.E. Teets: “Aluminum Coatings Via Kinetic Spray With Relatively Large Powder Particles,” Surf. Coat. Technol., 2002, 154, pp. 237–52.

Anon., ASM Metals Handbook, Vol. 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM International, Materials Park, OH, 1990.

T. Kinos, S.L. Chen, P. Siitonen, P. Kettunen: “Densification of Plasma-Sprayed Titanium and Tantalum Coatings,” J. Therm. Spray Technol., 1996, 4, pp. 439–44.

S.L. Lee, M. Cipollo, D. Windover, and C. Rickard: “Analysis of Magnetron-Sputtered Tantalum Coatings versus Electrochemically Deposited Tantalum from Molten Salt,” Surf. Coat. Technol. 1999, 120–121, pp. 44–52.

C. Hayes, J.L. Watson, and J.P. Walker: “Tantalum Coatings for the Petrochemical Industry” in Thermal. Spray Science and Technology, C.C. Berndt and S. Sampath, ed., ASM International, Materials Park, OH, 1995, pp. 589–93.

T.H. Van Steenkiste, J.R. Smith, R.E. Teets, J.J. Moleski, D.W. Gorkiewicz, R.P. Tison, D.R. Marantz, K.A. Kowalsky, W.L. Riggs, P.H. Zajchowski, B. Pilsner, R.C. McCune, and K.J. Barnett: “Kinetic Spray Coatings,” Surf. Coat. Technol., 1999, 111, pp. 62–71.

T.H. Van Steenkiste, J.R. Smith, R.E. Teets, J.J. Moleski, and D.W. Gorkiewicz, U.S. Patent 6 139 913, Kinetic Spray Coating Method and Apparatus (Oct. 31, 2000)

J.R. Smith, T.H. Van Steenkiste, and W.J. Meng, U.S. Patent 6 189 663, Spray Coatings for Suspension Damper Rods (Feb. 20, 2001).

G.H. Smith, N.Y. Kenmore, R.C. Eschenbach, and J.F. Pelton, U.S. Patent 2 861 900, Jet Plating of High Melting Point Materials (Nov. 25, 1958).

C.F. Rocheville, U.S. Patent 3 100 724, Device for Treating the Surface of a Workpiece (Aug. 13, 1963).

J.A. Browning: “What If We’re Right?” in Thermal Spray: A United Forum for Scientific and Technological Advances, C.C. Berndt ed., ASM International, Materials Park, OH, 1997, pp. 15–18.

J.A. Browning, U.S. Patent 5 271 96, Thermal Spray Method Utilizing In-Transit Powder Particle Temperatures Below Their Melting Point (Dec. 21, 1993).

A.P. Alkimov, V.F. Kosarev, A.N. Papyrin: “A Method of Cold Gas-Dynamic Deposition,” Dokl. Akad. Nauk,SSSR., 1062, 318, 1990.

A.P. Alkhimov, A.N. Papyrin, V.F. Kosarev, N.I. Nesterovich, and M.M. Shushpanov, U.S. Patent 5 302 414, Gas Dynamic Spraying Method for Appling a Coating (April 12, 1994).

R.C. McCune, A.N. Papyrin, J.N. Hall, W.L. Riggs II, and P.H. Zajchowski: “An Exploration of the Cold Gas-Dynamic Spray Method for Several Materials Systems” in Thermal Spray Science & Technology, C.C. Berndt and S. Sampath, ed., ASM International, Materials Park, OH, 1995, pp. 1–5.

R.C. McCune, W.T. Donlon, E.L. Cartwright, A.N. Papyrin, E.F. Rybicki, and J.R. Shadley: “Characterization of Copper and Steel Coatings Made by the Cold Gas-Dynamic Spray Method” Thermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 397–403.

R.C. Dykhuizen and M.F. Smith: “Gas Dynamic Principles of Cold Spray,” J. Therm. Spray Technol., 1998, 7, pp. 205–12.

M.F. Smith, J.E. Brockmann, R.C. Dykhuizen, D.L. Gilmore, R.A. Neiser, and T.J. Romer: “Cold Spray Direct Fabrication-High Rate, Solid State, Material Consolidation,” in Freeform, and Additive Fabrication, D. Dimos, S.C. Danforth, and M. Cima, ed., Materials Research Society, Warrendale, PA, 1999, pp. 65–76.

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, and S. Sampath: “Impact of High Velocity Cold Spray Particles,” J. Therm. Spray Technol., 1999, 8, p. 559.

D.L. Gilmore, R.C. Dykhuizen, R.A. Neiser, T.J. Roemer, and M.F. Smith: “Particle Velocity and Deposition Efficiency in the Cold Spray Process,” J. Therm. Spray Technol., 1999, 8, p. 576.

M. Jacobson, A.R. Cooper, and J. Nagy, Explosibility of Metal Powders U.S. Bureau of Mines, Washington, DC, RI 5624, 1960.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Van Steenkiste, T., Gorkiewicz, D.W. Analysis of tantalum coatings produced by the kinetic spray process. J Therm Spray Tech 13, 265–273 (2004). https://doi.org/10.1361/10599630419418

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/10599630419418