Abstract

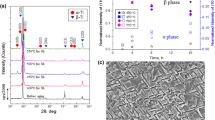

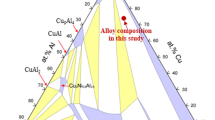

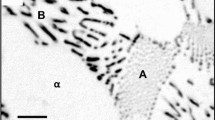

The aging of the NC 19 Fe Nb alloy (Inconel 718), previously quenched from 990 °C, is characterized by a hardness peak at 650 °C, then a maximum in hardness at about 750 °C. Over this temperature, the hardness progressively decreases. In the 550–650 °C temperature range, TEM observations have revealed that ß (Ni3Nb) precipitates are formed as long platelets parallel between them within the same grain, as well as extremely fine γ′[Ni3(Ti, Al)] particles responsible for the observed improvement in hardness. For a tempering temperature higher than 650 °C, a first hardening occurs after a 4 h treatment, which has been associated with the γ′ phase precipitation, with a more or less spherical shape. Beyond this time, a second hardening takes place linked to the γ″ phase precipitation (Ni3Nb, bct D022 structure), as thin platelet shaped, perfectly coherent with the matrix. The misfit between the γ and γ″ phases is about 3% in the 〈001〉 γ″ direction and lower than 1% in the 〈100〉γ″ and 〈010〉γ″ directions. During a longer aging at 750 °C, the γ″ platelets progressively dissolve while ß precipitates grow.

Similar content being viewed by others

References

D. F. Paulonis, J. M. Oblak, and D. S. Duvall, Trans. ASM 62, 611–622 (1969).

C. Slama, Thèse de Doctorat en Science, Université de Paris-Sud, Centre d’Orsay, 1993.

A. O. Basile and J. F. Radavich, Superalloys 718, 625 and Various Derivatives (The Minerals, Metals & Materials Society, Warrendale, PA, 1991), pp. 325–335.

A. E. Marsh, Metallurgia, 10–20 (1982).

I. Kirman, J. Iron and Steel Inst. 207, 1612–1618 (1969).

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee, Metall. Trans. 19A, 453–465 (1988).

K. N. Tu and D. Turnbull, Acta Metall. 15, 369 (1967).

K. N. Tu and D. Turnbull, Acta Metall. 17, 1263 (1967).

J. Bourgeot, G. Faivre, J. Manenc, and D. Thivellier, Mém. Scient. Rev. Mét. LXVI, N°11, 845 (1969).

J. L. Burger, R. R. Biederman, and W. H. Courts, Superalloy 718–Metallurgy and Applications (The Minerals, Metals & Materials Society, Warrendale, PA, 1989), pp. 207–217.

J. F. Radavich, Superalloy 718–Metallurgy and Applications (The Minerals, Metals & Materials Society, Warrendale, PA, 1989), pp. 229–240.

R. Cozar, Thèse de Docteur-Ingénieur, Université de Nancy 1, 1973.

M. G. Burke and M. K. Miller, Superalloys 718, 625 and Various Derivatives (The Minerals, Metals & Materials Society, Warrendale, PA, 1991), pp. 337–350.

R. Cozar and A. Pineau, Scripta Metall. 7, 851 (1973).

H. J. Wagner and A. M. Hall, DMIC; 217 (1965).

W. C. Hagel and H. Beattie, Precipitation Processes in Steels (Iron & Steel Inst., London, 1959), p. 98.

G. Faivre, Thèse de Docteur 3ème Cycle, Faculté des Sciences d’orsay, Université de Paris, 1969.

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee, Superalloys 718, 625, 706 and Various Derivatives, edited by E. A. Loria (The Minerals, Metals & Materials Society, Warrendale, PA, 1994), pp. 419–440.

R. Cozar and A. Pineau, Metall. Trans. 4, 47–59 (1973).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Slama, C., Servant, C. & Cizeron, G. Aging of the Inconel 718 alloy between 500 and 750 °C. Journal of Materials Research 12, 2298–2316 (1997). https://doi.org/10.1557/JMR.1997.0306

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1997.0306