Abstract

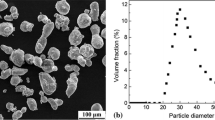

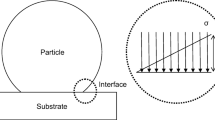

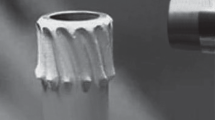

The objective of this article is to present microstructural evidence of a bonding mechanism between copper, which has been deposited by the cold spray process, and an aluminum substrate. Deposition conditions are varied to determine their effects on the nature of the bond. Mechanical measurements, such as adhesion strength and hardness, as well as visual methods are used to characterize the process. A ballistic model is proposed to explain the process.

Similar content being viewed by others

References

A. Papyrin, Cold Spray Technology, Adv. Mater. Proc., (September), 2001, p 49–51

R. McCune, W. Donlon, O. Popoola, and E. Cartwright, Characterization of Copper Layers Produced by Cold Gas-Dynamic Spraying, J. Thermal Spray Technol., Vol 9 (No. 1), 2000, p 73–82

T. Stoltenhoff, H. Kreye, and H. Richter, An Analysis of the Cold Spray Process and Its Coatings, J. Thermal Spray Technol., Vol 11 (No. 4), 2002, p 542–550

V. Radic, The State of Two-Metal Contact Boundary at High-Velocity Impact, The Scientific Journal FACTA UNIVERSITATIS Series: Mechanical Engineering, Vol 1 (No. 8), 2001, p 1017–1023

W. de Rosset, “Explosive Bonding of Refractory Metal Liners,” Report ARL-TR-3267, Army Research Laboratory, Aberdeen Proving Ground, MD, August, 2004

MIL-J-24445A, “Joint, Bimetallic Bonded, Aluminum to Steel,” Department of Defense Military Specification, March 1, 1971

M. Grujicic, J. Saylor, D. Beasely, W. DeRosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process, Appl. Surf. Sci., Vol 219 (No. 3–4), 2003, p 211–227

R.J. Eichelberger and J.W. Gehring, Effects of Meteoroid Impacts on Space Vehicles, ARS J., Vol 32 (No. 10), 1963, p 1583

R.L. Bjork, “Review of Physical Processes in Hypervelocity Impact and Penetration,” Rand Corporation Memorandum RM-3529-PR, U.S. Air Force Contract AF 49(638)-700, 1963

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Champagne, V.K., Helfritch, D., Leyman, P. et al. Interface material mixing formed by the deposition of copper on aluminum by means of the cold spray process. J Therm Spray Tech 14, 330–334 (2005). https://doi.org/10.1361/105996305X59332

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996305X59332