Abstract

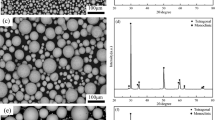

Thick (1.8 mm) thermal barrier coatings were air-plasma-sprayed onto two different substrate geometries, including small circular substrates and burner cans. Two different top-coating spray parameters were used, where the settings of the substrate temperature and the lamella thickness were varied. A segmentation crack network was found in the top coatings sprayed using a high substrate temperature and a high lamella thickness. The density of segmentation cracks was found to be independent of substrate geometry. No segmentation cracks were found in the top-coatings when a low substrate temperature and a low lamella thickness were used.

In the segmented burner can, after 1000 thermal shock cycles, the segmentation crack network was still stable and no severe cracks had formed in the top coating. In the nonsegmented burner can, cracks were formed after only 35 thermal shock cycles. Among the crack types, horizontally oriented cracks were found in the top coating close to, and sometimes reaching, the bond coating. Cracks of this type are not tolerated in thermal barrier coatings because they can cause failure of the coating.

Regarding the lifetime of the segmented burner can, it is believed the failure will be dependent on other mechanisms, such as bond-coating oxidation or top-coating decomposition.

Similar content being viewed by others

References

T. Khan, Heat-Resistant Materials/Superalloys, Adv. Mater. Process., Vol 1, 1990, p 19–20

P.D. Harmsworth and R. Stevens, Phase Composition and Properties of Plasma-Sprayed Zirconia Thermal Barrier Coatings, J. Mater. Sci., Vol 27, 1992, p 611–615

G. Johner, V. Wilms, K.K. Schweitzer, and P. Adam, Experimental and Theoretical Aspects of Thick Thermal Barrier Coatings for Turbine Applications, Thermal Spray: Advances in Coatings Technology, D.L. Houck, Ed., ASM International, 1988, p 155–166

J.E. Nerz, B.A. Kushner, and A.J. Rotolico, Taguchi Analysis of Thick Thermal Barrier Coatings, Thermal Spray Research and Applications, T.F. Bernecki, Ed., ASM International, 1991, p 669–673

T.A. Taylor, D.L. Appleby, A.E. Weatherill, and J. Griffiths, Plasma-Sprayed Yttria-Stabilized Zirconia Coatings: Structure-Property Relationships, Surf. Coat. Technol., Vol 43/44, 1990, p 470–480

T.A. Taylor, Thermal Properties and Microstructure of Two Thermal Barrier Coatings, Surf. Coat. Technol., Vol 54/55, 1992, p 53–57

H. Wang, H. Herman, G.A. Bancke, A. Adamski, and M. Wood, Flame Rig Testing of Thick Thermal Barrier Coatings, Protective Coatings: Processing and Characterization, R.M. Yazici, Ed., The Minerals, Metals & Materials Society, 1990, p 155–163

T.A. Taylor, Thermal Barrier Coatings for Substrates and Process for Producing it, U.S. Patent 5,073,433, 17 Dec 1991

C. Persson, Residual Stresses in Metal Matrix Composites after Plastic Straining and Thermal Cycling, Linköping Studies in Science and Technology, Licentiate Thesis No. 332, 1992

H. Toraya, M. Yoshimura, and S. Somiya, Calibration Curve for Quantitative Analysis of the Monoclinic-Tetragonal ZrO2 System by X-Ray Diffraction, J. Am. Ceram. Soc., Vol 67, 1984, p C119–121

H. Toraya, M. Yoshimura, and S. Somiya, Quantitative Analysis of Monoclinic-Stabilized Cubic ZrO2 Systems by X-Ray Diffraction, J. Am. Ceram. Soc., Vol 67, 1984, p C183–184

P. Bengtsson and J. Wigren, Segmentation Cracks in Plasma Sprayed Thick Thermal Barrier Coatings, Materials Solutions ’98, 12–15 Oct 98

P. Bengtsson, “Determination of Thermal Barrier Coating Thickness for Burner Can Rig Test in BE 7287-3,” Technical Report, Reg. No. 9940-062, Volvo Aero Corp., 1994

P. Bengtsson, T. Johannesson, and J. Wigren, Crack Structures in Plasma Sprayed Thermal Barrier Coatings as a Function of Deposition Temperature, Proc. 14th Int. Thermal Spray Conf., A. Ohmori, Ed. (Kobe, Japan), May 1995, p 513–518

J.H. Sun, E. Chang, C.H. Chao, and M.J. Cheng, The Spalling Modes and Degradation Mechanism of ZrO2-8 wt.% Y2O3/CVD-Al2O3/Ni-22Cr-10Al-1Y Thermal-Barrier Coatings, Oxid. Met., Vol 40 (No. 5/6), 1993, p 465–481

D. Hull and T.W. Clyne, An Introduction to Composite Materials, 2nd ed., Cambridge University Press, 1996

H. Scott, Phase Relationships in the Zirconia-Yttria System, J. Mater. Sci., Vol 10, 1975, p 1527–1535

R.A. Miller, J.L. Smialek, and R.G. Garlick, Phase Stability in Plasma-Sprayed, Partially Stabilized Zirconia-Yttria, Int. Conf. on the Sci. and Technol. of Zirconia, A.H. Heuer and L.W. Hobbs, Ed., 1981, p 241–253

J.R. Brandon and R. Taylor, Phase Stability of Zirconia-Based Thermal Barrier Coatings, Part I: Zirconia-Yttria Alloys, Surf. Coat. Technol., Vol 46, 1991, p 75–90

L. Lelait, S. Alpérine, and R. Mévrel, Alumina Scale Growth at Zirconia-MCrAlY Interface: A Microstructural Study, J. Mater. Sci., Vol 27, 1992, p 5–12

E.Y. Lee, R.R. Biederman, and R.D. Sisson, Diffusional Interactions and Reactions between a Partially Stabilized Zirconia Thermal Barrier Coating and the NiCrAlY Bond Coat, Mater. Sci. Eng., Vol A121, 1989, p 467–473

R.D. Maier, C.M. Scheuermann, and C.W. Andrews, Degradation of a Two-Layer Thermal Barrier Coating under Thermal Cycling, Am. Ceram. Soc. Bull., Vol 60 (No. 5), 1981, p 555–560

A.H. Bartlett and R. Dal Maschio, Failure Mechanisms of a Zirconia-8 wt% Yttria Thermal Barrier Coating, J. Am. Ceram. Soc., Vol 78 (No. 4), 1995, p 1018–1024

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bengtsson, P., Ericsson, T. & Wigren, J. Thermal shock testing of burner cans coated with a thick thermal barrier coating. J Therm Spray Tech 7, 340–348 (1998). https://doi.org/10.1361/105996398770350828

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996398770350828