Abstract

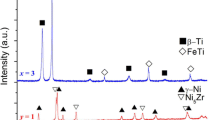

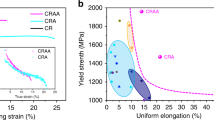

Using a Ti–Cu–Ni–Sn–Ta alloy as an example, we demonstrate a strategy for the in situ formation of nanocomposite microstructures that can lead to simultaneous high strength and ductility. Our approach employs copper mold casting for the production of bulk alloys from the melt, and the solidification microstructure is designed to be composed of micrometer-sized ductile dendrites uniformly distributed inside a matrix of nanoscale eutectic reaction products. The nanostructured matrix is achieved at a relatively deep eutectic, which facilitates the formation of an ultrafine eutectic microstructure over a range of cooling rates. The multi-component recipe stabilizes a ductile solid solution as the toughening phase and helps to reduce the eutectic spacing down to nanoscale. The multi-phase microstructure (including phase distributions, morphologies, and interfaces) has been examined in detaul using transmission electron microscopy (TEM) and high-resolution TEM. The metastable eutectic reaction and the nanoscale spacing achieved are explauned using thermodynamic and solidification modeling. The benefits expected from the microstructure design are illustrated using the high strength and large plasticity observed in mechanical property tests. Our nanocomposite design strategy is expected to be applicable to many alloy systems and constitutes another example of tauloring the microstructure on nanoscale for extraordinary properties.

Similar content being viewed by others

References

G.E. Dieter: Mechanical Metallurgy, 3rd edition (McGraw-Hill, Boston, MA, 1986), p. 212.

L.E. Mccandlish, B.H. Kear, and B.K. Kim: Chemical-processing of nanophase WC-Co composite powders. Mater. Sci. Technol. 6, 953 (1990).

L. He and E. Ma: Full-density nanocrystalline Fe–29Al–2Cr intermetallic consolidated from mechanically milled powders. J. Mater. Res. 11, 72 (1996).

K. Lu, J.T. Wang, and W.D. Wei: A new method for synthesizing nanocrystalline alloys. J. Appl. Phys. 69, 522 (1991).

K. Lu: Nanocrystalline metals crystallized from amorphous solids: Nanocrystallization, structure, and properties. Mat. Sci. Eng. R 16, 161 (1996).

C.C. Koch: Synthesis of nanostructured materials by mechanical milling: Problems and opportunities. Nanostruct. Mater. 9, 13 (1997).

V.L. Tellkamp, A. Melmed, and E.J. Lavernia: Mechanical behavior and microstructure of a thermally stable bulk nanostructured Al alloy. Metall. Mater. Trans. A 32, 2335 (2001).

C.C. Hays, C.P. Kim, and W.L. Johnson: Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses contauning in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 84, 2901 (2000).

U. Kühn, J. Eckert, N. Mattern, and L. Schultz: ZrNbCuNiAl bulk metallic glass matrix composites contauning dendritic bcc phase precipitates. Appl. Phys. Lett. 80, 2478 (2002).

H. Ma, J. Xu, and E. Ma: Mg-based bulk metallic glass composites with plasticity and high strength. Appl. Phys. Lett. 83, 2793 (2003).

C. Fan, R.T. Ott, and T.C. Hufnagel: Metallic glass matrix composite with precipitated ductile reinforcement. Appl. Phys. Lett. 81, 1020 (2002).

W.L. Johnson: Bulk glass-forming metallic alloys: Science and technology. MRS Bull. 24, 42 (1999).

Y.M. Wang, M. Chen, F. Zhou, and E. Ma: High tensile ductility in a nanostructured metal. Nature 419, 912 (2002).

G. He, J. Eckert, W. Löser, and L. Schultz: Novel Ti-base nanostructure-dendrite composite with enhanced plasticity. Nat. Mater. 2, 33 (2003).

E.A. Brandes and G.B. Brook: (Smithells Metals Reference Book. Oxford, Butterworth-Heinemann, Oxford, U.K., 1998), pp. 6–9.

K.C. Hari Kumar, I. Ansara, P. Wollants, and L. Delaey: Thermodynamic optimization of the Cu-Ti system. Z. Metall. 87, 666 (1996).

W. Kurz and D.J. Fisher: Dendrite growth in eutectic alloys: The couple zone. Interna. Met. Rev. 5–6, 177 (1979).

R.M. Srivastava, J. Eckert, W. Löser, B.K. Dhindaw, and L. Schultz: Cooling rate evaluation for bulk amorphous alloys from eutectic microstructures in casting processes. Mater. Trans. JIM 43, 1670 (2002).

E.R. Thompson and F.D. Lemkey: Unidirectional solidification of Co–Cr–C monovariant eutectic alloys. Met. Trans. 1, 2799 (1970).

R.S. Barclay, H.W. Kerr, and P. Niessen: Off-eutectic composite solidification and properties in Al–Ni and Al–Co alloys. J. Mater. Sci. 6, 1168 (1971).

R. Trivedi, J.T. Mason, J.D. Verhoeven, and W. Kurz: Eutectic spacing selection in Lead–based alloy systems. Met. Trans. A 22, 2523 (1991).

J.A. Juarez-Islas and H. Jones: Conditions for growth of extended Al-rich Al–Mn alloy solid solutions and Al-Al6Mn eutectic during rapid solidification. Acta Metall. 35, 499 (1987).

M.H. Burden and H. Jones: Determination of cooling rate in splatcooling from scale of microstructure. J. Inst. Metals 98, 249 (1970).

K.A. Jackson and J.D. Hunt: Lamellar and rod eutectic growth. Trans. auME 236, 1129 (1966).

. Fundamentals of Solidification, 4th edition, edited by W. Kurz and D.J. Fisher IV (Trans Tech, Zurich, Switzerland, 1998).

H. Jones: Rapid Solidification of Metal and Alloys. (The Institution of Metallurgists, London, Monograph No. 8, 1982).

J.M. Manero, F.J. Gil, and J.A. Planell: Deformation mechanisms of Ti-6Al-4V alloy with a martensitic microstructure subjected to oligocyclic fatigue. Acta Mater. 48, 3353 (2000).

A. Inoue: Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48, 279 (2000).

E. Ma: Nanocrystalline materials—Controlling plastic instability. Nat. Mater. 2, 7 (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/publications/jmr/policy.html.

Rights and permissions

About this article

Cite this article

Dau, Q.L., Sun, B.B., Sui, M.L. et al. High-performance bulk Ti-Cu-Ni-Sn-Ta nanocomposites based on a dendrite-eutectic microstructure. Journal of Materials Research 19, 2557–2566 (2004). https://doi.org/10.1557/JMR.2004.0332

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0332