Abstract

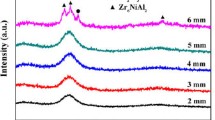

The addition of Ag to Cu–Zr alloys is very effective for the increase in the stability of supercooled liquid as well as the glass-forming ability (GFA). The large supercooled liquid region (ΔTx) exceeding 60 K in Cu–Zr–Ag ternary system was obtained in a wide range of 25–55 at.% Cu, 40–65 at.% Zr, and 5–25 at.% Ag. The best GFA was obtained around Cu45Zr45Ag10, and glassy alloy rods with diameters up to 6.0 mm were formed by copper mold casting. The bulk glassy alloys exhibit good mechanical properties, i.e., compressive fracture strength of 1780–1940 MPa, Young’s modulus of 106–112 GPa, compressive plastic elongation of 0.2–2.9%, and Vickers hardness of 534–599. The finding of the new Cu–Zr–Ag ternary glassy alloy system with high GFA and good mechanical properties is important for development and scientific studies of bulk glassy alloys.

Similar content being viewed by others

References

A. Inoue, K. Ohtera, K. Kita and T. Masumoto: New amorphous Mg–Ce–Ni alloys with high strength and good ductility. Jpn. J. Appl. Phys. 27, L2248 (1988).

A. Inoue, T. Zhang and T. Masumoto: Al–La–Ni amorphous alloys with a wide supercooled liquid region. Mater. Trans. JIM 30, 965 (1989).

A. Inoue, T. Zhang and T. Masumoto: Zr–Al–Ni amorphous alloys with high glass transition temperature and significant supercooled liquid region. Mater. Trans. JIM 31, 177 (1990).

A. Peker and W.L. Johnson: A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl. Phys. Lett. 63, 2342 (1993).

A. Inoue and S.G. Gook: Fe-based ferromagnetic glassy alloys with wide supercooled liquid region. Mater. Trans. JIM 36, 1180 (1995).

A. Inoue, T. Zhang and A. Takeuchi: Bulk amorphous alloys with high mechanical strength and good soft magnetic properties in Fe–TM–B (TM = IV–VIII group transition metal) system. Appl. Phys. Lett. 71, 464 (1997).

A. Inoue and B. Shen: Soft magnetic bulk glassy Fe–B–Si–Nb alloys with high saturation magnetization above 1.5 T. Mater. Trans. 43, 766 (2002).

Z.P. Lu, C.T. Liu and W.D. Porter: Structural amorphous steels. Phys. Rew. Lett. 92, 245503 (2004).

T. Itoi and A. Inoue: Thermal stability and soft magnetic properties of Co–Fe–M–B (M = Nb, Zr) amorphous alloys with large supercooled liquid region. Mater. Trans. JIM 41, 1256 (2000).

H. Koshiba and A. Inoue: Preparation and magnetic properties of Co-based bulk glassy alloys. Mater. Trans. 42, 2572 (2001).

X. Wang, I. Yoshii, A. Inoue, Y.H. Kim and I.B. Kim: Bulk amorphous Ni75−xNb5MxP20−yBy (M = Cr, Mo) alloys with large supercooling and high strength. Mater. Trans. JIM 40, 1130 (1999).

S. Yi, T.G. Park and D.H. Kim: Ni-based bulk amorphous alloys in the Ni–Ti–Zr–(Si, Sn) system. J. Mater. Res. 15, 2425 (2000).

T. Zhang and A. Inoue: New bulk glassy Ni-based alloys with high strength of 3000 MPa. Mater. Trans. 43, 708 (2002).

H.C. Yim, D. Xu and W.L. Johnson: Ni-based bulk metallic glass formation in the Ni–Nb–Sn and Ni–Nb–Sn–X (X = B,Fe,Cu) alloy systems. Appl. Phys. Lett. 82, 1030 (2003).

W. Zhang and A. Inoue: Formation and mechanical properties of Ni-based Ni–Nb–Ti–Hf bulk glassy alloys. Scripta Mater. 48, 641 (2003).

D. Xu, G. Duan and W.L. Johnson: Formation and properties of new Ni-based amorphous alloys with critical casting thickness up to 5 mm. Acta Mater. 52, 3493 (2004).

X.H. Lin and W.L. Johnson: Formation of Ti–Zr–Cu–Ni bulk metallic glasses. J. Appl. Phys. 78, 6514 (1995).

A. Inoue, W. Zhang, T. Zhang and K. Kurosaka: High-strength Cu-based bulk glassy alloys in Cu–Zr–Ti and Cu–Hf–Ti ternary systems. Acta Mater. 49, 3645 (2001).

A. Inoue and W. Zhang: Formation, Thermal stability and mechanical properties of Cu–Zr–Al bulk glassy alloys. Mater. Trans. 43, 2921 (2002).

A. Inoue and W. Zhang: Formation and mechanical properties of Cu–Hf–Al bulk glassy alloys with a large supercooled liquid region of over 90 K. J. Mater. Res. 18, 1435 (2003).

A. Inoue, T. Zhang and T. Masumoto: Preparation of bulky amorphous Zr–Al–Co–Ni–Cu alloys by copper mold casting and their thermal and mechanical properties. Mater. Trans. JIM 36, 391 (1995).

W.L. Johnson: Bulk glass-forming metallic alloys: Science and technology. MRS Bull. 24(10), 42 (1999).

T. Zhang and A. Inoue: Thermal and mechanical properties of Ti–Ni–Cu–Sn amorphous alloys with a wide supercooled liquid region before crystallization. Mater. Trans. JIM 39, 1001 (1998).

A. Inoue, T. Zhang, K. Kurosaka and W. Zhang: High-strength Cu-based bulk glassy alloys in Cu–Zr–Ti–Be system. Mater. Trans. 42, 1800 (2001).

A. Inoue, W. Zhang, T. Zhang and K. Kurosaka: Cu-based bulk glassy alloys with good mechanical properties in Cu–Zr–Hf–Ti system. Mater. Trans. 42, 1805 (2001).

T. Zhang, K. Kurosaka and A. Inoue: Thermal and mechanical properties of Cu-based Cu–Zr–Ti–Y bulk glassy alloys. Mater. Trans. 42, 2042 (2001).

T. Zhang, T. Yamamoto and A. Inoue: Formation, thermal stability and mechanical properties of (Cu0.6Zr0.3Ti0.1)100−xMx (M=Fe, Co, Ni) bulk glassy alloys. Mater. Trans. 43, 3222 (2002).

Y.S. Shin, J.H. Kim, D.M. Li, J.K. Li, H.J. Kim, H.G. Jeong and J.C. Bae: New Cu-based bulk metallic glasses with high strength of 2000 MPa. Mater. Sci. Forum 449–452, 945 (2004).

D.V. Louzguine and A. Inoue: Nanoparticles with icosahedral symmetry in Cu-based bulk glass former induced by Pd addition. Scripta Mater. 48, 1325 (2003).

C. Qin, K. Asami, T. Zhang, W. Zhang and A. Inoue: Corrosion behavior of Cu–Zr–Ti-Nb bulk glassy alloys. Mater. Trans. 44, 749 (2003).

Y.C. Kim, D.H. Kim and J.C. Lee: Formation of ductile Cu-based bulk metallic glass matrix composite by Ta addition. Mater. Trans. 44, 2224 (2003).

H. Men, W.T. Kim and D.H. Kim: Effect of titanium on glass-forming ability of Cu–Zr–Al alloys. Mater. Trans. 44, 1647 (2003).

C. Qin, W. Zhang, H. Kimura, K. Asami and A. Inoue: New Cu–Zr–Al–Nb bulk glassy alloys with high corrosion resistance. Mater. Trans. 45, 1958 (2004).

W. Zhang and A. Inoue: Thermal stability and mechanical properties of Cu-based bulk glassy alloys in Cu50(Zr1−xHfx)45Al5 system. Mater. Trans. 44, 2220 (2003).

D.H. Xu, G. Duan and W.L. Johnson: Unusual glass-forming ability of bulk amorphous alloys based on ordinary metal copper. Phys. Rev. Lett. 92, 245504 (2004).

A. Inoue: High strength bulk amorphous alloys with low critical cooling rates. Mater. Trans. JIM 36, 866 (1995).

A. Inoue: Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48, 279 (2000).

A. Inoue and W. Zhang: Formation, thermal stability and mechanical properties of Cu–Zr and Cu–Hf binary glassy alloy rods. Mater. Trans. 45, 584 (2004).

D. Xu, B. Lohwongwatana, G. Duan, W.L. Johnson and C. Garland: Bulk metallic glass formation in binary Cu-rich alloy series–Cu100−xZrx (x= 34, 36, 38.2, 40 at.%) and mechanical properties of bulk Cu64Zr36 glass. Acta Mater. 52, 2621 (2004).

D. Wang, Y. Li, B.B. Sun, M.L. Sui, K. Lu and E. Ma: Bulk metallic glass formation in the binary Cu–Zr system. Appl. Phys. Lett. 84, 4029 (2004).

B.M. Tang, D.Q. Zhao, M.X. Pan and W.H. Wang: Binary Cu–Zr bulk metallic glasses. Chin. Phys. Lett. 21, 901 (2004).

T. Zhang, A. Inoue, and T. Masumoto: (unpublished).

Metals Databook, edited by Japan Inst. Metals (Maruzen, Tokyo, Japan, 1983), p. 8.

F.R. Niessen: Cohesion in Metals (Elsevier Science Publishers, Amsterdam, The Netherlands, 1988), p. 224.

T.B. Massalski: Binary Alloy Phase Diagrams (ASM International, Materials Park, OH, 1990), p. 29.

H.S. Chen: Glassy metals. Rep. Prog. Phys. 43, 353 (1980).

Author information

Authors and Affiliations

Corresponding author

Additional information

Address all correspondence to this author.

Rights and permissions

About this article

Cite this article

Zhang, W., Inoue, A. High glass-forming ability and good mechanical properties of new bulk glassy alloys in Cu–Zr–Ag ternary system. Journal of Materials Research 21, 234–241 (2006). https://doi.org/10.1557/jmr.2006.0020

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0020