Abstract

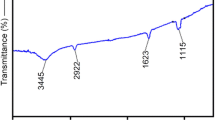

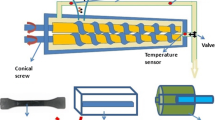

Hyperbranched polyurethane/Fe3O4 nanoparticles decorated multiwalled carbon nanotube (Fe3O4-MWCNT) nanocomposites were prepared by the in situ polymerization technique. The presence of Fe3O4 nanoparticles on the surface of the MWCNTs was confirmed by x-ray diffraction and transmission electron microscopic studies. The saturation magnetization value of Fe3O4-MWCNT was 0.23 emu/g. The glycidyl ether of bisphenol-A epoxy cured thermosetting nanocomposites exhibited enhanced tensile strength (6.4–38.5 MPa), scratch hardness (3.0–8.5 kg), and thermal stability (241–292 °C) with the increase of loading of Fe3O4-MWCNT (0–2 wt%). The nanocomposites possess good shape fixity over the repeated cycles of test. The nanocomposites also showed good shape recovery under the application of microwave irradiation. The shape recovery speed was found to be increased with the increase of the content of Fe3O4-MWCNT. Thus, the studied thermosetting nanocomposites have potential to be used as noncontact shape memory materials.

Similar content being viewed by others

References

W. Small, P. Singhal, T.S. Wilson, and D.J. Maitland: Biomedical applications of thermally activated shape memory polymer. J. Mater. Chem. 20, 3356 (2010).

K.M. Lee, H. Koerner, R.A. Vaia, T.J. Bunning, and T.J. White: Light-activated shape memory of glassy, azobenzene liquid crystalline polymer networks. Soft Matter 7, 4318 (2011).

C.M. Yakacki: Shape-memory and shape-changing polymers. Polym. Rev. 53, 1 (2013).

H.F. Lee, and H.H. Yu: Study of electroactive shape memory polyurethane–carbon nanotube hybrids. Soft Matter 7, 3801 (2011).

Y. Cai, J.S. Jiang, B. Zheng, and M.R. Xie: Synthesis and properties of magnetic sensitive shape memory Fe3O4/poly(ε-caprolactone)-polyurethane nanocomposites. J. Appl. Polym. Sci. 127, 49 (2013).

M. Haghayegh and G.M.M. Sadeghi: Synthesis of shape memory polyurethane/clay nanocomposites and analysis of shape memory, thermal, and mechanical properties. Polym. Compos. 33, 843 (2012).

M.K. Jang, A. Hartwig, and B.K. Kim: Shape memory polyurethanes cross-linked by surface modified silica particles. J. Mater. Chem. 19, 1166 (2009).

I.A. Rousseau: Challenges of shape memory polymers: A review of the progress toward overcoming SMP’s limitations. Polym. Eng. Sci. 48, 2075 (2008).

J.M. Cuevas, R. Rubio, J.M. Laza, J.L. Vilas, M. Rodriguez, and L.M. Leon: Shape memory composites based on glass-fibre-reinforced poly(ethylene)-like polymers. Smart Mater. Struct. 21, 035004 (2012).

J. Xu, W. Shi, and W. Pang: Synthesis and shape memory effects of Si–O–Si cross-linked hybrid polyurethanes. Polymer 47, 457 (2006).

C.S. Zhang, and Q.Q. Ni: Bending behavior of shape memory polymer based laminatesCompos. Struct. 78, 153 (2007).

H. Deka and N. Karak: Shape-memory property and characterization of epoxy resin-modified Mesua ferrea L. seed oil-based hyperbranched polyurethane. J. Appl. Polym. Sci. 116, 106 (2010).

R. Rajasekaran and M. Alagar: Mechanical properties of bismaleimides modified polysulfone epoxy matrices. Int. J. Polym. Mater. 56, 911 (2007).

K.P. Unnikrishnan and E.T. Thachil: Toughening of epoxy resins. Des. Monomers Polym. 9, 129 (2006).

M. Hemmati, A. Narimani, H. Shariatpanahi, A. Fereidoon, and M.G. Ahangari: Study on morphology, rheology and mechanical properties of thermoplastic elastomer polyolefin (TPO)/carbon nanotube nanocomposites with reference to the effect of polypropylene-grafted-maleic anhydride (PP-g-MA) as a compatibilizer. Int. J. Polym. Mater. 60, 384 (2011).

M. Rahmat and P. Hubert: Carbon nanotube–polymer interactions in nanocomposites: A review. Compos. Sci. Technol. 72, 72 (2011).

Y.T. Wang, C.S. Wang, H.Y. Yin, L.L. Wang, H.F. Xie, and R.S. Cheng: Carboxyl-terminated butadiene-acrylonitrile-toughened epoxy/carboxyl-modified carbon nanotube nanocomposites: Thermal and mechanical properties. Express Polym. Lett. 6, 719 (2012).

J.C. Zhao, F.P. Du, X.P. Zhou, W. Cui, X.M. Wang, H. Zhu, X.L. Xie, and Y.W. Mei: Thermal conductive and electrical properties of polyurethane/hyperbranched poly(urea-urethane)-grafted multi-walled carbon nanotube composites. Composites Part B 42, 2111 (2011).

S. Taheri, E. Nakhlband, and H. Nazockdast: Microstructure and multiwall carbon nanotube partitioning in polycarbonate/acrylonitrile-butadiene-styrene/multiwall carbon nanotube nanocomposites. Polym. Plast. Technol. Eng. 52, 300 (2013).

N.G. Sahoo, S. Rana, J.W. Cho, L. Li, and S.H. Chan: Polymer nanocomposites based on functionalized carbon nanotubes. Prog. Polym. Sci. 35, 837 (2010).

P. Song, Y. Shen, B. Du, Z. Guo, and Z. Fang: Fabrication of fullerene-decorated carbon nanotubes and their application in flame-retarding polypropylene. Nanoscale 1, 118 (2009).

J. Khanderi, R.C. Hoffmann, A. Gurlo, and J.J. Schneider: Synthesis and sensoric response of ZnO decorated carbon nanotubes. J. Mater. Chem. 19, 5039 (2009).

Q. Zhang, M. Zhu, Q. Zhang, Y. Li, and H. Wang: The formation of magnetite nanoparticles on the sidewalls of multi-walled carbon nanotubes. Compos. Sci. Technol. 69, 633 (2009).

L. Kong, X. Lu, and W. Zhang: Facile synthesis of multifunctional multiwalled carbon nanotubes/Fe3O4 nanoparticles/polyaniline composite nanotubes. J. Solid State Chem. 181, 628 (2008).

H.Y. Li, C.M. Chang, K.Y. Hsu, and Y.L. Liu: Poly(lactide)-functionalized and Fe3O4 nanoparticle-decorated multiwalled carbon nanotubes for preparation of electrically-conductive and magnetic poly(lactide) films and electrospun nanofibers. J. Mater. Chem. 22, 4855 (2012).

Y. Zhan, R. Zhao, Y. Lei, F. Meng, J. Zhong, and X. Liu: A novel carbon nanotubes/Fe3O4 inorganic hybrid material: Synthesis, characterization and microwave electromagnetic properties. J. Magn. Magn. Mater. 323, 1006 (2011).

S. Ni, S. Lin, Q. Pan, F. Yang, K. Huang, and D. He: Hydrothermal synthesis and microwave absorption properties of Fe3O4 nanocrystals. J. Phys. D: Appl. Phys. 42, 055004 (2009).

S. Dutta and N. Karak: Effect of the NCO/OH ratio on the properties of Mesua Ferrea L. seed oil-modified polyurethane resins. Polym. Int. 55, 49 (2006).

H. Kalita and N. Karak: Mesua ferrea L. seed oil-based hyperbranched shape memory polyurethanes: Effect of multifunctional component. Polym. Eng. Sci. 52, 2454 (2012).

Y.C. Jung, H.H. So, and J.W. Cho: Water-responsive shape memory polyurethane block copolymer modified with polyhedral oligomeric silsesquioxane. J. Macromol. Sci. Phys. 45, 453 (2006).

Y. Zhang, R.J. Heath, and D.J. Hourston: Morphology, mechanical properties, and thermal stability of polyurethane–epoxide resin interpenetrating polymer network rigid foams. J. Appl. Polym. Sci. 75, 406 (2000).

S.D. Desai, A.L. Emanuel, and V.K. Sinha: Polyester polyol-based polyurethane adhesive; effect of treatment on rubber surface. J. Polym. Res. 10, 141 (2003).

S. Thakur and N. Karak: Green reduction of graphene oxide by aqueous phytoextracts. Carbon 50, 5331 (2012).

J.O. Park, K.Y. Rhee, and S.J. Park: Silane treatment of Fe3O4 and its effect on the magnetic and wear properties of Fe3O4/epoxy nanocomposites. Appl. Surf. Sci. 256, 6945 (2010).

H. Deka, N. Karak, R.D. Kalita, and A.K. Buragohain: Biocompatible hyperbranched polyurethane/multi-walled carbon nanotube composites as shape memory materials. Carbon 48, 2013 (2010).

H. Kalita and N. Karak: Bio-based hyperbranched polyurethane/Fe3O4 nanocomposites as shape memory materials. Polym. Adv. Technol. doi: 10.1002/pat.3149.

S. Rana, N. Karak, J.W. Cho, and Y.H. Kim: Enhanced dispersion of carbon nanotubes in hyperbranched polyurethane and properties of nanocomposites. Nanotechnology 19, 495707 (2008).

S.K. Yadav, S.S. Mahapatra, and J.W. Cho: Synthesis of mechanically robust antimicrobial nanocomposites by click coupling of hyperbranched polyurethane and carbon nanotubes. Polymer 53, 2023 (2012).

S.S. Mahapatra, S.K. Yadav, H.J. Yoo, J.W. Cho, and J.S. Park: Highly branched polyurethane: Synthesis, characterization and effects of branching on dispersion of carbon nanotubes. Composites Part B 45, 165 (2013).

L. Viry, C. Mercader, P. Miaudet, C. Zakri, A. Derre, A. Kuhn, M. Maugey, and P. Poulin: Nanotube fibers for electromechanical and shape memory actuators. J. Mater. Chem. 20, 3487 (2010).

W. Zhou, X. Hu, X. Bai, S. Zhou, C. Sun, J. Yan, and P. Chen: Synthesis and electromagnetic, microwave absorbing properties of core–shell Fe3O4–poly(3, 4-ethylenedioxythiophene) microspheres. ACS Appl. Mater. Interfaces 3, 3839 (2011).

Acknowledgment

The authors express their gratitude and thanks to the research project assistance granted by the Department of Science and Technology (DST), India, through Grant No. SR/S3/ME/0020/2009-SERC, dated 9th July, 2010, SAP (University Grants Commission, UGC), India through Grant No. F.3-30/2009 (SAP-II) and FIST program-2009 (DST), India through the Grant No.SR/FST/CSI-203/209/1 dated 06.05.2010. Mangesh Mahajan is gratefully acknowledged for the magnetic measurement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kalita, H., Karak, N. Hyperbranched polyurethane/Fe3O4 nanoparticles decorated multiwalled carbon nanotube thermosetting nanocomposites as microwave actuated shape memory materials. Journal of Materials Research 28, 2132–2141 (2013). https://doi.org/10.1557/jmr.2013.213

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.213