Abstract

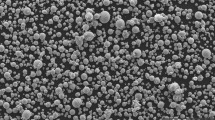

The present work demonstrates the synthesis of Cu–10 wt% TiB2 composites with a theoretical density of more than 90% by tailoring the spark plasma sintering (SPS) conditions in the temperature range of 400–700 °C. Interestingly, 10 wt% Pb addition to Cu–10 wt% TiB2 lowers the sinter density and the difference in the densification behavior of the investigated compositions was discussed in reference to the current profile recorded during a SPS cycle. The sintering kinetics and phase assemblage were also discussed in reference to surface melting of the constituents prior to bulk melting temperature, temperature dependent wettability of Pb on Cu, diffusion kinetics of Cu as well as the formation of various oxides. An important result is that a high hardness of around 2 GPa and relative density close to 92% ρtheoretical was achieved for the Cu–10 wt% TiB2–10 wt% Pb composite, and such a combination has never been achieved before using any conventional processing route.

Similar content being viewed by others

References

J.R. Groza and J.C. Gibeling: Principles of particle selection for dispersion–strengthened copper. Mater. Sci. Eng., A 171(1–2), 115 (1993).

B. Basu, G.B. Raju, and A.K. Suri: Processing and properties of monolithic TiB2 based materials. Int. Mater. Rev. 51(6), 352 (2006).

Z.A. Munir, U.A. Tamburini, and M. Ohyanagi: The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 41(3), 763 (2006).

R.G. Munro: Material properties of titanium diboride. J. Res. Nat. Inst. Stand. Technol. 105(5), 709 (2000).

M. Guo, K. Shen, and M. Wang: Relationship between microstructure, properties and reaction conditions for Cu–TiB2 alloys prepared by in situ reaction. Acta Mater. 57(15), 4568 (2009).

X.H. Zhang, C. Yan, and Z.Z. Yu: In-situ combustion synthesis of ultrafine TiB2 particles reinforced Cu matrix composite. J. Mater. Sci. 39(14), 4683 (2004).

M. Lopez, D. Corredor, C. Camurri, V. Vergara, and J. Jimenez: Performance and characterization of dispersion strengthened Cu–TiB2 composite for electrical use. Mater. Charact. 55(4–5), 252 (2005).

Z.Y. Ma and S.C. Tjong: High temperature creep behavior of in–situ TiB2 particulate reinforced copper–based composite. Mater. Sci. Eng., A 284(1–2), 70 (2000).

S.J. Dong, Y. Zhou, Y.W. Shi, and B.H. Chang: Formation of a TiB2–reinforced copper–based composite by mechanical alloying and hot pressing. Metall. Mater. Trans. A 33A(4), 1275 (2002).

P. Yih and D.D.L. Chung: Titanium diboride copper-matrix composites. J. Mater. Sci. 32(7), 1703 (1997).

C. Biselli, D.G. Morris, and N. Randall: Mechanical alloying of high strength copper alloys containing TiB2 and Al2O3 dispersoid particles. Scr. Metall. Mater. 30(10), 1327 (1994).

Y.S. Kwon, D.V. Dudina, M.A. Korchagin, and O.I. Lomovsky: Microstructure changes in TiB2–Cu nanocomposite during sintering. J. Mater. Sci. 39(16–17), 5325 (2004).

A.S. Sharma, K. Biswas, B. Basu, and D. Chakravarty: Spark plasma sintering of nanocrystalline Cu and Cu–10 wt% Pb alloy. Metall. Mater. Trans. A 42A(7), 2072 (2011).

Q.S. Mei and K. Lu: Melting and superheating of crystalline solids: From bulk to nanocrystals. Prog. Mater. Sci. 52(8), 1175 (2007).

B. Pluis, A.W.D. Gon, J.W.M. Frenken, and J.F. Veen: Crystal face dependence of surface melting. Phys. Rev. Lett. 59(23), 2678 (1987).

H.M. Pinxteren and J.W.M. Frenken: Incomplete melting of Pb (001) and vicinal surfaces. Surf. Sci. 275(3), 383 (1992).

H. Hakkinen and M. Manninen: Computer simulation of disordering and premelting of low index faces of copper. Phys. Rev. B 46(3), 1725 (1992).

R.M. German, P. Suri, and S.J. Park: Review: Liquid phase sintering. J. Mater. Sci. 44(1), 1 (2009).

J.F. Veen: Melting and freezing at surfaces. Surf. Sci. 433–435, 1 (1999).

L. Felberbaum, A. Rossoll, and A. Mortensen: A stereoscopic method for dihedral angle measurement. J. Mater. Sci. 40(12), 3121 (2005).

D. Empl, L. Felberbaum, V. Laporte, D. Chatain, and A. Mortensen: Dihedral angles in Cu–1 wt% Pb: Grain boundary energy and grain boundary triple line effects. Acta Mater. 57(8), 2527 (2009).

Smithells Metals Reference Book, 7th ed. edited by E.A. Brandes and G.B. Brook (Butterworth–Heinemann, London, 1992).

Acknowledgments

The use of SPS facility at IIT Kanpur, procured with partial funding from the Department of Science and Technology, Government of India as well as CARE funding from IIT Kanpur, is gratefully acknowledged. The authors would also like to acknowledge the help rendered by Mr. C.S. Tiwary in obtaining EPMA results and Drs. Ubhi Singh and Ritwik Basu for EBSD analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, A.S., Mishra, N., Biswas, K. et al. Densification kinetics, phase assemblage and hardness of spark plasma sintered Cu–10 wt% TiB2 and Cu–10 wt% TiB2–10 wt% Pb composites. Journal of Materials Research 28, 1517–1528 (2013). https://doi.org/10.1557/jmr.2013.119

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.119